A Blank Safety Checklist Template for Workplace Compliance provides a comprehensive framework to ensure all safety protocols are met effectively. This template helps businesses systematically identify hazards, verify safety measures, and maintain regulatory standards. Utilizing it promotes a safer work environment and reduces the risk of accidents or violations.

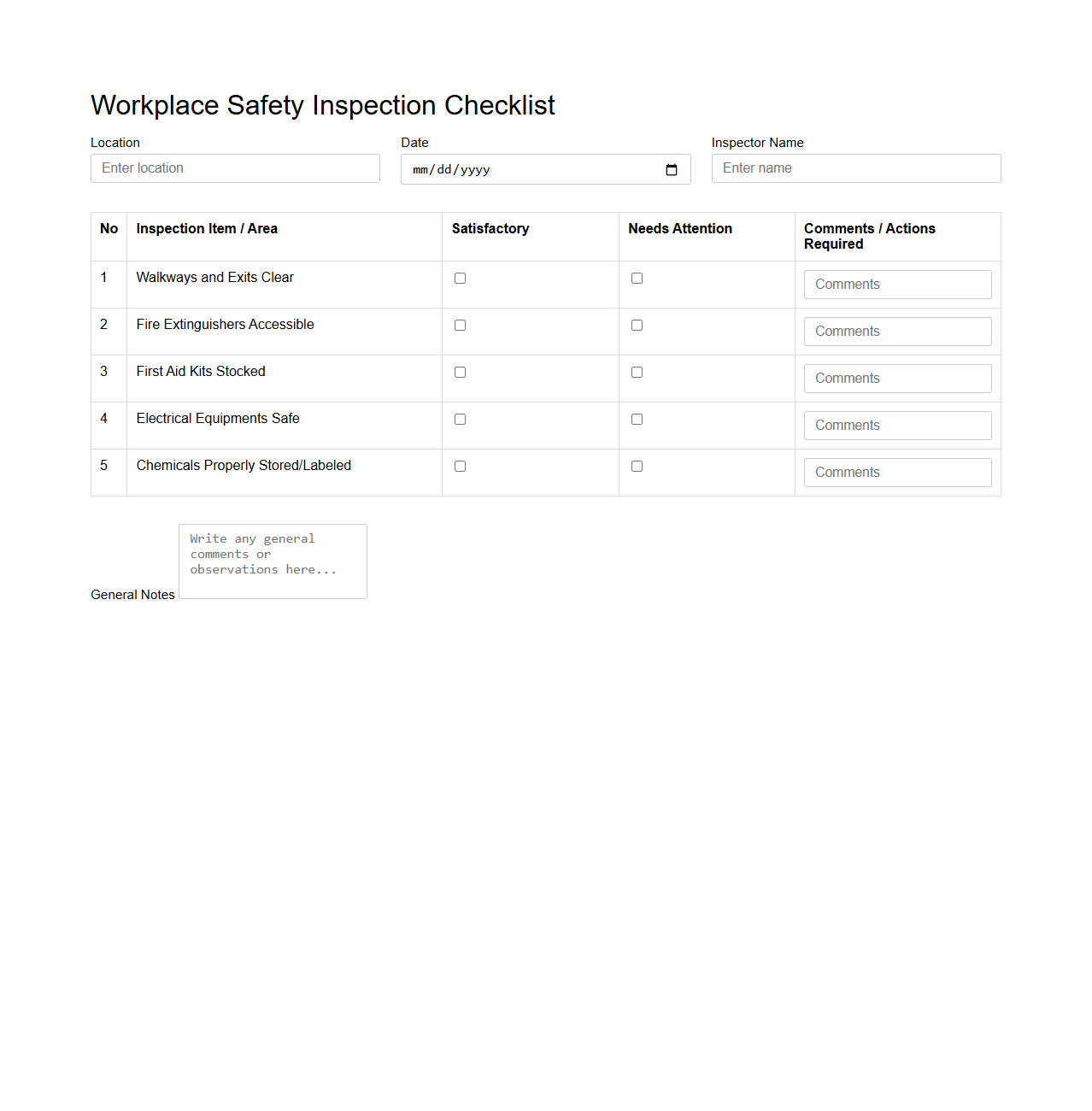

Workplace Safety Inspection Checklist Template

A

Workplace Safety Inspection Checklist Template document is a structured tool designed to systematically evaluate and identify potential hazards within a work environment. It ensures compliance with occupational health and safety regulations by guiding inspectors through critical safety checkpoints, equipment status, and procedural adherence. Regular use of this template promotes a safer workplace, reduces the risk of accidents, and supports continuous improvement in safety standards.

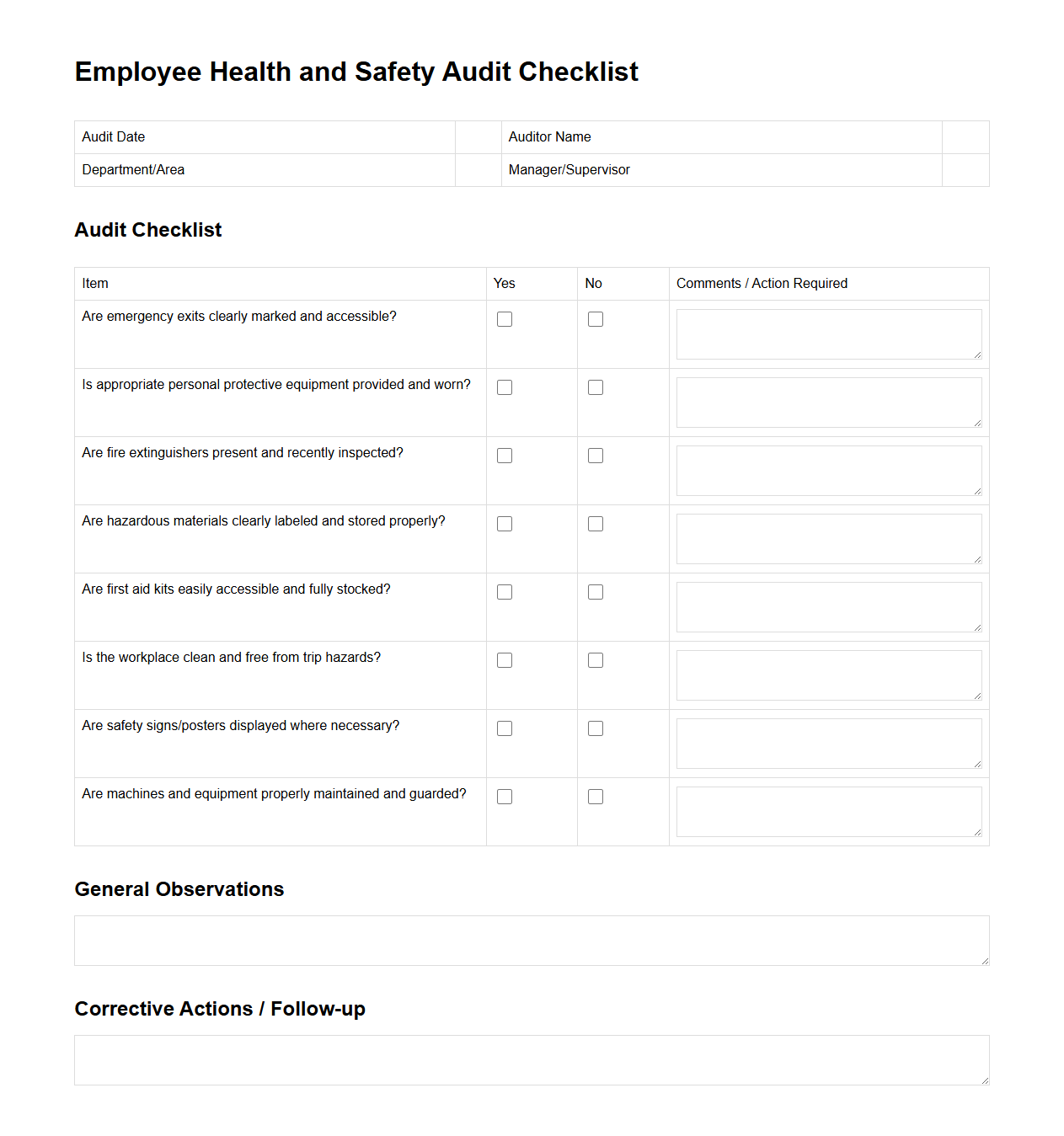

Employee Health and Safety Audit Checklist

An

Employee Health and Safety Audit Checklist document is a comprehensive tool used to systematically evaluate workplace conditions, ensuring compliance with occupational health and safety regulations. It helps identify potential hazards, assess risk management practices, and verify the effectiveness of safety protocols to protect employees. Regular use of this checklist supports organizations in maintaining a safe working environment and minimizing workplace accidents.

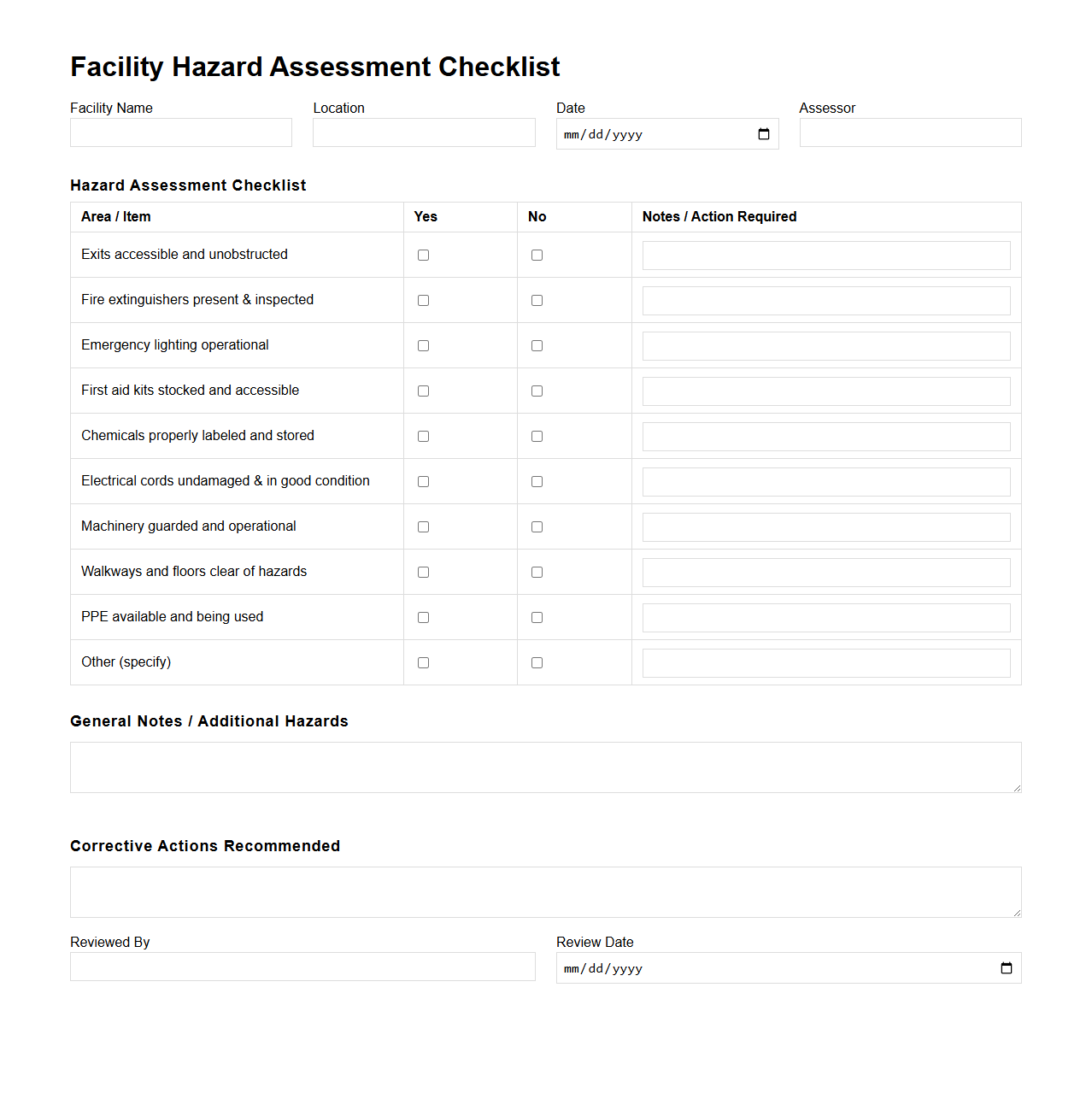

Facility Hazard Assessment Checklist

The

Facility Hazard Assessment Checklist document systematically identifies potential risks and hazards present in a workplace or facility to ensure compliance with safety regulations. It serves as a critical tool for safety managers to evaluate environmental conditions, machinery, and operational processes for hazards that could lead to accidents or injuries. Regular use of this checklist supports proactive risk management and promotes a safer working environment.

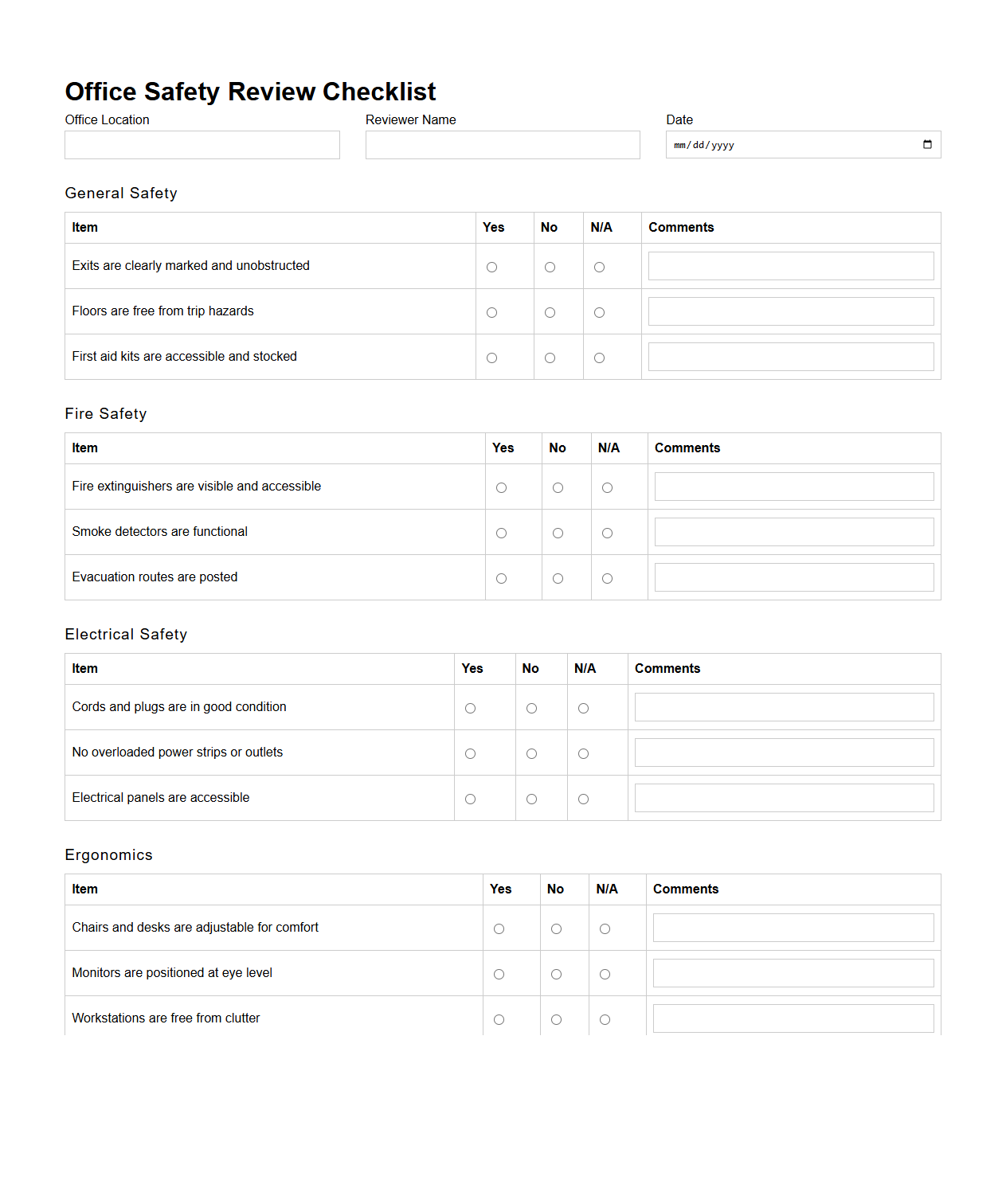

Office Safety Review Checklist

An

Office Safety Review Checklist document is a comprehensive tool used to systematically assess potential hazards and ensure compliance with workplace safety standards. It includes detailed inspection items covering fire safety, ergonomic setups, electrical equipment, and emergency protocols to minimize risks and promote a secure working environment. Regular use of this checklist supports proactive identification of safety issues and helps maintain adherence to occupational health regulations.

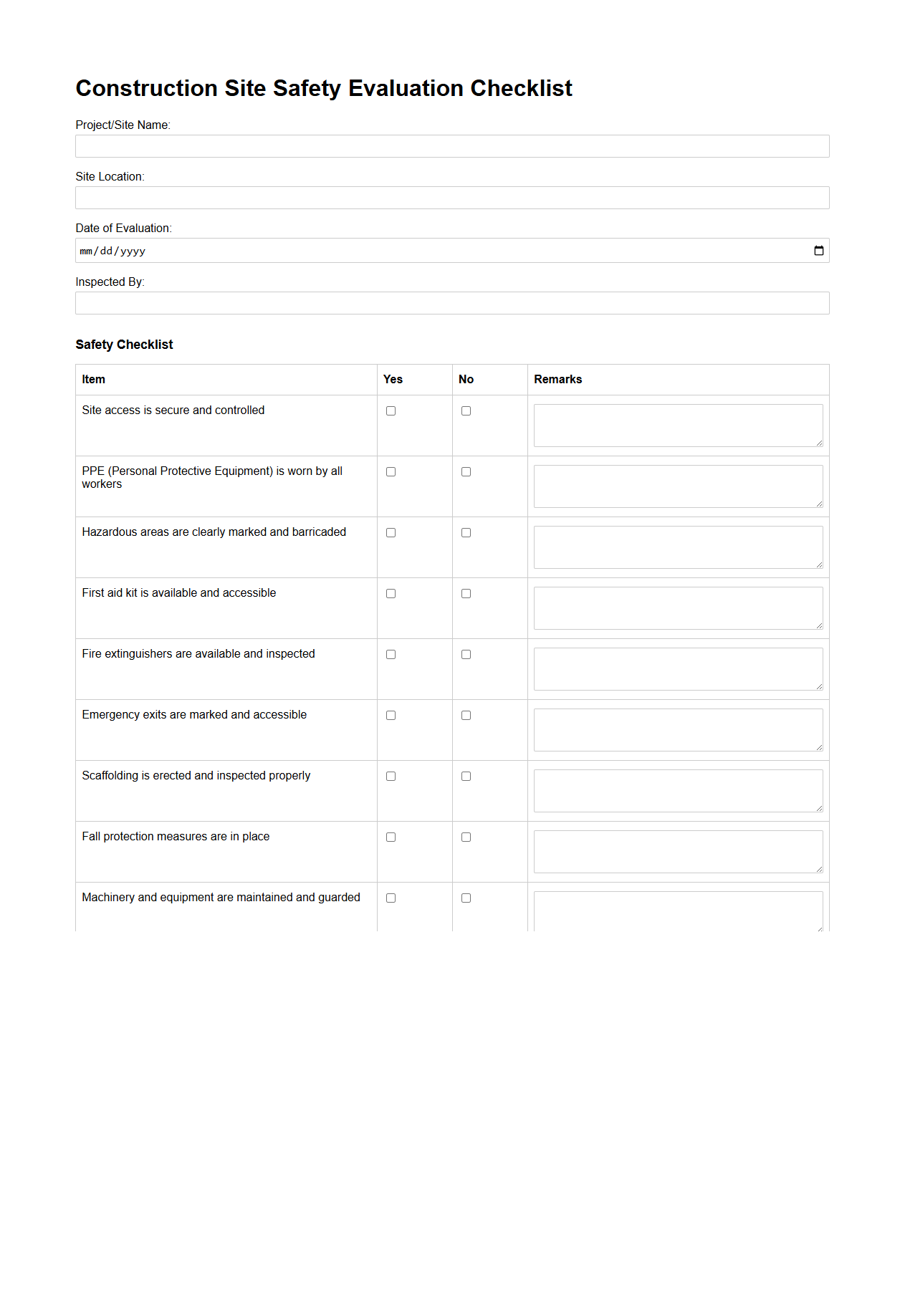

Construction Site Safety Evaluation Checklist

A

Construction Site Safety Evaluation Checklist document is a systematic tool used to identify hazards and ensure compliance with safety regulations on construction sites. It includes detailed criteria covering equipment inspection, worker protective gear, site conditions, and emergency protocols. This checklist helps maintain a safe working environment by regularly assessing risks and promoting proactive safety measures.

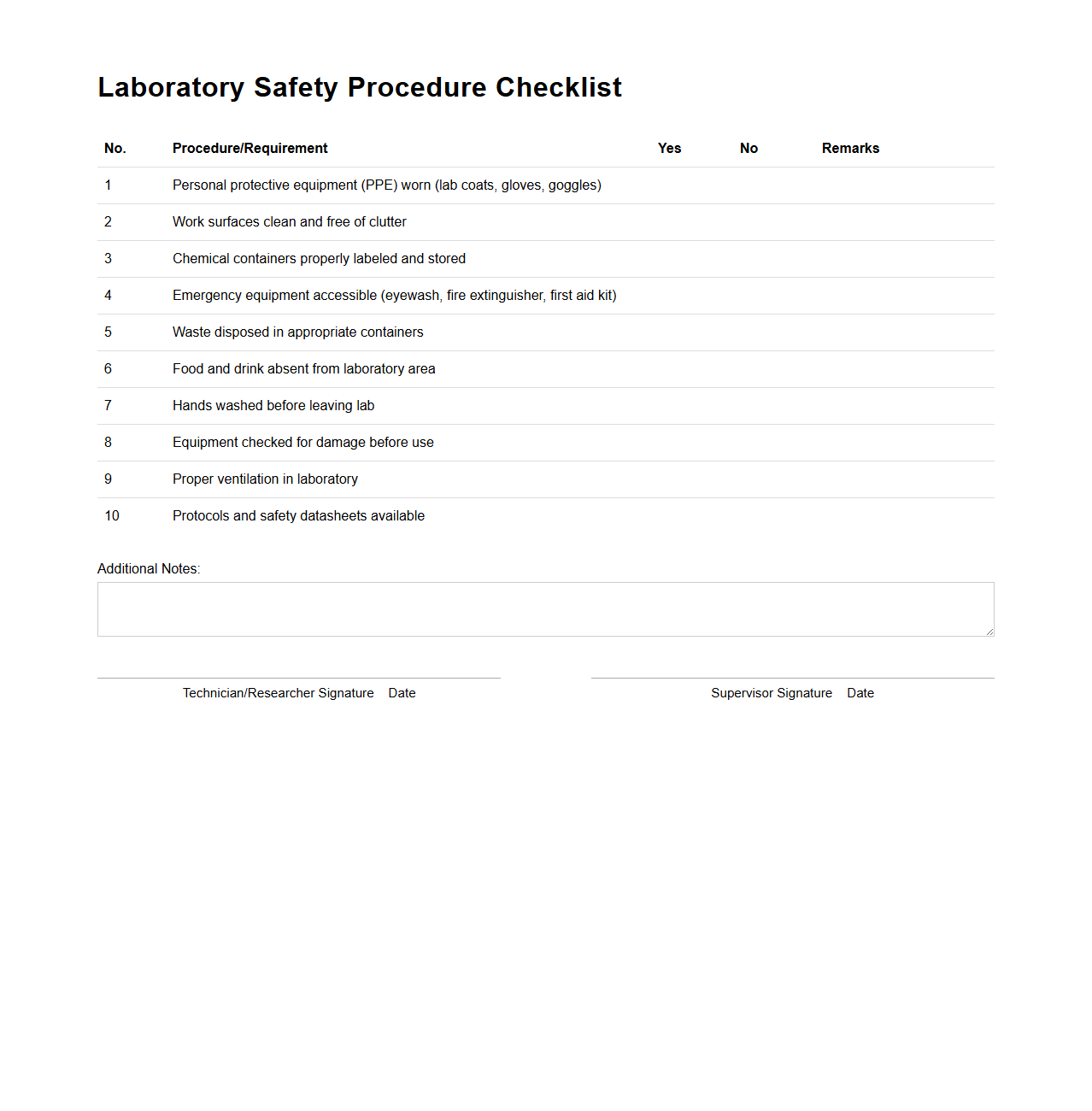

Laboratory Safety Procedure Checklist

A

Laboratory Safety Procedure Checklist document is a structured guide that ensures compliance with safety protocols by outlining essential safety measures and best practices in laboratory environments. It helps laboratory personnel systematically verify that all equipment, chemicals, and procedures meet regulatory standards to prevent accidents and maintain a safe working space. Regular use of this checklist enhances hazard identification, risk management, and promotes accountability in laboratory safety management.

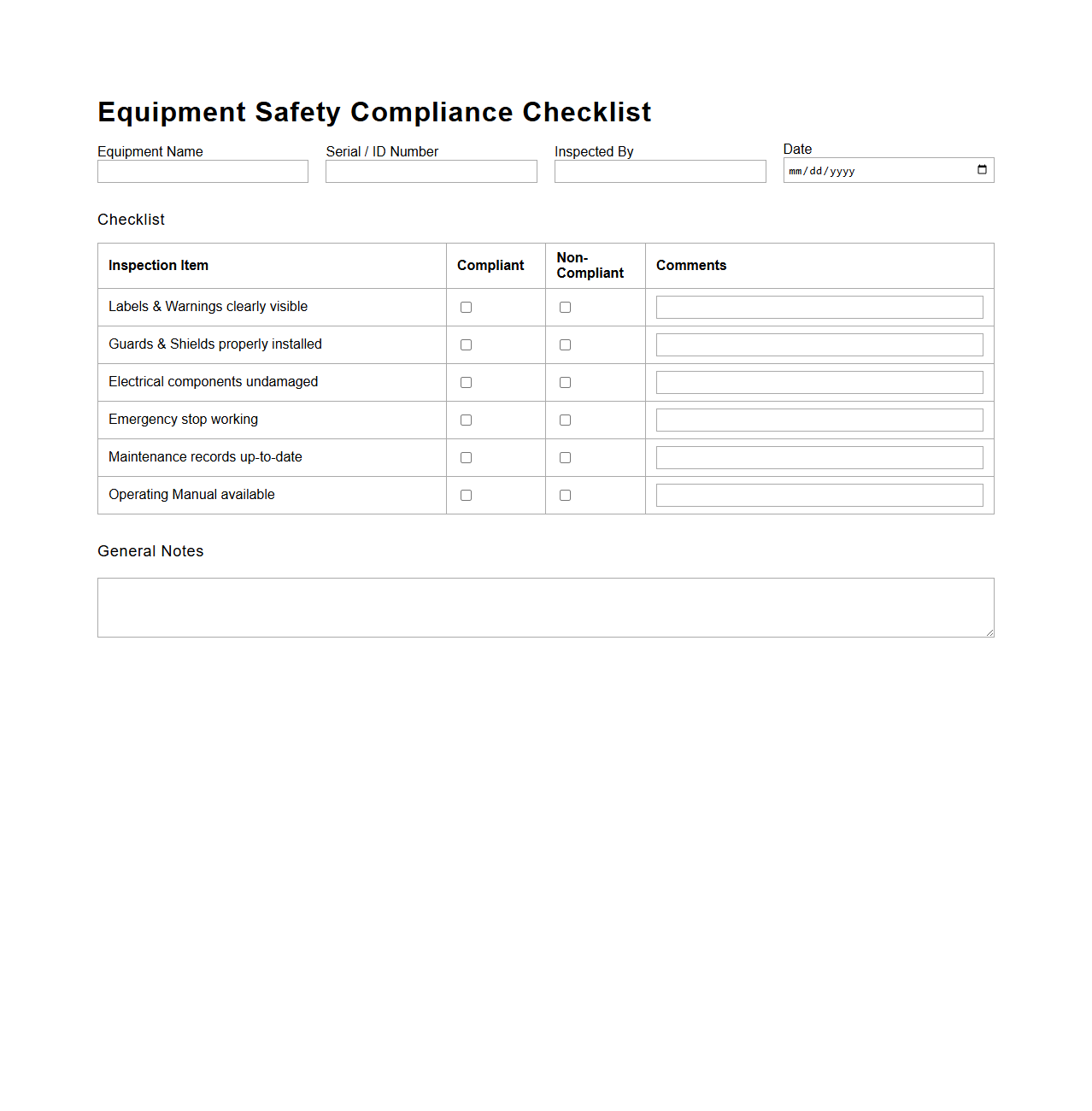

Equipment Safety Compliance Checklist

The

Equipment Safety Compliance Checklist document is a comprehensive tool used to ensure that machinery and equipment meet regulatory and safety standards. It outlines specific criteria and inspection points for verifying operational safety, maintenance status, and adherence to legal requirements. This checklist helps organizations minimize risks, prevent accidents, and maintain a safe working environment.

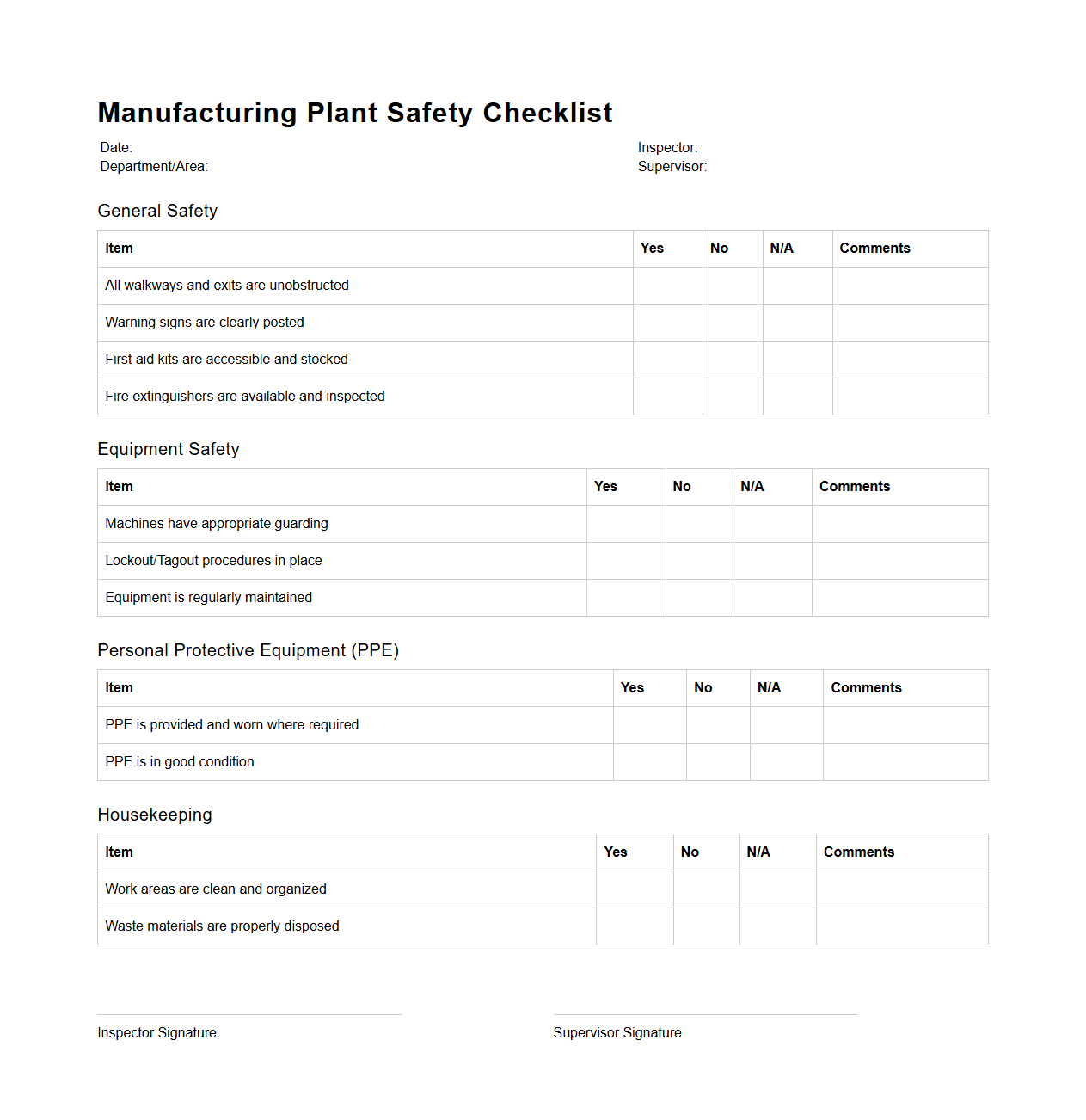

Manufacturing Plant Safety Checklist

A

Manufacturing Plant Safety Checklist document is a comprehensive tool used to systematically identify and mitigate potential hazards within a manufacturing facility. It includes detailed assessments of equipment, machinery, employee practices, and environmental conditions to ensure compliance with safety regulations and industry standards. Regular use of this checklist helps prevent accidents, promotes workplace safety, and supports continuous improvement in operational risk management.

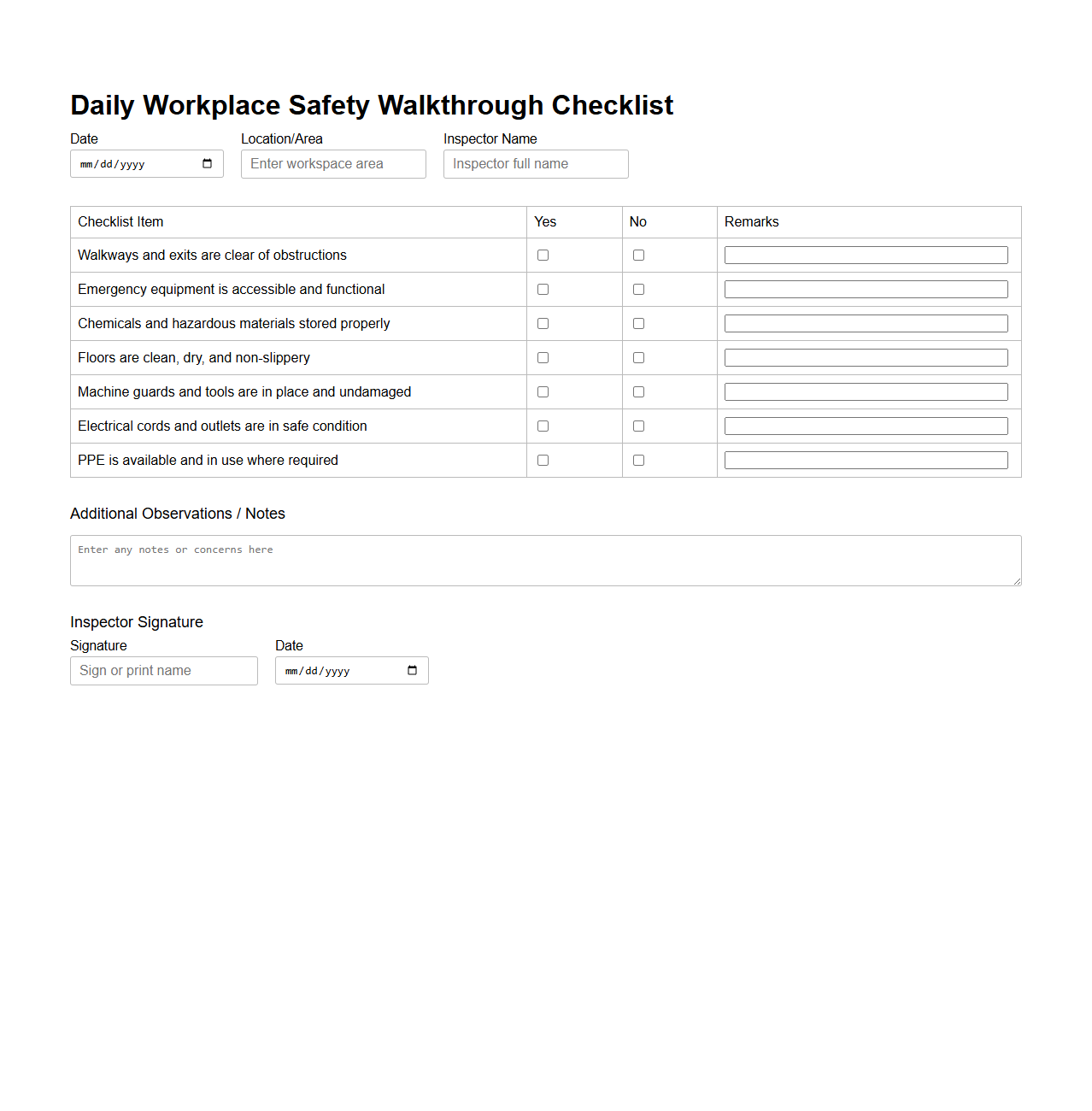

Daily Workplace Safety Walkthrough Checklist

The

Daily Workplace Safety Walkthrough Checklist document is a critical tool used to systematically inspect and identify potential hazards in a work environment. It ensures compliance with safety regulations by guiding employees or safety officers through predefined safety checkpoints such as equipment conditions, emergency exits, and personal protective gear usage. Regular use of this checklist helps prevent accidents, enhances overall workplace safety culture, and supports continuous risk management efforts.

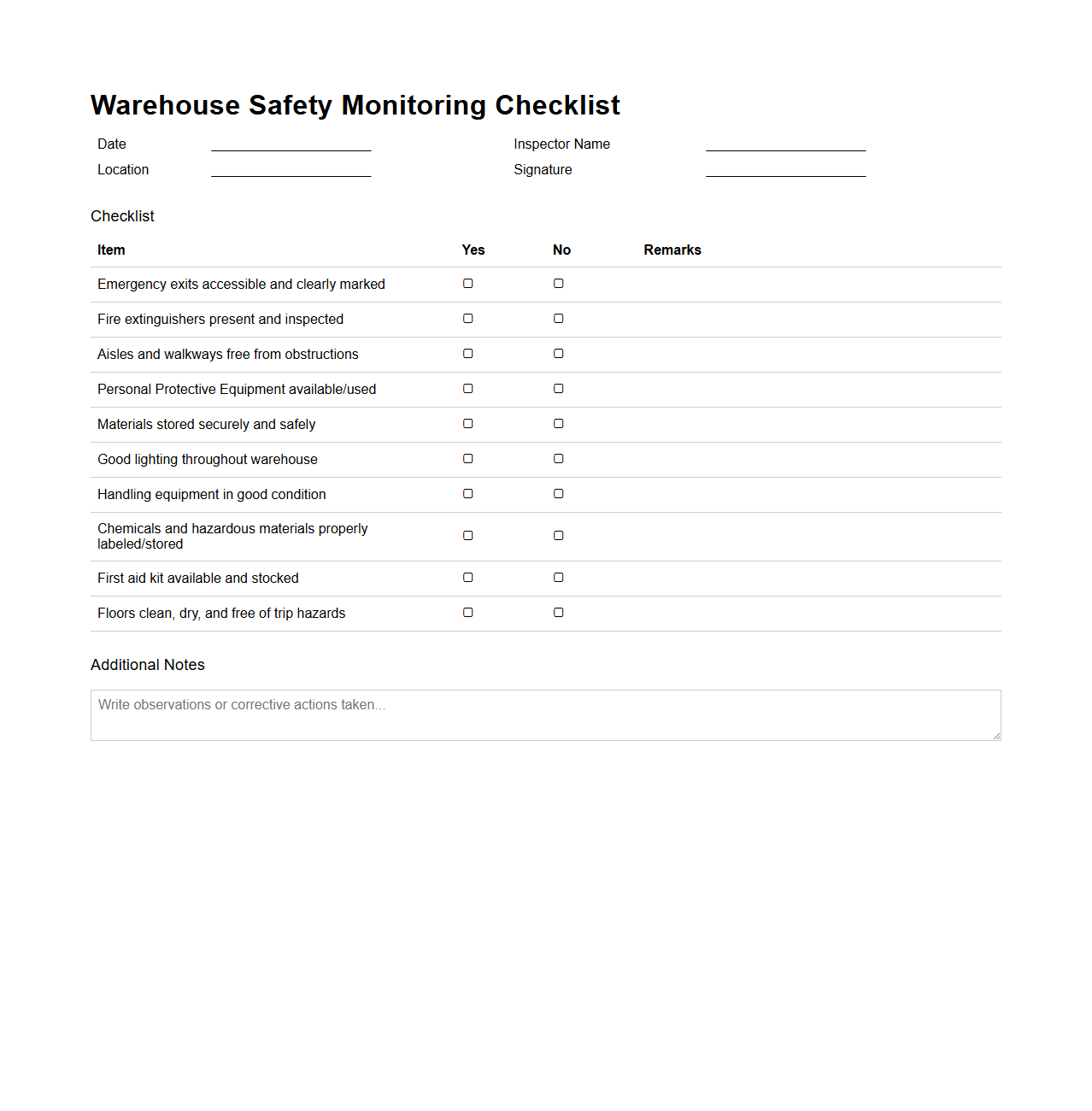

Warehouse Safety Monitoring Checklist

A

Warehouse Safety Monitoring Checklist document is a comprehensive tool used to systematically evaluate and ensure workplace safety standards within a warehouse environment. It outlines specific safety protocols, hazard identifications, equipment inspections, and compliance requirements to minimize risks and prevent accidents. Regular use of this checklist supports adherence to OSHA regulations and promotes a culture of safety awareness among warehouse staff.

Which specific hazards should be itemized in a blank safety checklist for compliance documentation?

A blank safety checklist should include physical hazards such as slips, trips, and falls. It must also cover chemical hazards like exposure to harmful substances and proper storage. Additionally, ergonomic risks and potential electrical hazards should be itemized to ensure comprehensive coverage.

How do you validate that the completed checklist meets industry-specific workplace safety requirements?

Validation involves cross-referencing the checklist items with the latest industry regulations and safety standards. Conducting periodic audits ensures that all checklist components are accurately completed and aligned with compliance criteria. Engaging qualified safety professionals to review the checklist enhances its credibility and effectiveness.

What evidence of corrective action should be included in a blank safety checklist template?

The template should have a section for documenting the description of the identified hazard and the immediate corrective action taken. Providing fields for responsible personnel and deadlines to complete the fix is essential. Additionally, space for verification signatures confirms that corrective measures have been properly implemented.

How frequently should a blank safety checklist be reviewed and updated for ongoing compliance?

Standard practice recommends reviewing and updating safety checklists at least annually or whenever new regulations are introduced. Frequent reviews ensure the checklist remains current with workplace changes and emerging hazards. Regular updates promote continuous improvement of safety protocols and compliance maintenance.

Which digital tools support automated tracking of blank safety checklist completion for audits?

Platforms such as SafetyCulture iAuditor and Procore offer automated checklist tracking and real-time compliance reporting. These tools provide cloud-based storage and audit trails to streamline documentation retrieval. Integration with mobile devices enables seamless on-site data capture and analysis.