The Blank Manufacturing Order Template for Production Planning helps streamline the organization of production tasks by clearly outlining materials, quantities, and timelines. This template ensures efficient resource allocation and minimizes production delays. Using a standardized format improves communication across teams and enhances overall workflow management.

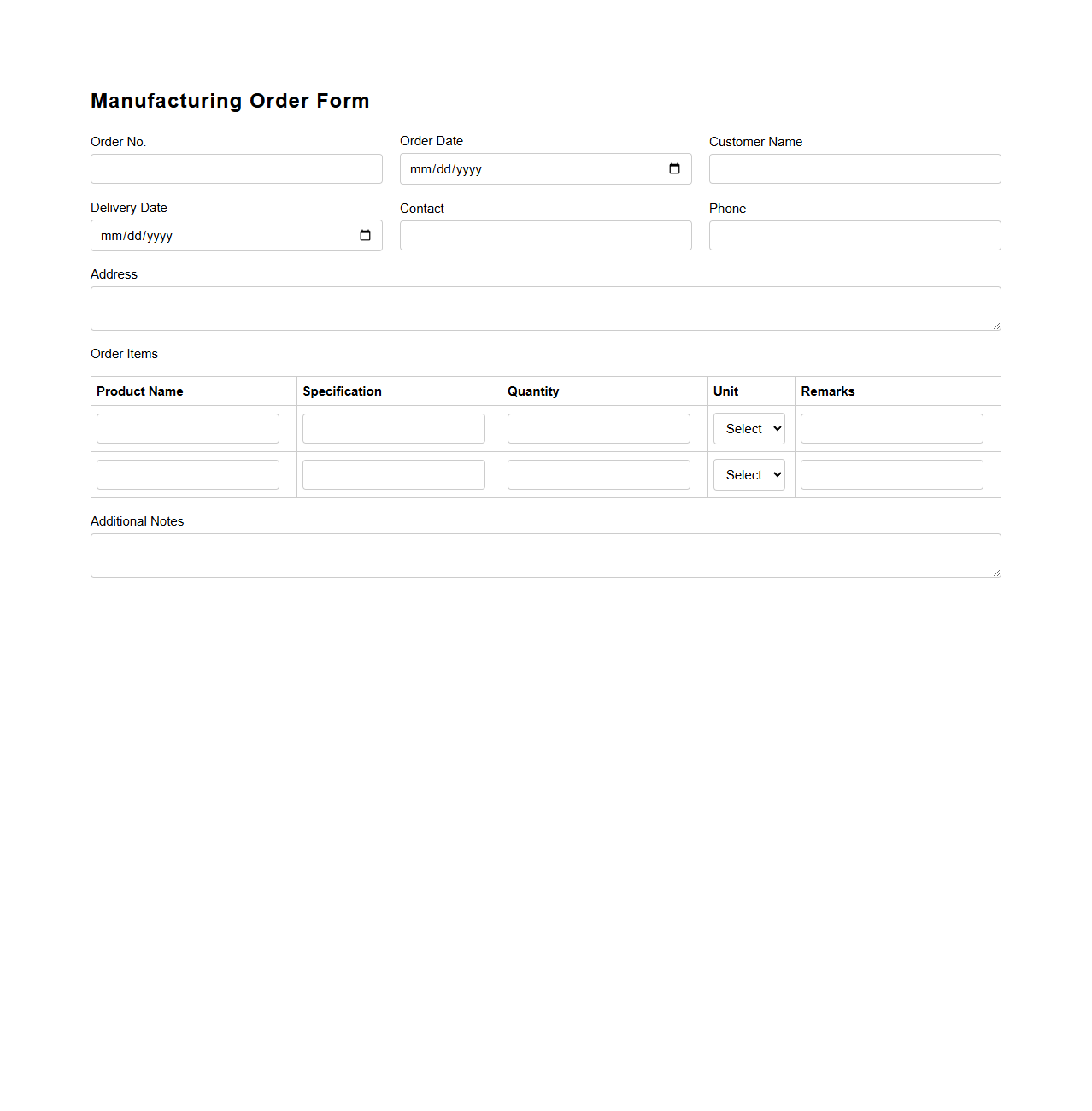

Simple Manufacturing Order Form Template

A

Simple Manufacturing Order Form Template is a structured document used to streamline the production process by clearly outlining the specifications, quantities, and deadlines for manufacturing products. It helps manufacturers reduce errors, ensure consistency, and maintain accurate records for inventory and workflow management. This template typically includes fields for product details, order number, client information, and production instructions.

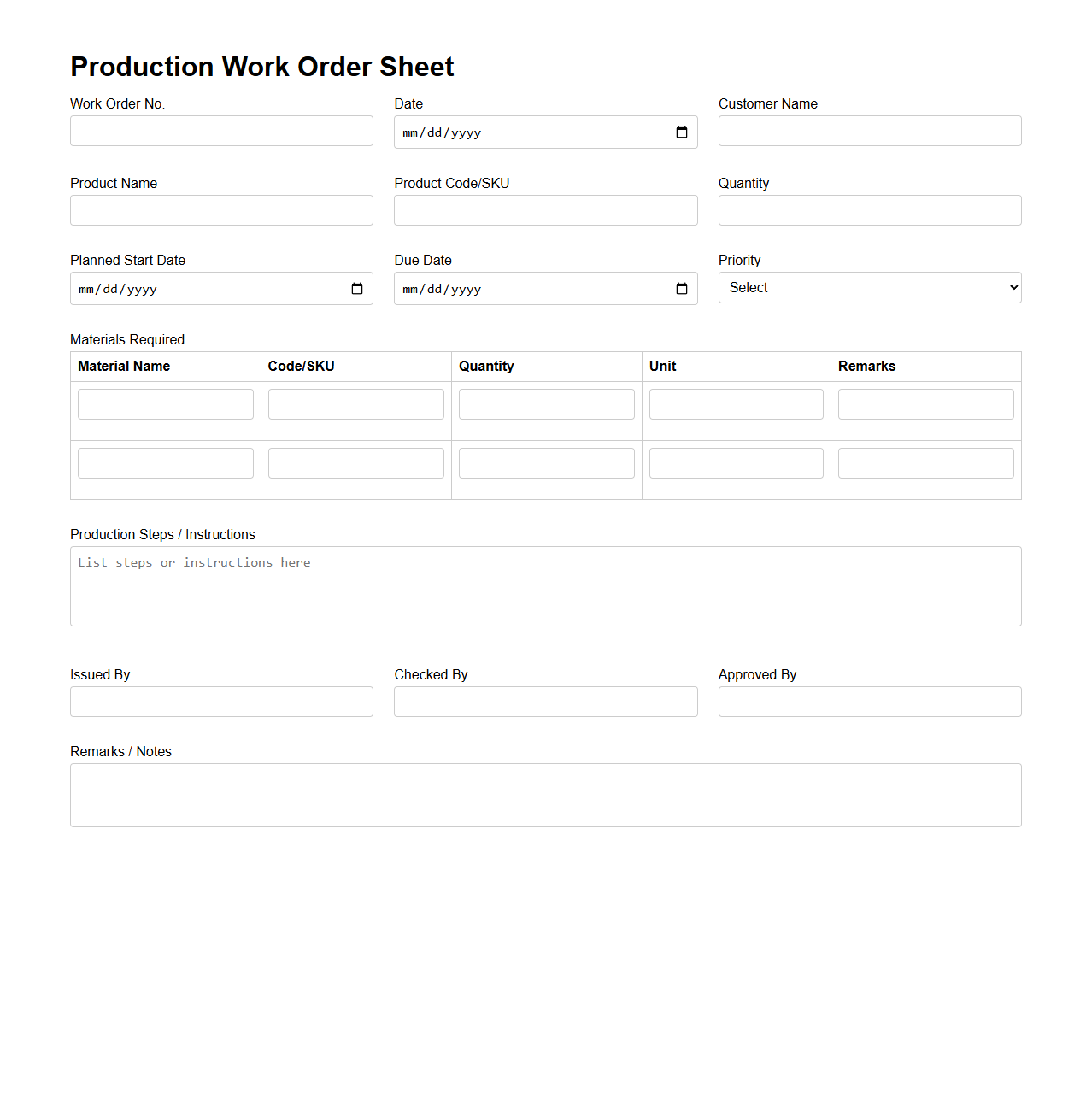

Customizable Production Work Order Sheet

A

Customizable Production Work Order Sheet document is a tailored form used in manufacturing to outline detailed instructions for producing specific items, ensuring clear communication between departments. It includes fields for materials, labor requirements, timelines, and quality control checkpoints, allowing businesses to adapt the sheet to their unique processes. This customization enhances workflow efficiency, reduces errors, and supports accurate tracking of production progress.

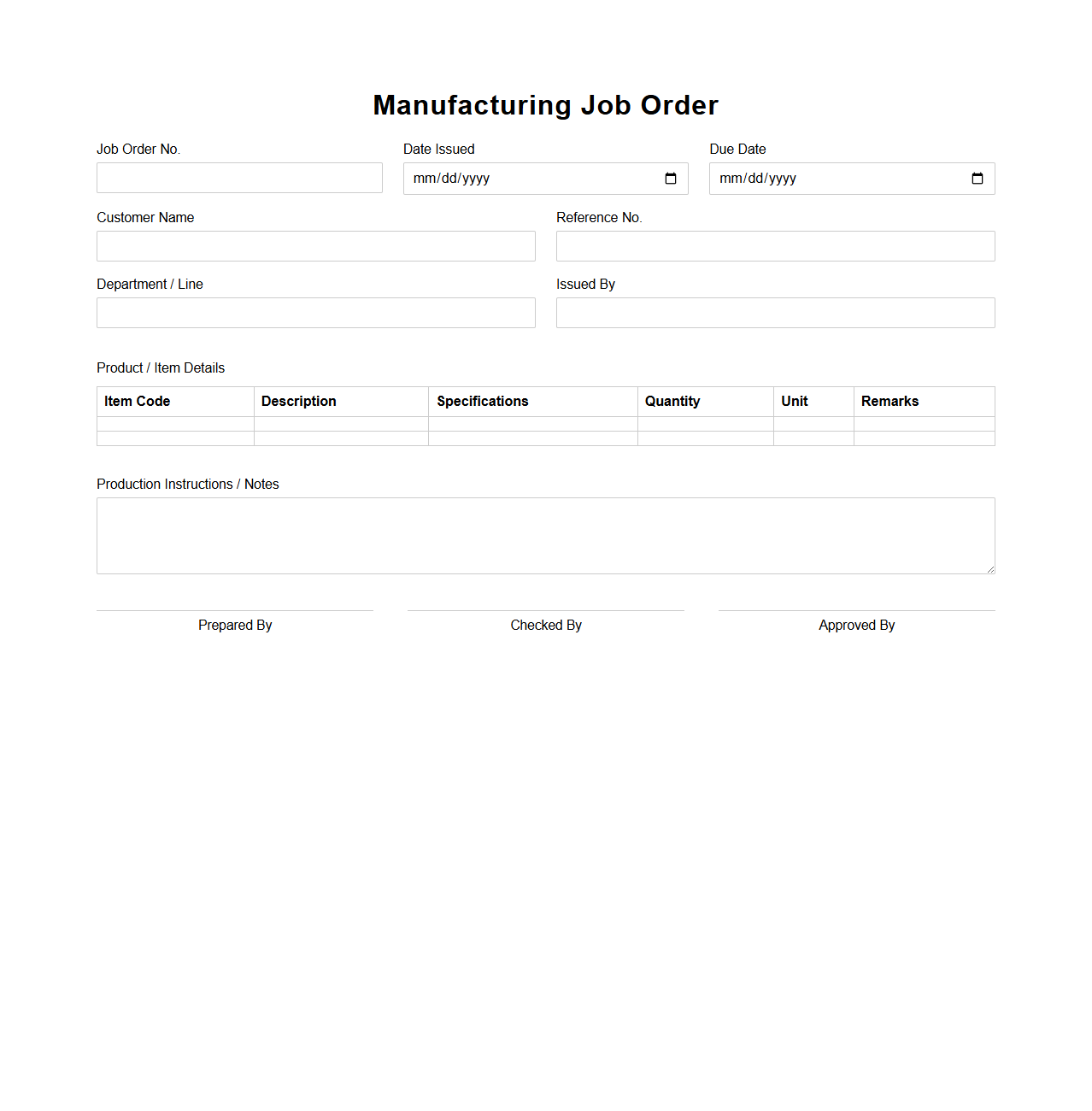

Manufacturing Job Order Template for Factories

A

Manufacturing Job Order Template for factories is a structured document used to outline specific production tasks, materials required, labor details, and timelines for manufacturing orders. This template ensures clear communication and tracking of each job from initiation to completion, improving workflow efficiency and resource management. Factories utilize this document to maintain consistency, reduce errors, and optimize the overall manufacturing process.

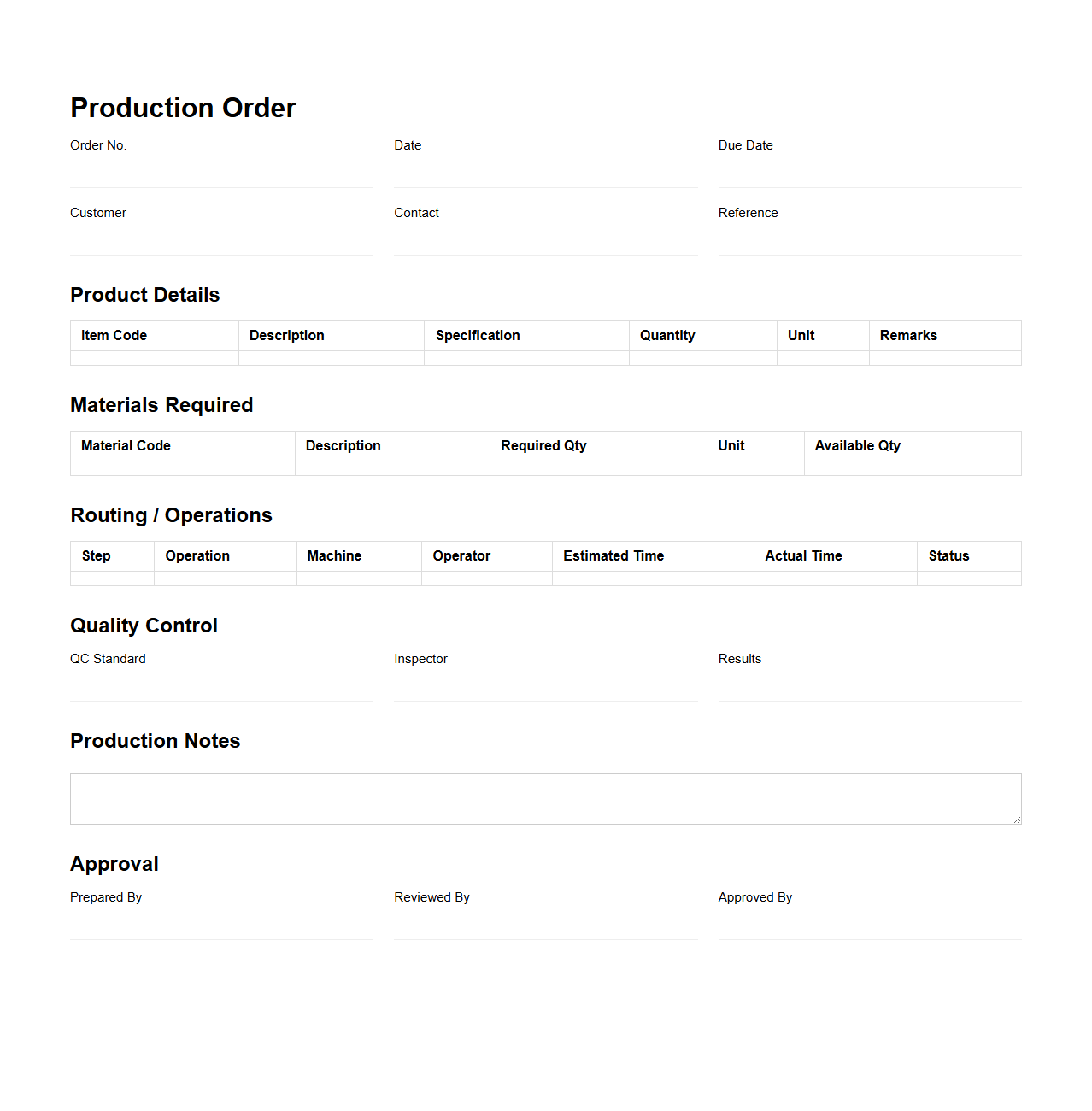

Detailed Production Order Document Template

A

Detailed Production Order Document Template serves as a comprehensive blueprint for manufacturing processes, outlining specific instructions, materials, timelines, and quality standards required to execute a production run efficiently. This template enables clear communication among production teams, procurement, and quality control departments, ensuring consistency and reducing errors. By standardizing key production details, it enhances workflow management and supports accurate tracking of manufacturing progress.

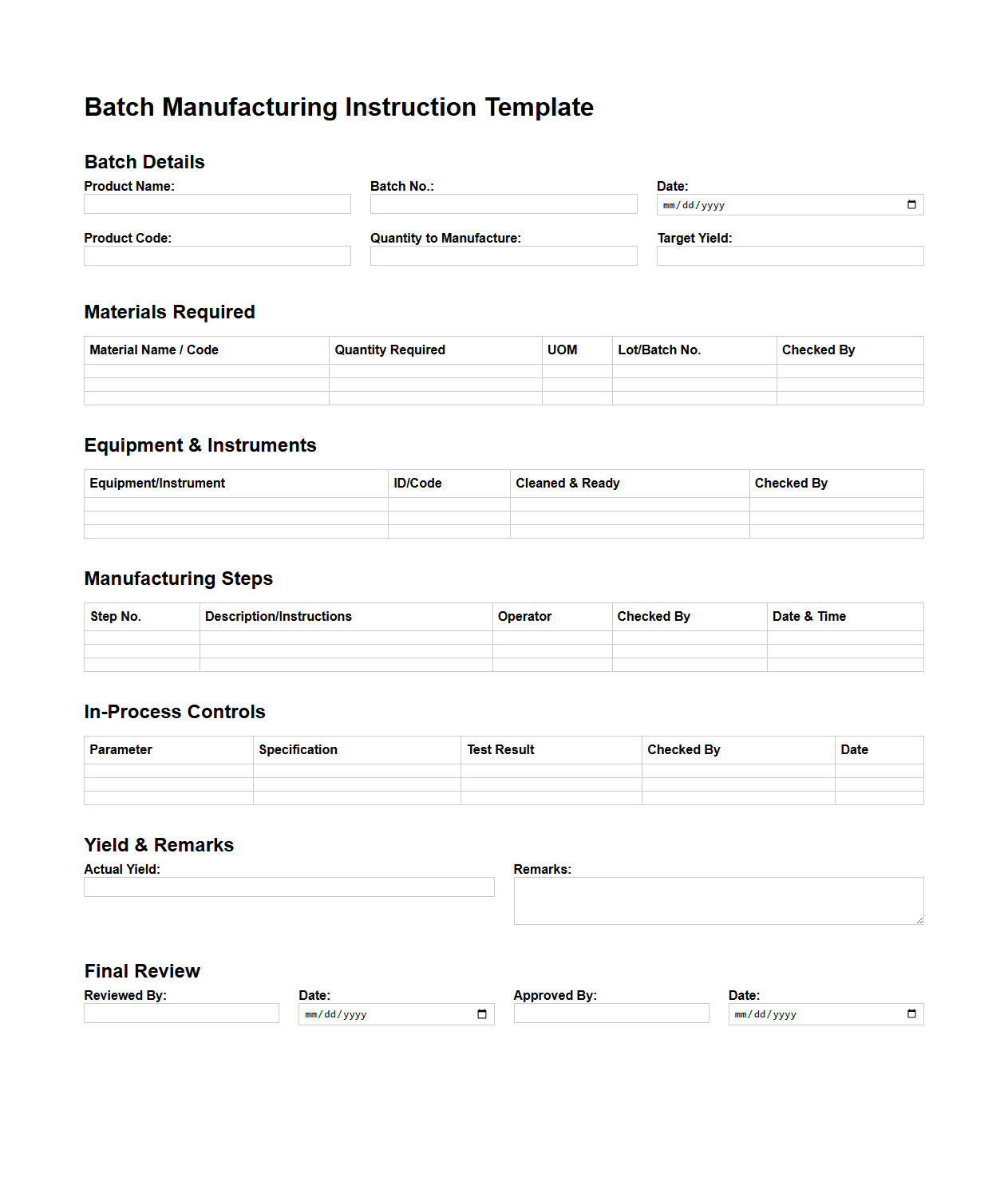

Batch Manufacturing Instruction Template

A

Batch Manufacturing Instruction Template document is a structured guide used in production facilities to ensure consistent and accurate execution of manufacturing processes for a specific batch of products. It includes detailed step-by-step instructions, materials required, equipment settings, quality control checks, and safety protocols to maintain product quality and compliance with industry standards. This template streamlines communication between production teams and supports regulatory documentation requirements.

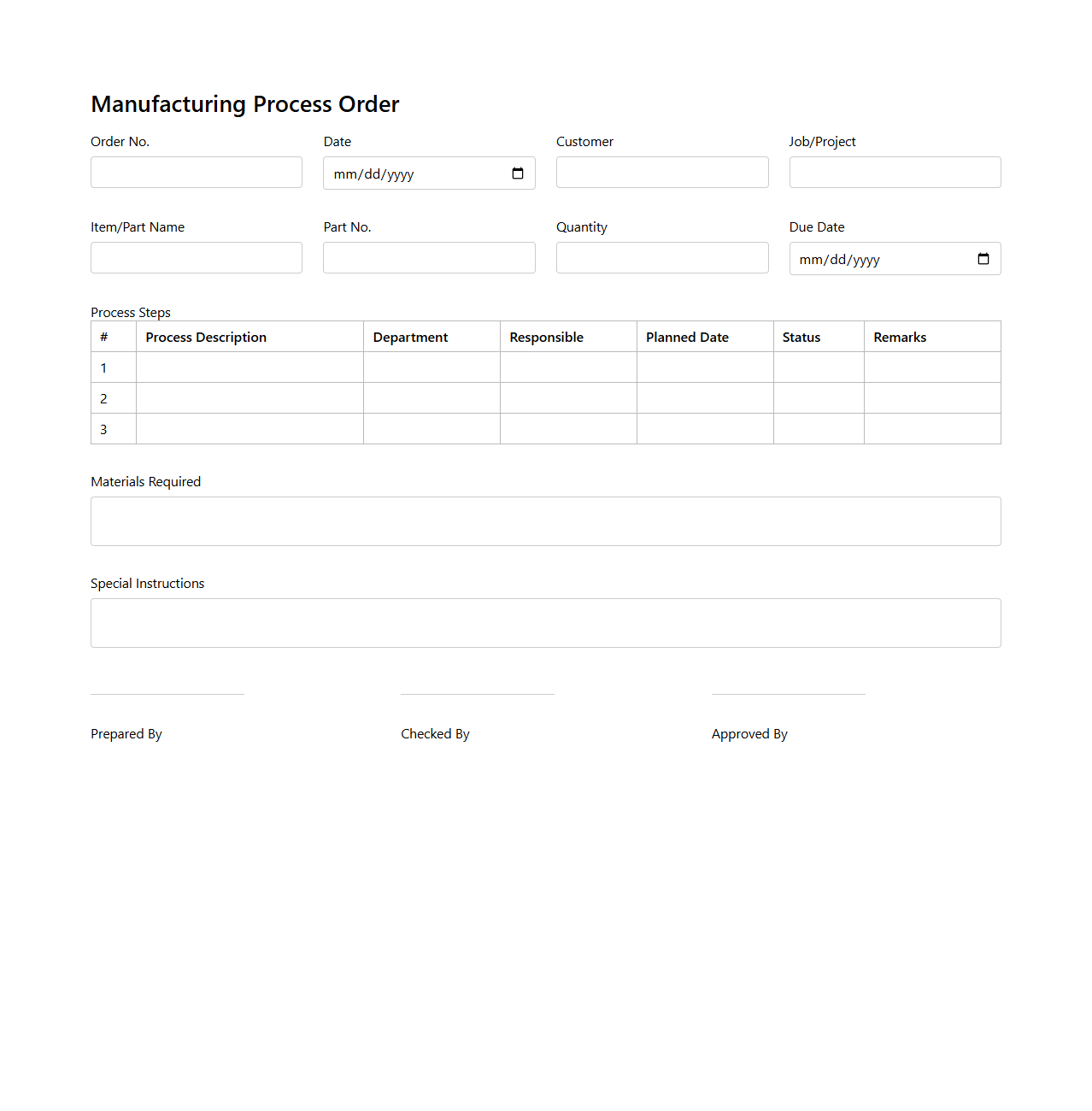

Manufacturing Process Order Blank Layout

A

Manufacturing Process Order Blank Layout document serves as a standardized template that outlines the step-by-step instructions and sequencing of tasks required to produce a specific product. It typically includes operation details, work centers, material requirements, and time allocations, ensuring efficient workflow management. This document is essential for maintaining consistency, tracking production progress, and optimizing resource utilization in manufacturing operations.

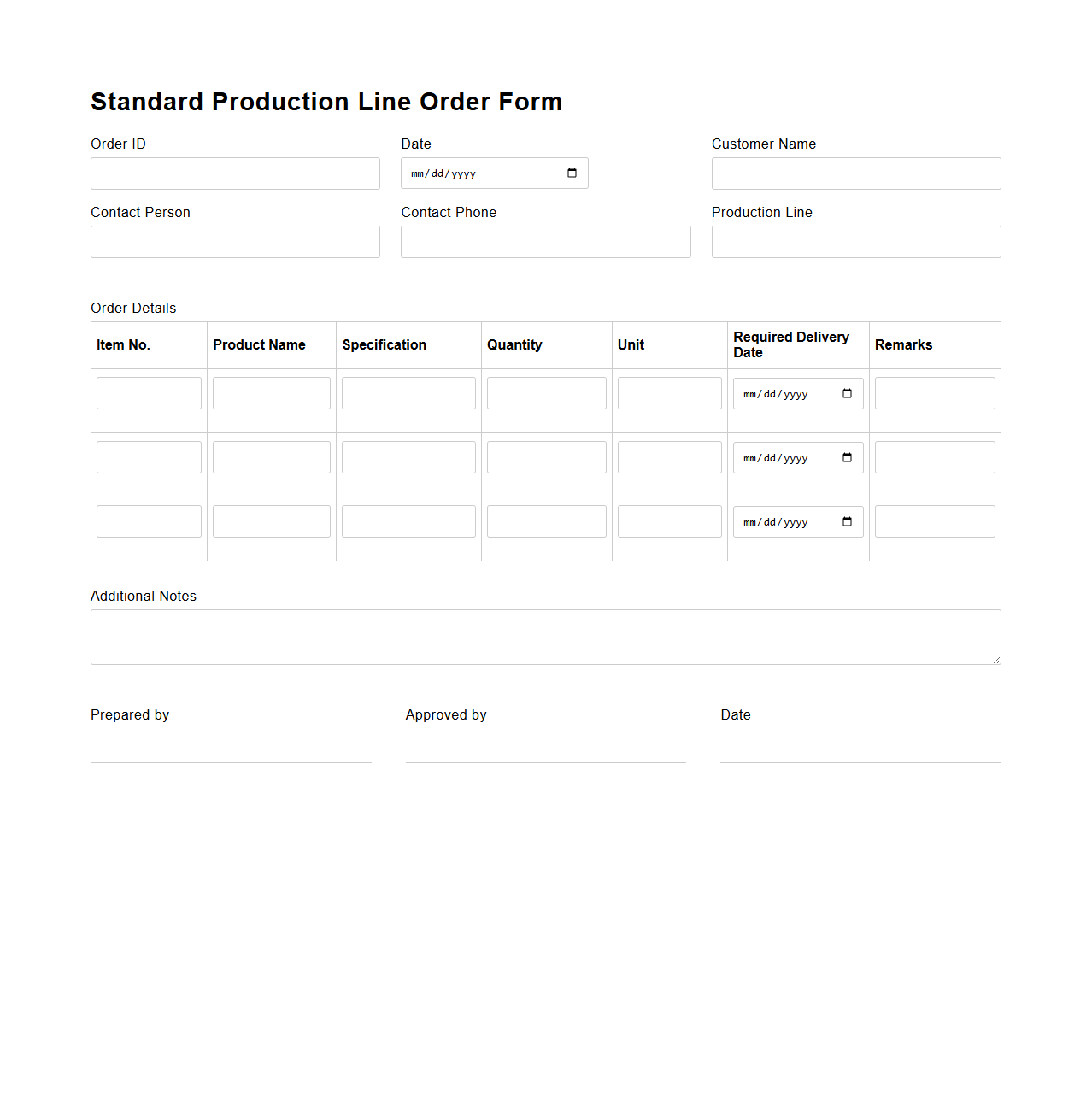

Standard Production Line Order Form

A

Standard Production Line Order Form document serves as a critical tool for recording and organizing production requests within manufacturing operations. It outlines specific details such as product types, quantities, required materials, and scheduled timelines to ensure accurate and efficient workflow management. This form helps streamline communication between departments, reducing errors and enhancing overall production efficiency.

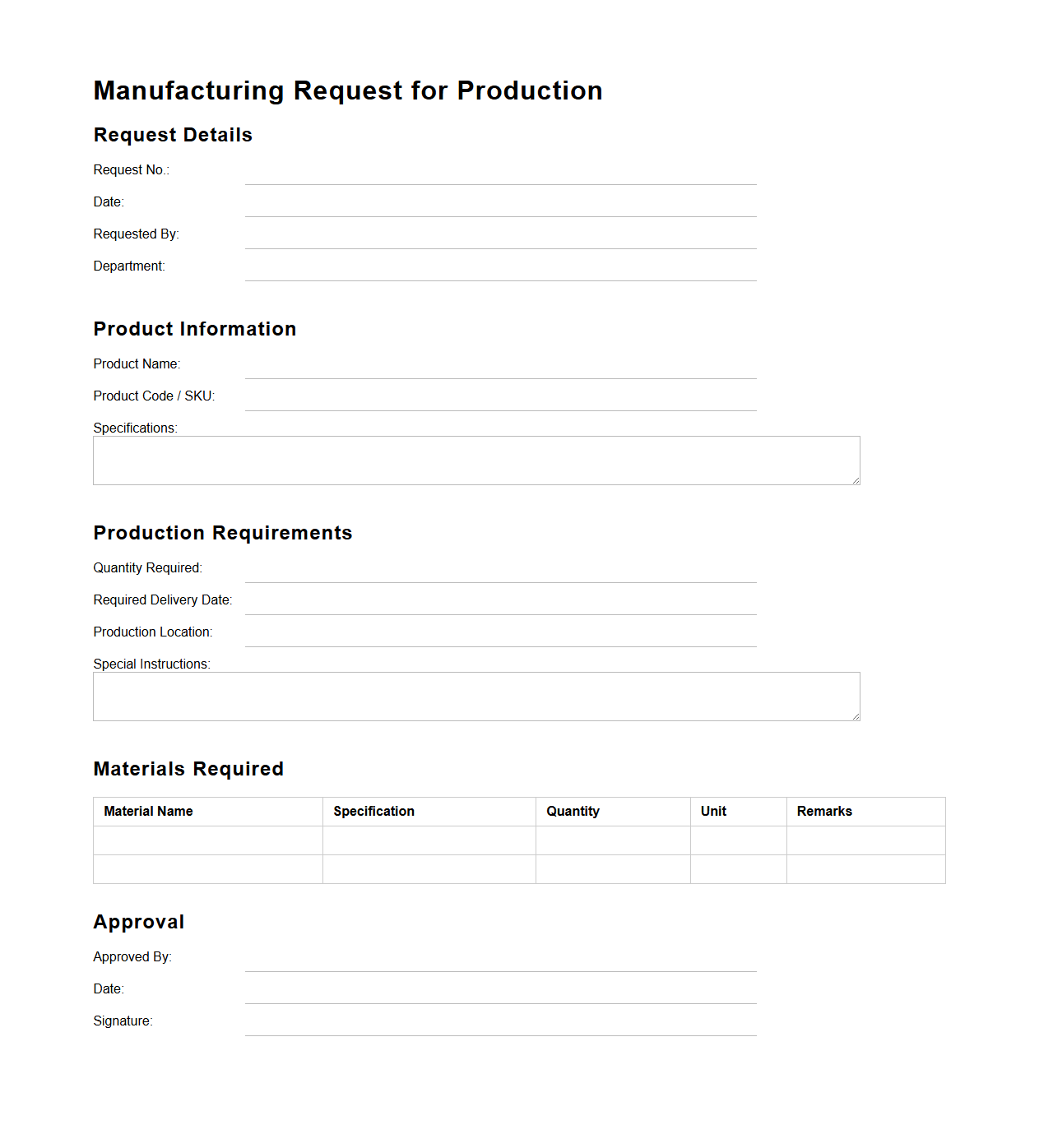

Manufacturing Request for Production Template

A

Manufacturing Request for Production Template document serves as a standardized form used to initiate and authorize the production process within manufacturing facilities. It contains essential details such as product specifications, quantity, production deadlines, and resource requirements to streamline communication between departments. This template enhances efficiency by ensuring consistency, accuracy, and compliance with manufacturing protocols.

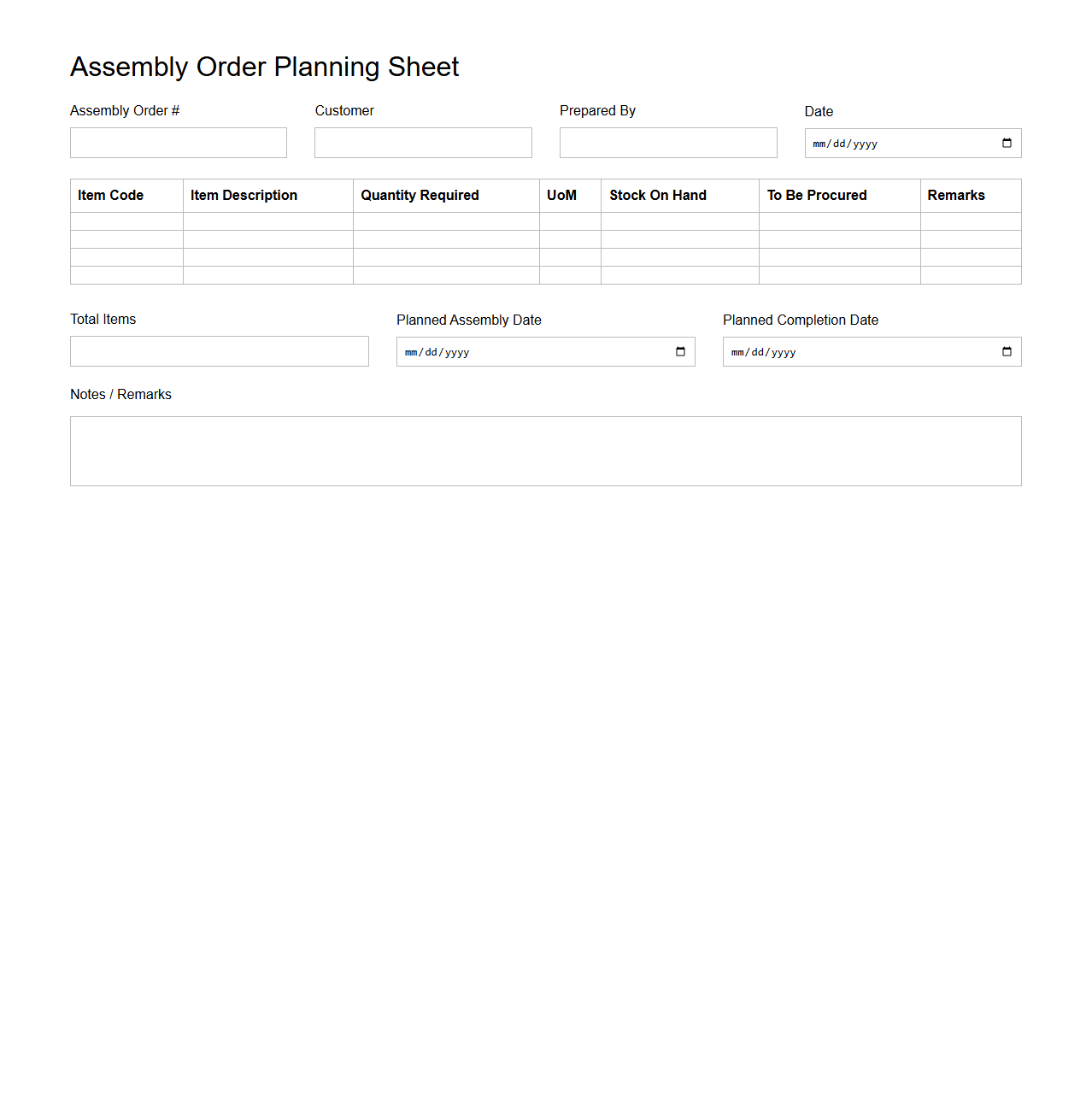

Assembly Order Planning Sheet

The

Assembly Order Planning Sheet document serves as a detailed guide outlining the sequence and requirements for assembling products in manufacturing. It includes information such as component lists, assembly steps, labor allocations, and timelines to ensure efficient production workflows. This document is essential for coordinating resources and optimizing the assembly line to meet production targets.

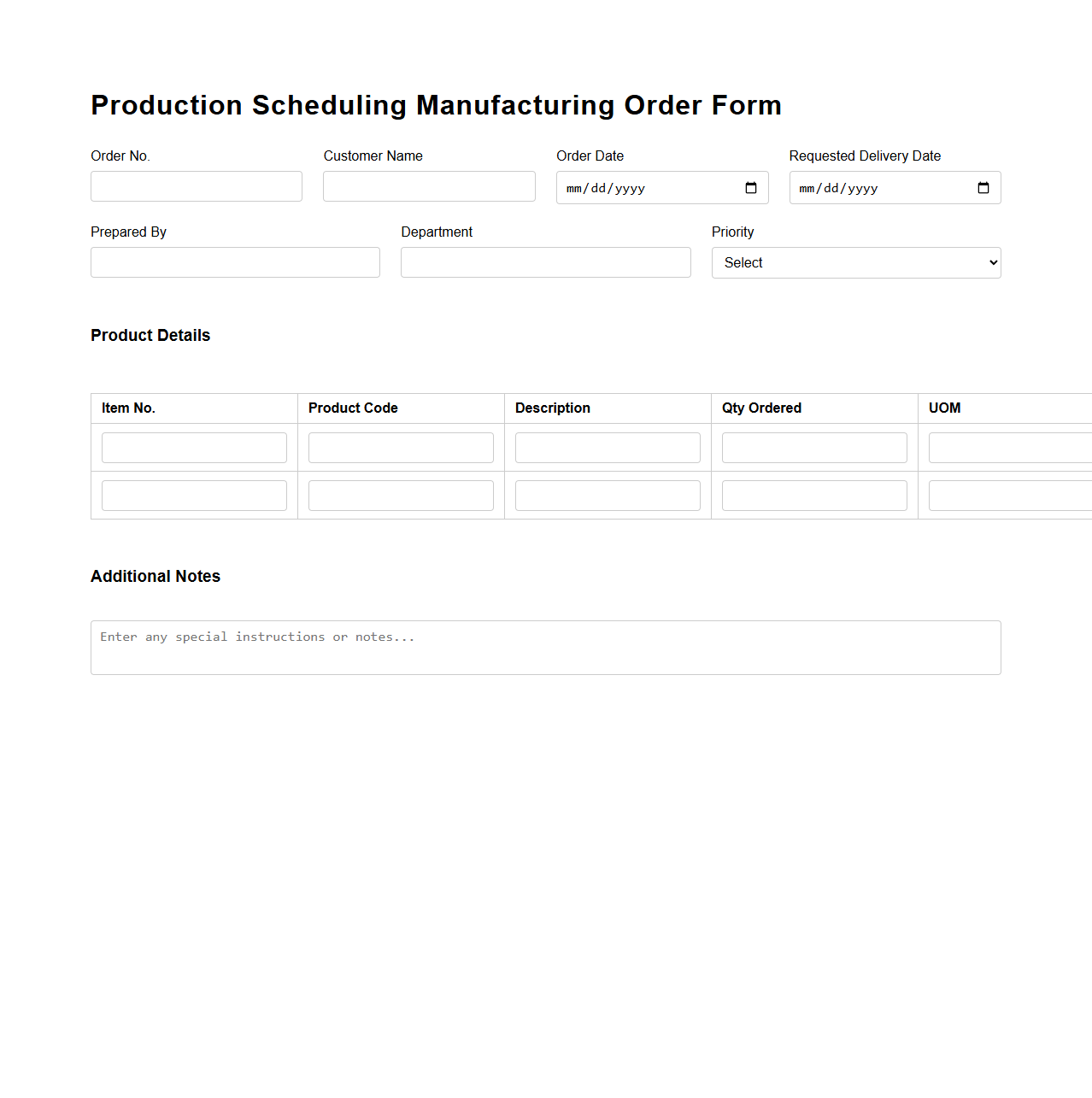

Production Scheduling Manufacturing Order Form

A

Production Scheduling Manufacturing Order Form is a critical document used to organize and plan the manufacturing process by detailing the specific production tasks, timelines, and resources required for a manufacturing order. It helps ensure efficient workflow, resource allocation, and timely completion of manufacturing targets by providing a clear schedule and instructions for production teams. This document plays a vital role in optimizing production efficiency and minimizing delays in the manufacturing supply chain.

What key fields should be included in a blank manufacturing order template for efficient production planning?

A blank manufacturing order template must include fields such as order number, product details, quantity, and due date to facilitate smooth production scheduling. Including supplier information and bill of materials (BOM) ensures clear communication and resource allocation. Additionally, fields for priority level and special instructions help manage workflow and custom requirements efficiently.

How can version control be implemented in blank manufacturing order documents?

Implementing version control in blank manufacturing order documents involves using a systematic naming convention with version numbers and timestamps for each revision. Utilizing document management software or cloud platforms enables real-time tracking and update history. This practice prevents confusion and ensures accuracy by maintaining a clear audit trail of all changes.

What are best practices for digitally signing a blank manufacturing order form?

Best practices for digitally signing a blank manufacturing order form include using secure and compliant digital signature tools that verify signer identity. Integrating electronic signature workflows within production management systems enhances process automation and reduces paperwork. It is crucial to store signed documents securely to ensure traceability and legal validity.

How is lead time calculated using data from a blank manufacturing order?

Lead time calculation uses data points such as order receipt date, processing start date, and expected completion date within the manufacturing order. Understanding the duration of procurement, production, and quality control phases allows accurate estimation of total lead time. This calculation aids in optimizing scheduling and managing customer expectations effectively.

What compliance checks must a blank manufacturing order meet for ISO-certified production planning?

For ISO-certified production planning, manufacturing orders must ensure completeness, traceability, and adherence to documented procedures. The template should include fields for quality inspections and approval signatures to meet ISO standards. Regular audits and updates to the order form help maintain compliance with industry regulations and continuous improvement protocols.