A Blank Quality Control Checklist Template for Manufacturing provides a structured format to systematically inspect products and processes, ensuring compliance with industry standards. This template helps identify defects, track quality issues, and maintain consistency throughout the production cycle. Using a customizable checklist enhances efficiency and accuracy in quality assurance procedures.

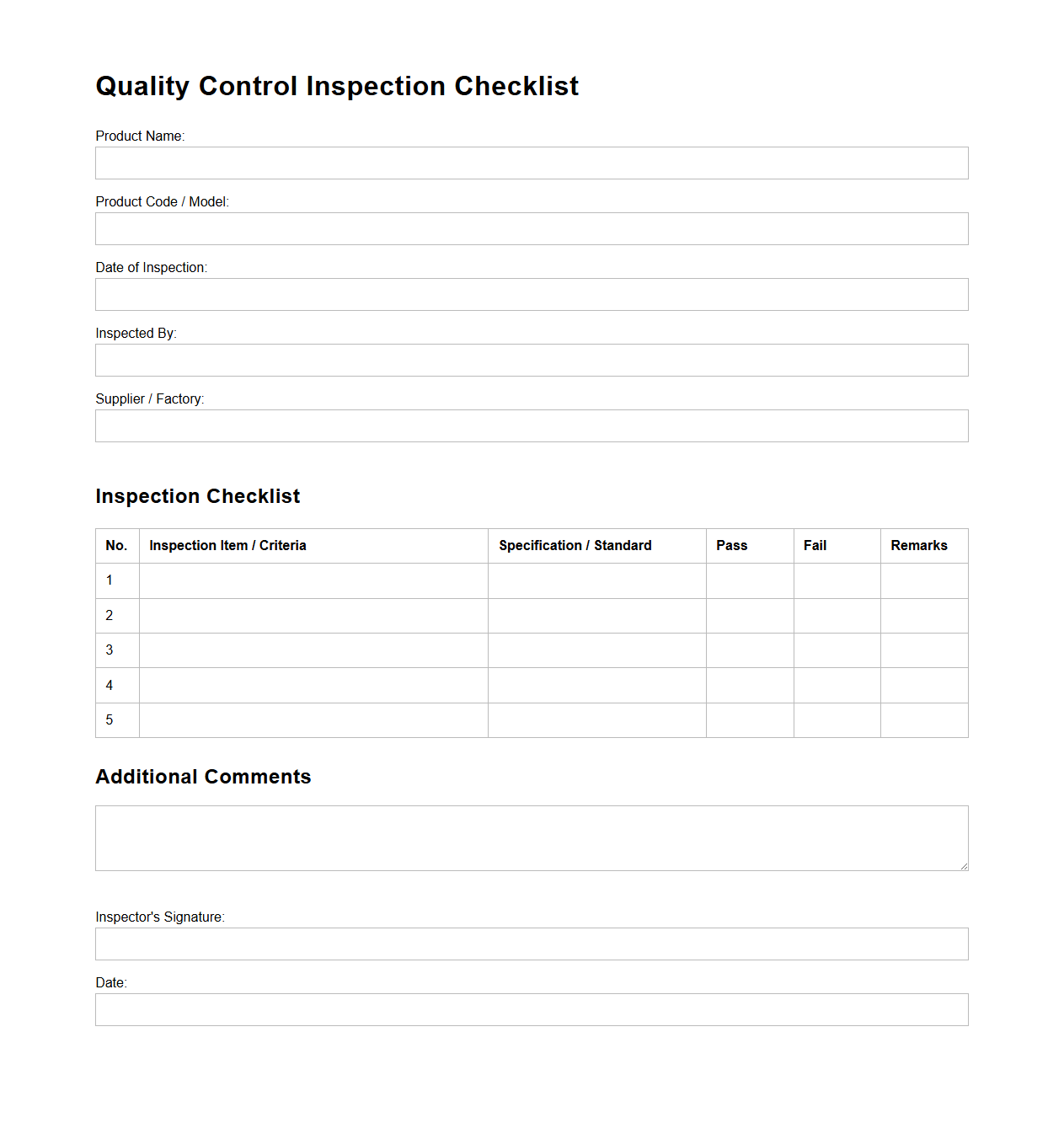

Blank Quality Control Inspection Checklist Template for Manufacturing

A

Blank Quality Control Inspection Checklist Template for Manufacturing is a structured document used to systematically verify product standards and processes during production. It helps inspectors track compliance with quality specifications, identify defects, and ensure consistency throughout manufacturing stages. This template supports improved accuracy, efficiency, and documentation in quality assurance workflows.

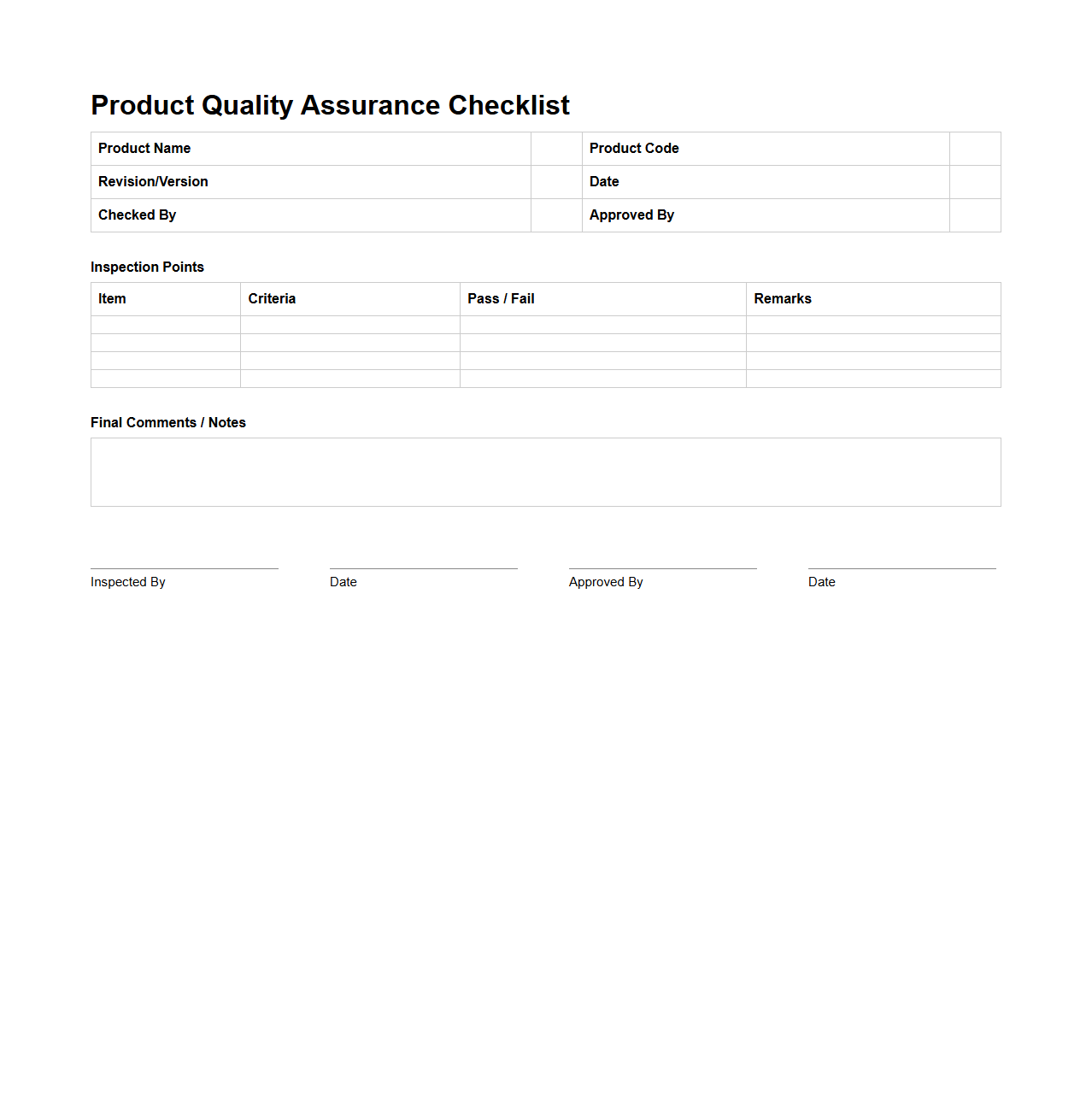

Blank Product Quality Assurance Checklist for Manufacturing

A

Blank Product Quality Assurance Checklist for manufacturing is a structured document designed to systematically verify product quality at various stages of the production process. It helps ensure compliance with industry standards, identifies defects, and maintains consistent product specifications. Manufacturers use this checklist as a critical tool to monitor quality control, reduce errors, and enhance overall product reliability.

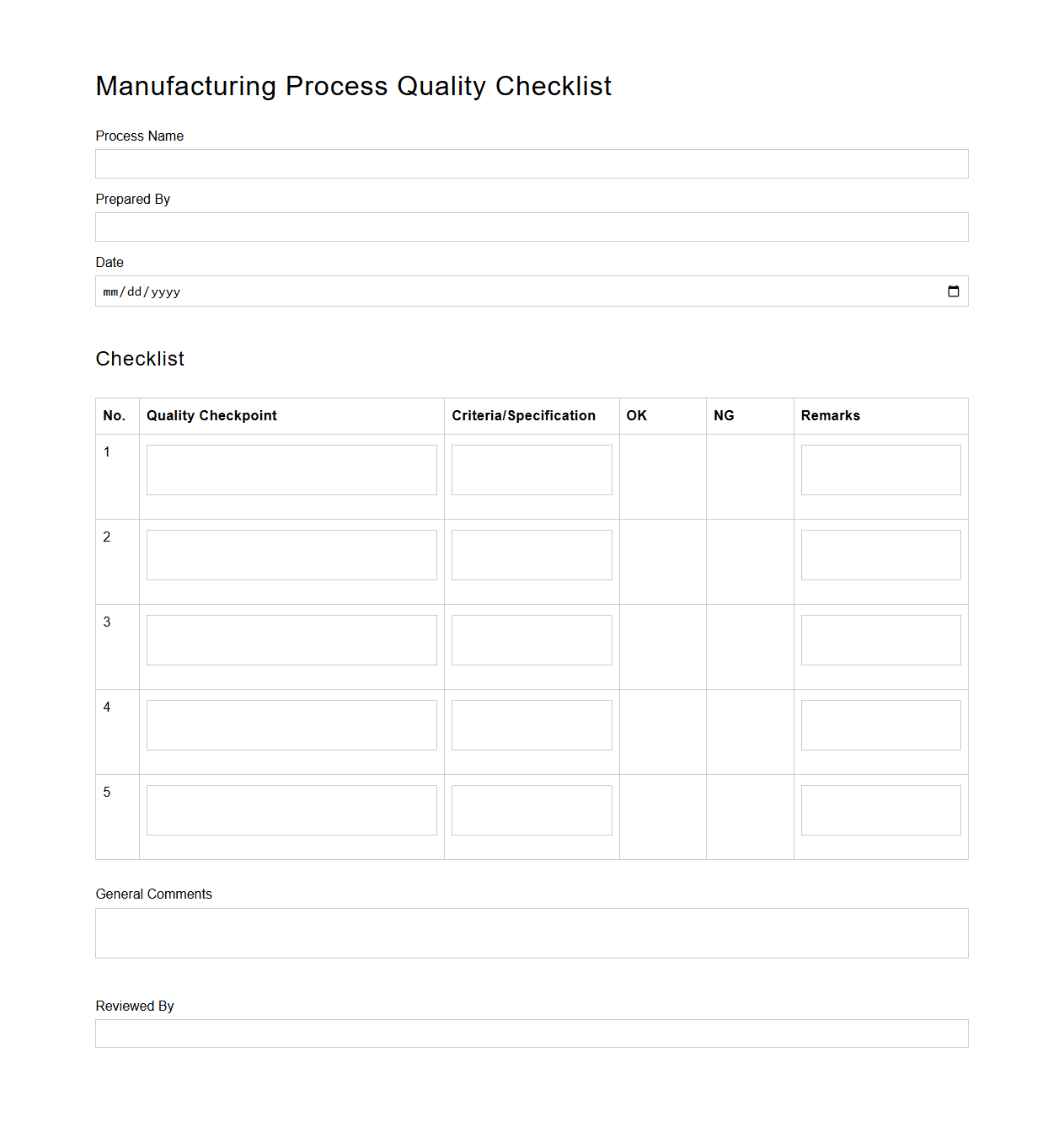

Blank Manufacturing Process Quality Checklist Template

The

Blank Manufacturing Process Quality Checklist Template document serves as a structured tool to ensure every phase of the manufacturing process meets specified quality standards. It systematically captures critical checkpoints, measurements, and inspections to maintain consistency and compliance with industry regulations. This template enhances quality assurance by enabling efficient tracking and identification of defects or deviations throughout production stages.

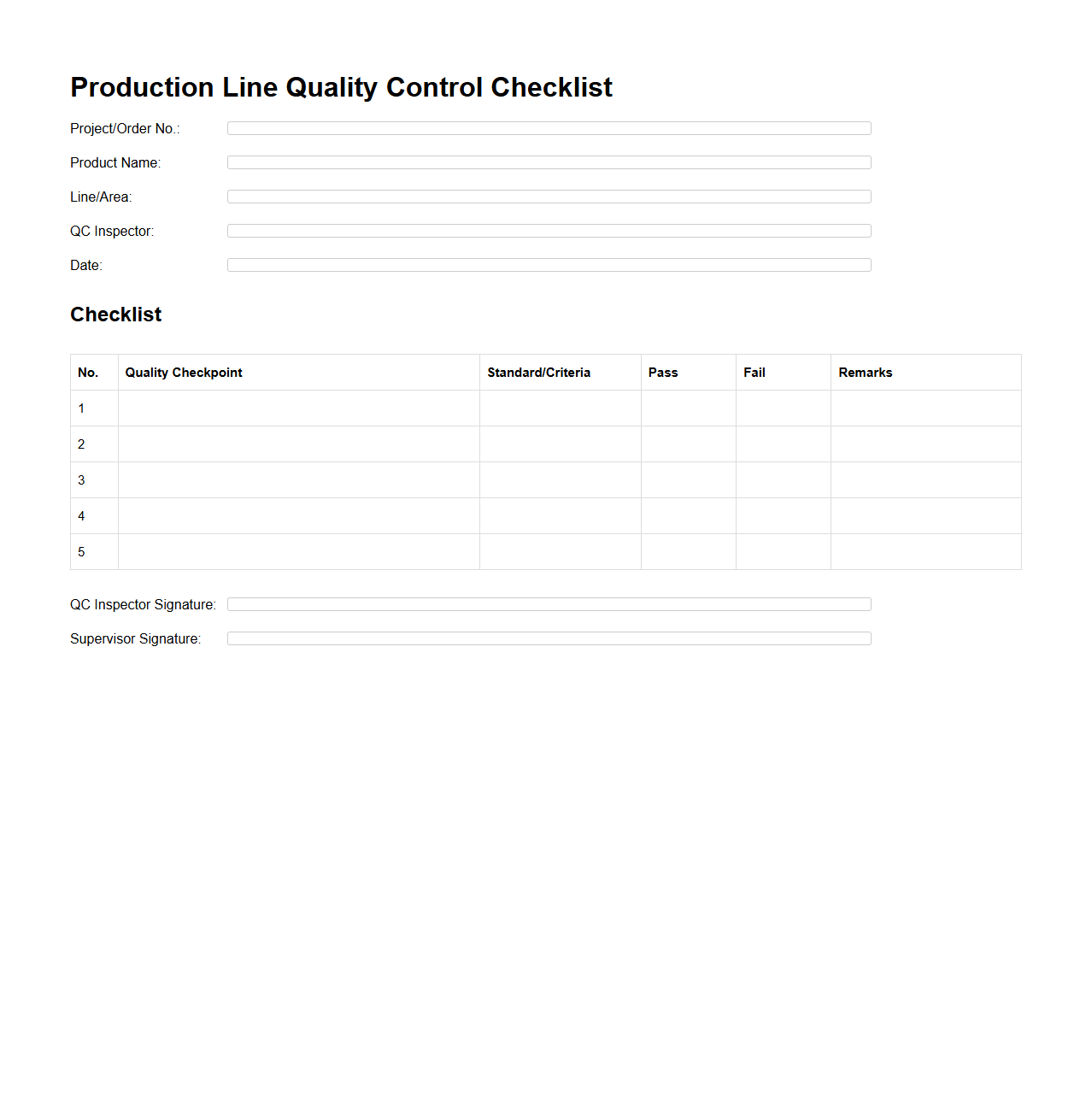

Blank Production Line Quality Control Checklist

The

Blank Production Line Quality Control Checklist is a standardized document used to ensure all critical quality parameters are consistently monitored during manufacturing processes. It facilitates systematic tracking of production stages, identifying defects, and verifying compliance with industry standards. This checklist improves product reliability and minimizes errors by providing clear, actionable inspection criteria for quality control teams.

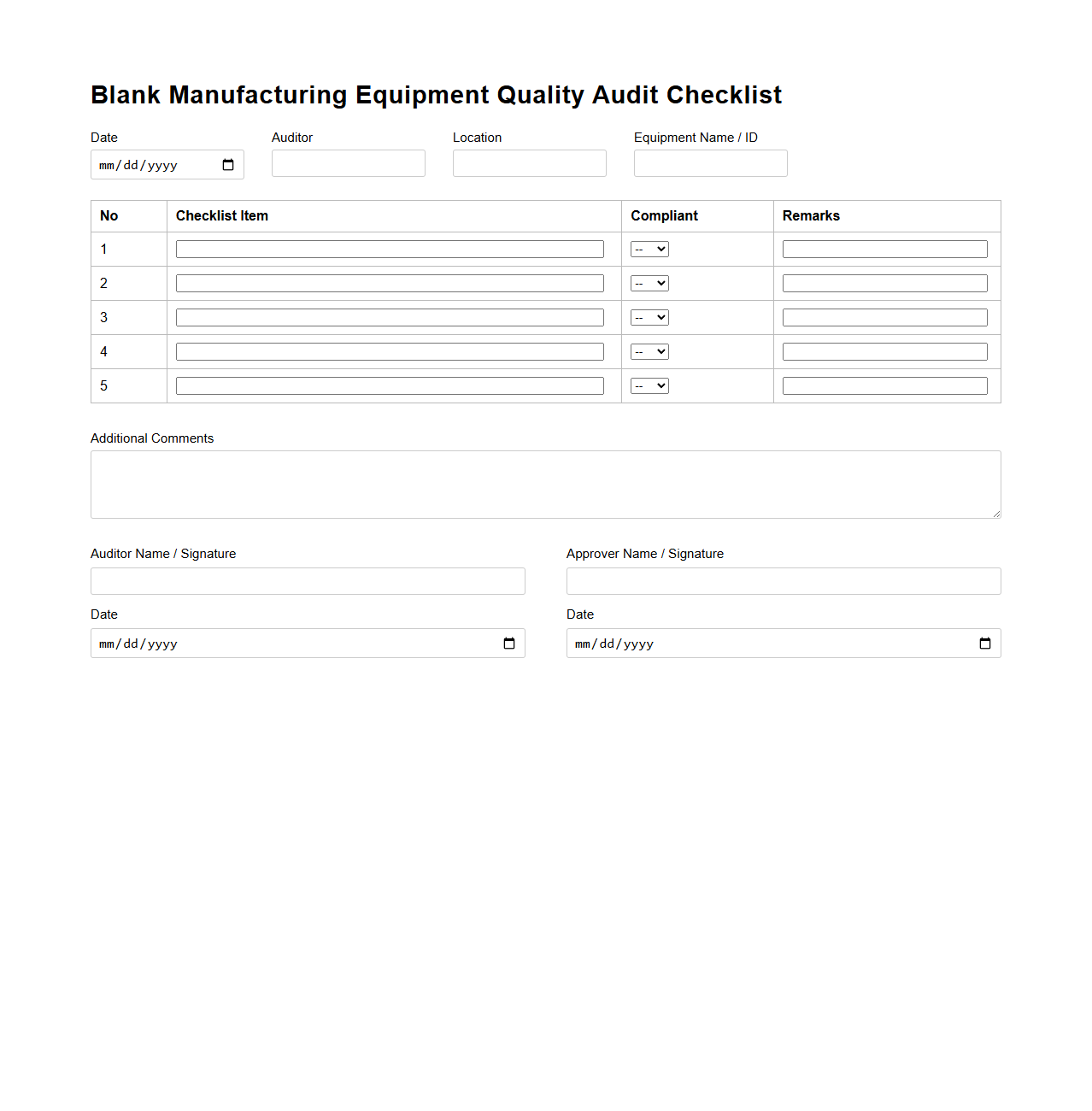

Blank Manufacturing Equipment Quality Audit Checklist

A

Blank Manufacturing Equipment Quality Audit Checklist document serves as a standardized tool to systematically evaluate the condition, functionality, and compliance of manufacturing equipment. It ensures consistent quality control by detailing specific inspection criteria, maintenance verification, and safety checks, facilitating accurate identification of equipment performance issues. This checklist supports manufacturing facilities in maintaining operational efficiency and meeting regulatory standards.

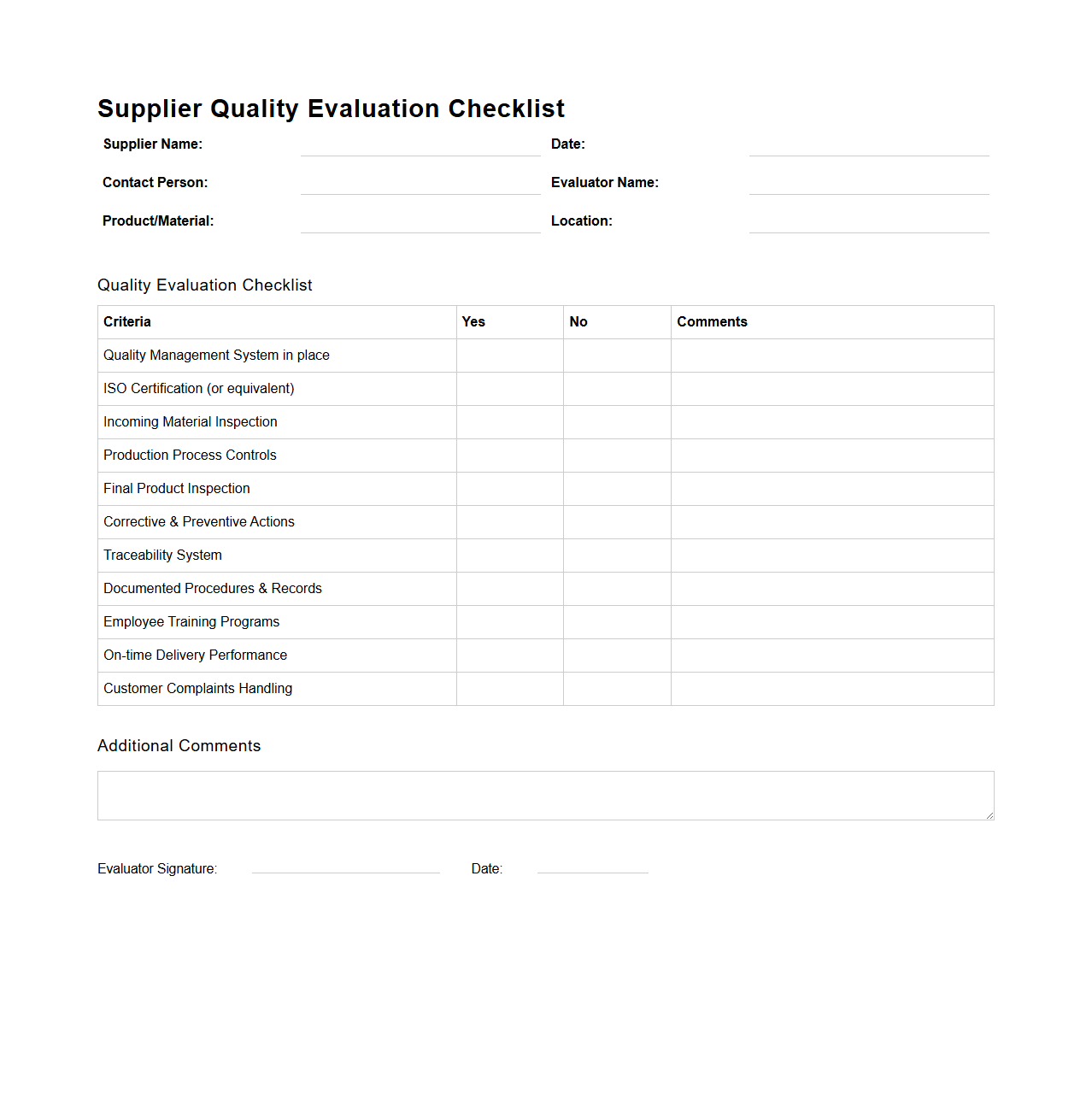

Blank Supplier Quality Evaluation Checklist for Manufacturing

The

Blank Supplier Quality Evaluation Checklist for manufacturing is a standardized document used to assess and verify the quality standards of suppliers before approving them for production. It includes critical criteria such as material specifications, process controls, compliance certifications, and delivery performance to ensure suppliers meet the manufacturing requirements. This checklist helps streamline supplier audits, minimize defects, and maintain consistent product quality throughout the supply chain.

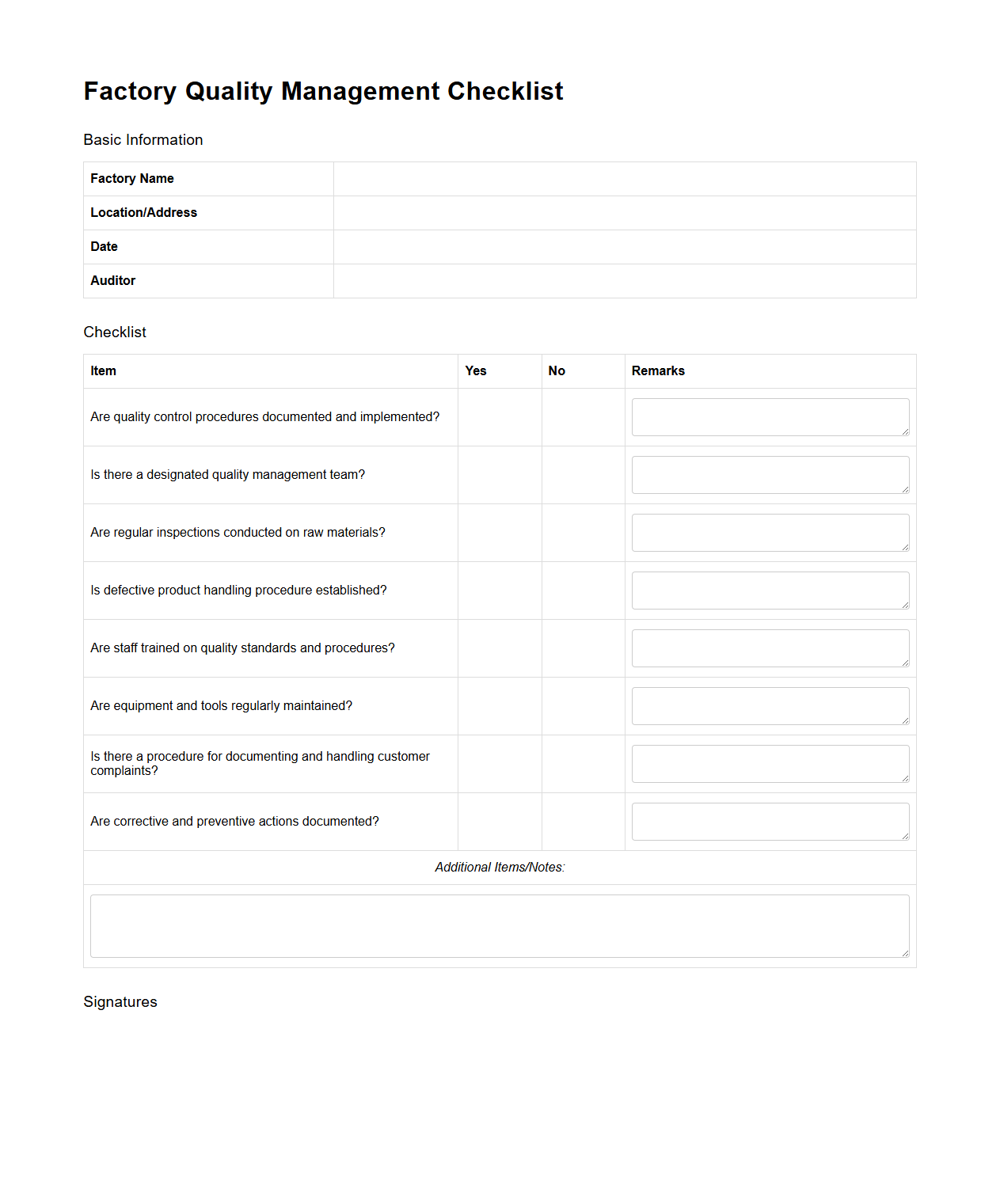

Blank Factory Quality Management Checklist Template

The

Blank Factory Quality Management Checklist Template document serves as a structured tool designed to streamline quality assurance processes in manufacturing environments. It facilitates the systematic inspection of equipment, materials, and processes to ensure compliance with established standards and regulatory requirements. By using this template, factories can maintain consistent product quality, minimize defects, and enhance overall operational efficiency.

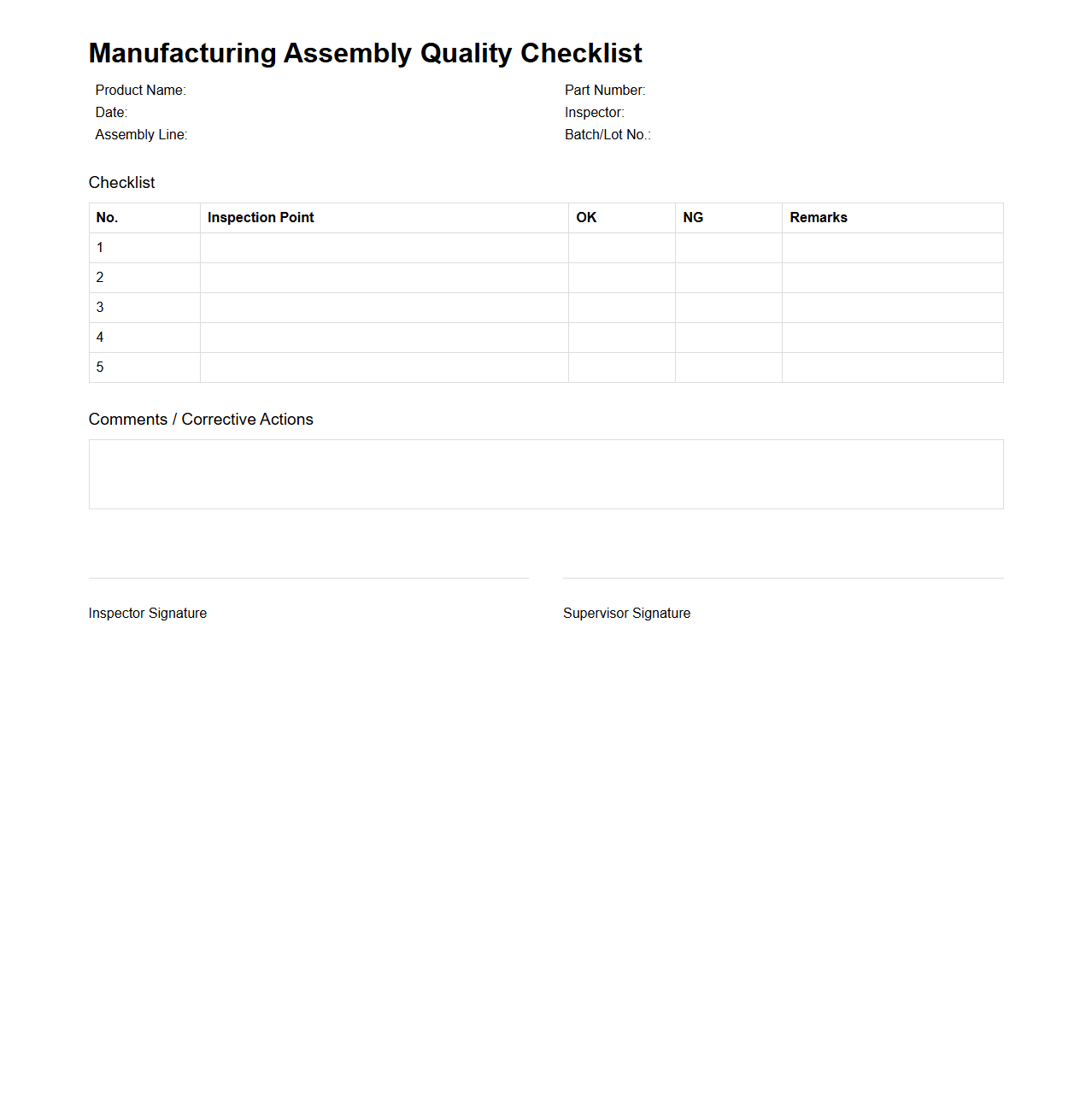

Blank Manufacturing Assembly Quality Checklist

A

Blank Manufacturing Assembly Quality Checklist document serves as a standardized template used to systematically verify each step and component in the assembly process. It ensures consistent adherence to quality standards by capturing critical data points such as inspection criteria, defect identification, and compliance checks. This document is essential for maintaining product reliability, minimizing errors, and facilitating continuous improvement within manufacturing operations.

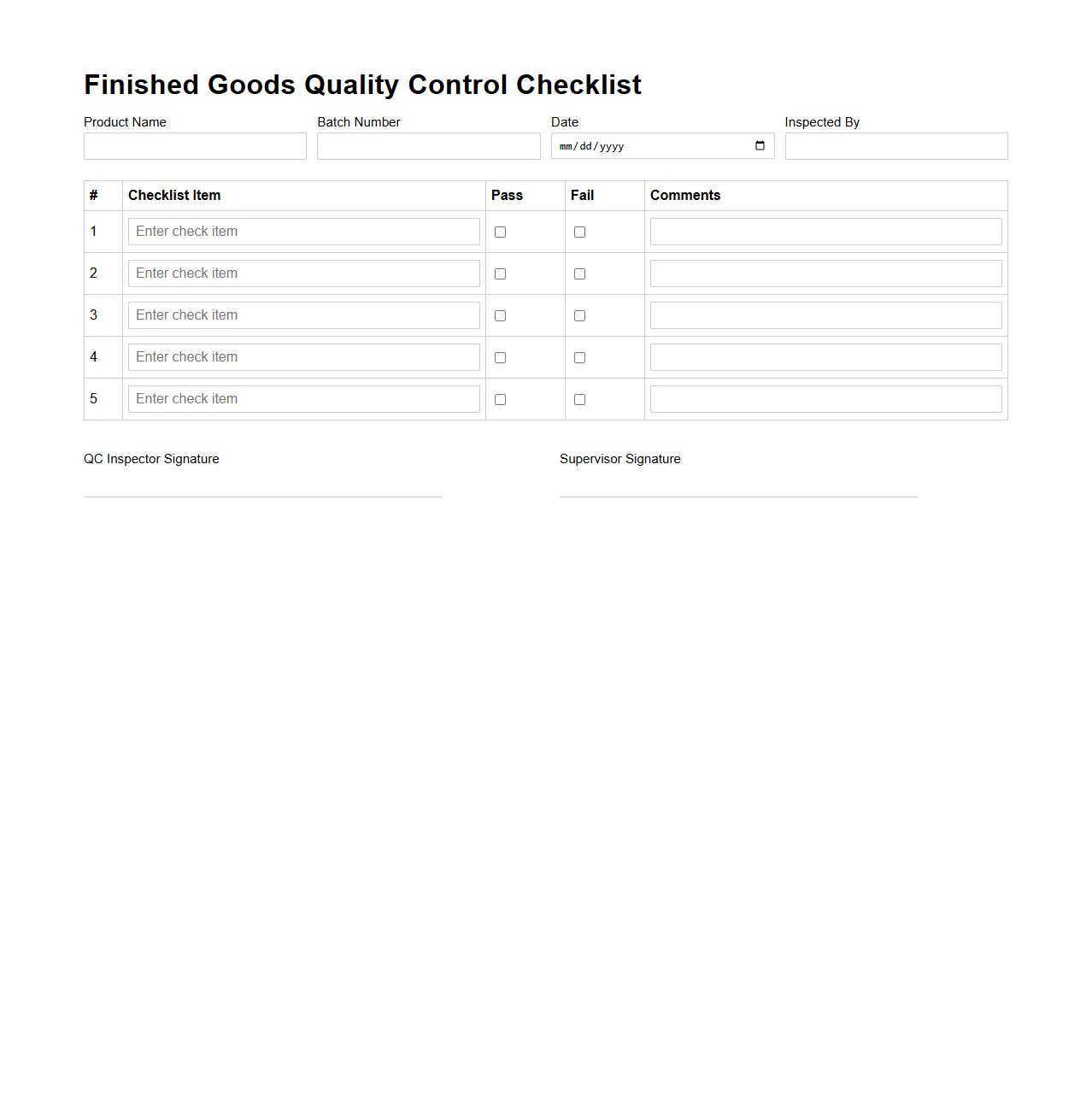

Blank Finished Goods Quality Control Checklist

The

Blank Finished Goods Quality Control Checklist is a critical document used in manufacturing and production to ensure that final products meet specified standards before shipment. It systematically guides quality inspectors through essential criteria such as dimensions, appearance, functionality, and packaging integrity. This checklist helps identify defects, maintain consistency, and ensure customer satisfaction by verifying compliance with industry regulations and internal quality benchmarks.

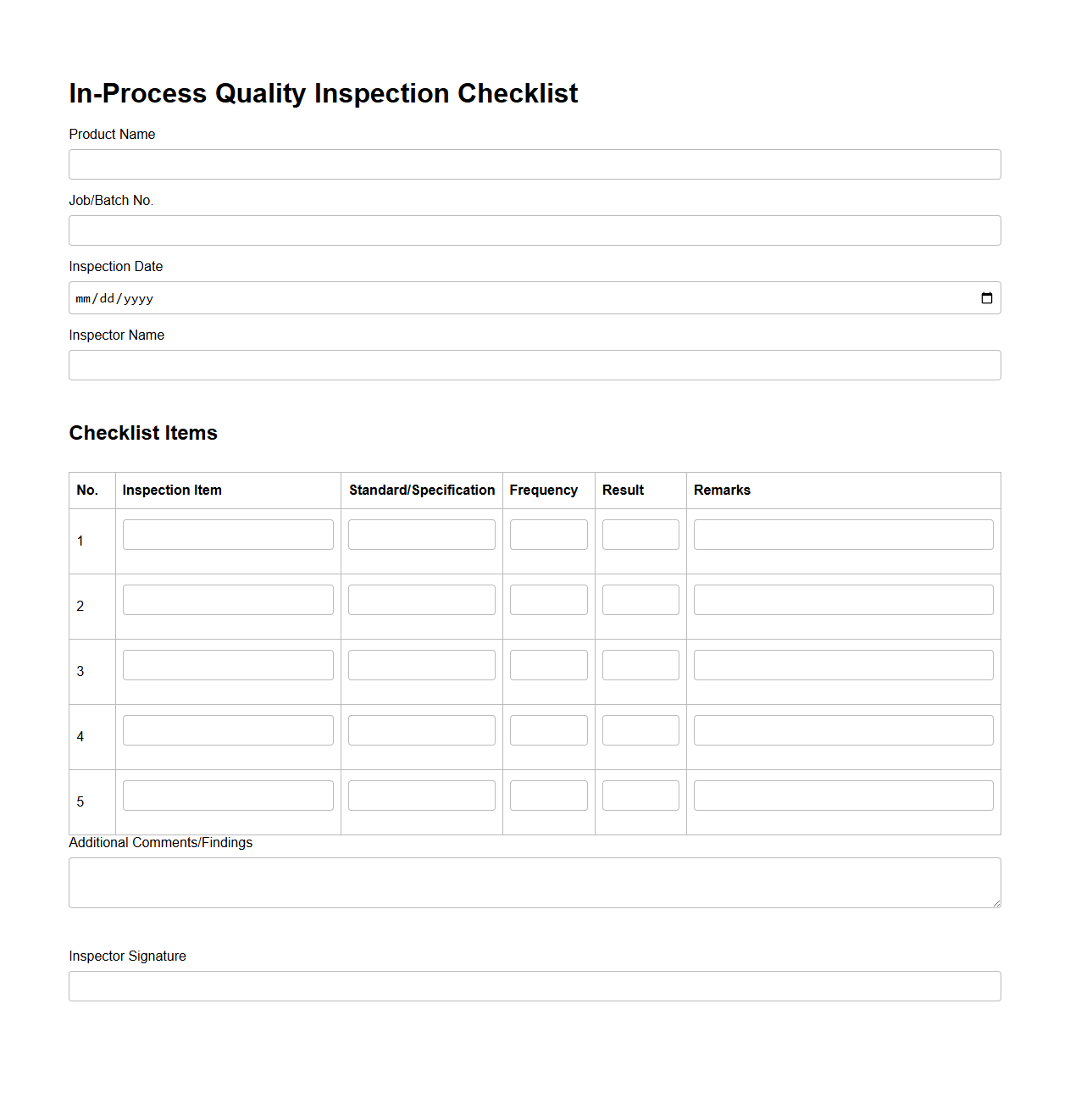

Blank In-Process Quality Inspection Checklist for Manufacturing

The

Blank In-Process Quality Inspection Checklist for manufacturing is a standardized document used to systematically record inspection results during various stages of the production process. It ensures that each critical quality parameter is checked, defects are identified early, and corrective actions can be implemented promptly to maintain product standards. This checklist typically includes inspection criteria, measurement methods, acceptance limits, and space for inspector comments, facilitating consistent quality control and compliance with manufacturing specifications.

What are the essential fields to include in a blank quality control checklist for manufacturing documents?

Essential fields in a blank quality control checklist include the inspection date, inspector name, and product details to ensure traceability. Additional fields such as defect type, severity, and corrective actions help in identifying and resolving issues promptly. Including a final approval section verifies that the product meets all quality standards before release.

How can digital blank QC checklists improve audit traceability in manufacturing?

Digital blank QC checklists enhance audit traceability by automatically timestamping and storing inspection data in secure databases. This improves data accuracy and facilitates easy retrieval during audits, reducing the risk of lost or incomplete records. Moreover, digital tools can integrate with ERP systems, providing real-time visibility into quality performance across production lines.

What common errors occur when filling out a blank quality control checklist for production lines?

Common errors in filling out blank quality control checklists include missing data entries, inaccurate defect descriptions, and inconsistent application of acceptance criteria. These mistakes can lead to incorrect quality assessment, causing delays or non-compliance with standards. Ensuring thorough training and using standardized forms helps minimize such errors.

How should a blank QC checklist be tailored for different manufacturing processes (e.g., electronics vs. textiles)?

A blank QC checklist should be customized to reflect the specific requirements of each manufacturing process, such as solder joint inspection for electronics or fabric defect checks for textiles. Tailoring includes adjusting field labels, inspection criteria, and sampling methods to align with process complexity. This ensures relevant quality metrics are captured accurately for effective control.

Which quality standards (ISO, Six Sigma) frequently require custom blank checklists for compliance documentation?

ISO standards, such as ISO 9001, and Six Sigma methodologies often necessitate custom blank checklists to document compliance and continuous improvement efforts. These checklists support process standardization, risk identification, and quality performance measurement. Custom forms ensure that specific regulatory and operational requirements are consistently met.