A Blank Production Schedule Template for Manufacturing provides a structured framework to efficiently plan and monitor the production process. It helps manufacturers allocate resources, track progress, and manage deadlines to ensure timely product delivery. This customizable template enhances workflow organization and boosts overall operational productivity.

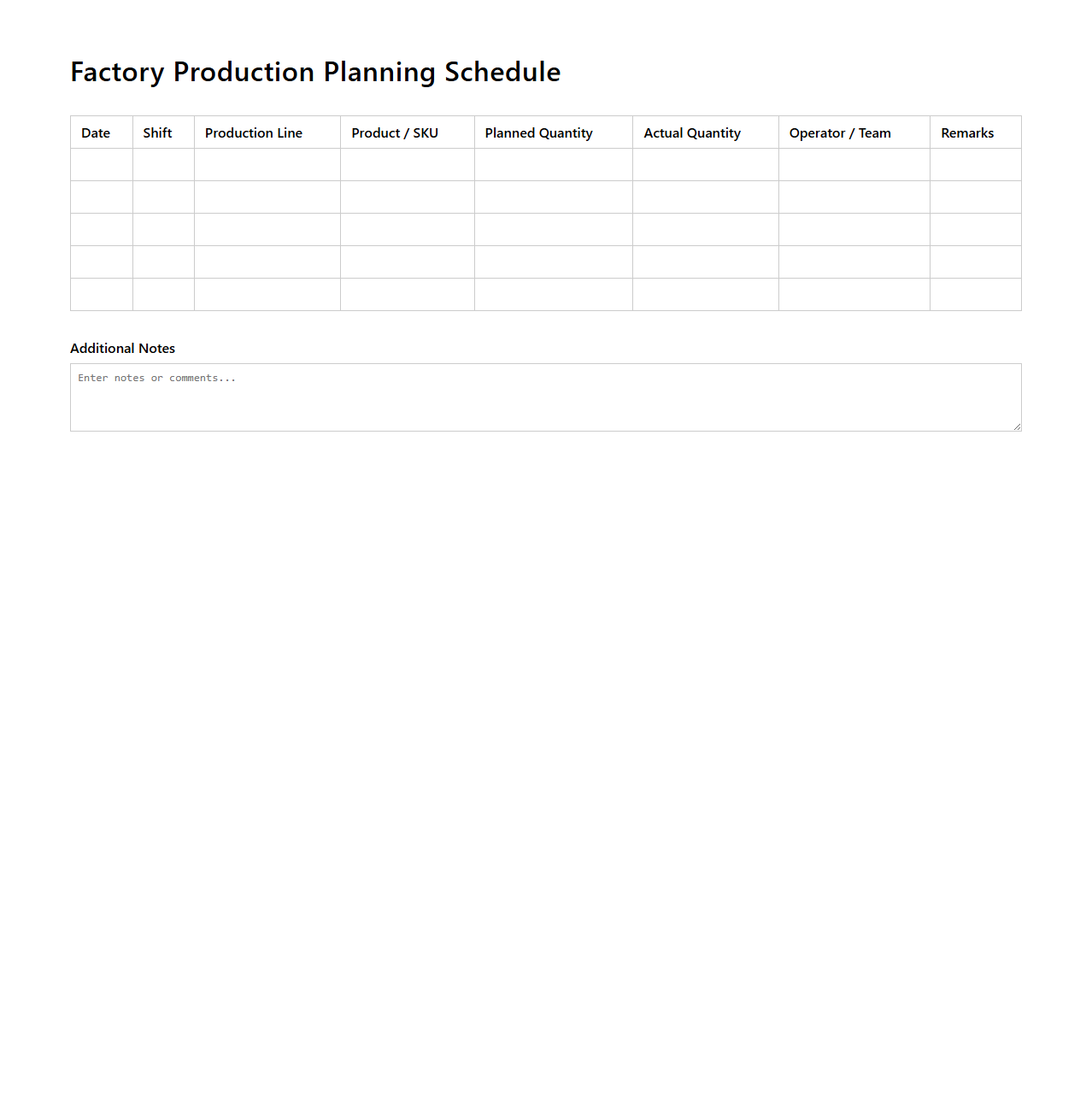

Blank Factory Production Planning Schedule Template

The

Blank Factory Production Planning Schedule Template document is a structured tool designed to organize and streamline manufacturing workflows by outlining daily, weekly, or monthly production tasks. It facilitates the allocation of resources, tracks progress, and ensures timely completion of factory outputs, improving operational efficiency. This template supports better decision-making and minimizes downtime by providing a clear schedule for all production activities.

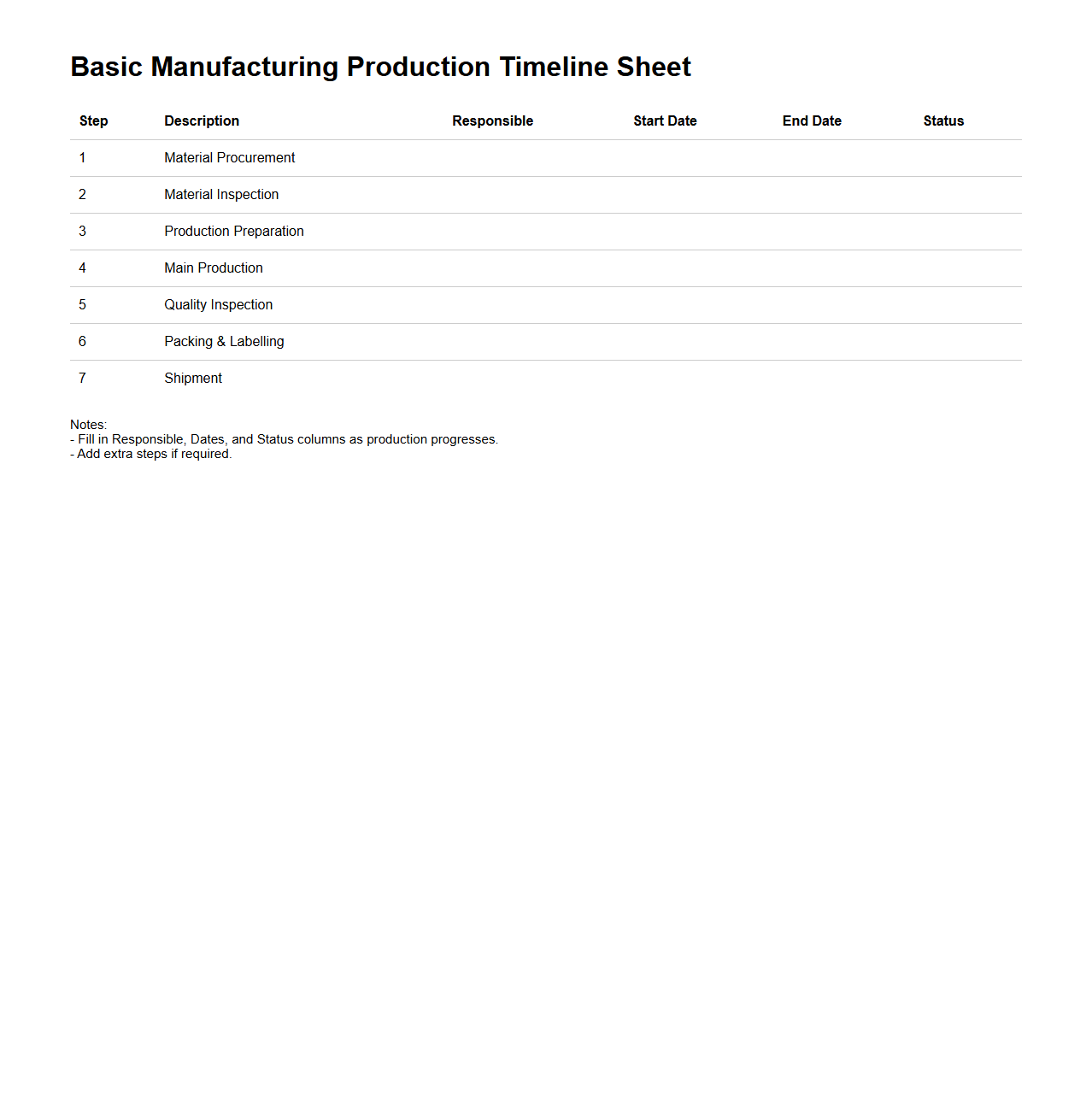

Basic Manufacturing Production Timeline Sheet

A

Basic Manufacturing Production Timeline Sheet is a detailed document outlining the sequential phases and timeframes for the production process in manufacturing. It helps in tracking progress, scheduling tasks, and ensuring efficient resource allocation to meet deadlines. This timeline is essential for coordinating activities from raw material acquisition to final product delivery.

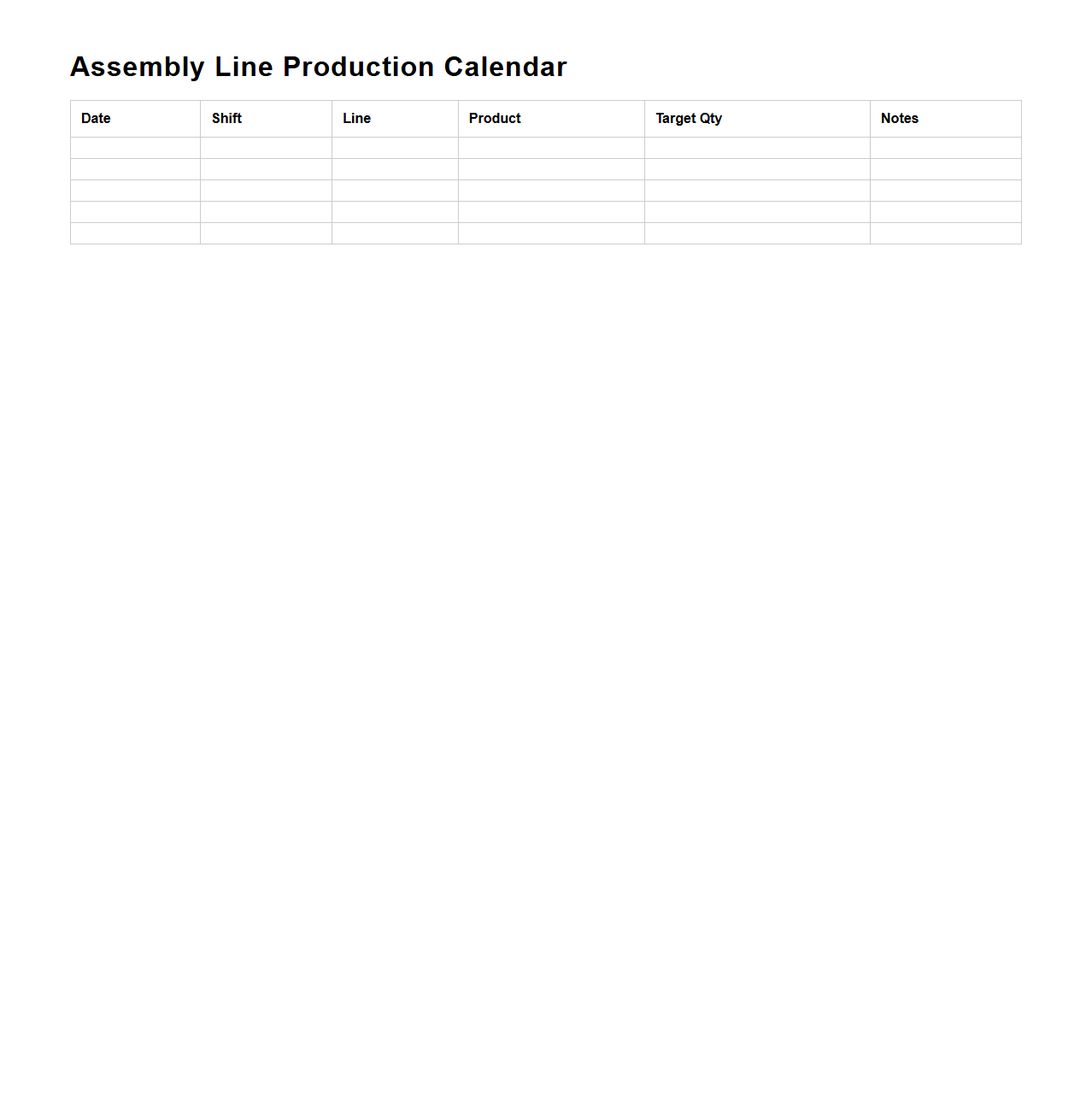

Empty Assembly Line Production Calendar Template

An

Empty Assembly Line Production Calendar Template is a structured document designed to organize and schedule manufacturing tasks across an assembly line efficiently. It enables production managers to allocate time slots for various processes, track workflow, and identify potential bottlenecks to optimize overall productivity. By using this template, companies can ensure precise timeline management and improve coordination among different production stages.

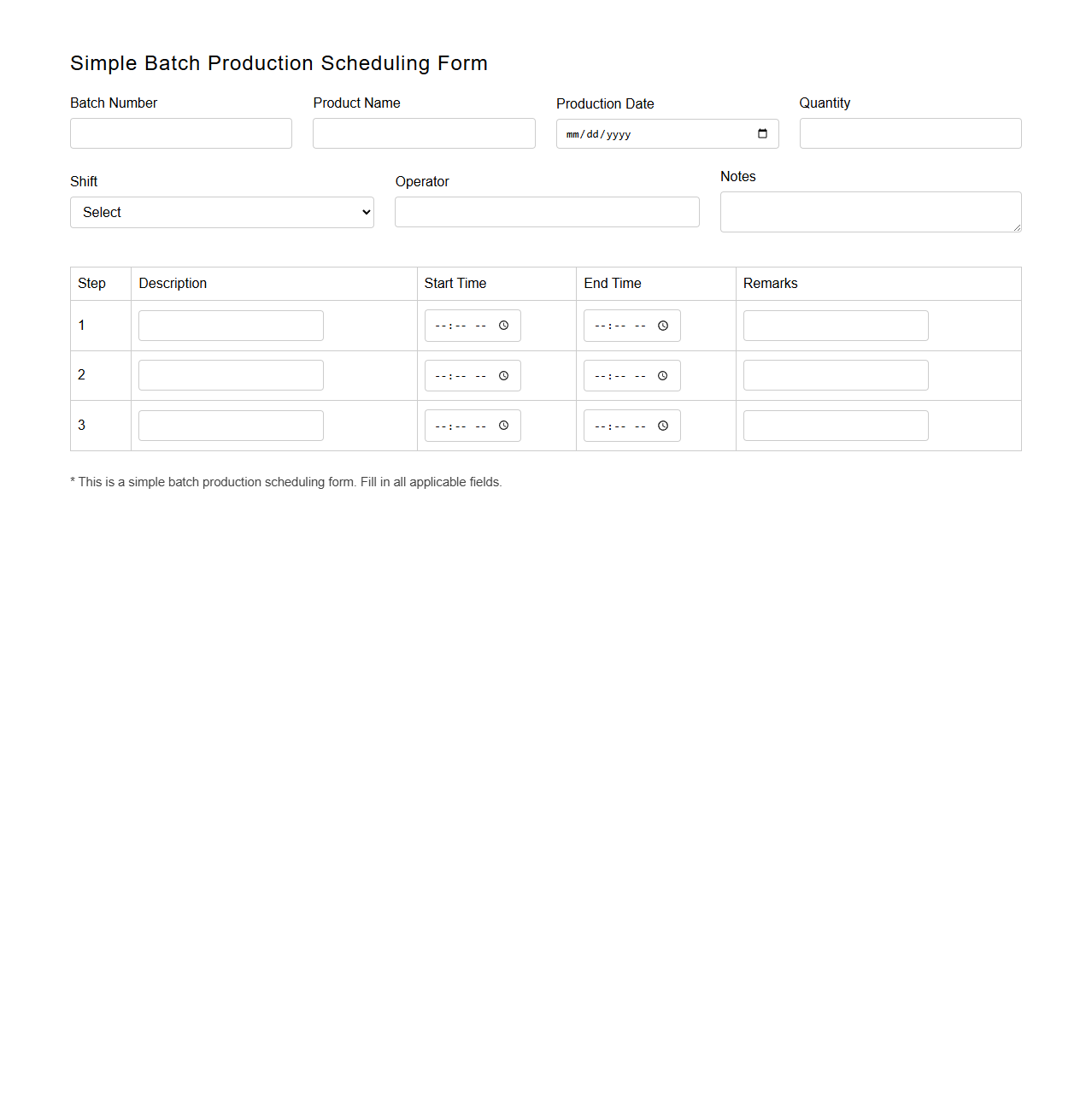

Simple Batch Production Scheduling Form

The

Simple Batch Production Scheduling Form is a document used to organize and plan the manufacturing process of products in batches. It includes essential details such as batch size, production start and end dates, resource allocation, and workflow sequences to ensure efficient use of time and materials. This form helps in minimizing production delays, optimizing equipment usage, and maintaining consistent product quality throughout the batch process.

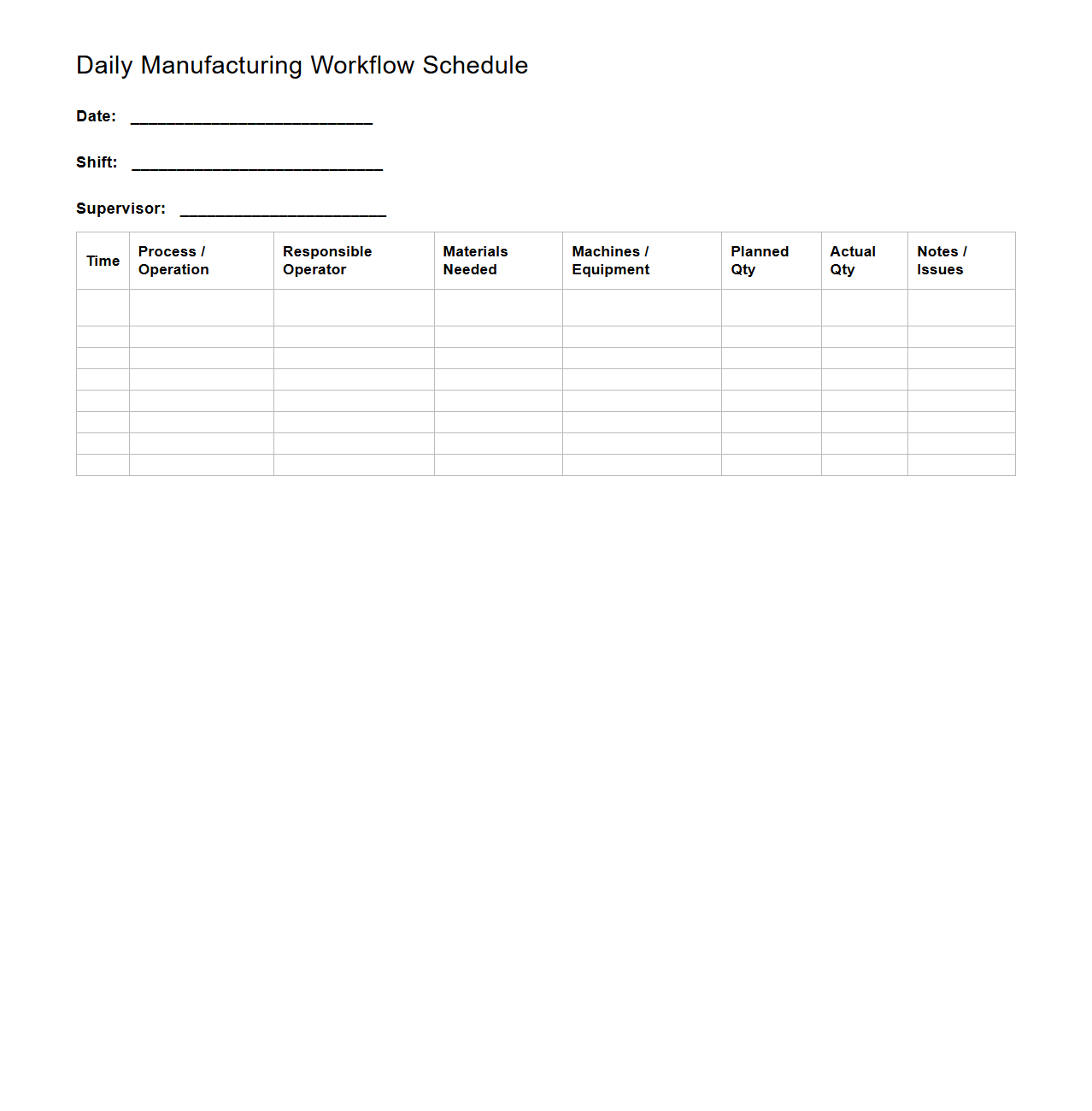

Unfilled Daily Manufacturing Workflow Schedule

The

Unfilled Daily Manufacturing Workflow Schedule document is a critical tool used to track and manage incomplete or pending tasks within a manufacturing process on a daily basis. It provides detailed insights into production bottlenecks, resource allocation inefficiencies, and workflow disruptions, enabling managers to prioritize corrective actions promptly. Maintaining this schedule enhances operational transparency and supports continuous improvement in manufacturing efficiency.

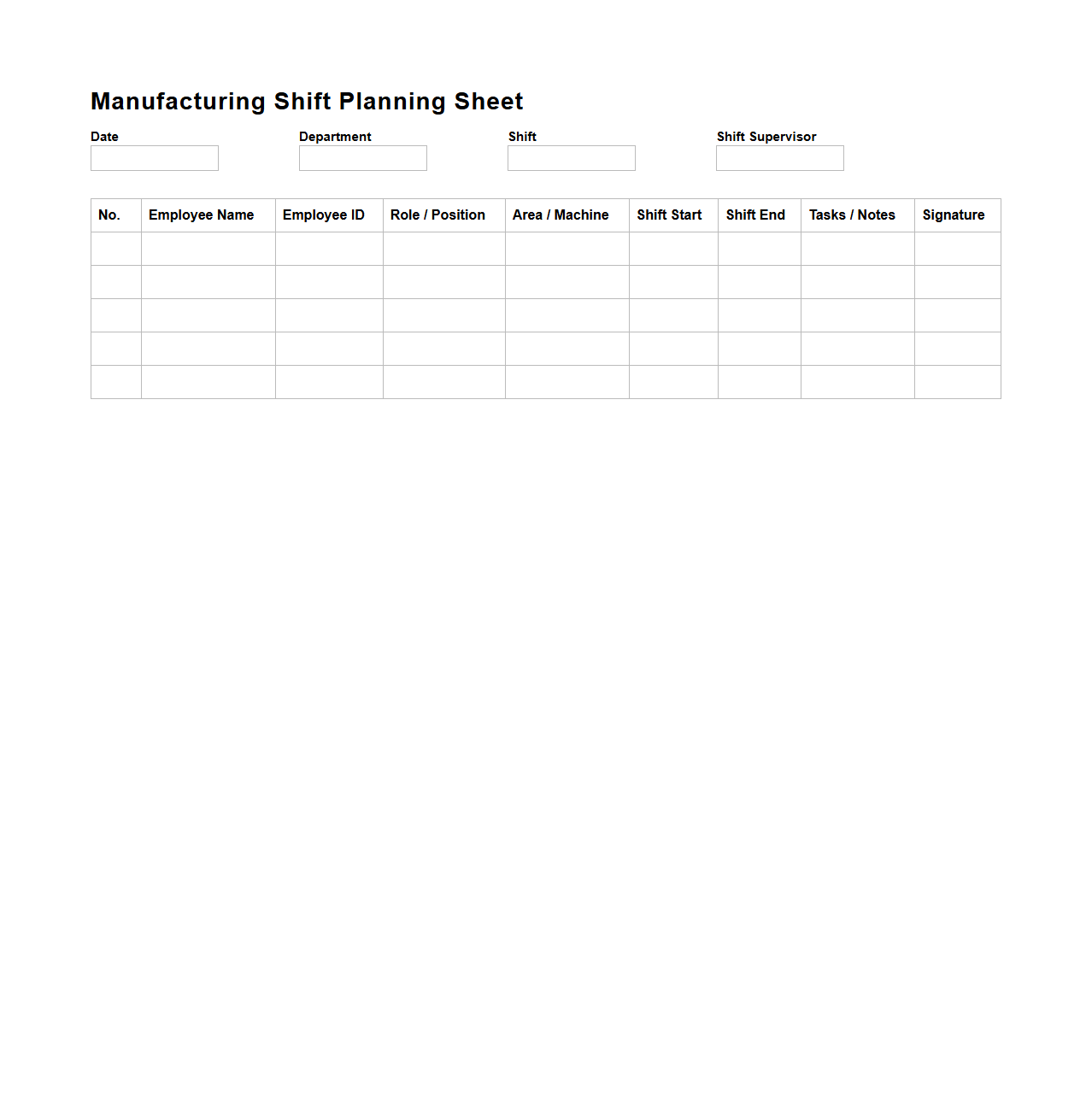

Plain Manufacturing Shift Planning Sheet

A

Plain Manufacturing Shift Planning Sheet is a structured document used to organize and schedule workforce shifts in manufacturing environments. It outlines employee assignments, shift timings, and production targets for each shift, ensuring efficient resource allocation and operational continuity. This sheet helps managers track labor distribution, monitor productivity, and optimize manufacturing workflow.

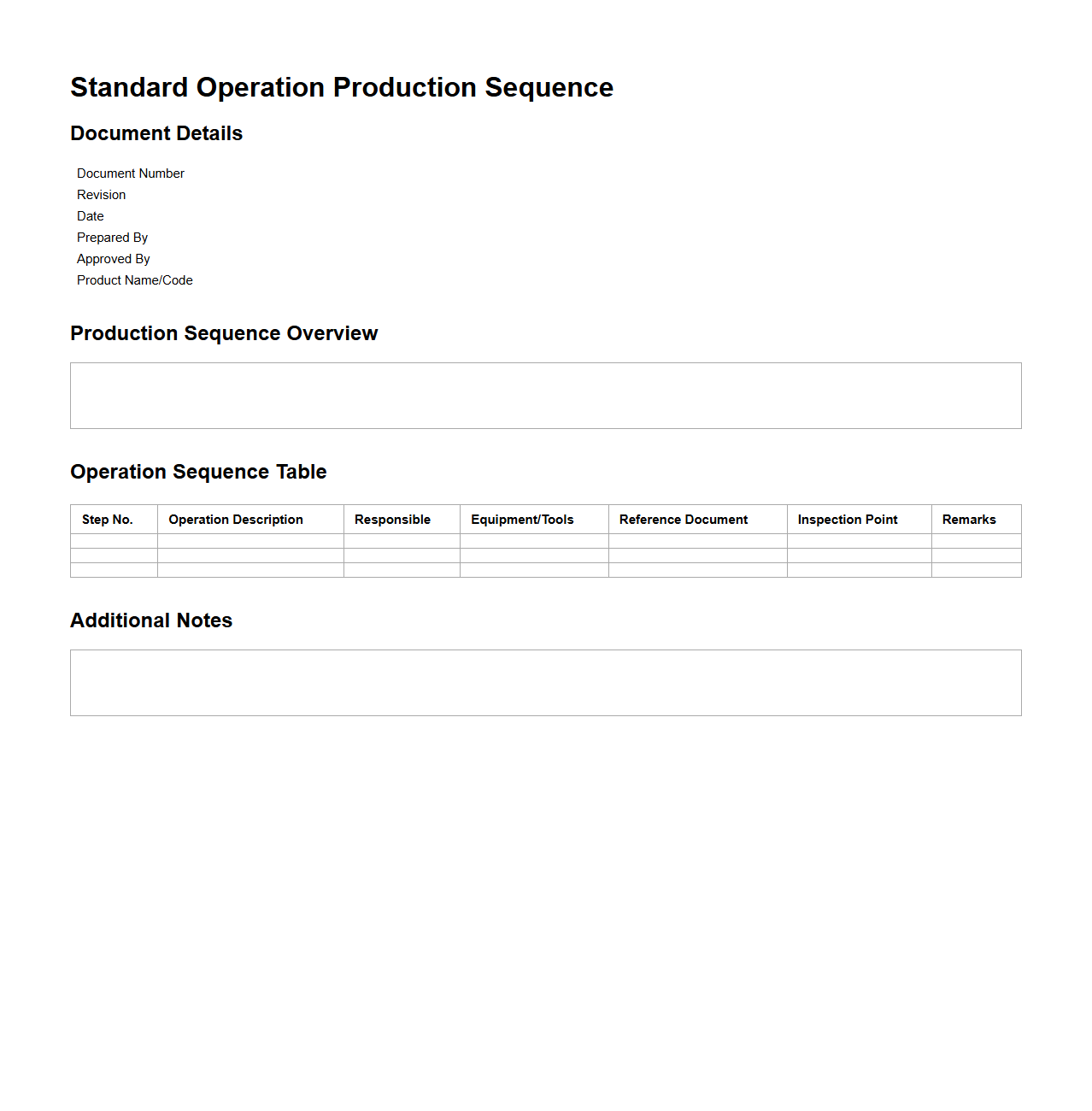

Standard Operation Production Sequence Document

The

Standard Operation Production Sequence Document outlines detailed, step-by-step instructions for manufacturing processes to ensure consistency and quality in production. It serves as a crucial reference for operators, specifying the order of tasks, equipment settings, and safety protocols to optimize efficiency and minimize errors. By standardizing production sequences, this document supports adherence to regulatory requirements and facilitates training and process improvements.

Minimalist Production Order Tracking Template

A

Minimalist Production Order Tracking Template is a streamlined document designed to monitor the progress of manufacturing orders efficiently. It focuses on essential data such as order number, production stages, deadlines, and status updates to ensure clear and concise tracking without unnecessary complexity. This template enhances workflow transparency and helps managers quickly identify bottlenecks in the production process.

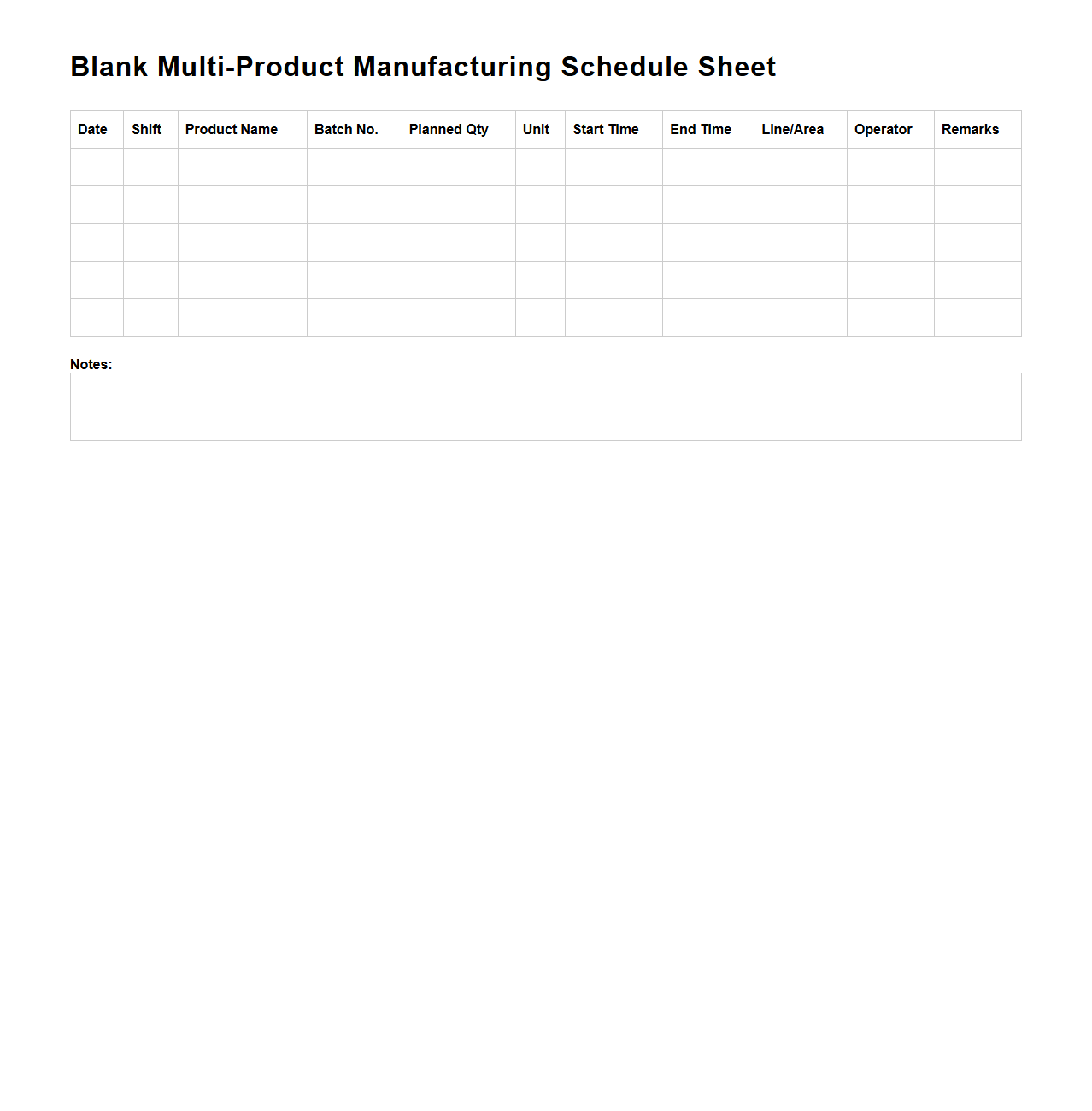

Blank Multi-Product Manufacturing Schedule Sheet

The

Blank Multi-Product Manufacturing Schedule Sheet is a crucial document used to organize and plan production timelines for multiple products simultaneously. It helps manufacturing teams allocate resources, track progress, and manage deadlines efficiently across various product lines. This sheet typically includes columns for product names, batch sizes, start and end dates, and assigned workstations to ensure smooth workflow coordination.

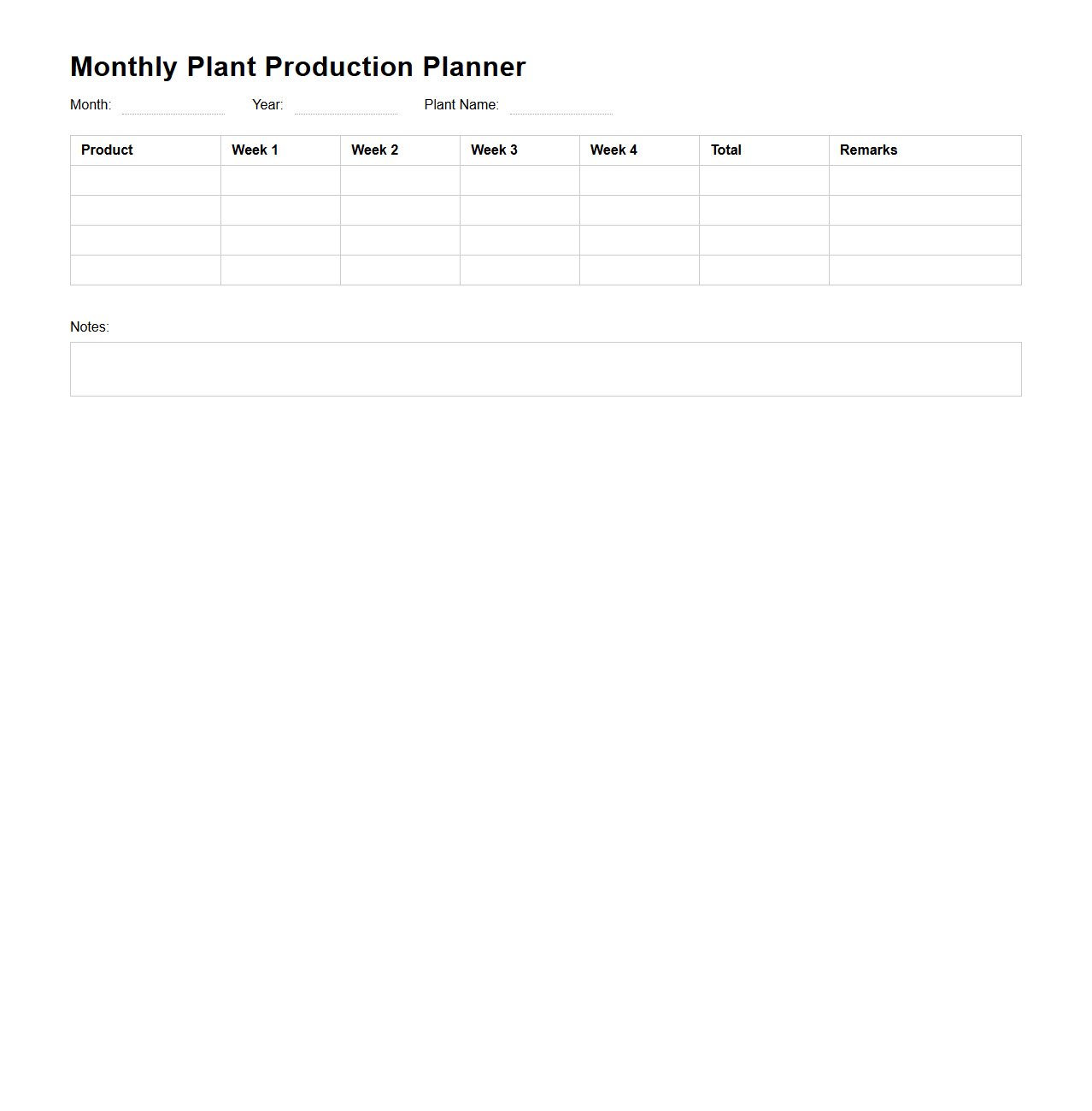

Skeleton Monthly Plant Production Planner

The

Skeleton Monthly Plant Production Planner document serves as a foundational tool to outline and schedule the production activities of a manufacturing plant on a monthly basis. It includes key elements such as production targets, resource allocation, machine availability, and workforce planning to ensure efficient operations. This planner helps in tracking progress, managing bottlenecks, and optimizing the overall production workflow.

What key data fields should be included in a blank production schedule template for batch manufacturing?

A blank production schedule template for batch manufacturing must include fields such as batch number, production start and end dates, and product quantity. Additionally, it should have sections for machine allocation, operator assignment, and quality control checkpoints. Including these fields ensures comprehensive tracking and smooth operational flow throughout the production process.

How can a blank production schedule help optimize raw material allocation?

A blank production schedule enables precise planning by outlining the quantities and timings of each batch, which directly affects raw material orders. This proactive layout minimizes waste and overstock by aligning raw material requirements with actual production needs. As a result, businesses can improve inventory turnover and reduce holding costs efficiently.

What are common time interval options in manufacturing production schedules?

Manufacturing production schedules typically use time intervals such as hourly, daily, or weekly to organize tasks and resources effectively. Selecting the right time interval depends on the production complexity and batch size. Accurate interval selection supports better workflow management and timely production completion.

How does a blank production schedule accommodate shift changes and labor assignments?

A blank production schedule can include designated sections for shift timings and specific labor assignments to ensure clarity in workforce management. This helps in coordinating transitions smoothly between shifts and maintaining consistent production output. Clear labor allocation also enhances accountability and job focus throughout the batch process.

What version control methods are best for managing blank production schedule documents?

Effective version control for production schedule documents involves using cloud-based collaboration tools, which provide real-time updates and access control. Maintaining a version history with timestamps helps track changes and prevents conflicts. Additionally, standardized naming conventions and backups ensure document integrity and easy retrieval.