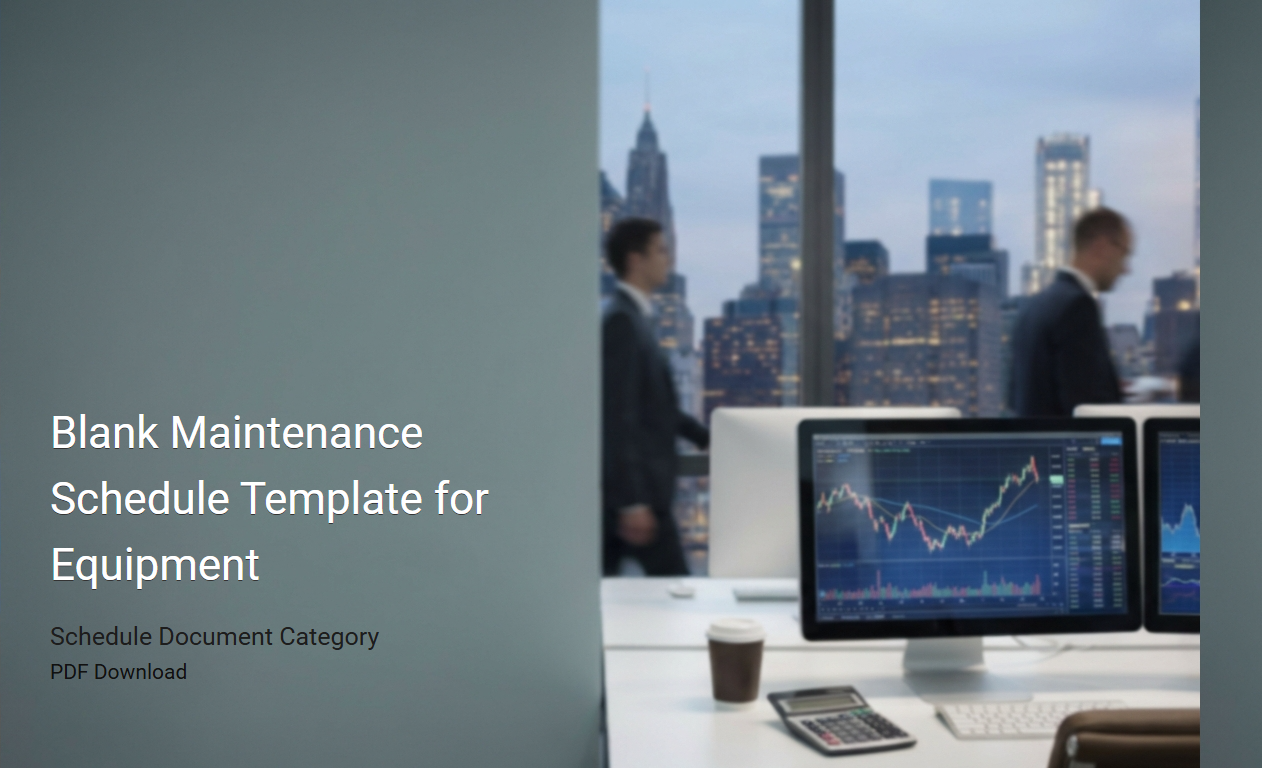

Equipment Preventive Maintenance Schedule Template

An

Equipment Preventive Maintenance Schedule Template document is a structured tool designed to help organizations plan, track, and manage routine maintenance tasks for machinery and equipment. It includes key details such as maintenance dates, task descriptions, responsible personnel, and equipment identification, ensuring consistent upkeep and minimizing downtime. Utilizing this template enhances asset longevity, improves operational efficiency, and reduces unexpected repair costs.

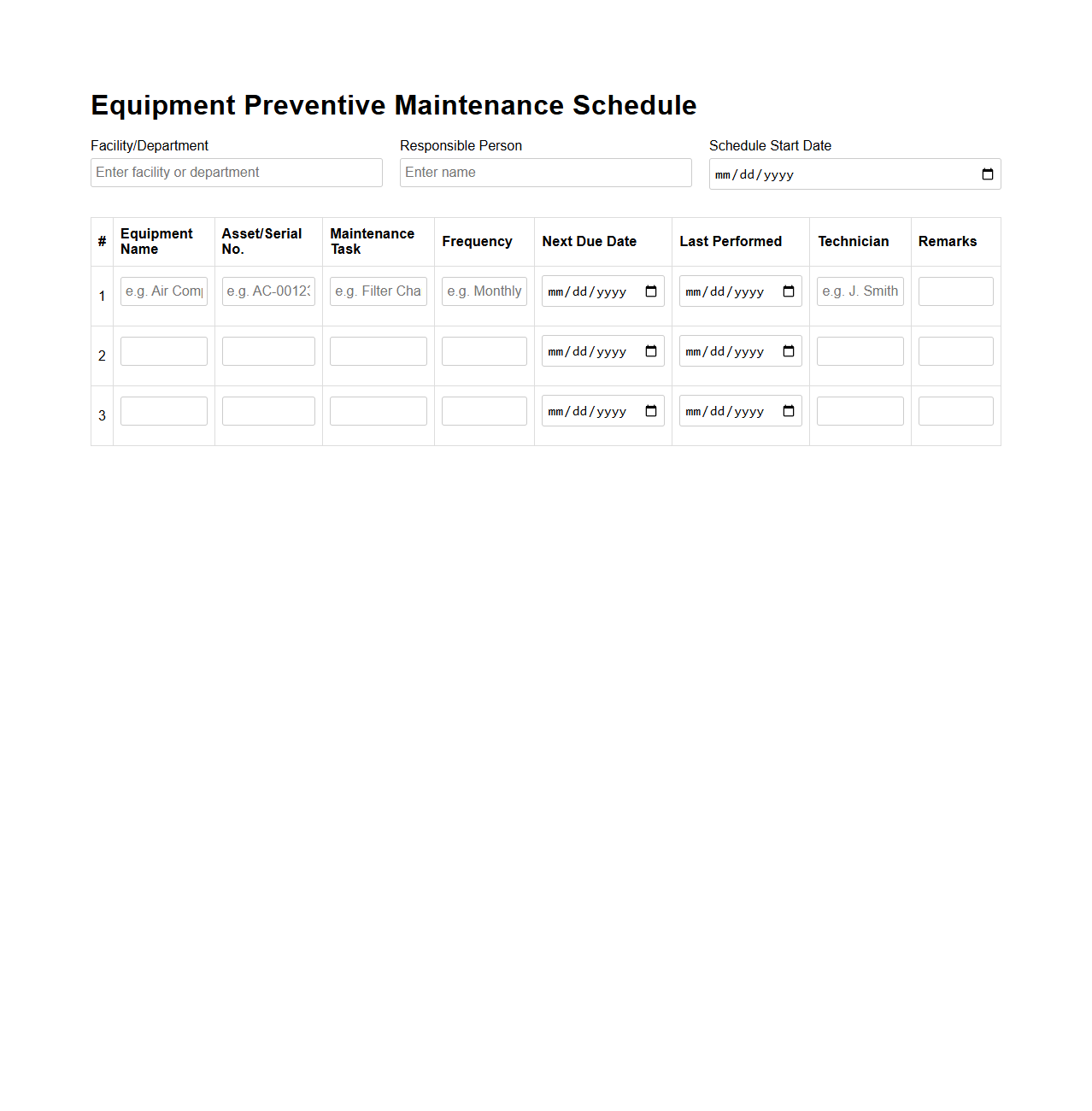

Machinery Maintenance Planning Template

A

Machinery Maintenance Planning Template document is a structured tool designed to schedule, track, and manage routine maintenance tasks for industrial equipment. It helps ensure timely inspections, lubrication, repairs, and part replacements, minimizing downtime and extending machinery lifespan. By organizing essential information such as maintenance dates, assigned personnel, and task status, this template enhances operational efficiency and reliability.

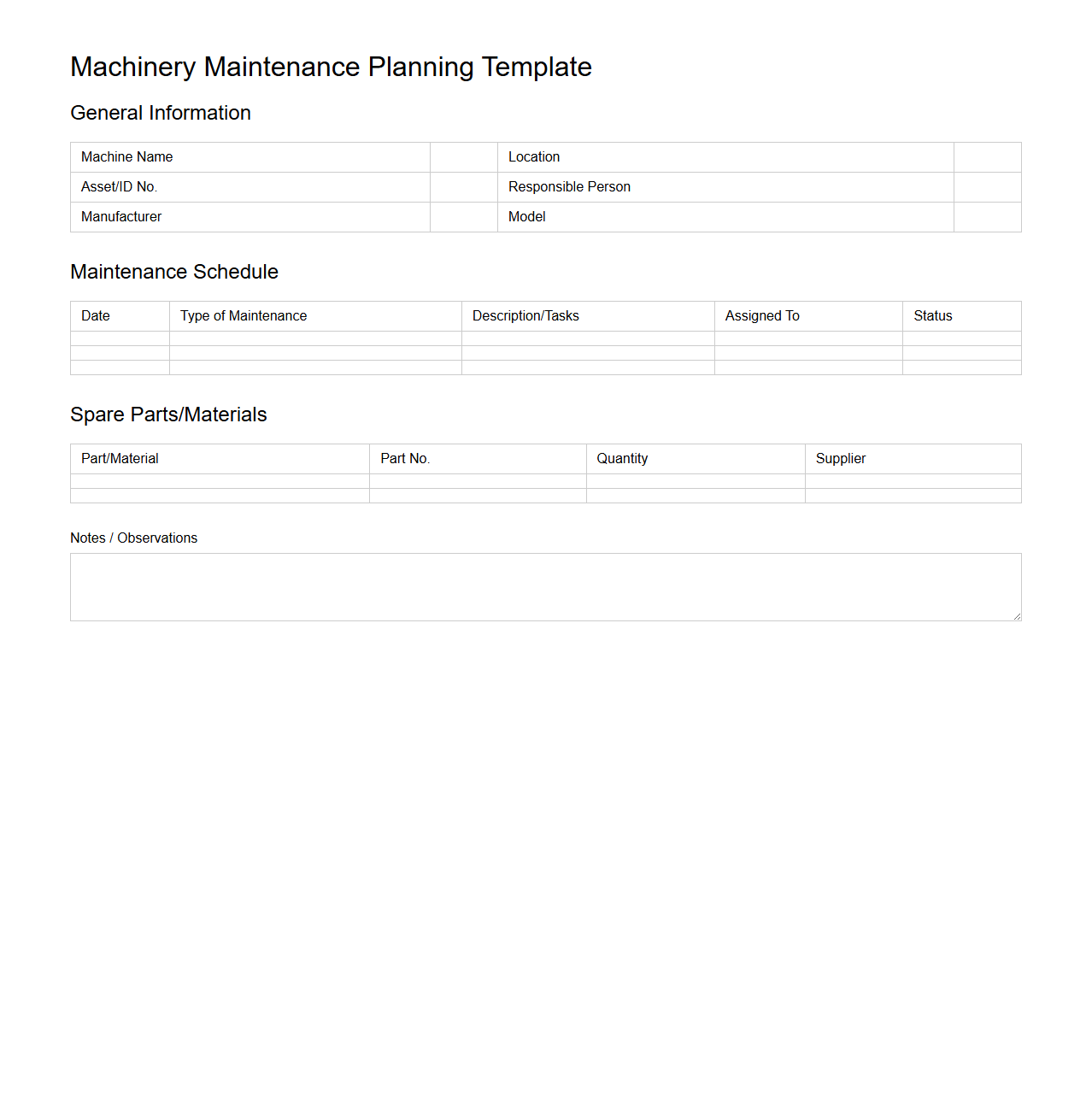

Scheduled Equipment Service Log Template

A

Scheduled Equipment Service Log Template document is designed to track routine maintenance and servicing activities for equipment, ensuring timely upkeep and reducing downtime. It records essential details such as service dates, tasks performed, technician information, and equipment condition, facilitating organized maintenance management. This template helps improve equipment longevity, compliance with safety standards, and operational efficiency.

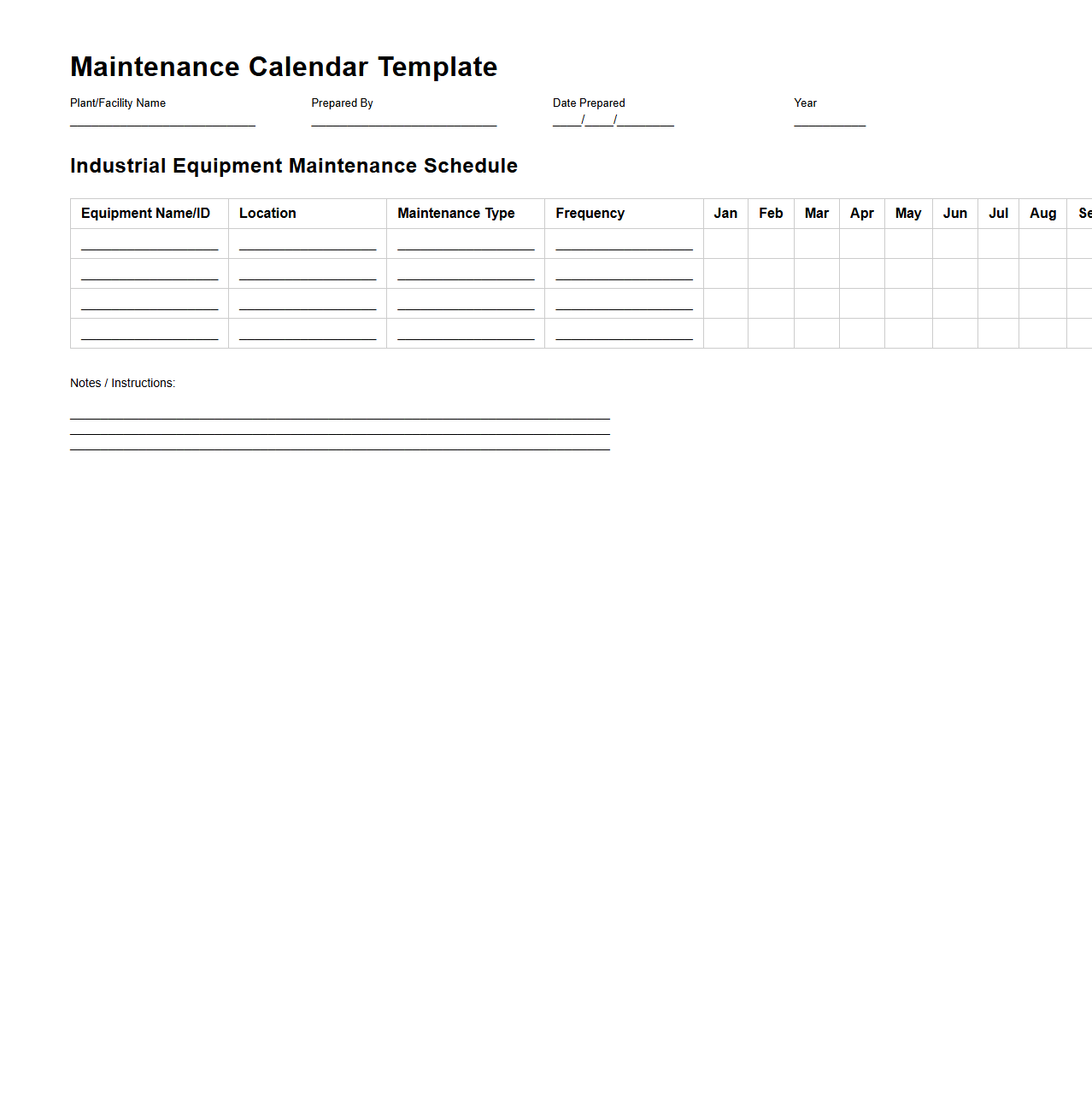

Maintenance Calendar Template for Industrial Equipment

A

Maintenance Calendar Template for Industrial Equipment is a structured document designed to schedule and track regular maintenance tasks, inspections, and repairs for machinery in manufacturing plants or industrial settings. It helps ensure timely upkeep, minimizing downtime and extending equipment lifespan by documenting critical dates, responsible personnel, and maintenance activities. This template enhances operational efficiency and compliance with safety standards by providing a clear, organized maintenance plan.

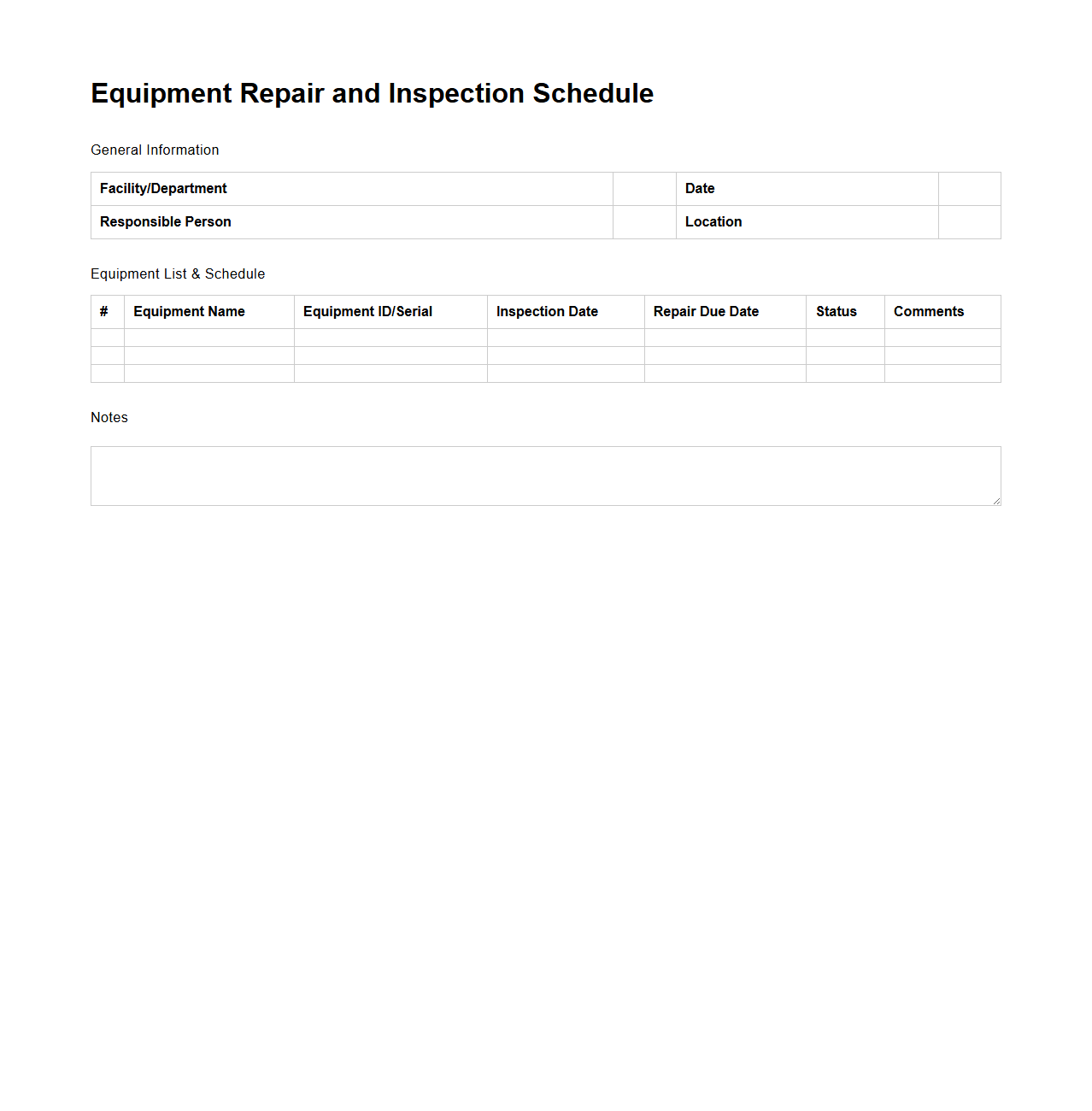

Equipment Repair and Inspection Schedule Template

An

Equipment Repair and Inspection Schedule Template is a structured document designed to systematically track maintenance, repairs, and inspections of machinery or equipment. It helps businesses ensure timely upkeep, prevent breakdowns, and comply with safety regulations by logging dates, technician details, and specific repair tasks. Utilizing this template boosts operational efficiency and extends the lifespan of critical assets through organized maintenance management.

Facility Equipment Maintenance Tracking Sheet

A

Facility Equipment Maintenance Tracking Sheet is a document designed to record and monitor the maintenance activities of equipment within a facility. It helps ensure timely inspections, repairs, and preventive maintenance, reducing downtime and extending equipment lifespan. This tracking sheet typically includes details such as equipment ID, maintenance dates, performed tasks, and responsible personnel for effective facility management.

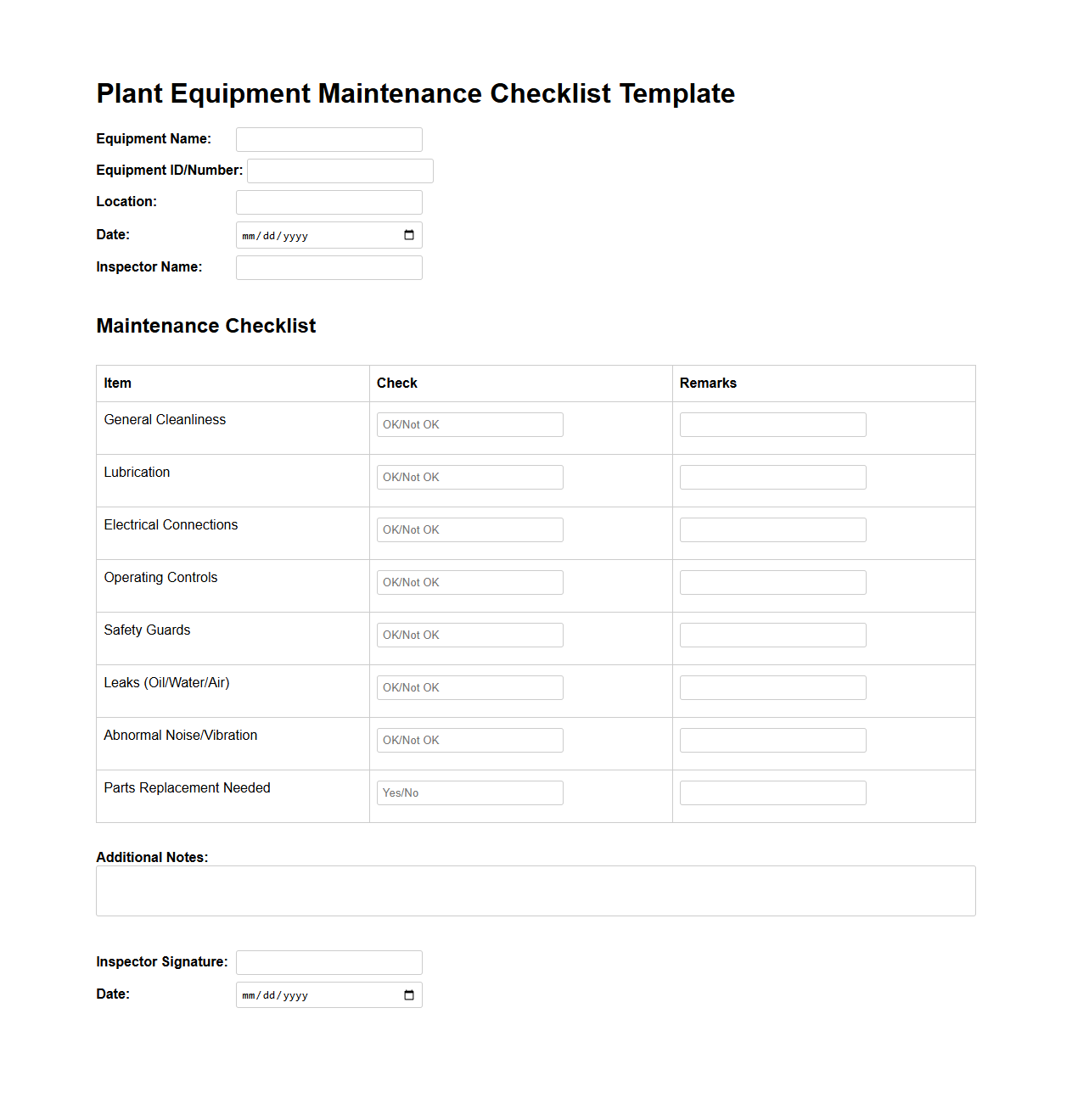

Plant Equipment Maintenance Checklist Template

A

Plant Equipment Maintenance Checklist Template document is a structured tool designed to systematically track and schedule routine inspections, servicing, and repairs of industrial machinery. It helps ensure compliance with safety standards, minimizes equipment downtime, and extends the operational lifespan of plant assets. This template typically includes detailed checkpoints, maintenance frequencies, and records of performed tasks for efficient asset management.

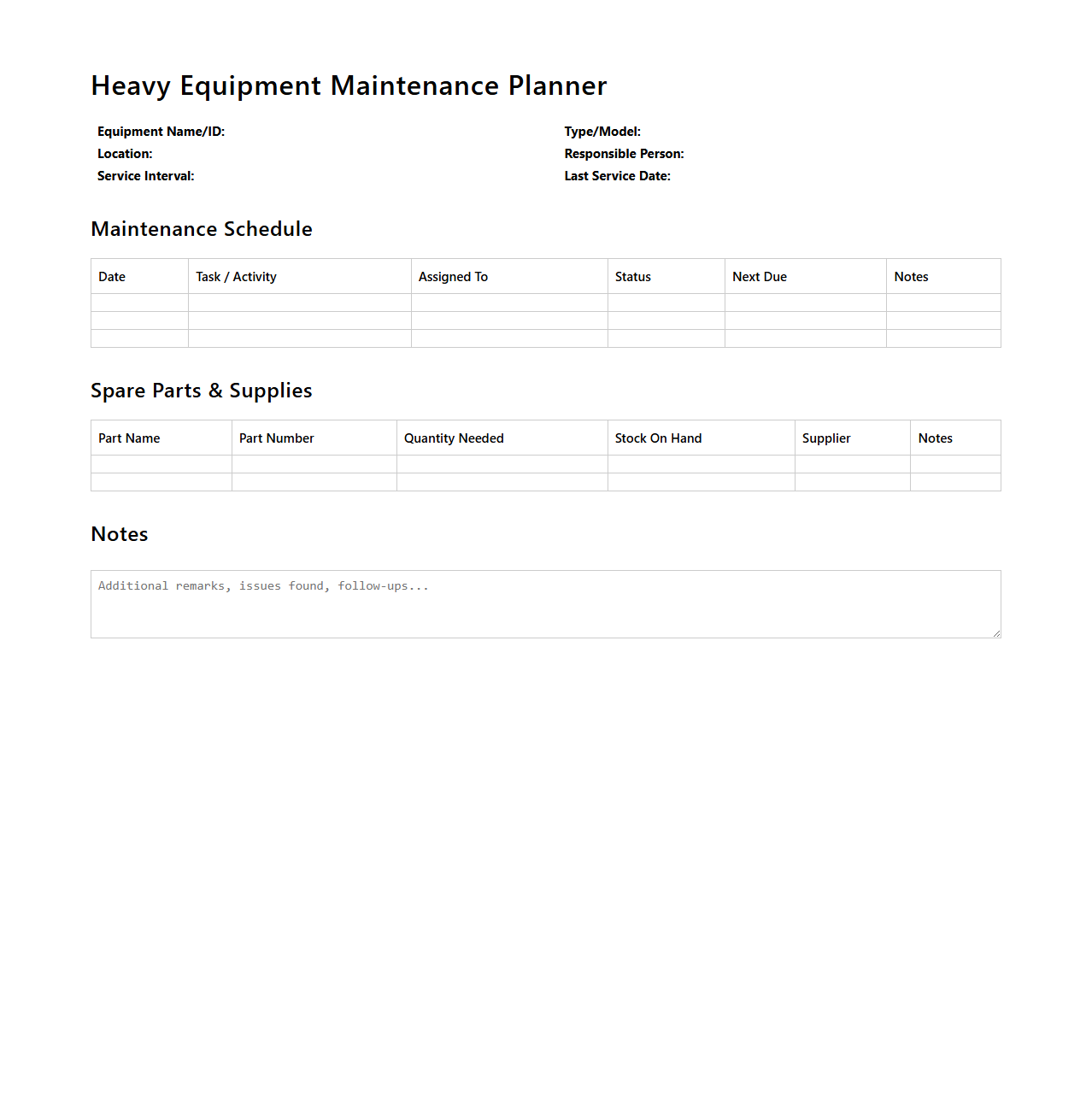

Heavy Equipment Maintenance Planner Template

A

Heavy Equipment Maintenance Planner Template document is designed to streamline the scheduling and tracking of preventative maintenance tasks for construction, mining, and agricultural machinery. It includes fields for recording equipment details, maintenance dates, service types, and responsible personnel, ensuring timely upkeep and reducing downtime. Proper use of this template enhances operational efficiency by promoting systematic maintenance and extending the lifespan of heavy equipment.

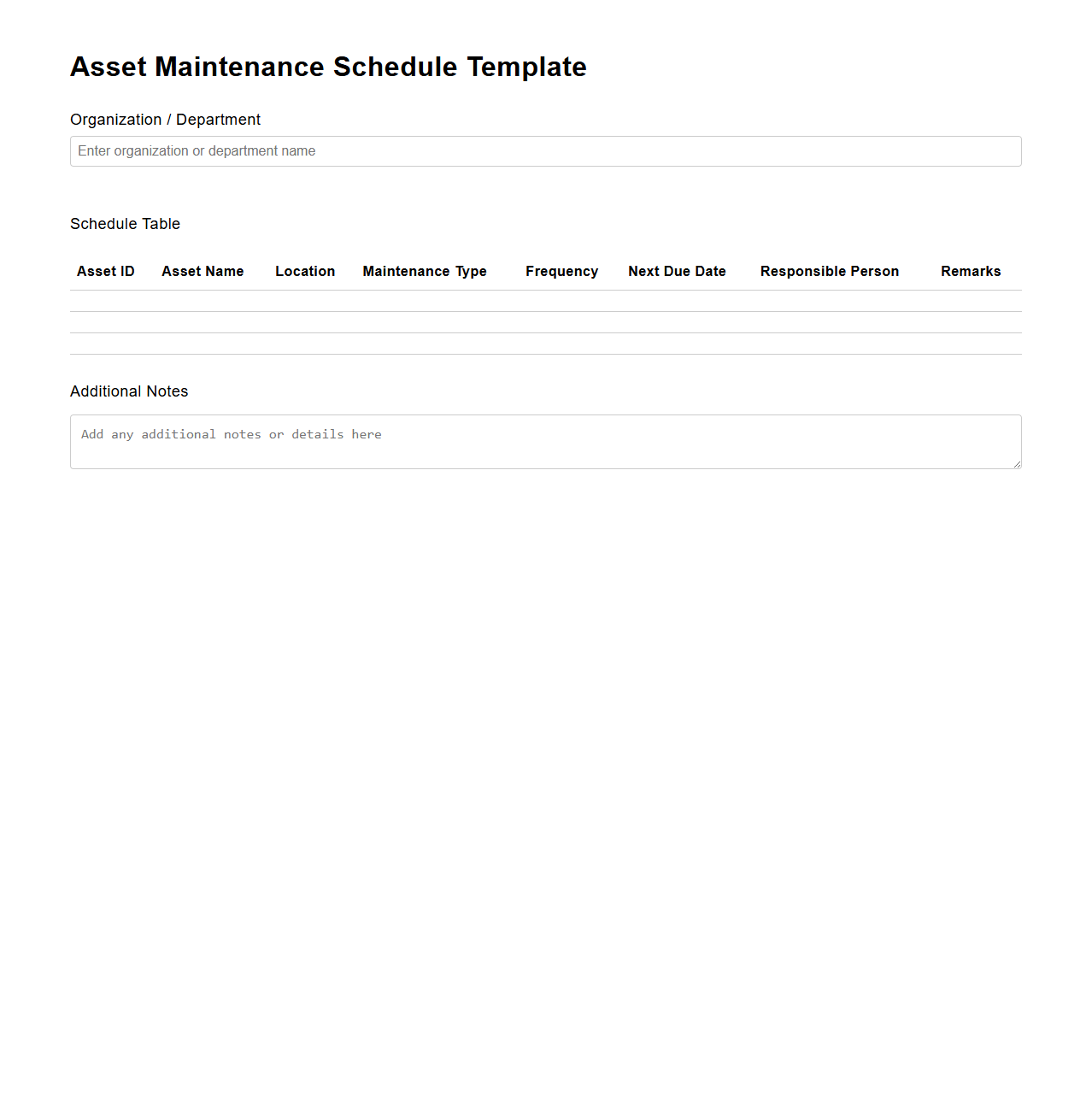

Asset Maintenance Schedule Organization Template

The

Asset Maintenance Schedule Organization Template document is a structured tool designed to systematically plan and track maintenance activities for equipment and machinery within an organization. It helps ensure timely inspections, repairs, and preventive maintenance, reducing downtime and extending asset lifespan. By organizing maintenance tasks, schedules, and responsible personnel, this template improves operational efficiency and asset reliability.

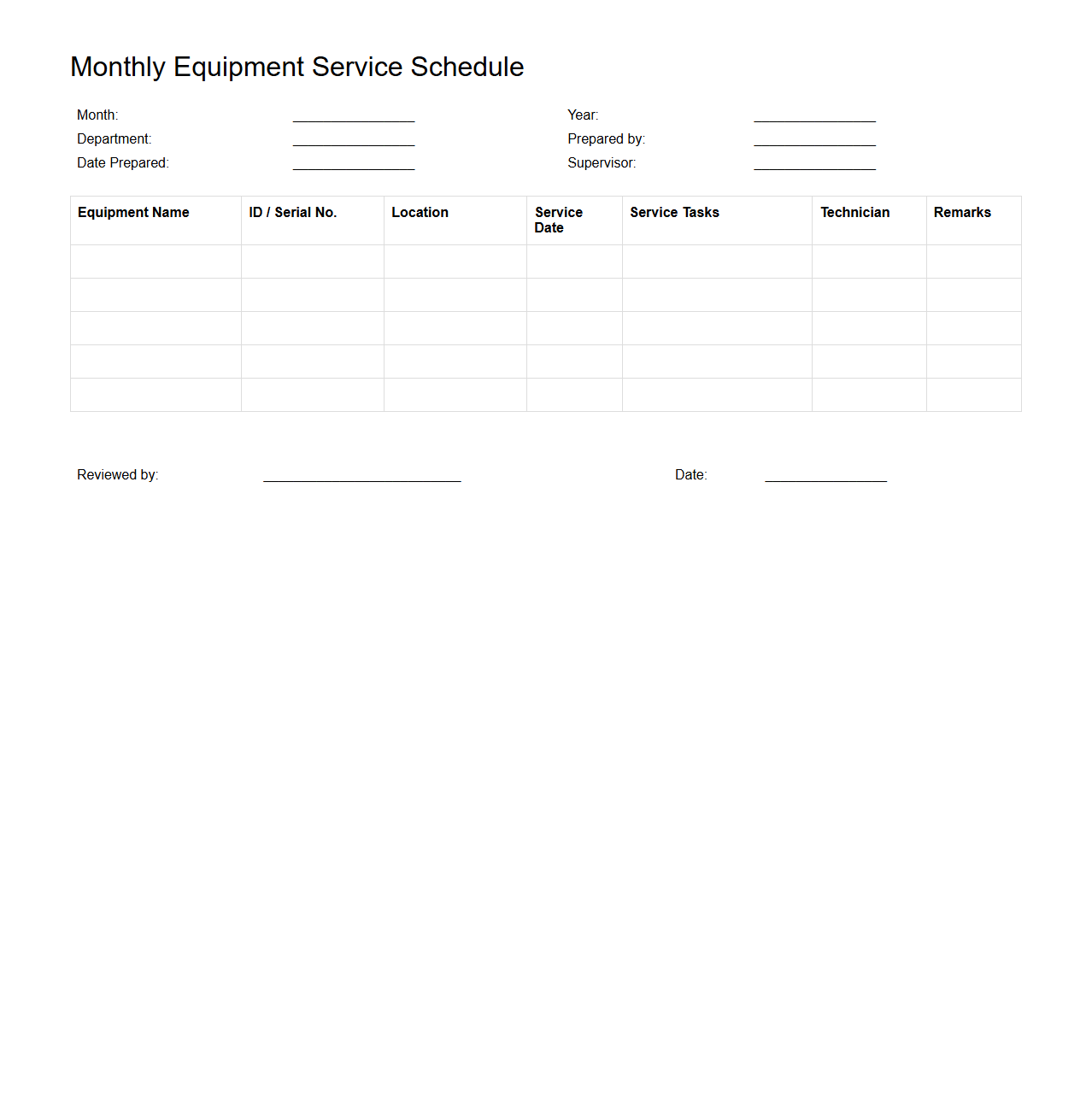

Monthly Equipment Service Schedule Template

A

Monthly Equipment Service Schedule Template document organizes routine maintenance tasks for machinery, ensuring timely inspections and repairs to maximize operational efficiency. It lists equipment details, service dates, responsible technicians, and specific maintenance activities, facilitating consistent tracking and accountability. This template helps prevent breakdowns, extend equipment lifespan, and support compliance with industry safety standards.

What key data fields should be included in a blank maintenance schedule for specific equipment types?

A blank maintenance schedule should include fields such as equipment ID, description, location, and maintenance type. Additional fields like date of last maintenance, next scheduled maintenance, and assigned technician are crucial. Including specific task details and required materials enhances clarity and efficiency.

How often should maintenance intervals be documented for high-usage equipment?

Maintenance intervals for high-usage equipment should be documented based on manufacturer recommendations and operational conditions. Typically, intervals range from weekly to monthly, depending on equipment stress levels. Accurate documentation ensures timely servicing and prevents unexpected failures.

What is the recommended format for tracking completion and technician signatures on a blank schedule?

The recommended format includes a clear table with columns for task description, completion date, and technician signature. Using digital or printed checkboxes helps confirm task completion efficiently. This format ensures accountability and easy verification of maintenance activities.

How can a blank maintenance schedule be customized for regulatory compliance in different industries?

Customization involves integrating industry-specific regulatory requirements such as safety checks, inspection standards, and reporting protocols. Adding compliance checklists and audit trails supports adherence to legal mandates. Tailoring schedules to include documentation fields for certifications enhances regulatory transparency.

What digital tools are best for converting a blank maintenance schedule into an automated reminder system?

Top digital tools include CMMS software like Fiix, UpKeep, and Maintenance Connection that offer automation features. These platforms integrate scheduling, notifications, and record-keeping for seamless maintenance management. Leveraging mobile apps and cloud access further enhances real-time monitoring and reminders.