A Blank Maintenance Schedule Template for Equipment Tracking helps streamline regular inspections and repairs to ensure optimal equipment performance. It enables efficient tracking of maintenance tasks, reducing downtime and extending the lifespan of assets. Using this template simplifies organizing schedules, improving maintenance reliability, and enhancing overall operational efficiency.

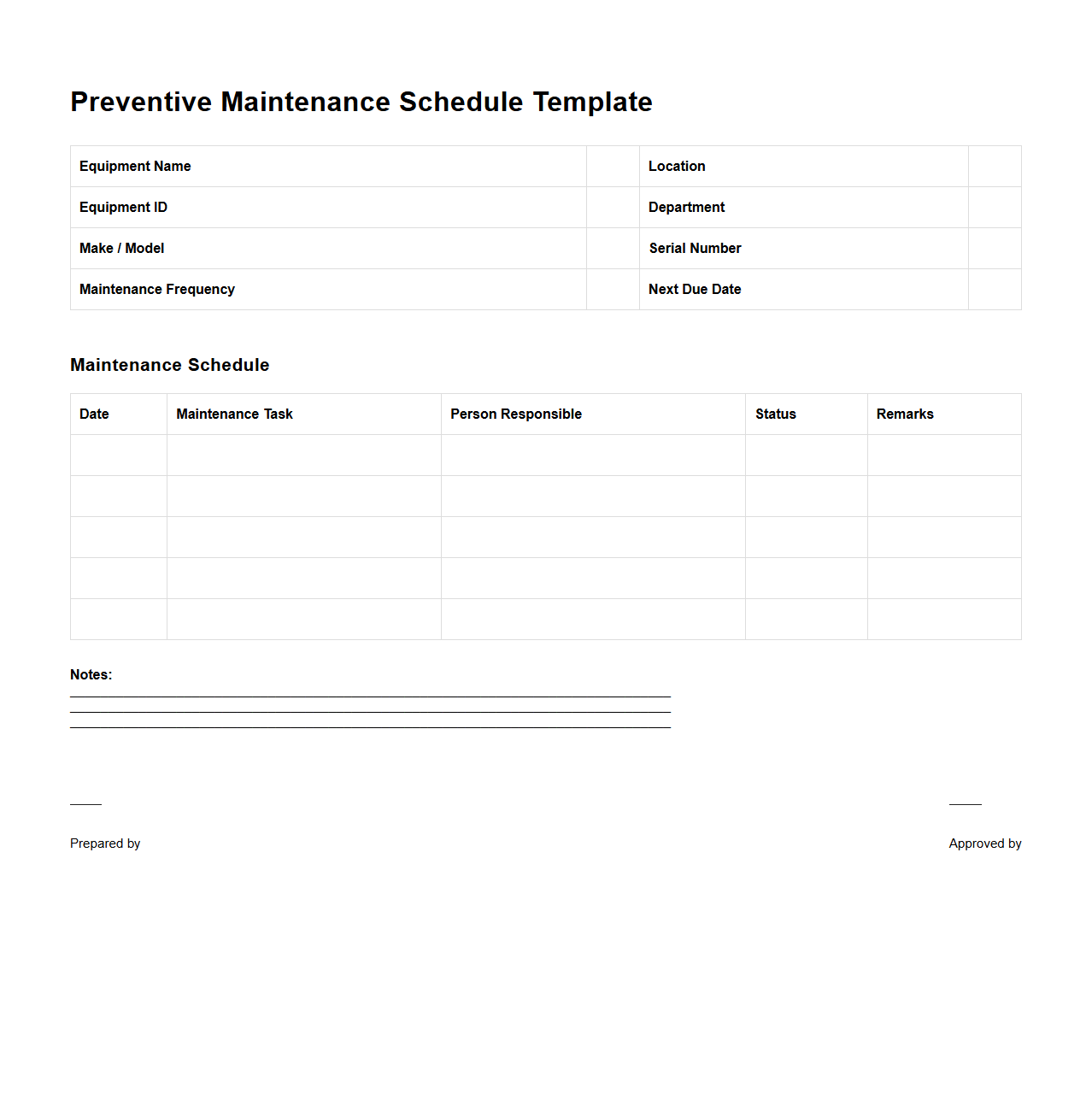

Blank Preventive Maintenance Schedule Template for Equipment

A

Blank Preventive Maintenance Schedule Template for Equipment is a structured document designed to organize and track routine maintenance tasks for machinery and assets. It outlines specific maintenance activities, frequencies, and responsible personnel to ensure equipment reliability and reduce downtime. This template enhances operational efficiency by enabling proactive maintenance planning and timely interventions.

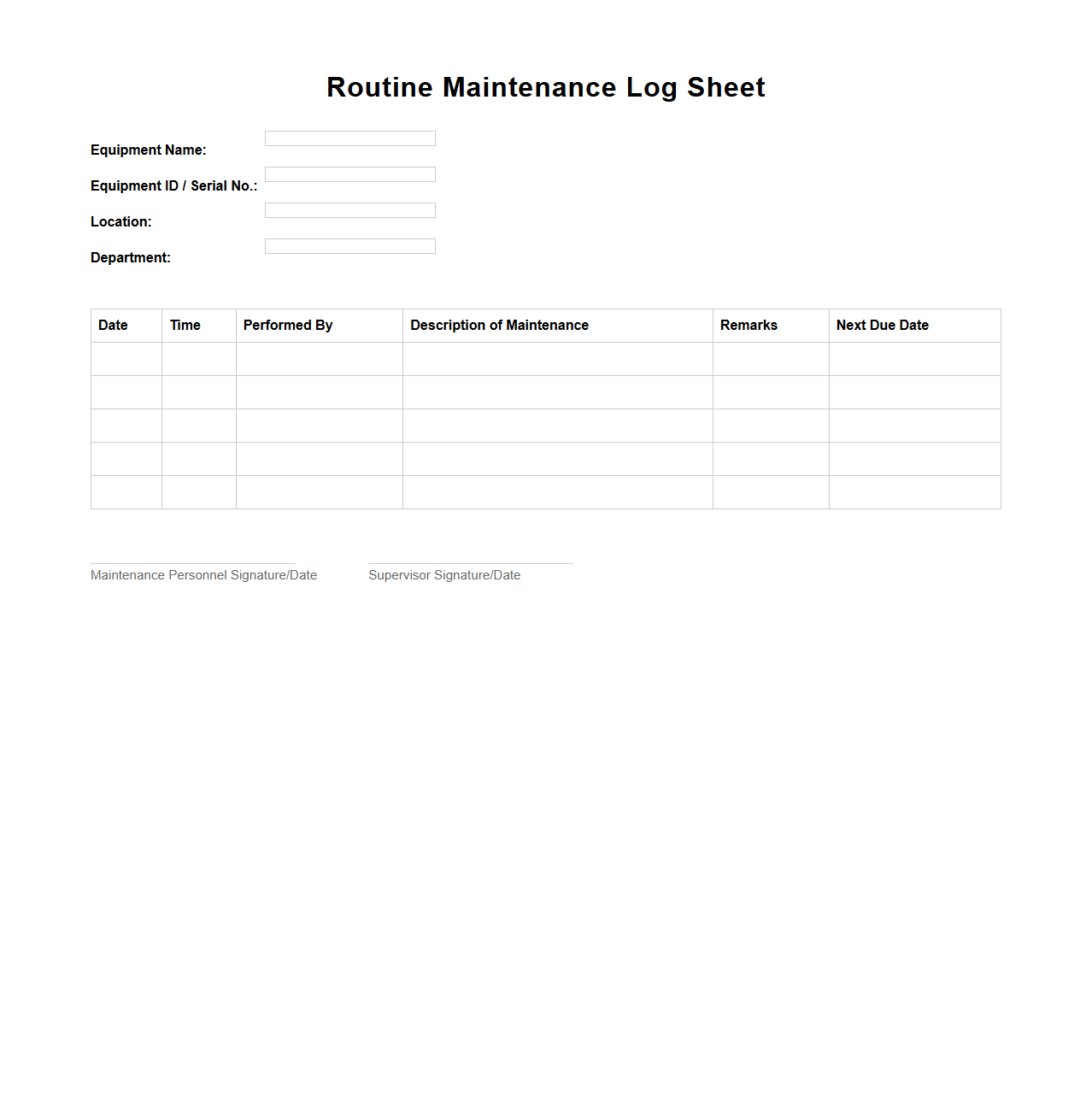

Blank Routine Maintenance Log Sheet for Equipment Monitoring

A

Blank Routine Maintenance Log Sheet for Equipment Monitoring is a structured document designed to record the regular inspection, servicing, and repair activities of machinery or equipment. It helps track maintenance schedules, operational status, and any issues encountered, ensuring timely upkeep and minimizing downtime. This log sheet is essential for maintaining equipment reliability and extending asset lifespan in industrial and manufacturing environments.

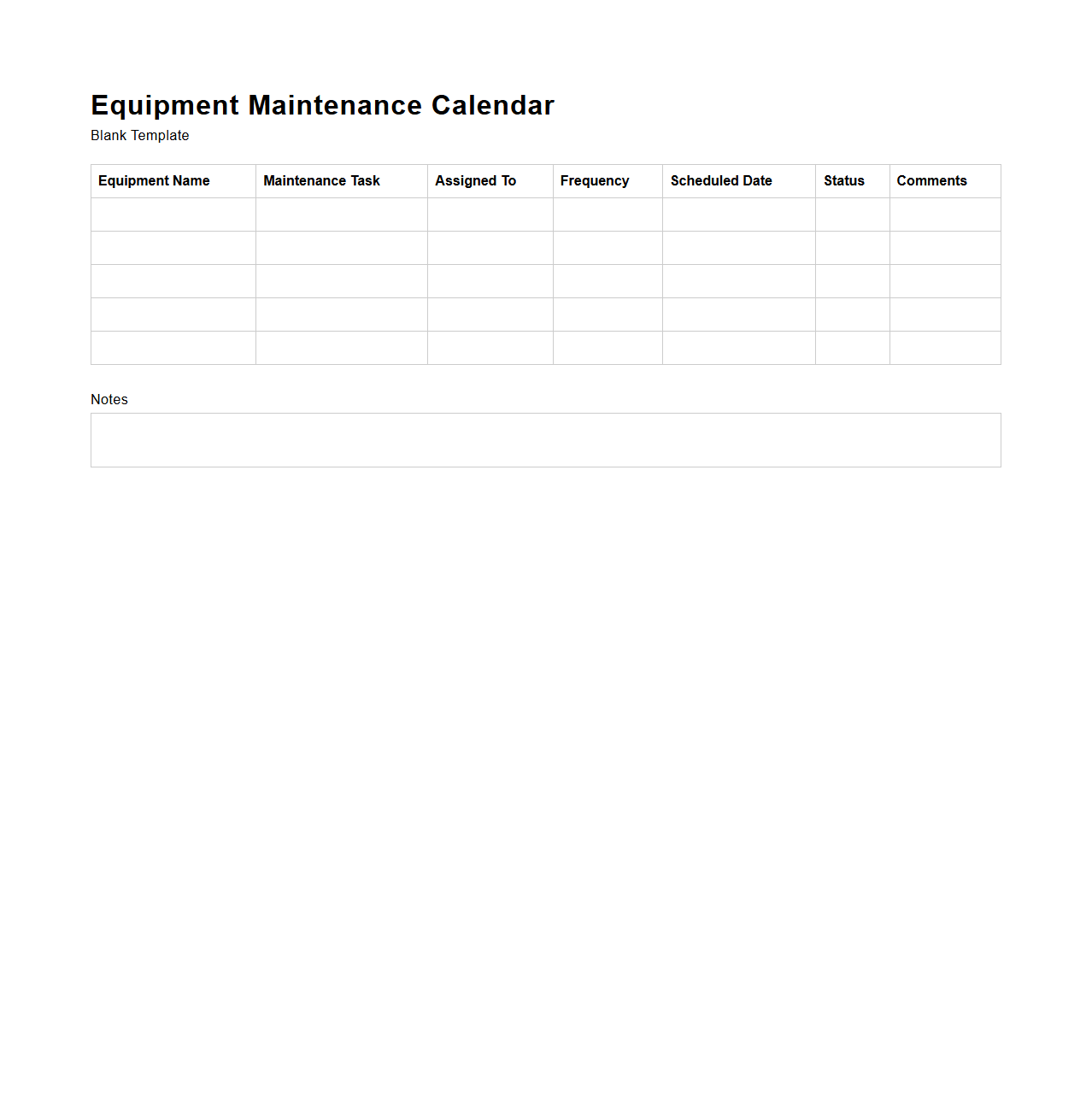

Blank Equipment Maintenance Calendar Template

A

Blank Equipment Maintenance Calendar Template is a structured document designed to schedule and track regular maintenance tasks for machinery and equipment. It helps organizations organize maintenance dates, assign responsibilities, and ensure timely servicing to prevent breakdowns and extend the lifespan of assets. This template supports efficient maintenance planning by providing clear visibility into upcoming and overdue maintenance activities.

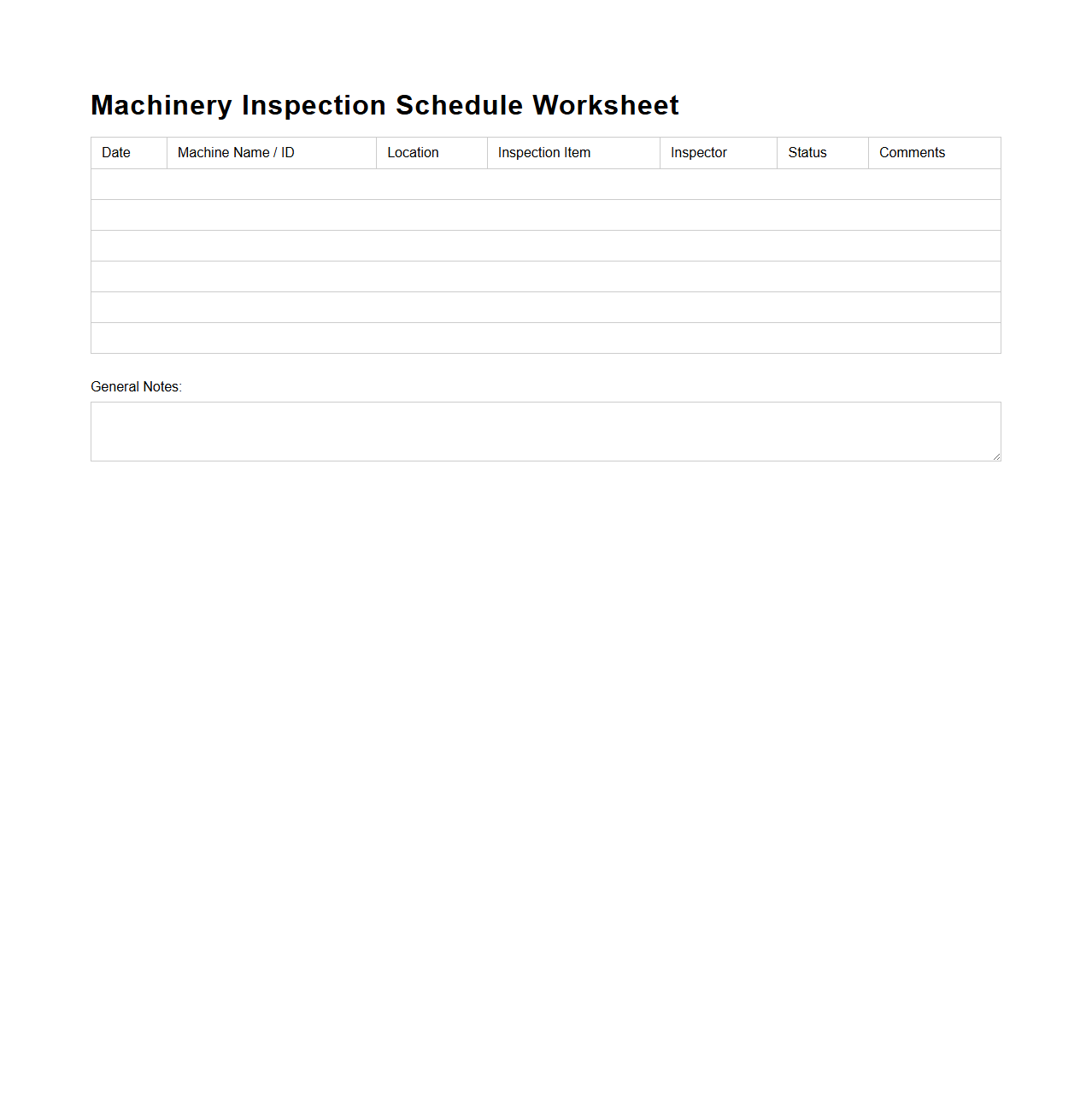

Blank Machinery Inspection Schedule Worksheet

The

Blank Machinery Inspection Schedule Worksheet document is a structured template used to plan and track regular inspections of machinery, ensuring operational efficiency and safety. It typically includes fields for equipment identification, inspection dates, checklist items, and notes on maintenance needs. This worksheet helps maintenance teams systematically monitor machine conditions, minimize downtime, and comply with safety regulations.

Blank Equipment Service History Tracking Form

The

Blank Equipment Service History Tracking Form is a crucial document used to systematically record maintenance and repair activities for machinery and equipment. This form helps organizations keep detailed logs of service dates, types of repairs, parts replaced, and technician notes, ensuring equipment reliability and compliance with safety standards. Consistent use of this form enhances asset management and extends the operational life of equipment through timely interventions.

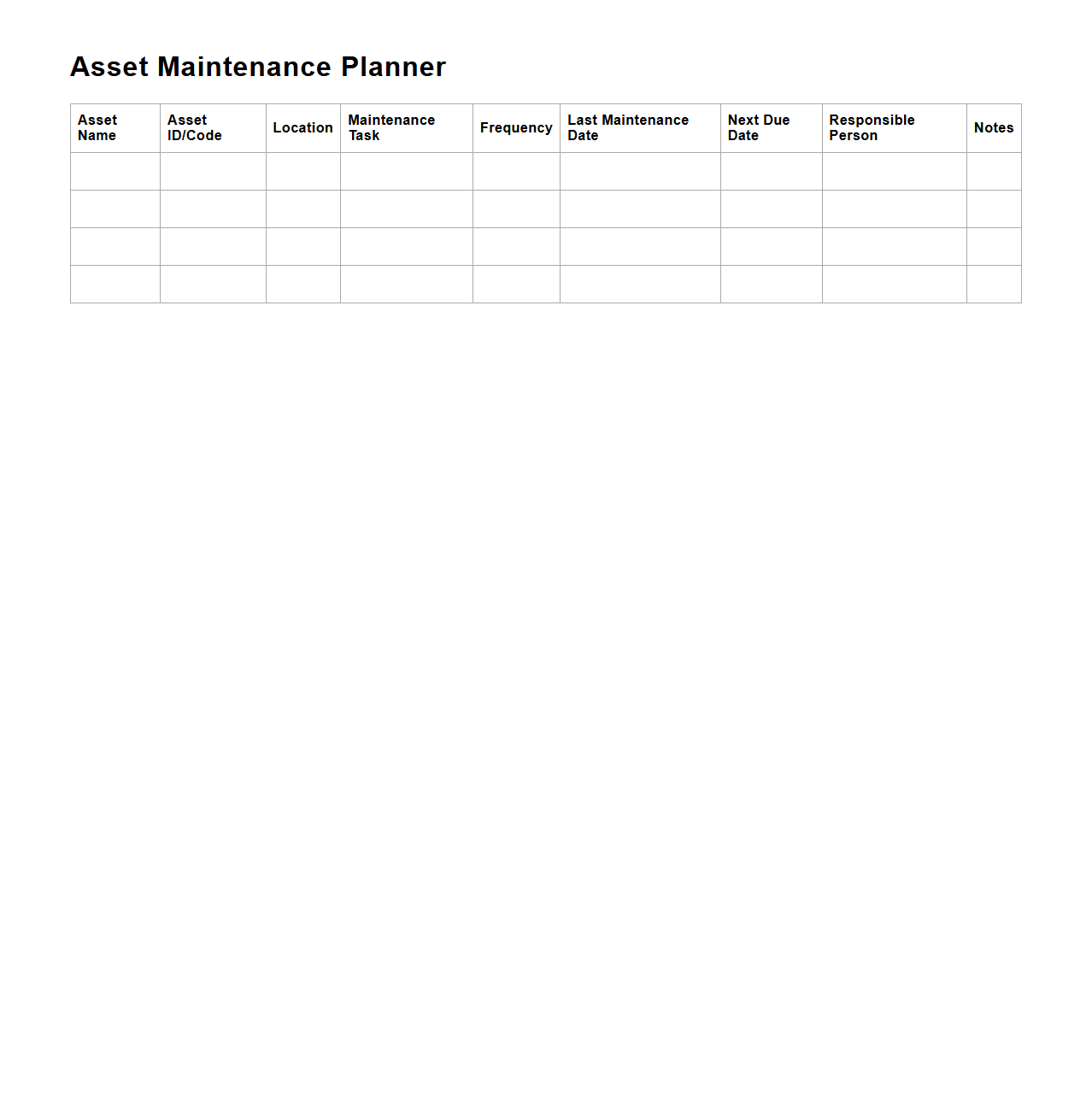

Blank Asset Maintenance Planner Spreadsheet

The

Blank Asset Maintenance Planner Spreadsheet is a versatile document designed to help organizations systematically schedule, track, and manage the upkeep of their physical assets. It typically includes sections for asset identification, maintenance tasks, frequency, responsible personnel, and status updates, enabling efficient resource allocation and minimizing downtime. Utilizing this planner promotes organized record-keeping and proactive maintenance strategies, enhancing asset longevity and operational reliability.

Blank Equipment Downtime Tracking Schedule

The

Blank Equipment Downtime Tracking Schedule document serves as a structured template for recording periods when machinery or equipment is not operational. It captures critical data such as the start and end times of downtime, reasons for the stoppage, and any maintenance actions taken. This document is essential for analyzing equipment performance and identifying areas to improve productivity and reduce operational disruptions.

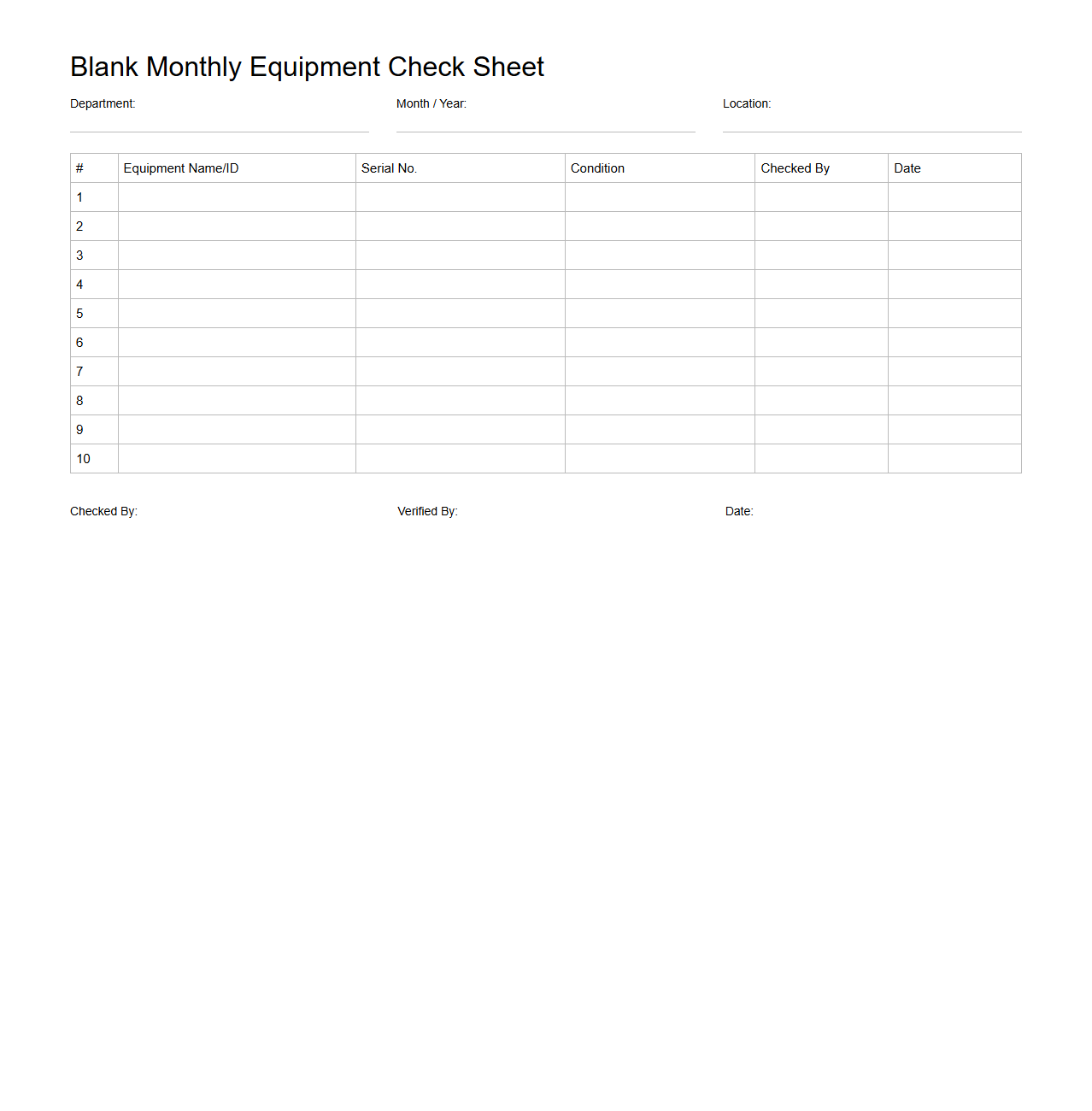

Blank Monthly Equipment Check Sheet Template

The

Blank Monthly Equipment Check Sheet Template is a standardized document designed to track the regular inspection and maintenance status of machinery and equipment. It ensures that all essential components are reviewed systematically to prevent operational failures and extend equipment lifespan. This template typically includes fields for recording equipment condition, maintenance activities performed, and any necessary repairs or replacements identified during the monthly checks.

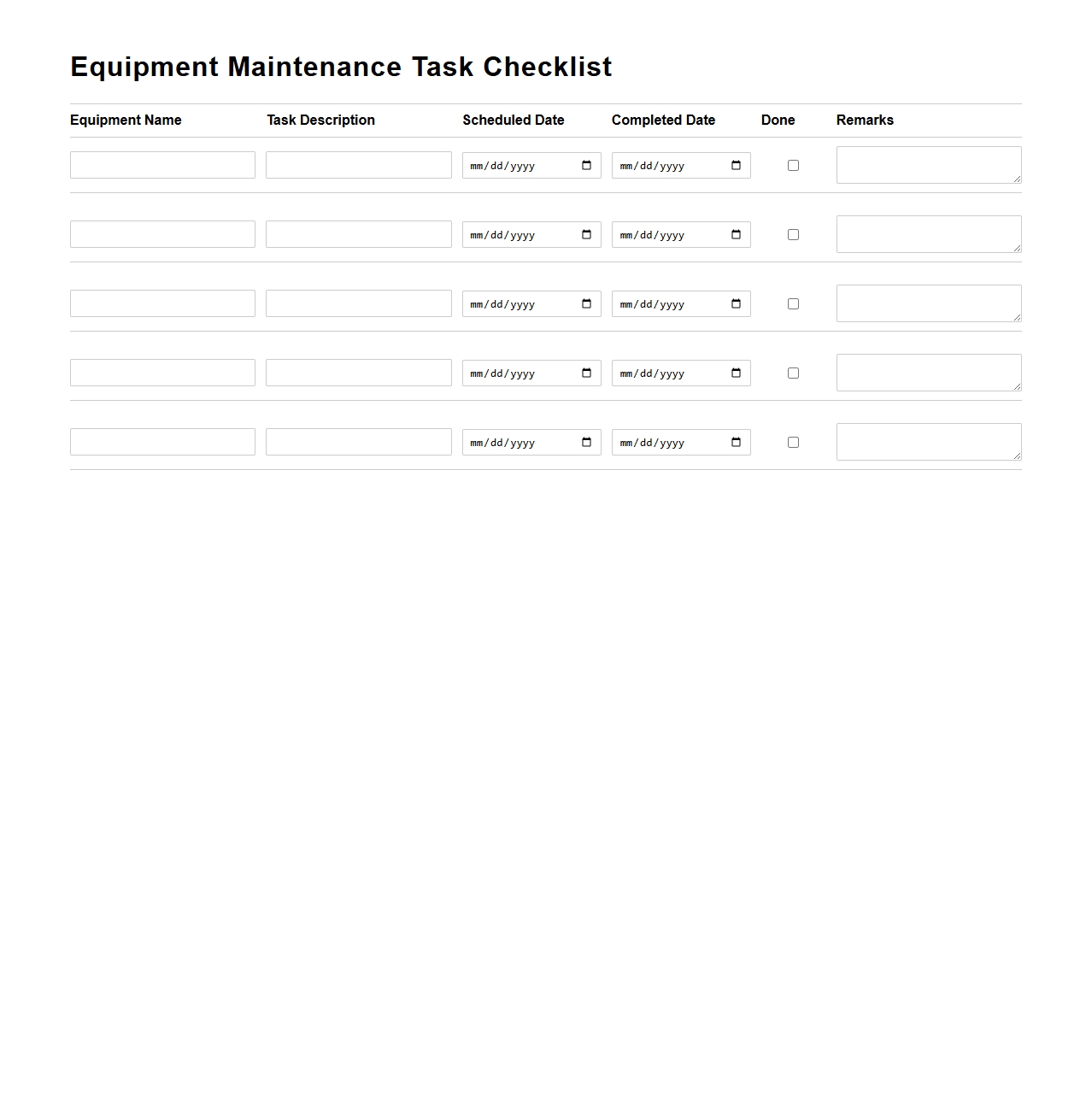

Blank Equipment Maintenance Task Checklist

A

Blank Equipment Maintenance Task Checklist document is a structured form used to systematically record and monitor routine maintenance activities for machinery and equipment. It helps ensure all necessary tasks are completed on schedule, promoting operational efficiency and preventing equipment failure. This checklist typically includes sections for task description, frequency, responsible personnel, and completion status to support consistent maintenance practices.

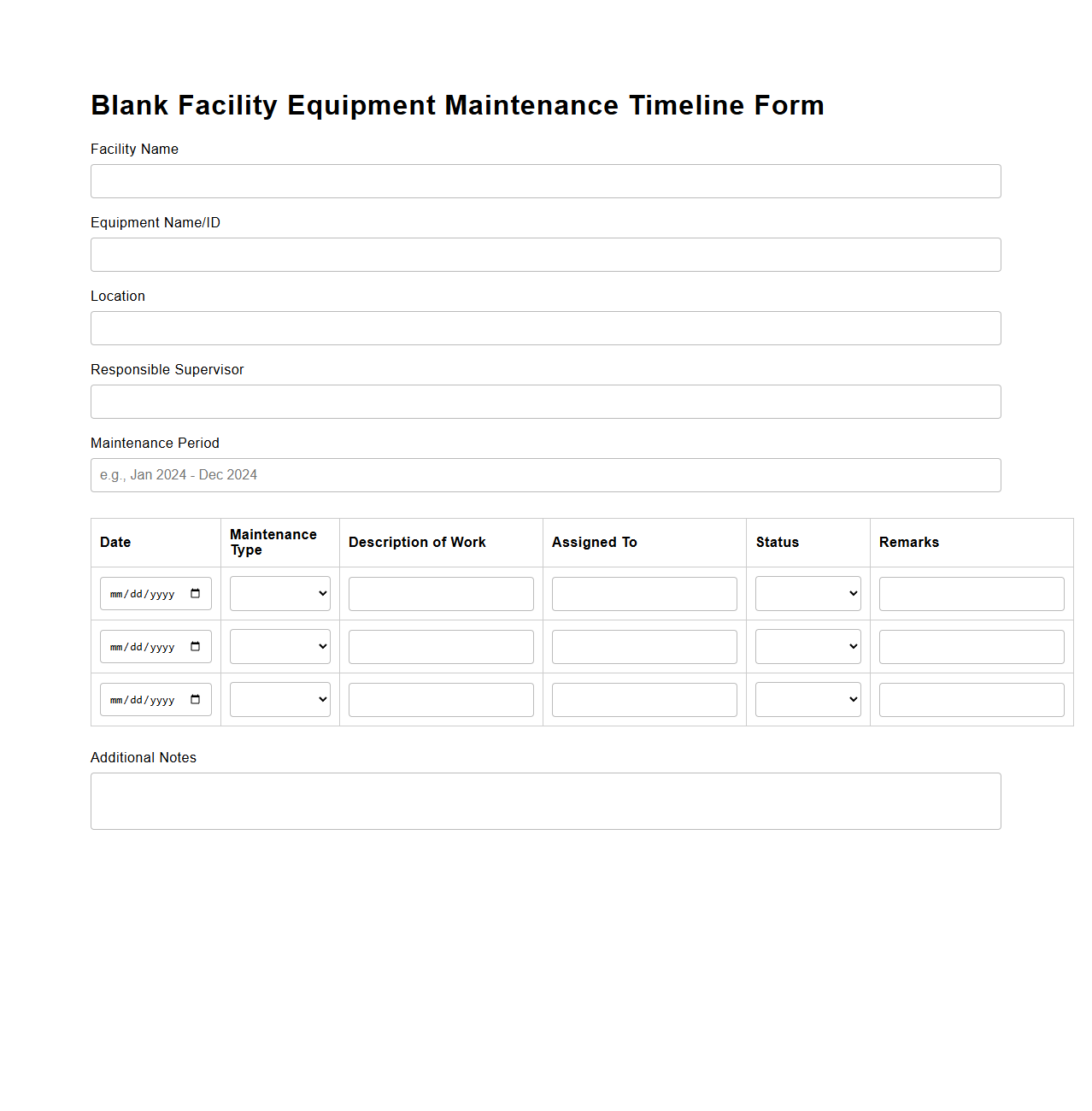

Blank Facility Equipment Maintenance Timeline Form

The

Blank Facility Equipment Maintenance Timeline Form is a structured document designed to track and schedule maintenance activities for various equipment within a facility. It allows facility managers to record maintenance dates, tasks performed, and upcoming service deadlines, ensuring equipment operates efficiently and downtime is minimized. This form enhances asset management by providing a clear, organized timeline that supports preventive maintenance and compliance with safety regulations.

How often should the Blank Maintenance Schedule be reviewed and updated for accuracy?

The Blank Maintenance Schedule should be reviewed regularly to ensure its accuracy and effectiveness. Typically, a quarterly review is recommended to capture any changes in equipment condition or operational requirements. Additionally, updates should be made immediately after any significant maintenance task or incident.

Which specific equipment categories require custom tracking fields in the Blank Maintenance Schedule?

Custom tracking fields in the Blank Maintenance Schedule are essential for categories like HVAC systems, electrical equipment, and heavy machinery. These fields allow for detailed monitoring of unique maintenance needs and performance indicators. Tailoring these fields ensures precision in tracking and enhances overall schedule management.

What protocols exist for logging missed or delayed maintenance within the schedule?

The Blank Maintenance Schedule incorporates strict protocols for logging missed or delayed tasks to maintain operational safety and efficiency. All missed maintenance must be documented with reasons and rescheduling plans in the system. This transparency helps prevent future delays and aids in accountability.

How is maintenance priority determined and highlighted in the Blank Maintenance Schedule template?

Maintenance priority in the Blank Maintenance Schedule is determined based on equipment criticality, safety impact, and operational urgency. Priorities are clearly highlighted using color codes or flags within the schedule template. This visual differentiation enables quick decision-making and resource allocation.

Are there digital integrations available for automatic alerts in the Blank Maintenance Schedule system?

Yes, the Blank Maintenance Schedule system supports digital integrations with various platforms for automatic maintenance alerts. Common integrations include email notifications, SMS reminders, and mobile app alerts. These features ensure timely notifications and improve maintenance compliance.

![]()