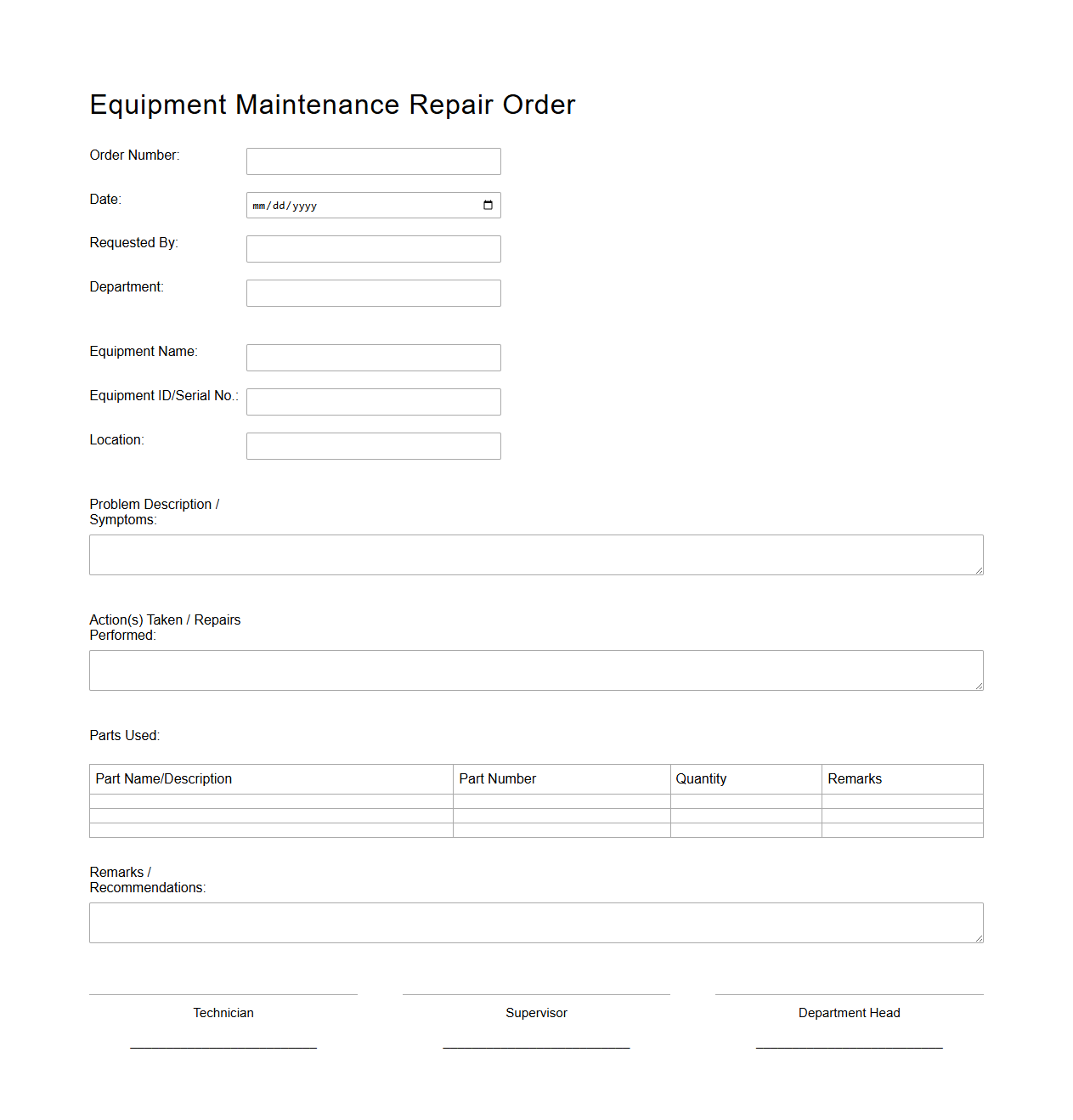

Equipment Maintenance Repair Order Template

An

Equipment Maintenance Repair Order Template document is a structured form used to track and document repair and maintenance activities for machinery and equipment. It includes fields for recording details such as equipment identification, description of the issue, repair actions taken, parts used, labor hours, and authorization signatures. This template ensures efficient communication, accountability, and accurate record-keeping to optimize equipment uptime and prolong asset lifespan.

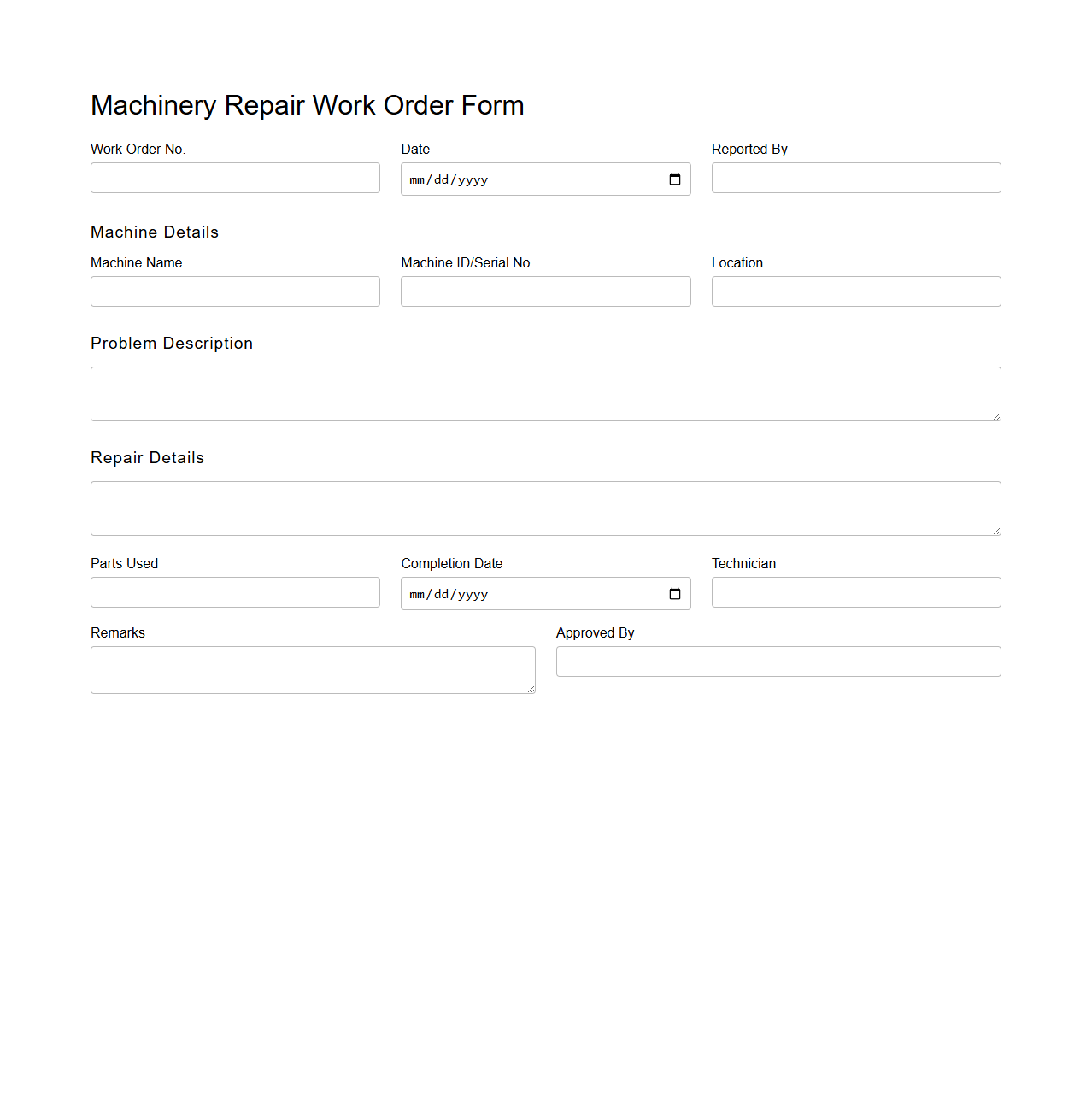

Machinery Repair Work Order Form

A

Machinery Repair Work Order Form is a standardized document used to request, authorize, and track maintenance or repair tasks for industrial equipment. It includes essential details such as equipment identification, description of the problem, assigned personnel, required parts, and estimated completion time. This form ensures clear communication, efficient workflow, and accurate record-keeping throughout the machinery repair process.

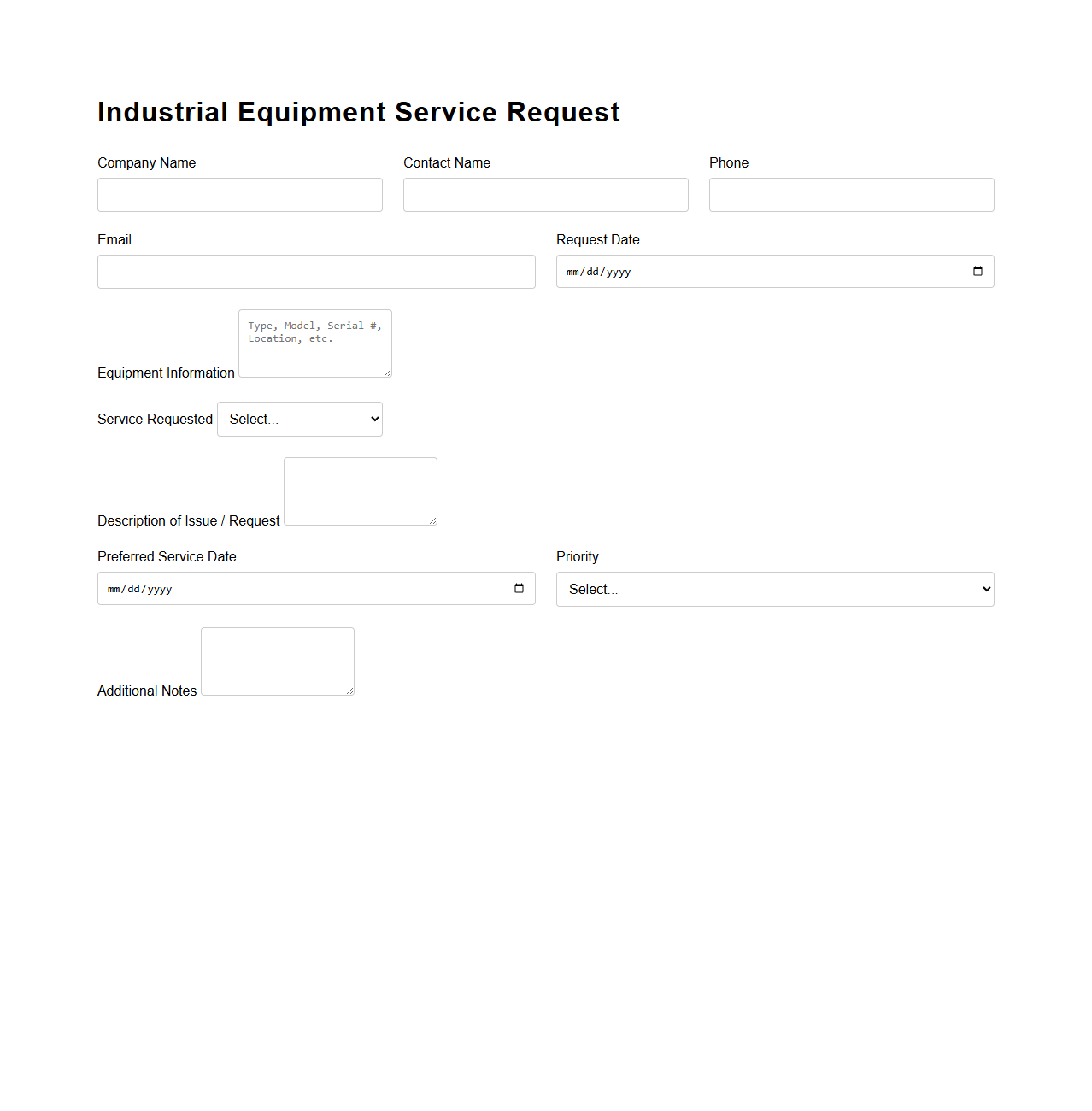

Industrial Equipment Service Request Template

The

Industrial Equipment Service Request Template document is a standardized form designed to streamline the process of reporting maintenance or repair needs for machinery in industrial settings. It captures essential details such as equipment identification, issue description, urgency level, and contact information to ensure efficient communication between operators and service teams. This template enhances workflow by prioritizing requests and tracking service history, reducing downtime and improving operational efficiency.

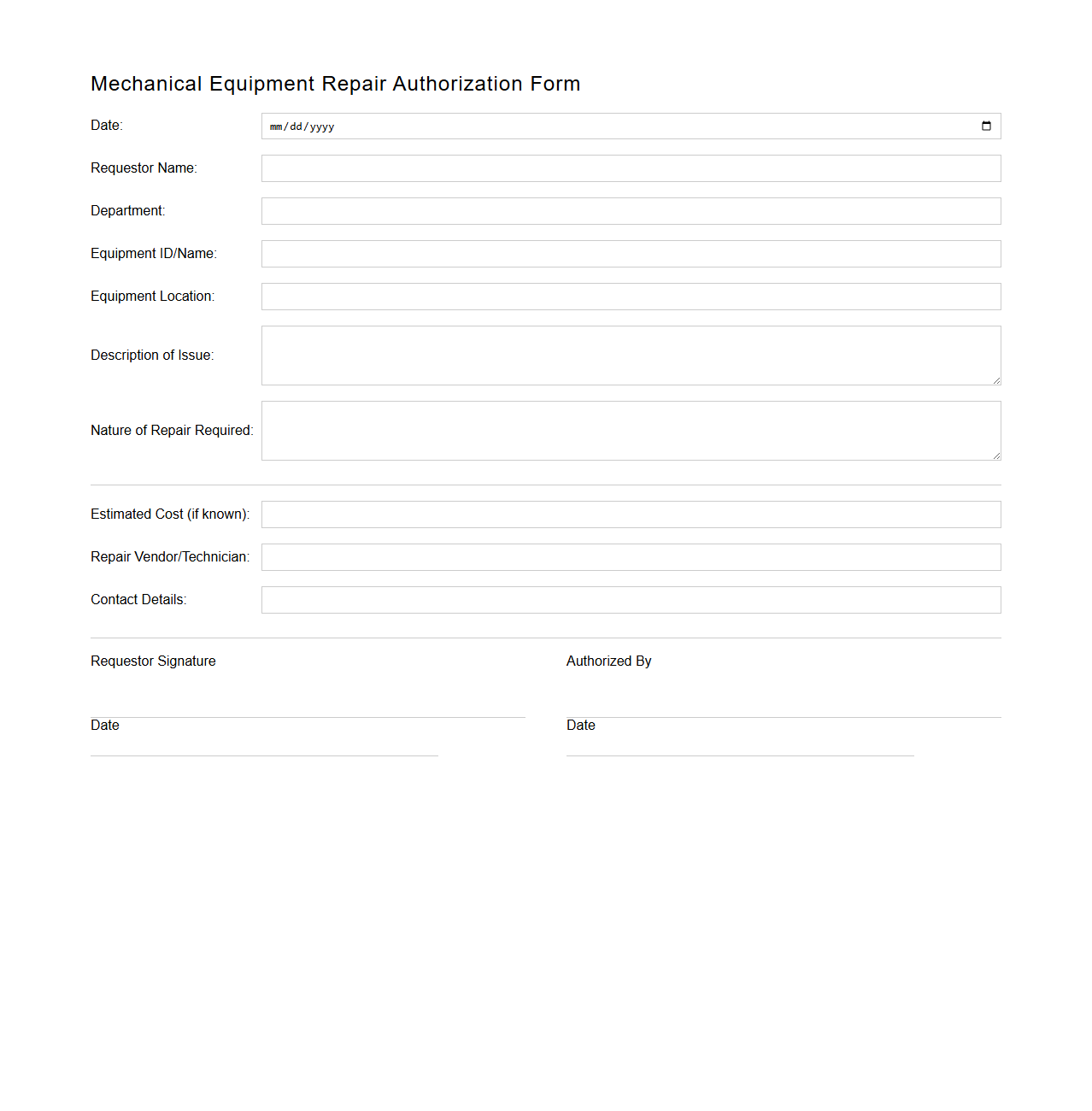

Mechanical Equipment Repair Authorization Form

The

Mechanical Equipment Repair Authorization Form is a critical document used to formally approve and document the repair process for mechanical equipment in industrial, commercial, or facility management settings. It includes detailed information such as the equipment identification, nature of the malfunction, repair instructions, estimated costs, and authorization signatures from relevant personnel to ensure accountability and traceability. This form helps streamline maintenance operations, control repair expenses, and maintain equipment reliability and safety standards.

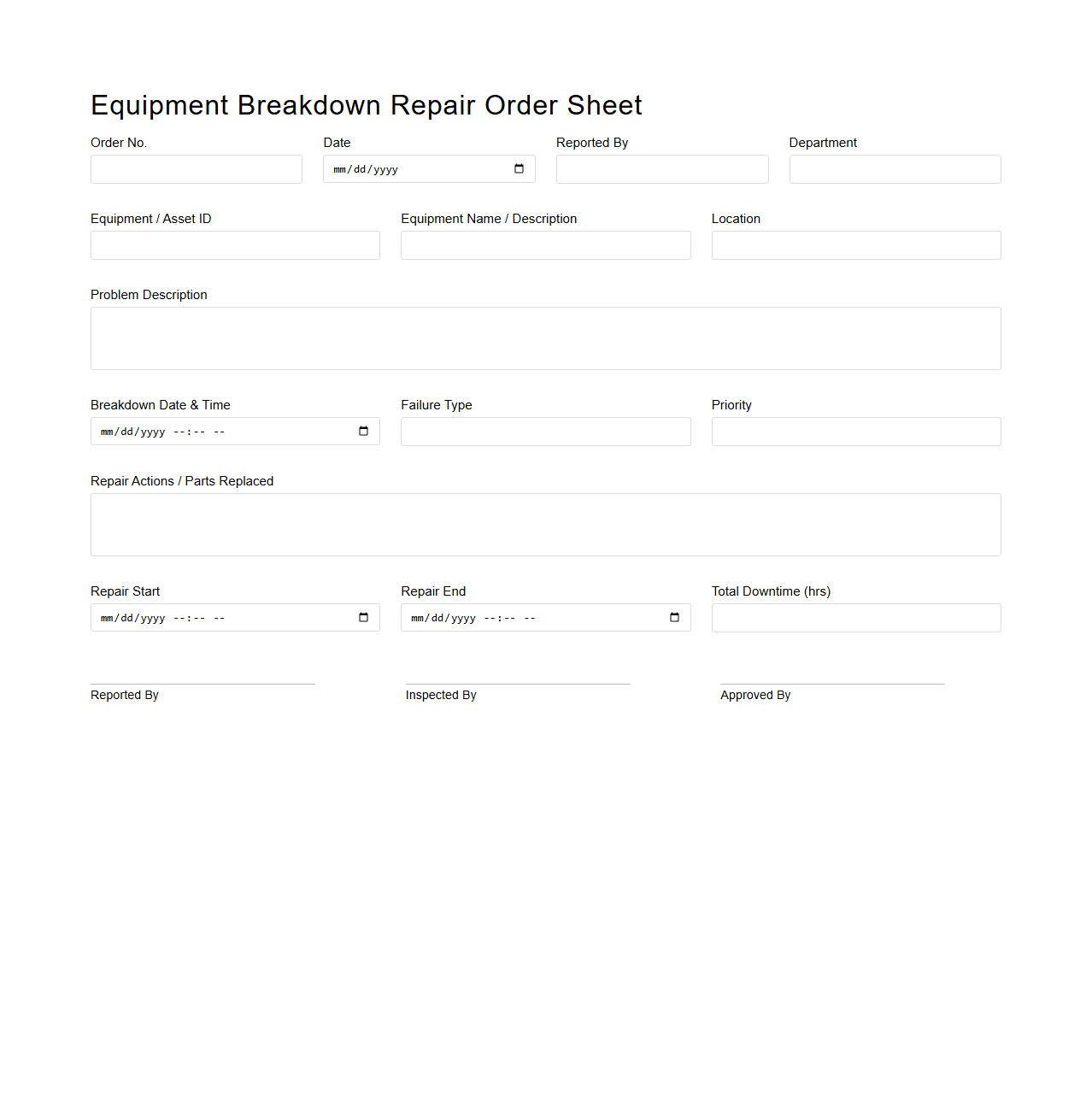

Equipment Breakdown Repair Order Sheet

The

Equipment Breakdown Repair Order Sheet document serves as a detailed record for tracking the repair process of malfunctioning machinery or equipment. It includes critical information such as the type of equipment, nature of the breakdown, repair actions taken, parts replaced, and labor costs incurred. This document ensures efficient workflow management and accurate maintenance history for future reference.

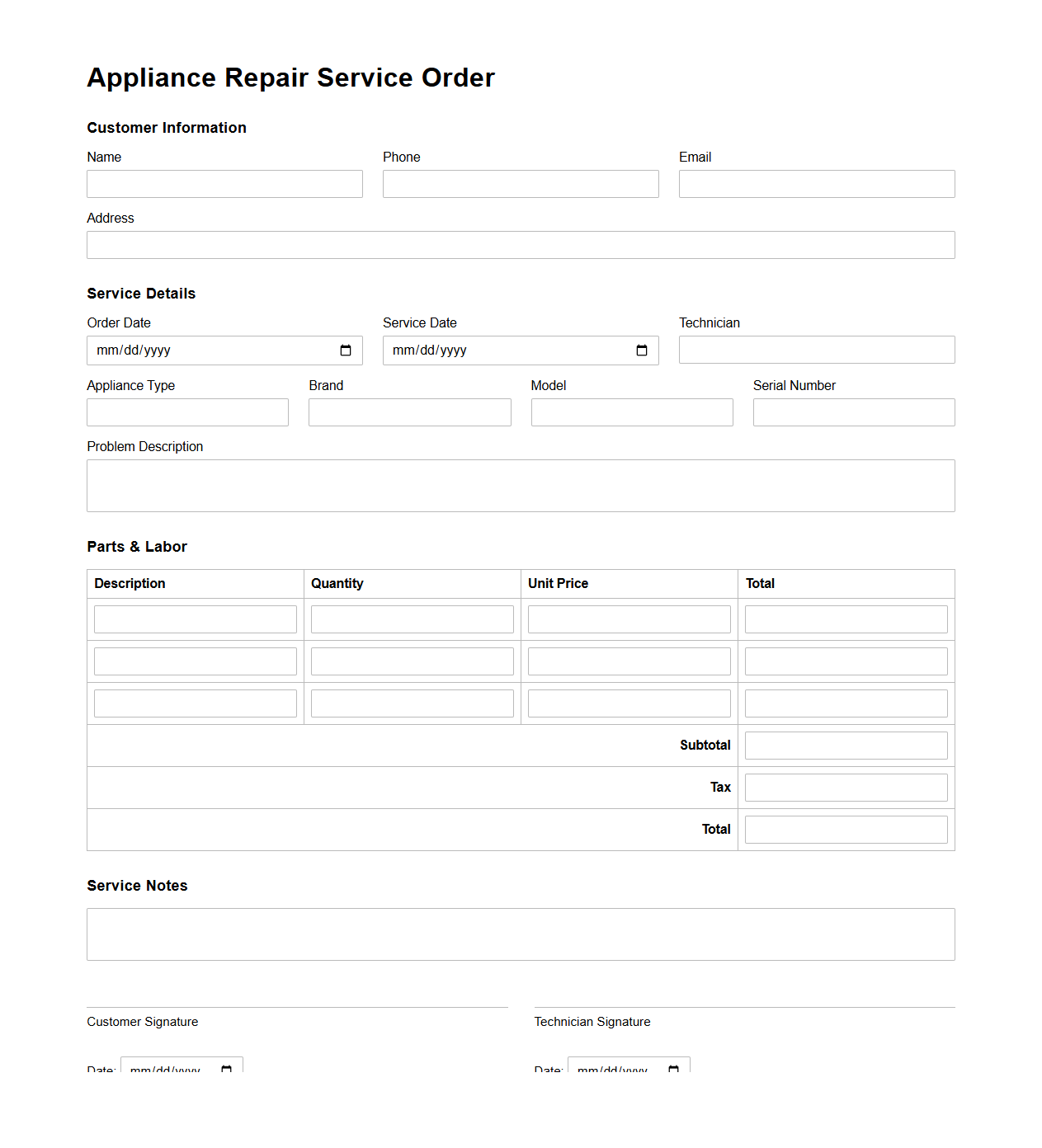

Appliance Repair Service Order Template

An

Appliance Repair Service Order Template document is a structured form used by technicians and service providers to record detailed information about repair requests, including customer details, appliance type, service performed, and parts used. This template ensures accurate tracking of service tasks, streamlines communication between customers and repair teams, and facilitates billing and warranty documentation. Using this standardized document enhances efficiency and accountability in appliance repair operations.

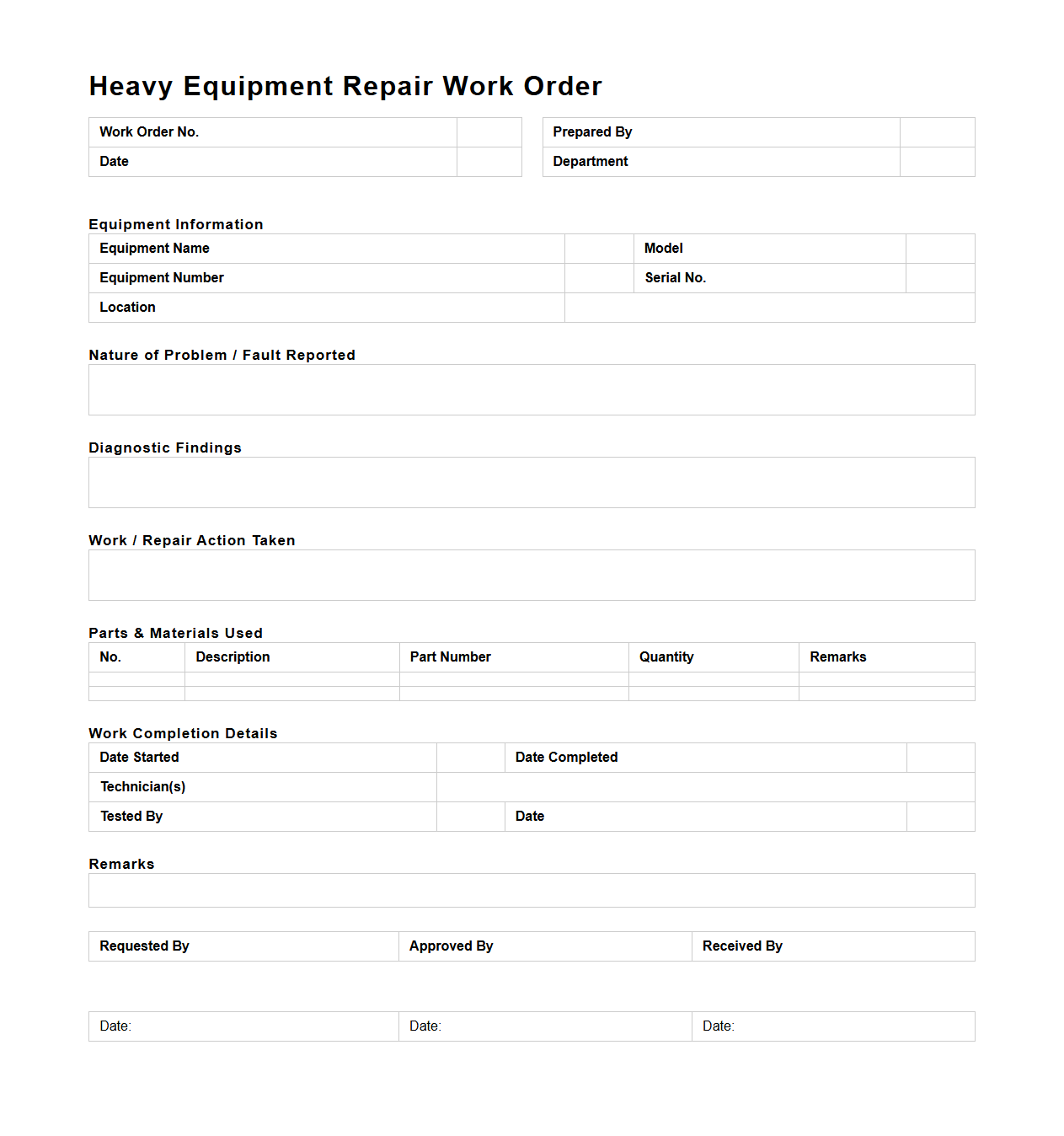

Heavy Equipment Repair Work Order Format

A

Heavy Equipment Repair Work Order Format document serves as a structured template to record specific details related to the maintenance and repair of heavy machinery. It typically includes fields for equipment identification, description of the issue, labor and parts required, technician details, and cost estimates. This format ensures clear communication, efficient workflow management, and accurate tracking of repairs for optimal equipment performance.

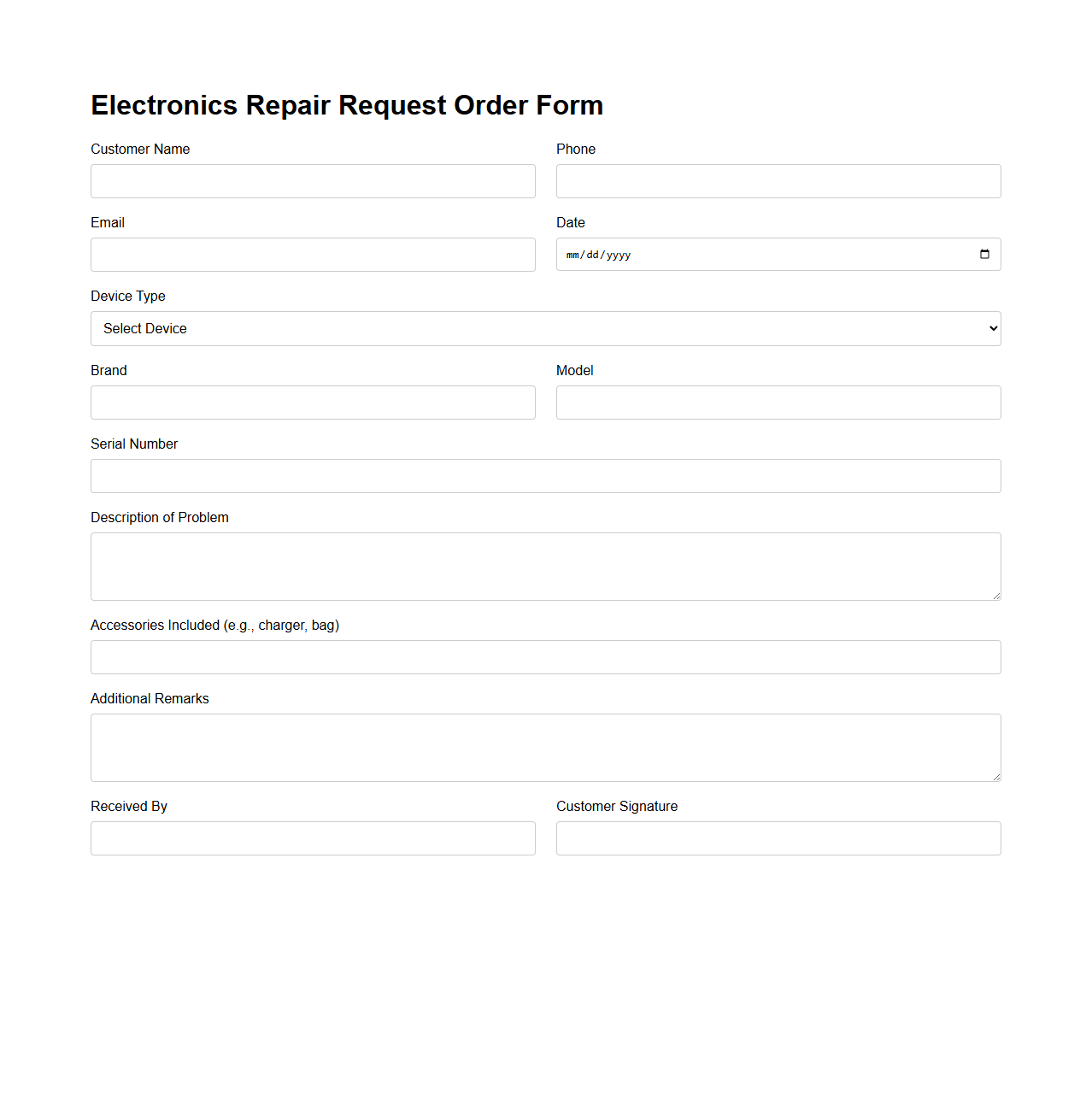

Electronics Repair Request Order Form

An

Electronics Repair Request Order Form is a document used to detail and track the repair process of electronic devices. It includes essential information such as the device type, serial number, reported issues, customer contact details, and authorization for repair. This form ensures accurate service documentation, facilitates communication between technicians and customers, and helps maintain accountability throughout the repair workflow.

Facility Equipment Maintenance Work Order Template

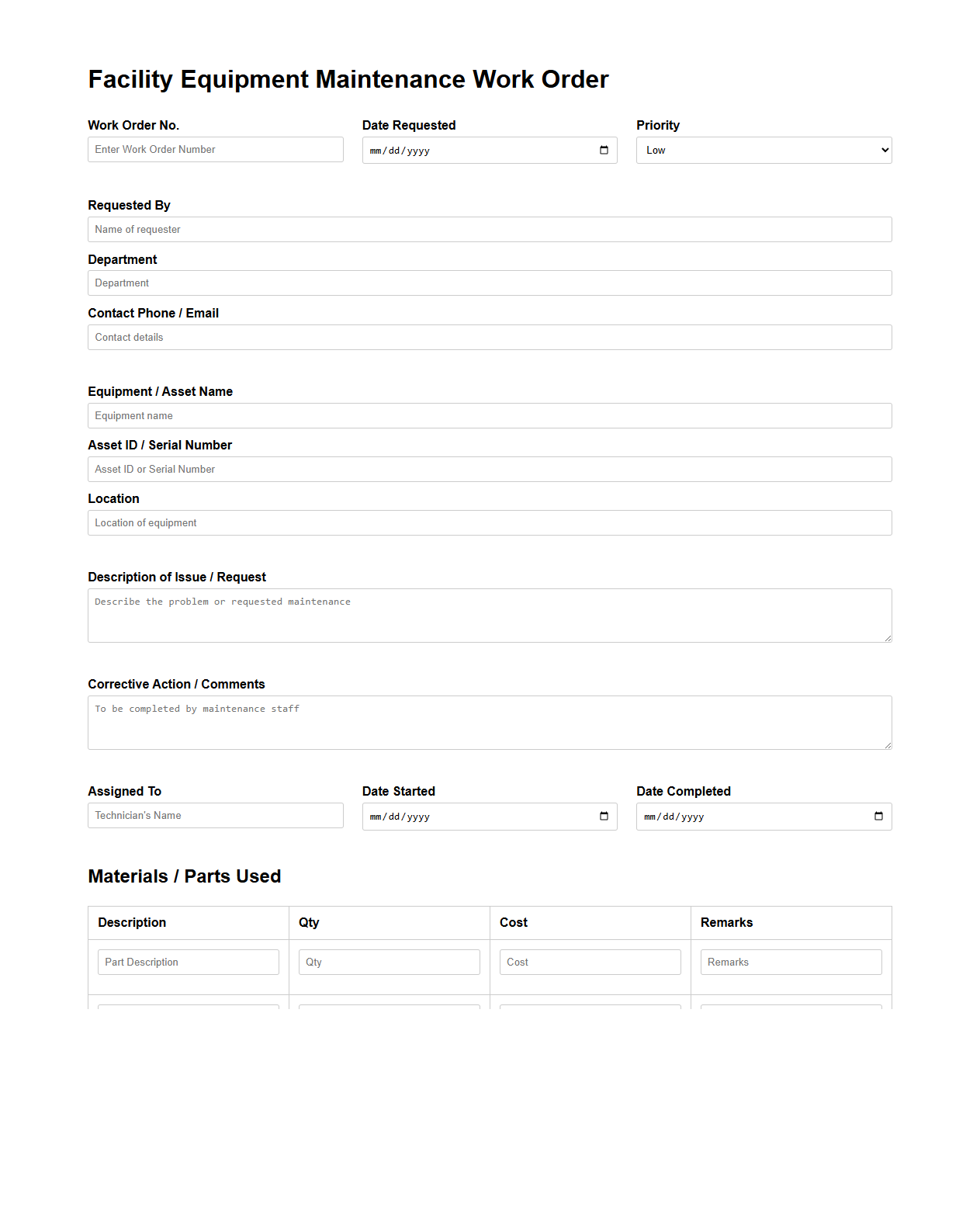

A

Facility Equipment Maintenance Work Order Template document is a structured form used to schedule, track, and manage maintenance tasks for facility equipment efficiently. It includes essential details such as equipment identification, maintenance descriptions, assigned personnel, and completion timelines to ensure systematic upkeep and minimize downtime. This template enhances communication between maintenance teams and facility managers, promoting timely repairs and preventing equipment failures.

HVAC Equipment Service Repair Order Sheet

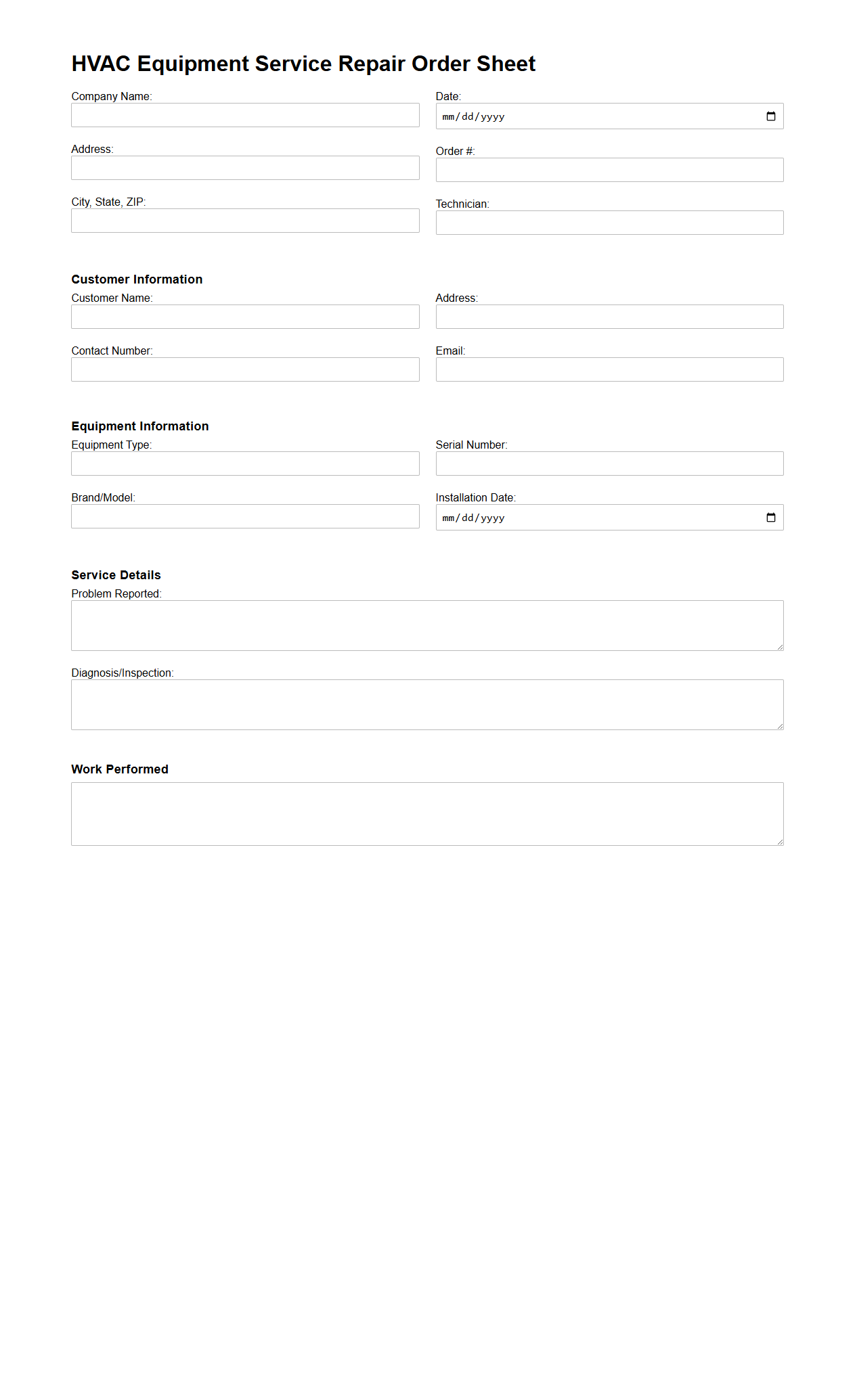

The

HVAC Equipment Service Repair Order Sheet document serves as a detailed record of maintenance and repair activities performed on heating, ventilation, and air conditioning systems. It includes essential information such as customer details, equipment specifications, reported issues, diagnostic findings, parts used, and labor performed. This document ensures accurate tracking of service history and supports efficient communication between technicians, clients, and service providers.

What specific equipment details are required in a blank repair order letter?

A blank repair order letter must include equipment identification such as model and serial numbers. It should also specify the description of the equipment to ensure clarity. Detailed condition and reported issues provide necessary context for the repair process.

How can warranty status be documented in a blank repair order for equipment repairs?

Warranty status should be clearly indicated in a dedicated warranty information section. This section may include the purchase date, warranty period, and any applicable terms and conditions. Proper documentation helps in verifying coverage for repair costs.

What sections address authorization and cost estimates in a blank repair order letter?

The authorization section requires customer approval signatures to proceed with repairs. Cost estimates are typically outlined in a repair cost breakdown section. Both elements ensure transparency and agreement before work begins.

How should safety compliance be referenced within a blank repair order for equipment repairs?

Safety compliance must be included in a regulatory adherence or safety standards section. This ensures all repairs meet relevant industry safety guidelines. Such references protect both the technician and company from liability.

What fields capture technician assignment in a blank equipment repair order letter?

Technician assignment fields include the technician's name, contact information, and credentials or certifications. These details facilitate accountability and proper task allocation. Tracking technician information enhances communication and repair quality.