A Blank Maintenance Checklist Template for Equipment Servicing provides a structured format to track routine inspections and repairs efficiently. This template ensures all critical components are evaluated systematically, helping prevent unexpected breakdowns and extend equipment lifespan. Easy to customize, it supports consistent maintenance practices and improves overall operational reliability.

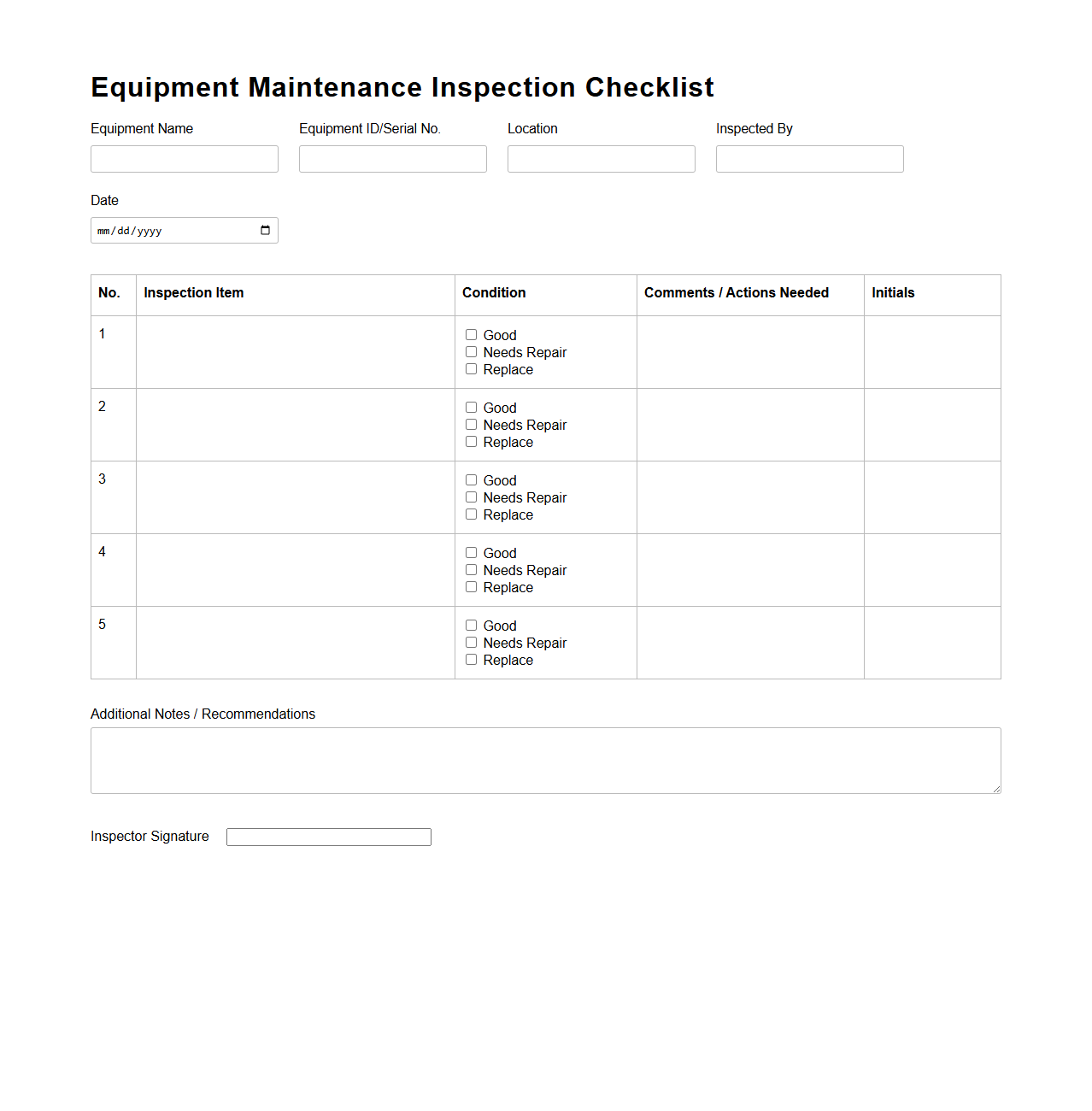

Equipment Maintenance Inspection Checklist Template

The

Equipment Maintenance Inspection Checklist Template document is a structured tool designed to systematically assess the condition and performance of machinery and equipment. It ensures that all critical components are examined regularly to prevent breakdowns, enhance safety, and maintain operational efficiency. This checklist typically includes inspection criteria, maintenance schedules, and space for recording observations and corrective actions.

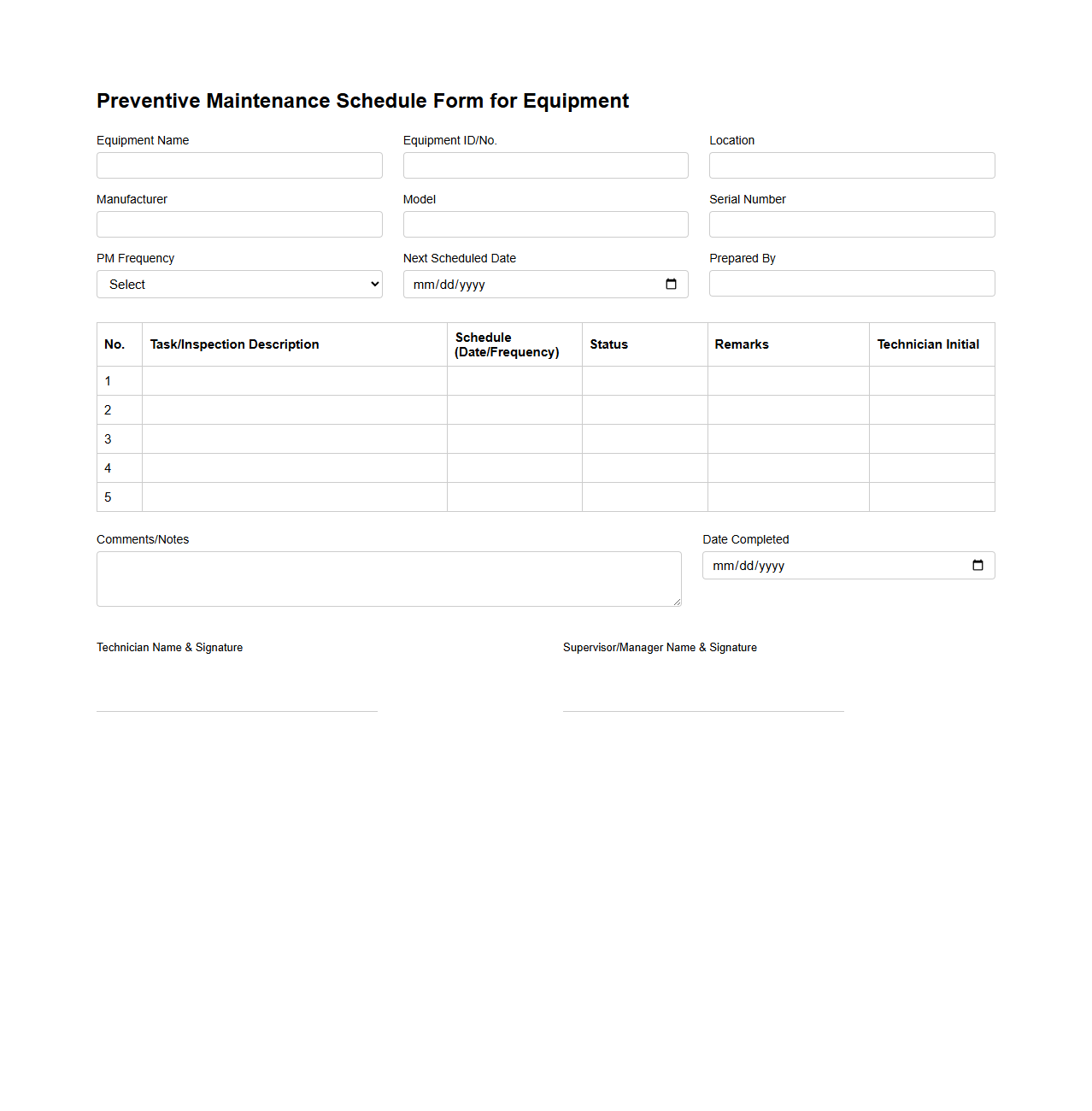

Preventive Maintenance Schedule Form for Equipment

The

Preventive Maintenance Schedule Form for Equipment is a critical document used to systematically plan and track routine maintenance tasks to ensure optimal performance and longevity of machinery. It outlines specific maintenance activities, frequencies, and responsible personnel, helping to minimize unexpected breakdowns and costly repairs. By adhering to this schedule, organizations enhance equipment reliability and operational efficiency.

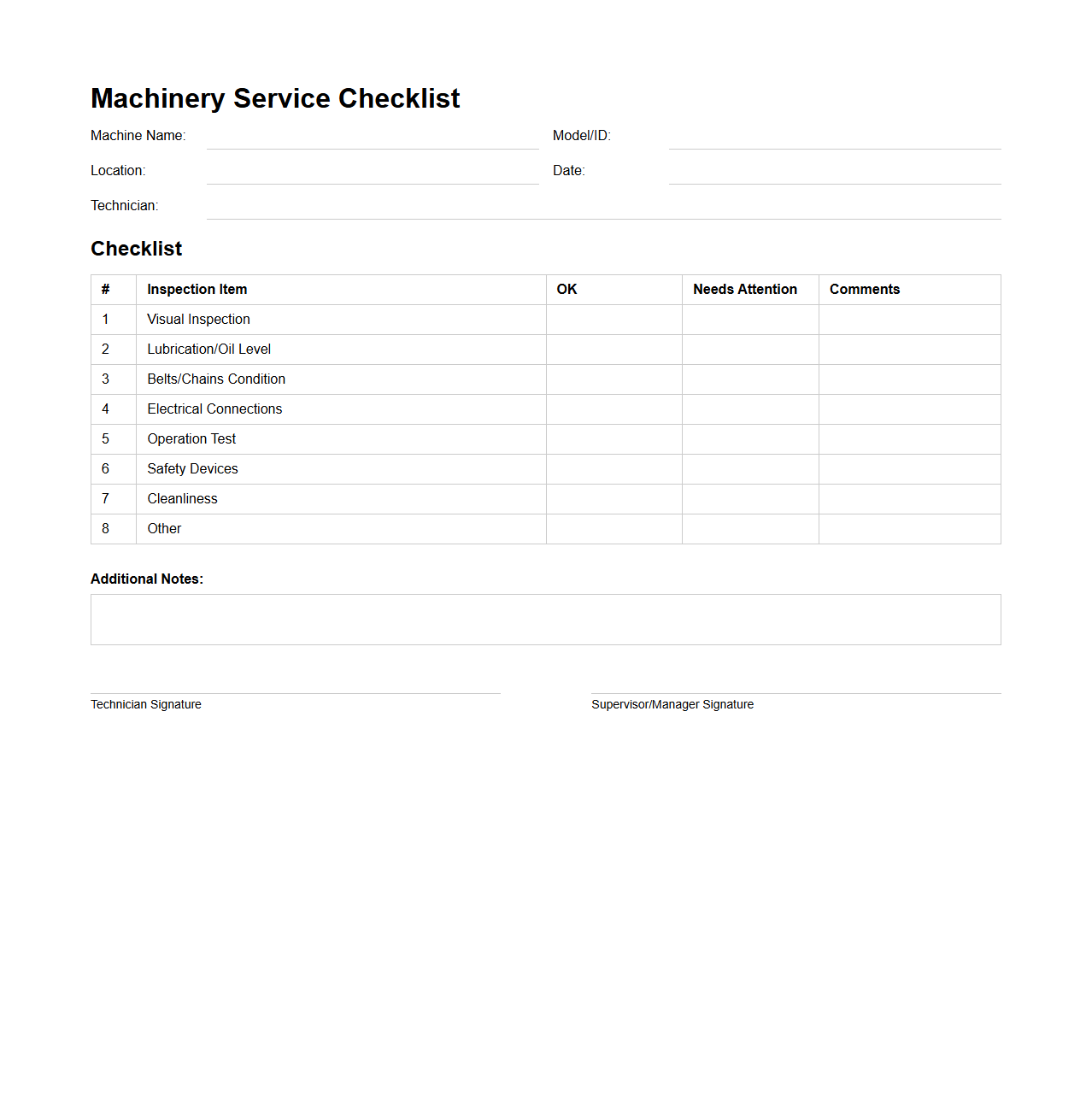

Machinery Service Checklist Template

A

Machinery Service Checklist Template is a standardized document designed to guide technicians through routine maintenance tasks and inspections for machinery. It ensures all critical components, such as lubrication points, safety features, and operational controls, are systematically checked to prevent equipment failure and extend machine lifespan. This template improves maintenance consistency, reduces downtime, and enhances safety compliance across industrial settings.

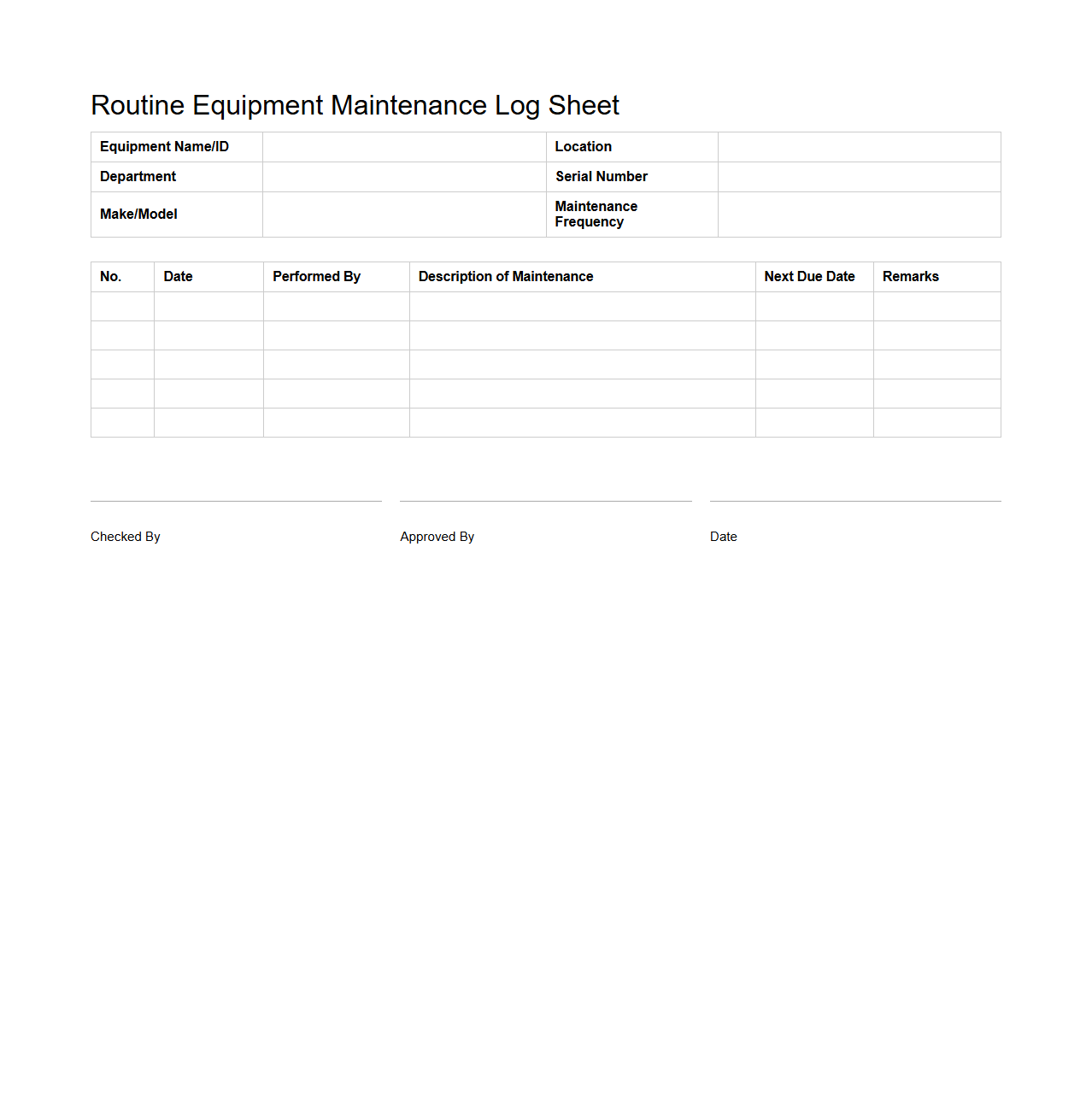

Routine Equipment Maintenance Log Sheet

A

Routine Equipment Maintenance Log Sheet document is a detailed record used to systematically track the regular servicing, inspections, and repairs of machinery or equipment. It ensures consistent monitoring of maintenance activities, helping to prevent unexpected breakdowns and extend equipment lifespan. This log typically includes information such as dates, performed tasks, technician notes, and equipment condition updates.

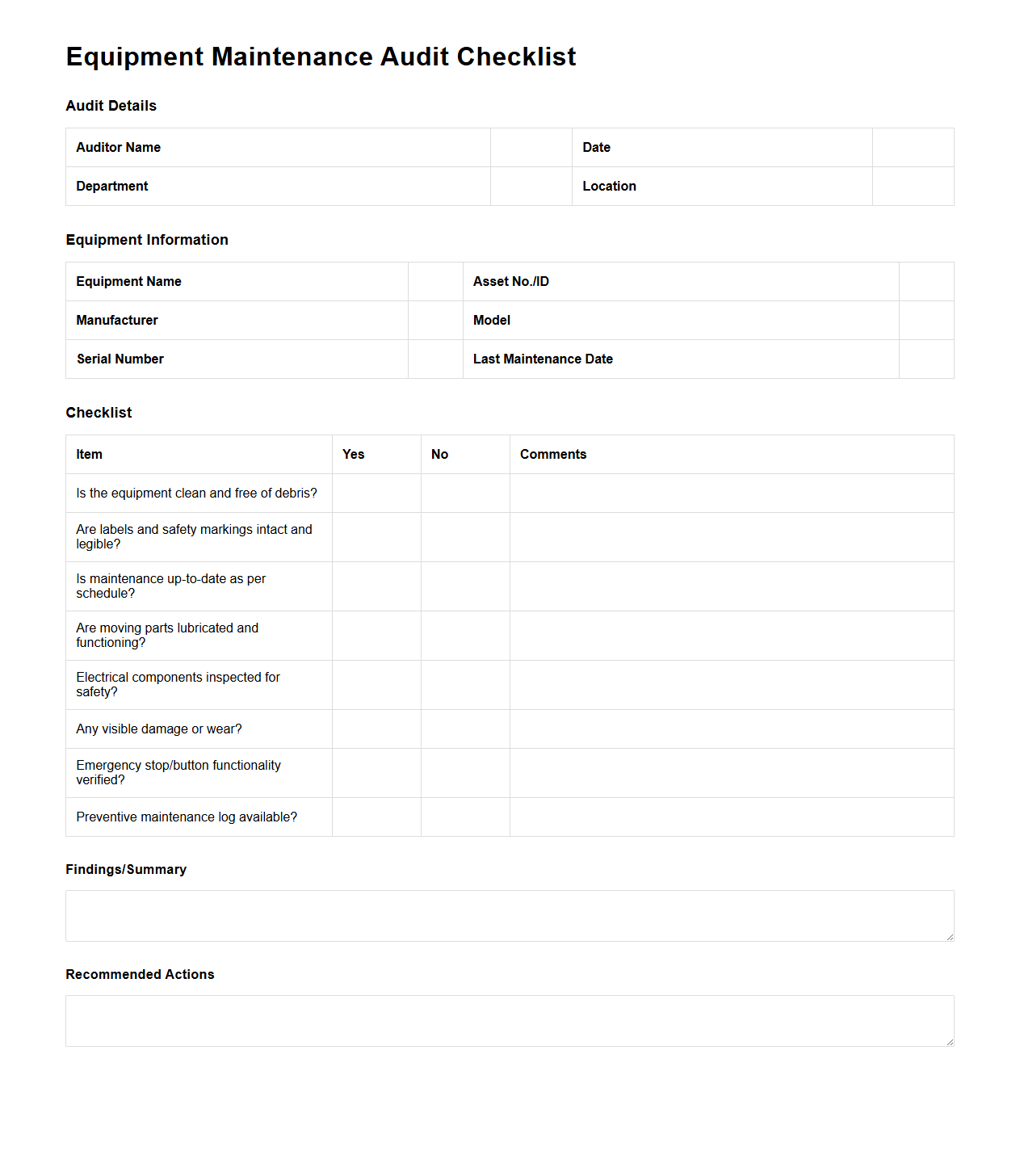

Equipment Maintenance Audit Checklist

An

Equipment Maintenance Audit Checklist document is a structured tool used to systematically evaluate the condition, performance, and compliance of machinery and equipment within an organization. It ensures that maintenance activities are performed consistently, identifies potential issues before they lead to equipment failure, and helps maintain operational efficiency and safety standards. By documenting all inspection points and maintenance tasks, this checklist facilitates accurate tracking and reporting for continuous equipment reliability improvement.

Machine Maintenance Tracking Sheet

A

Machine Maintenance Tracking Sheet document is a detailed log used to monitor and record the maintenance activities of machinery, ensuring efficient operation and minimizing downtime. It includes fields for machine identification, date of service, type of maintenance performed, technician details, and any observed issues or repairs needed. This document helps organizations optimize equipment lifespan, plan preventive maintenance schedules, and maintain compliance with safety standards.

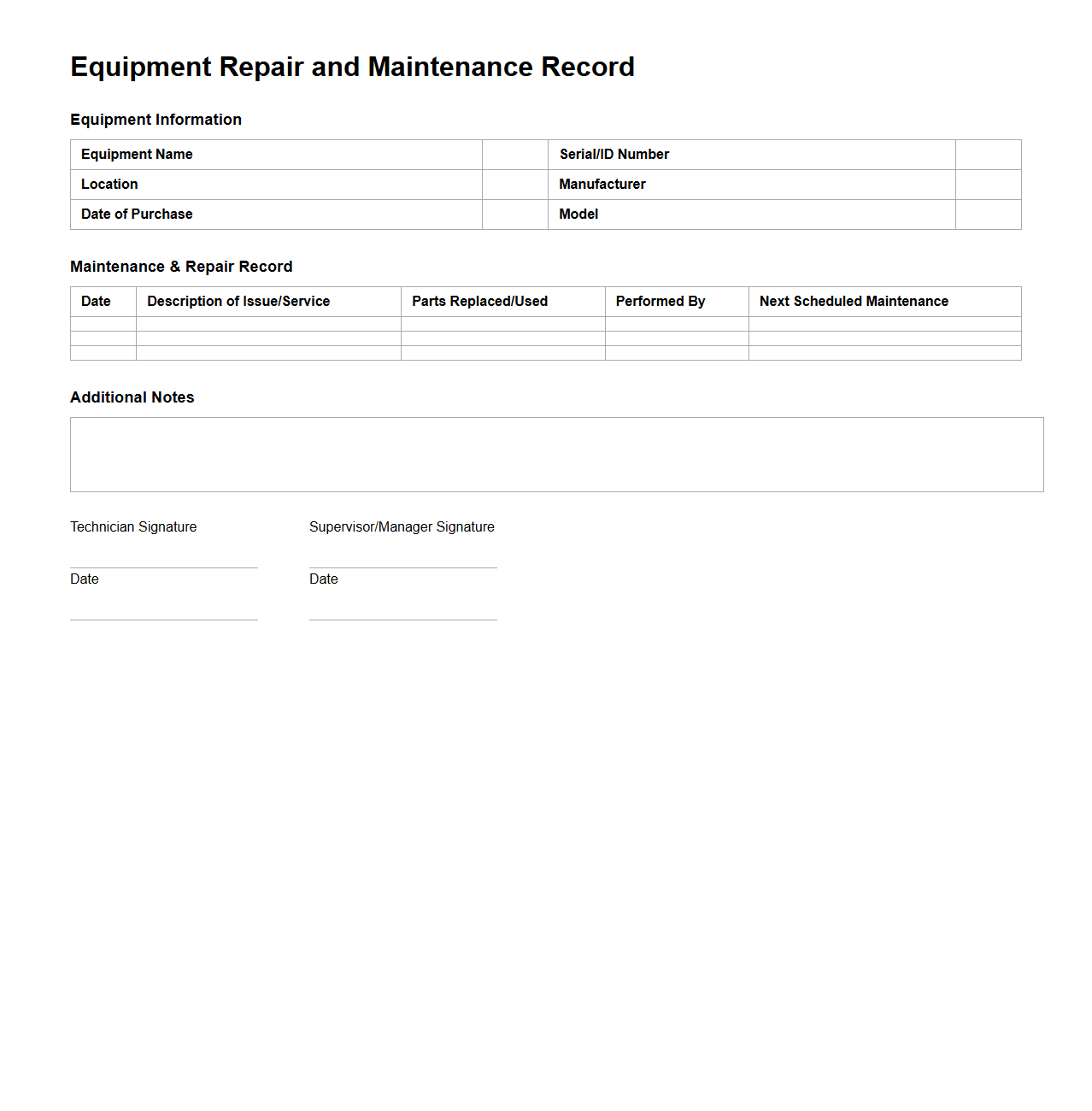

Equipment Repair and Maintenance Record Template

An

Equipment Repair and Maintenance Record Template document is a structured form used to systematically track and document all repair and maintenance activities performed on machinery and equipment. It captures essential details such as dates of service, types of repairs, parts replaced, technician information, and maintenance schedules to ensure operational efficiency and compliance. This record helps organizations maintain asset reliability, reduce downtime, and plan future maintenance effectively.

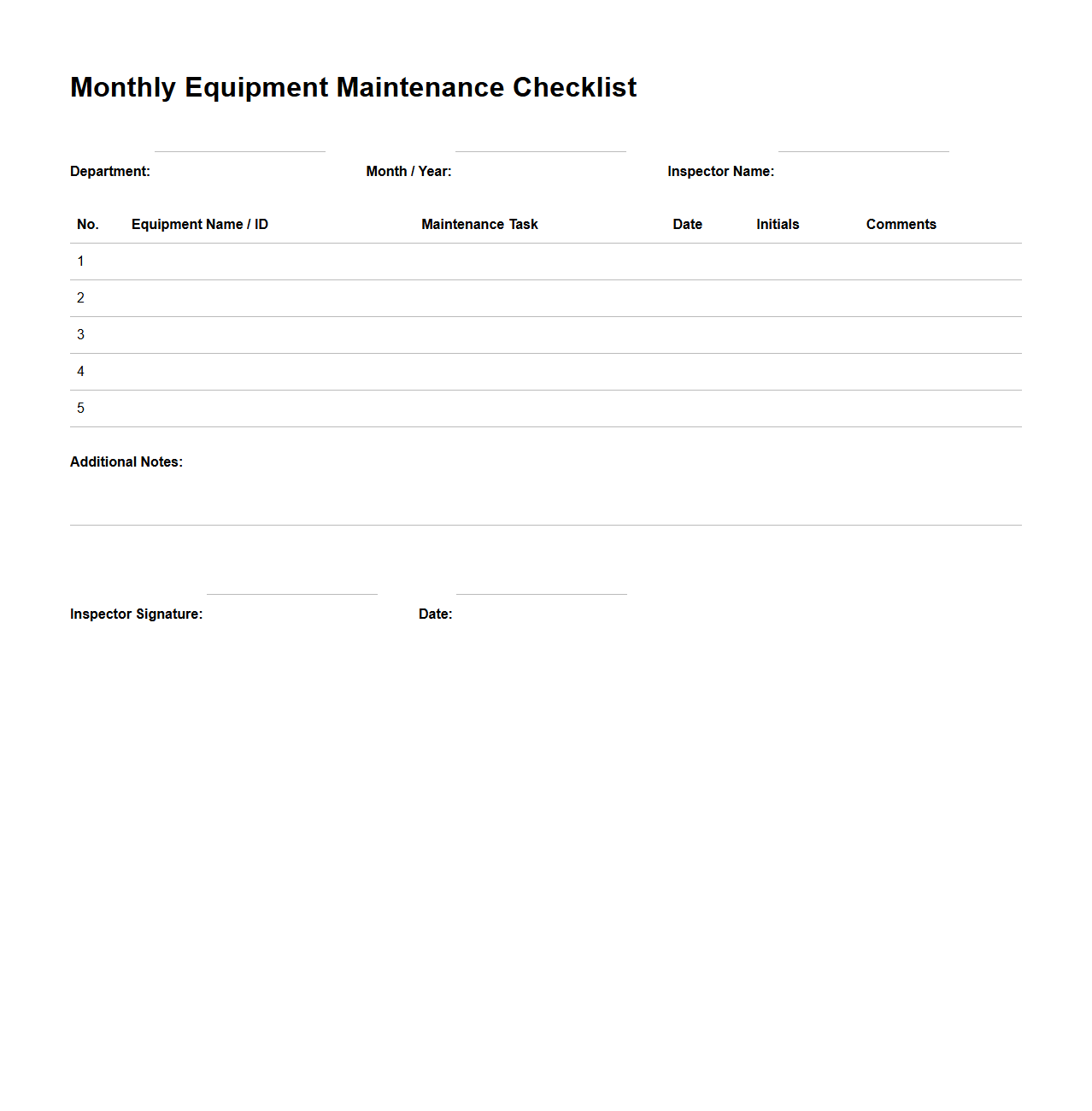

Monthly Equipment Maintenance Checklist

A

Monthly Equipment Maintenance Checklist document is a structured tool used to ensure all machinery and equipment undergo regular inspections and servicing, minimizing downtime and extending operational lifespan. It lists specific tasks and safety checks that need to be performed, helping maintenance teams systematically track condition and performance issues. This checklist promotes consistent maintenance practices, enhances equipment reliability, and supports compliance with industry standards.

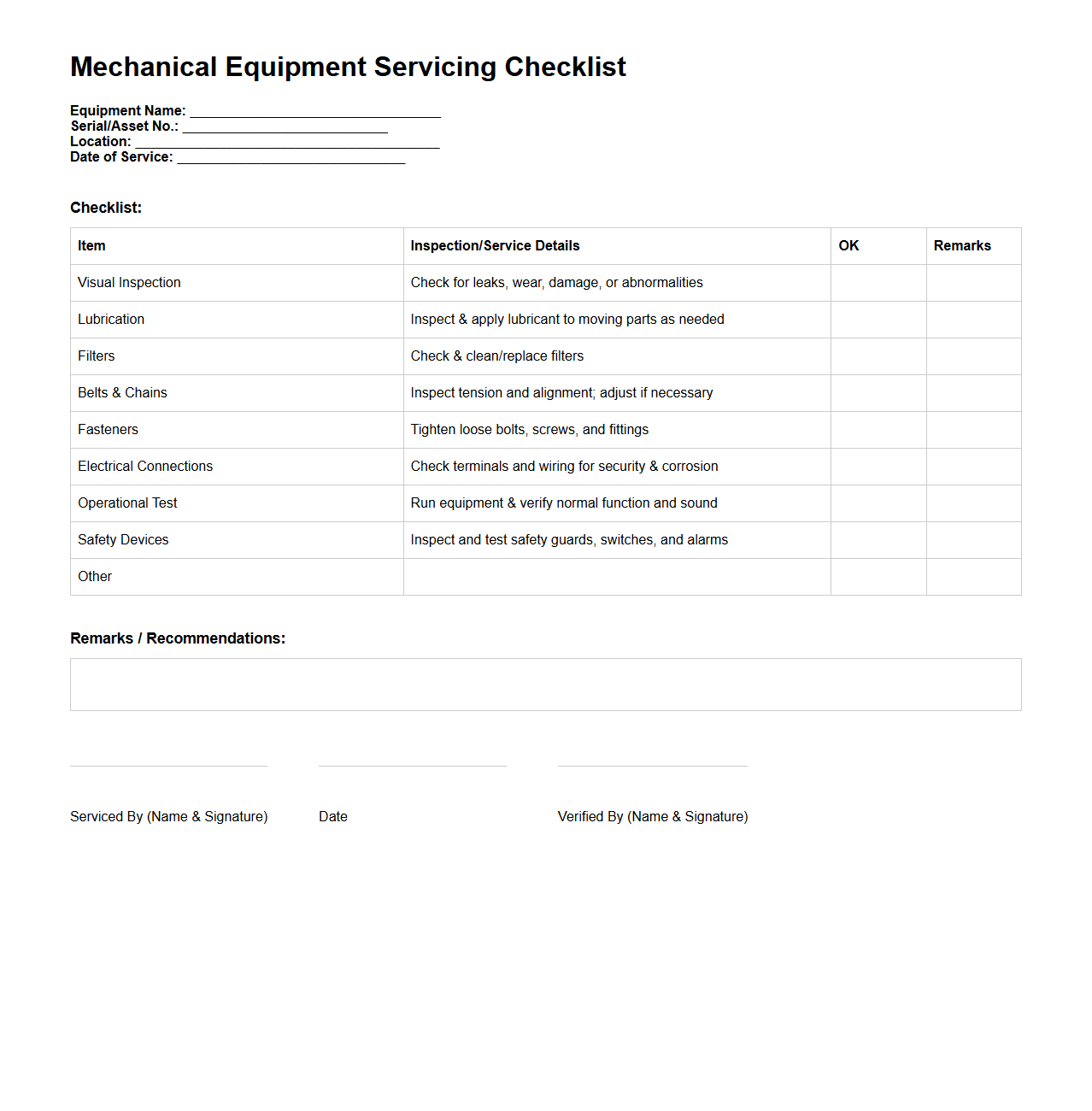

Mechanical Equipment Servicing Checklist

A

Mechanical Equipment Servicing Checklist document ensures systematic inspection, maintenance, and repair of machinery to enhance operational efficiency and safety. It outlines specific tasks, schedules, and standards for servicing various mechanical systems, reducing downtime and preventing costly failures. Proper use of this checklist supports compliance with industry regulations and extends equipment lifespan.

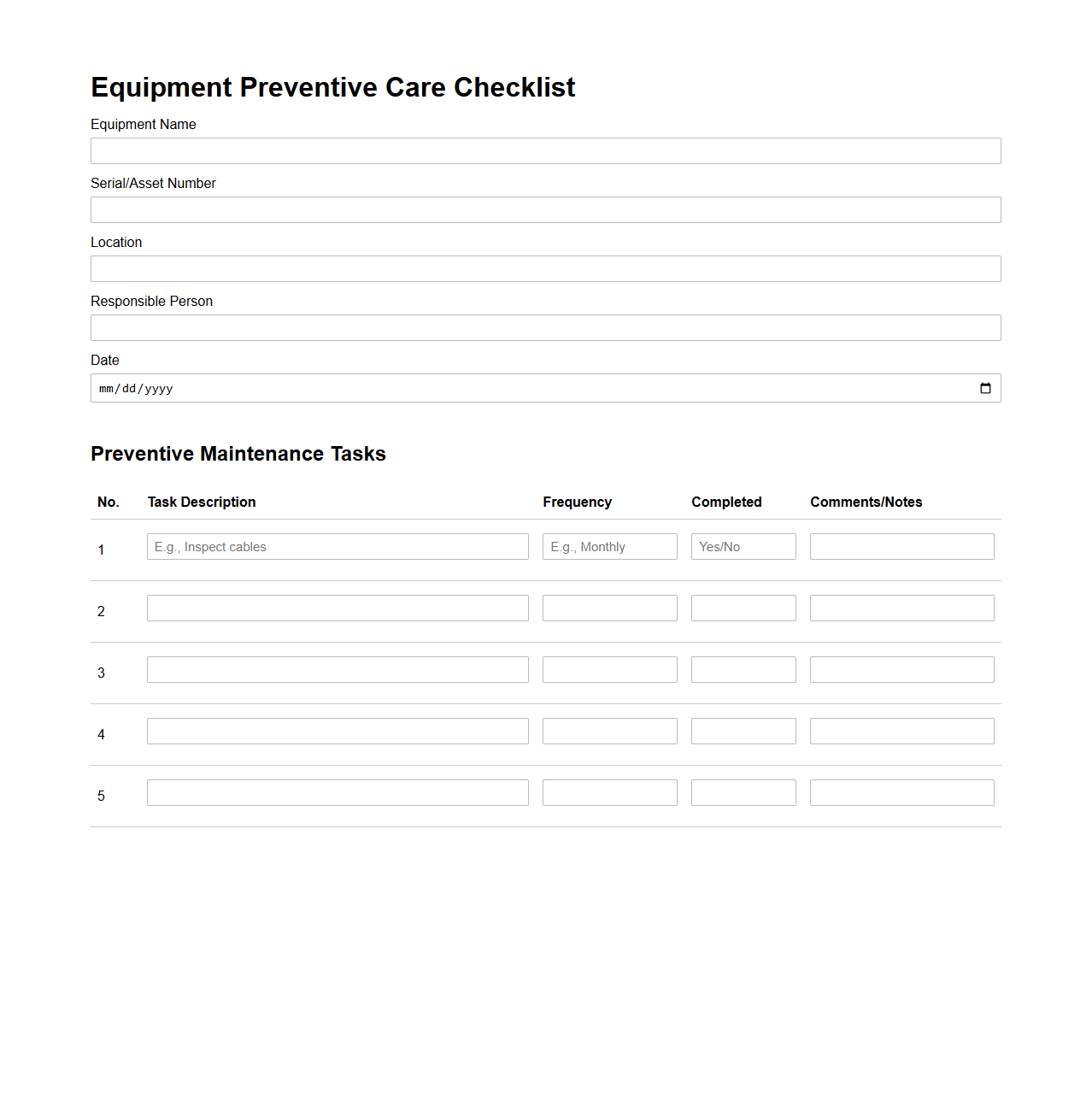

Equipment Preventive Care Checklist Template

An

Equipment Preventive Care Checklist Template document is a structured tool designed to ensure regular maintenance and inspection of machinery and equipment to prevent breakdowns and extend lifespan. It includes detailed sections for recording scheduled tasks, maintenance dates, responsible personnel, and condition assessments. Using this template improves operational efficiency, reduces downtime, and supports compliance with safety standards.

What essential fields should be included in a blank maintenance checklist for equipment servicing logs?

A maintenance checklist should include fields for equipment identification, such as serial number and model. It must also contain sections for the date and time of service, along with the technician's name. Additionally, detailed fields for recording the type of maintenance performed, observations, and any necessary repairs are crucial.

How do you customize a maintenance checklist template to fit specific equipment types or industry standards?

Customization begins with understanding the specific equipment requirements and operational parameters. Tailor the checklist by incorporating industry standards and regulatory guidelines to ensure compliance. Adding equipment-specific tasks and prioritizing critical checks enhances the checklist's relevancy and effectiveness.

What common mistakes should be avoided when creating a blank maintenance checklist for equipment servicing?

Avoid creating checklists that are overly generic and lack key equipment-specific details. Failure to include clear instructions or standardized terminology can lead to inconsistent maintenance records. Also, neglecting to update the checklist regularly causes it to become obsolete and less useful over time.

How can digital tools enhance the effectiveness of a blank maintenance checklist for equipment maintenance tracking?

Digital tools enable real-time data capture and easier access to maintenance histories, enhancing accuracy. Automated reminders and alerts improve adherence to scheduled maintenance timelines. Additionally, integration with asset management systems facilitates comprehensive oversight and reporting.

What compliance requirements must a maintenance checklist meet for regulatory inspections in equipment servicing?

Checklists must align with regulatory standards such as OSHA, ISO, or industry-specific regulations based on the equipment type. They should include documentation fields for safety checks, calibration verification, and service intervals. Proper record-keeping and audit trail capabilities are essential to demonstrate compliance during inspections.