A Blank Job Order Template for Manufacturing streamlines production tracking by providing a structured format to document job details, materials, labor, and costs. This template enhances efficiency by ensuring all manufacturing steps are clearly outlined and recorded, reducing errors and improving workflow management. It is an essential tool for managing job orders and maintaining accurate production records in manufacturing environments.

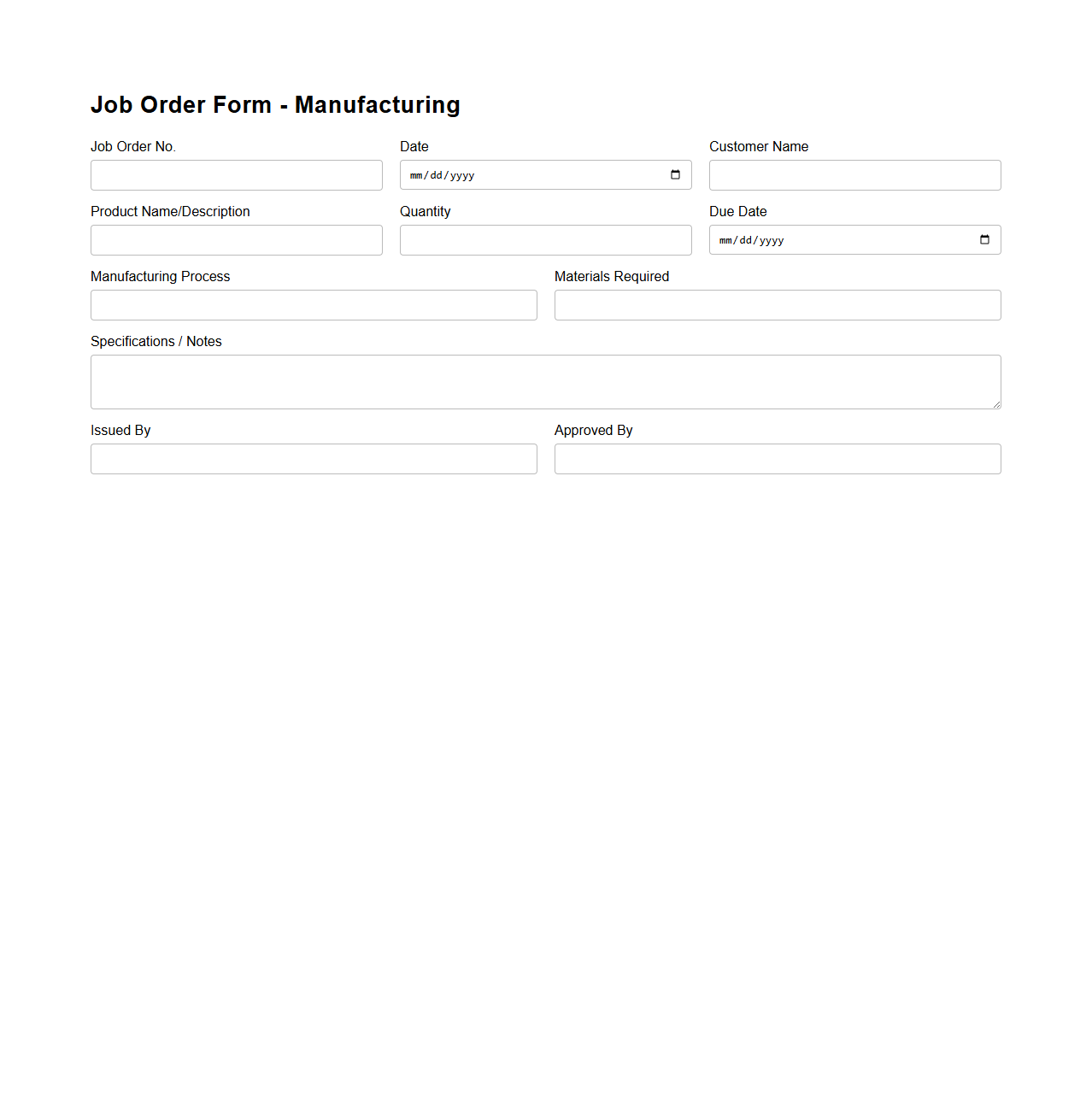

Simple Job Order Form for Manufacturing Processes

A Simple Job Order Form for Manufacturing Processes document is a critical tool used to streamline production by recording specific details about individual manufacturing jobs, such as job description, materials required, quantities, and timelines. This form helps ensure accurate tracking of work orders, resource allocation, and progress monitoring within the manufacturing workflow. Implementing a

Simple Job Order Form enhances operational efficiency and minimizes errors in production management.

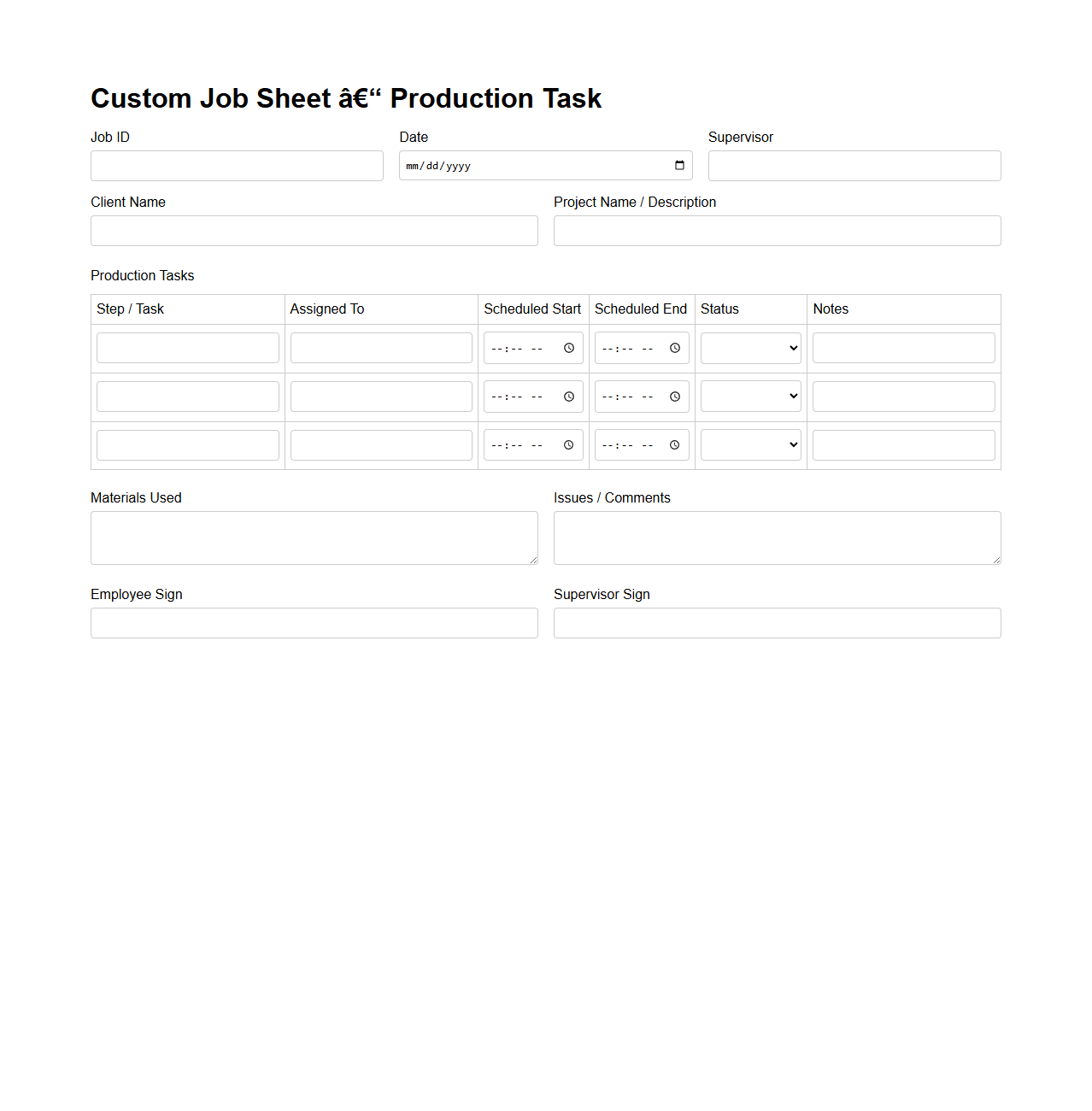

Custom Job Sheet Template for Production Tasks

A

Custom Job Sheet Template for Production Tasks is a tailored document designed to streamline and organize the recording of specific production activities, materials used, and task progress. It ensures accurate tracking of job details, worker assignments, and time management, improving operational efficiency. This template is essential for maintaining consistency, enhancing communication, and facilitating performance analysis within manufacturing or production environments.

Manufacturing Work Order Layout for Job Tracking

The

Manufacturing Work Order Layout for Job Tracking document serves as a structured template that outlines each step, resource, and timeline necessary to complete a production job efficiently. It includes detailed job instructions, material requirements, labor allocation, and progress checkpoints, enabling precise monitoring and control throughout the manufacturing process. This document enhances visibility, reduces errors, and supports timely delivery by aligning workflow with production goals.

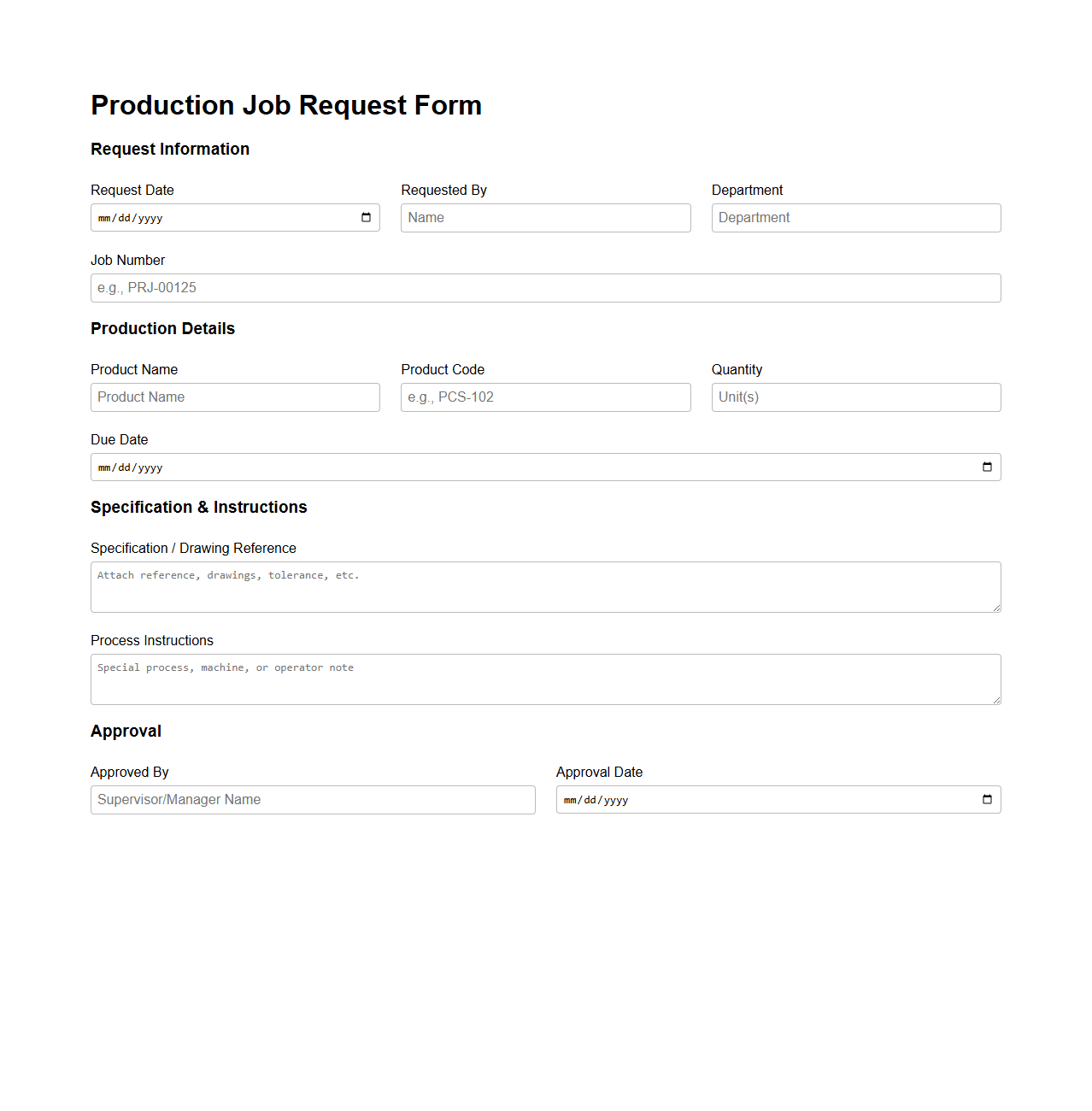

Production Job Request Form for Factory Use

The

Production Job Request Form for factory use is a standardized document utilized to initiate and authorize manufacturing tasks within a production facility. It details essential information such as job specifications, materials required, quantity, deadlines, and responsible personnel to ensure accurate and efficient workflow management. This form streamlines communication between departments and helps maintain production schedules, resource allocation, and quality control standards.

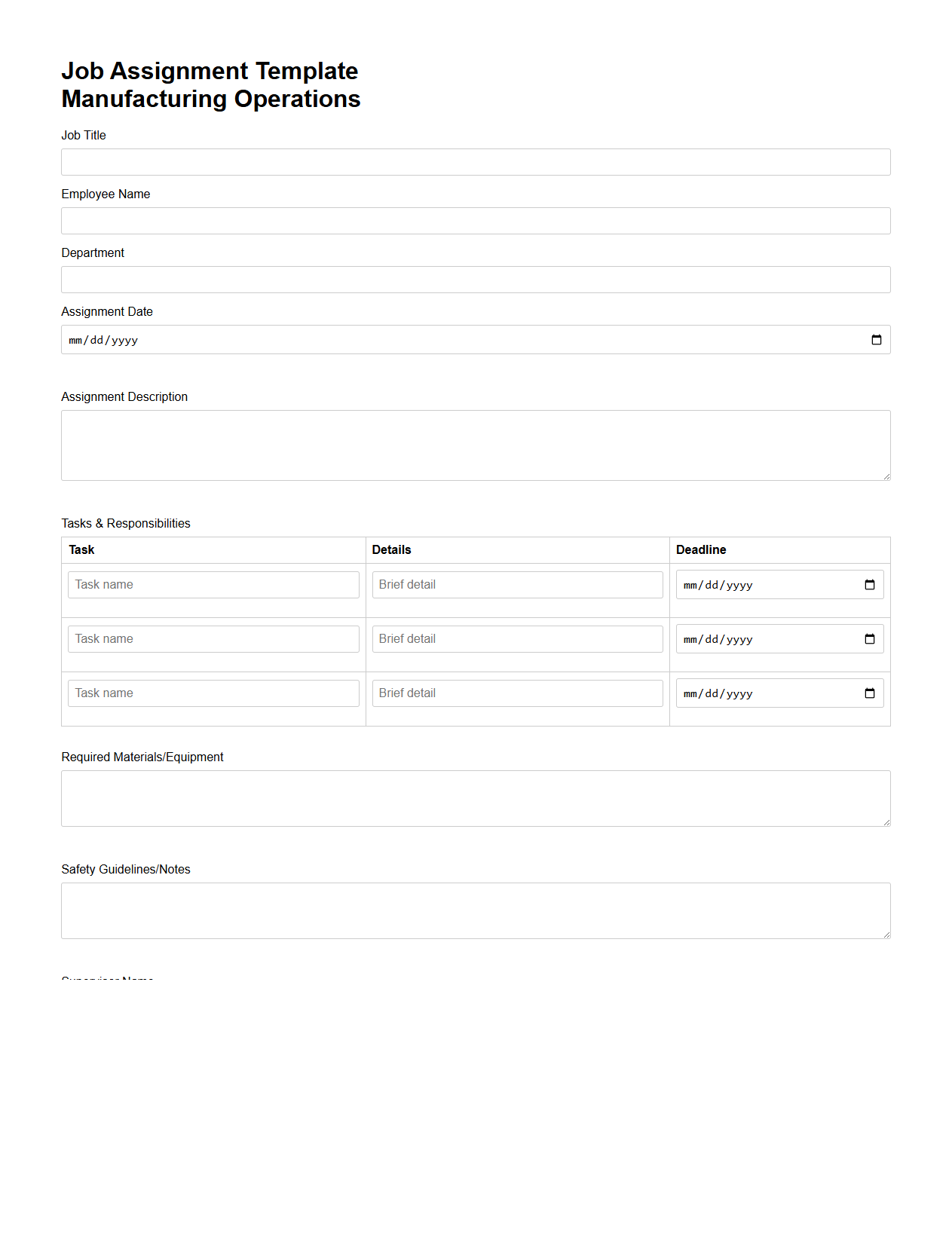

Job Assignment Template for Manufacturing Operations

A

Job Assignment Template for Manufacturing Operations document serves as a structured framework to allocate specific tasks and responsibilities to workers within a production environment. It outlines detailed job roles, required skills, and timelines to ensure efficient workflow and adherence to production schedules. This template enhances communication between supervisors and employees, promoting consistency and accountability in manufacturing processes.

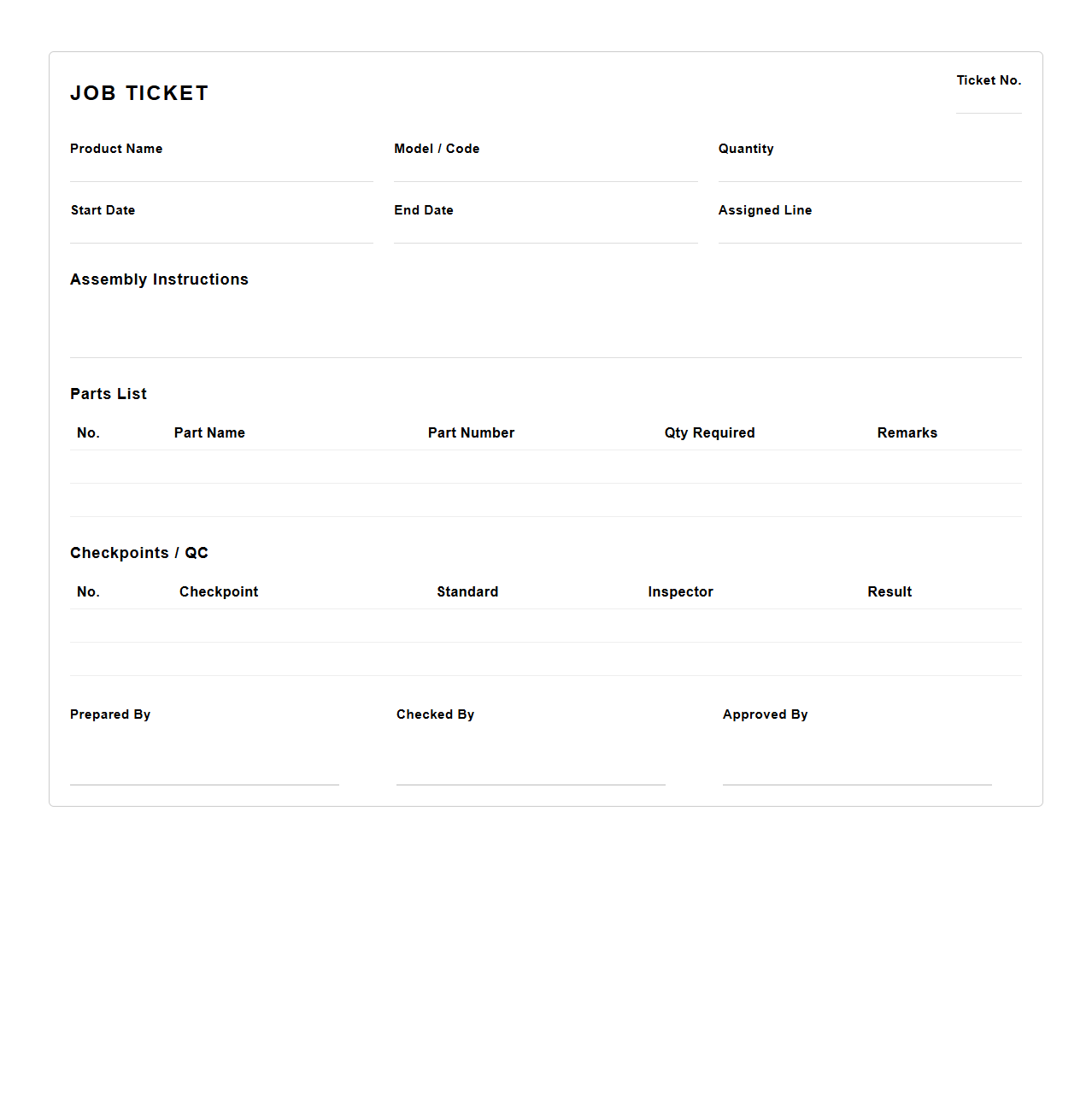

Job Ticket Template for Assembly Line Management

A

Job Ticket Template for Assembly Line Management is a standardized document used to outline the specific tasks, materials, and timelines required for each stage of the assembly process. It ensures efficient workflow by providing detailed instructions and accountability for workers, helping to reduce errors and improve productivity. This template is essential for tracking job progress, managing resources, and maintaining consistent quality control throughout the production cycle.

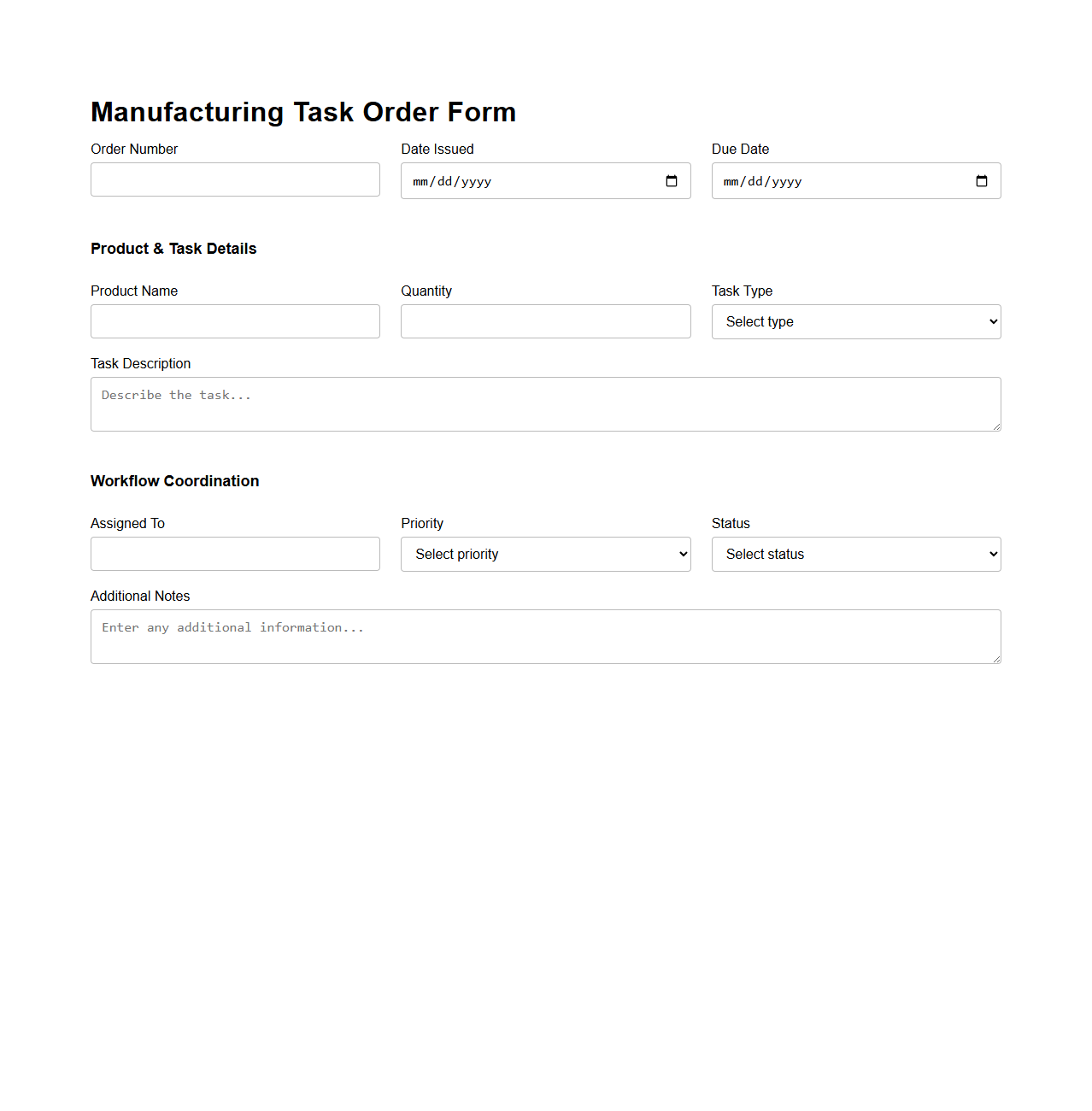

Manufacturing Task Order Form for Workflow Coordination

A

Manufacturing Task Order Form for Workflow Coordination document serves as a detailed instruction sheet that outlines specific production tasks, schedules, and resource allocations to ensure efficient manufacturing processes. It facilitates clear communication between departments by organizing workflow steps, assigning responsibilities, and tracking progress in real-time. This document is crucial for minimizing delays, optimizing resource use, and maintaining consistent product quality throughout the manufacturing cycle.

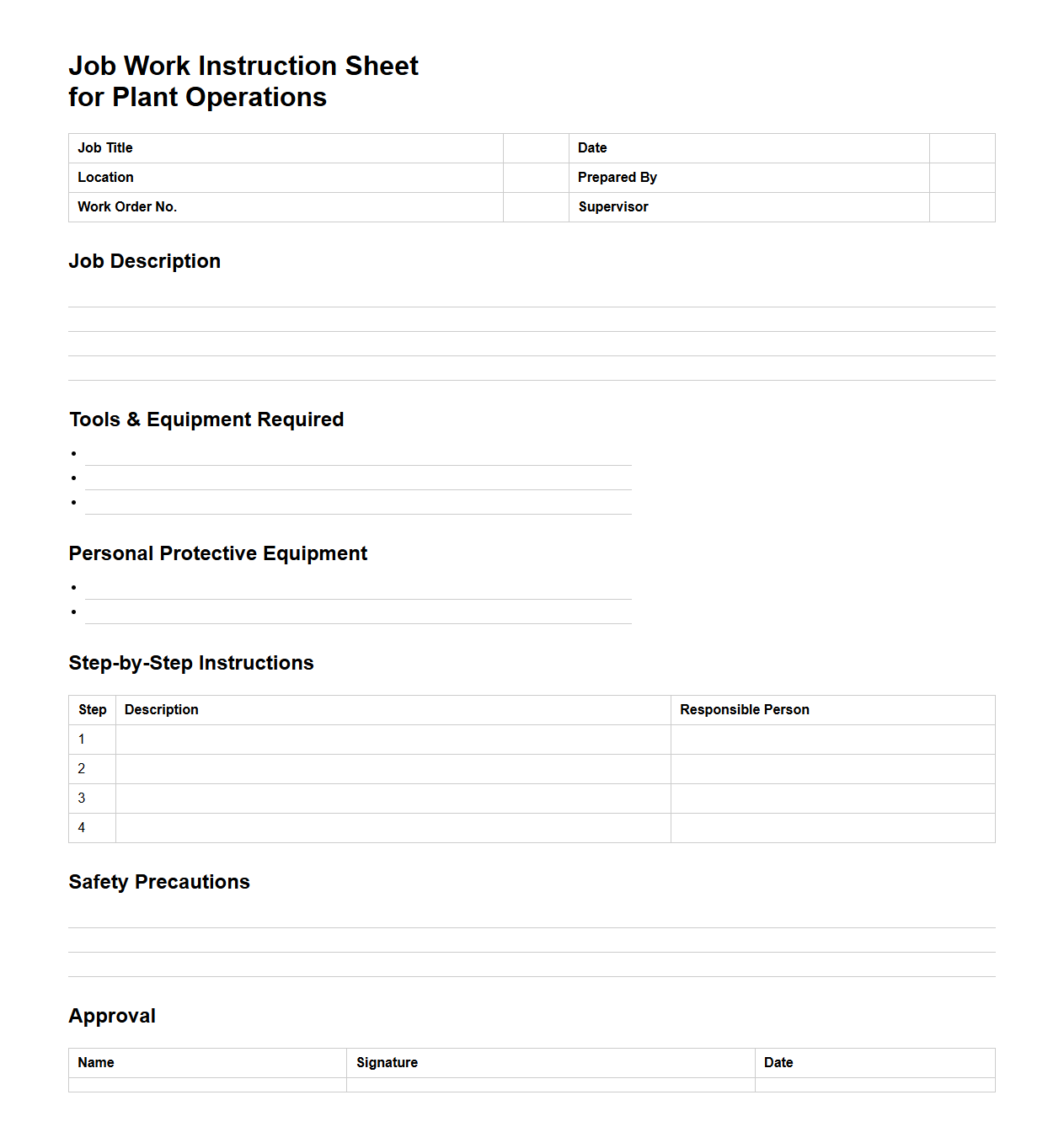

Job Work Instruction Sheet for Plant Operations

A

Job Work Instruction Sheet for Plant Operations is a detailed document that outlines step-by-step procedures necessary to perform specific tasks within an industrial plant. It includes essential safety protocols, required tools, materials, and quality standards to ensure consistent and efficient execution of operations. This sheet serves as a critical reference to minimize errors, enhance productivity, and maintain compliance with operational guidelines.

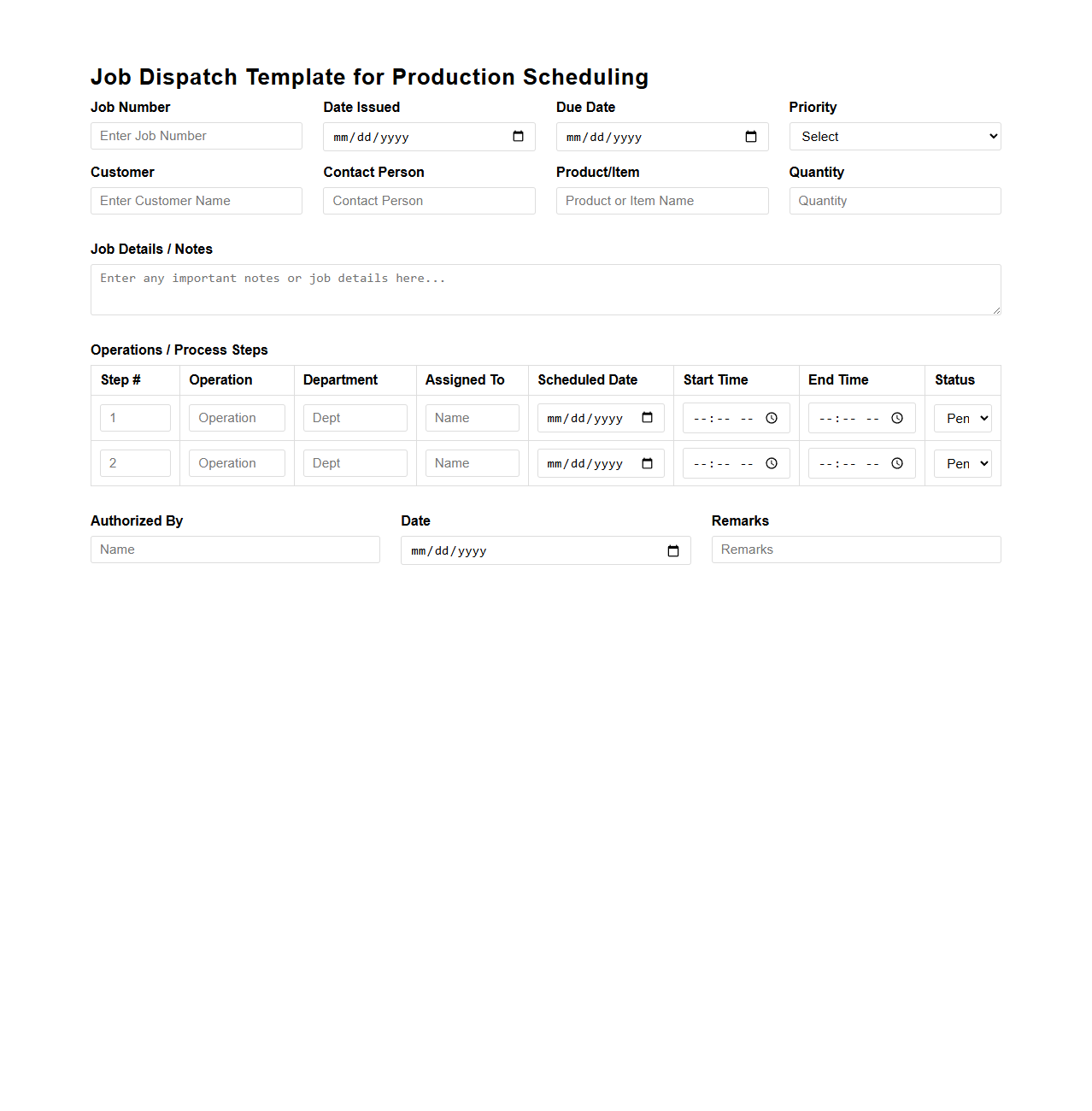

Job Dispatch Template for Production Scheduling

The

Job Dispatch Template for Production Scheduling is a structured document designed to streamline the allocation and tracking of manufacturing tasks. It organizes job orders by priority, resources, and deadlines, ensuring efficient workflow and minimizing downtime. This template enhances communication between production teams and management by providing clear instructions and timelines for each job phase.

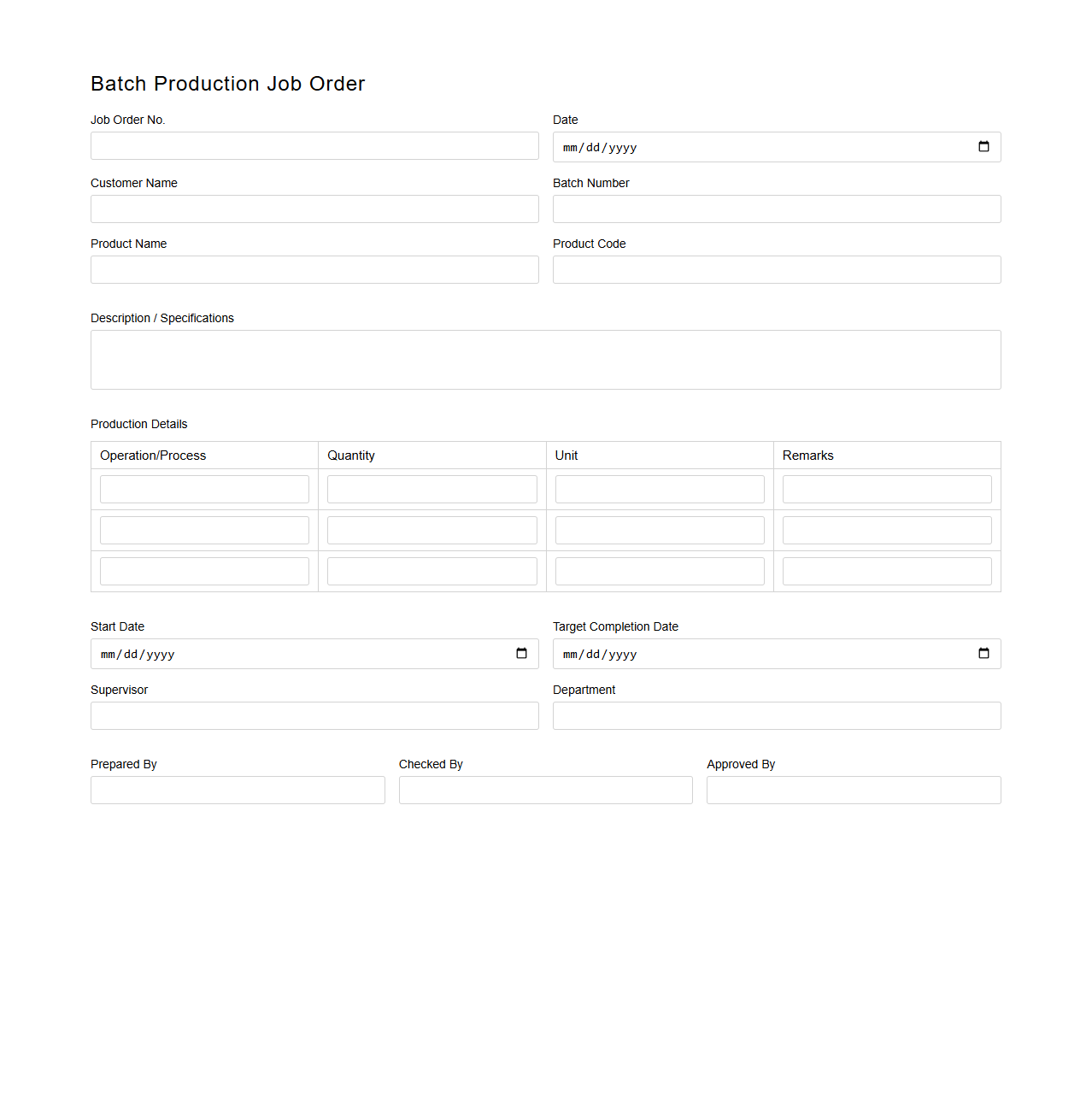

Batch Production Job Order Format for Factories

The

Batch Production Job Order Format for factories is a structured document that details specific instructions and requirements for manufacturing a set quantity of products within a batch. It includes key information such as raw material specifications, production steps, labor allocation, and quality standards to ensure consistent output. This format helps streamline workflow, track progress, and maintain accurate records of each job order in the production process.

What key fields should a blank job order form for manufacturing include?

A blank job order form must contain essential fields such as job number, customer details, and description of the product. It should also include quantity, start and end dates, and responsible department or personnel. These fields ensure clarity and traceability throughout the manufacturing process.

How do you specify material requirements on a job order letter?

Material requirements should be clearly detailed under a dedicated material specifications section, listing types, grades, and quantities needed. This ensures that the procurement team can source the exact materials required. Proper documentation minimizes delays and maintains production quality.

What is the standard format for numbering blank job orders in manufacturing?

The standard format commonly uses a combination of letters and numbers representing the year, department, and sequential order, such as JO-2024-001. This systematic approach facilitates easy tracking and reference of job orders. Consistency in numbering helps maintain organized records.

How are quality control checkpoints referenced in a blank job order letter?

Quality control checkpoints are typically listed in a QC section with clear stages and criteria for inspection. Each checkpoint might include a description, responsible inspector, and pass/fail criteria to ensure product standards. Referencing these checkpoints fosters accountability and ensures compliance.

What details about delivery deadlines are typically required on a manufacturing job order?

Delivery deadlines must specify the exact due date and time, including any intermediate deadlines for production milestones. This information helps coordinate logistics and keeps production on schedule. Clear deadlines are crucial to meeting customer expectations and avoiding penalties.