A Blank Inspection Checklist Template for Quality Control provides a structured format to systematically evaluate products or processes, ensuring adherence to quality standards. It simplifies tracking inspection criteria and identifying defects or discrepancies. This tool enhances consistency and accuracy in quality assessments across various industries.

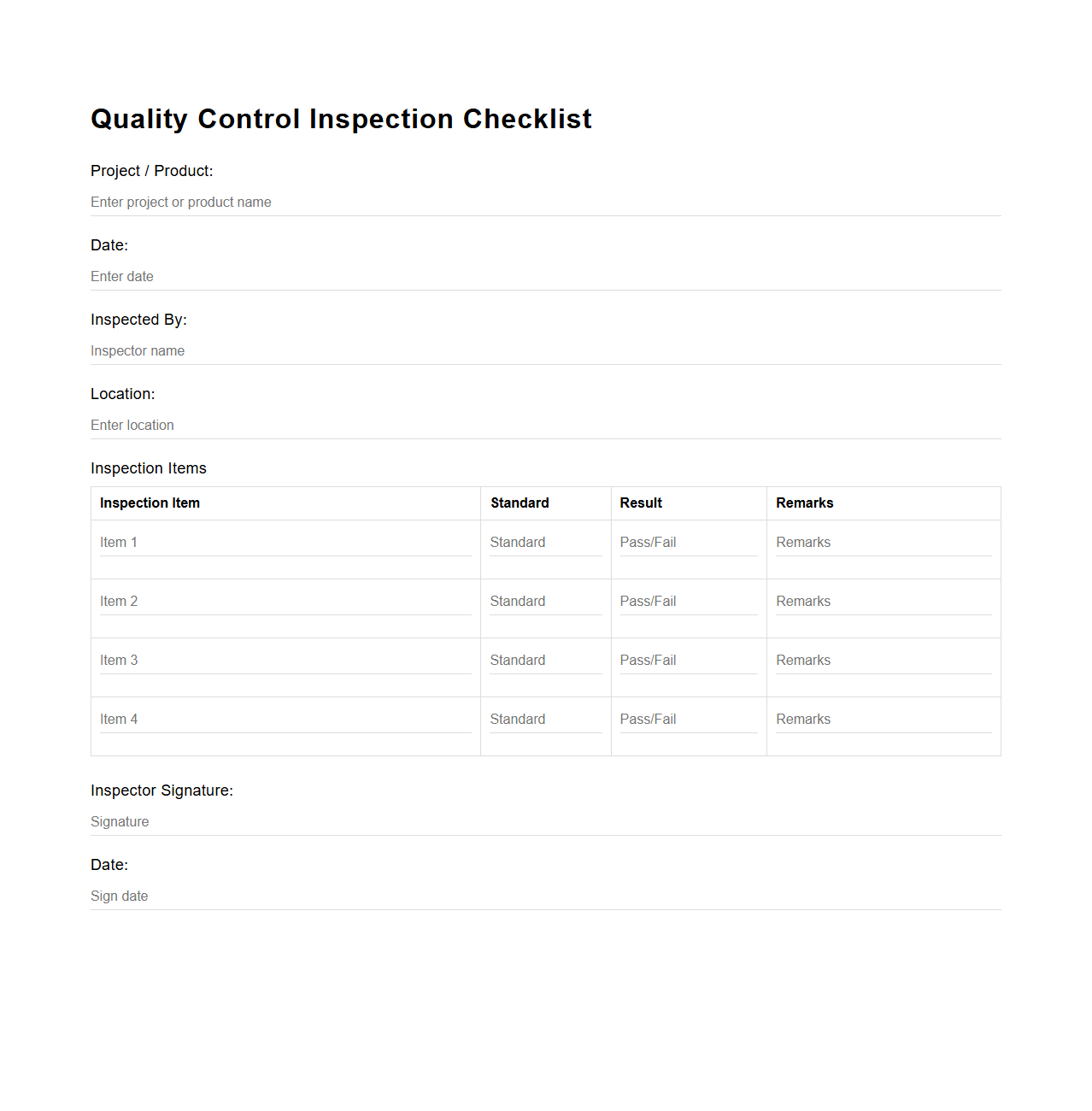

Blank Quality Control Inspection Checklist Template

A

Blank Quality Control Inspection Checklist Template document is a structured tool designed to systematically record and verify the quality standards of products or services during inspection processes. It includes predefined sections for inspectors to note defects, measurements, and compliance with industry specifications, ensuring consistent quality assessment. This template enhances accuracy, streamlines reporting, and facilitates continuous improvement in manufacturing or service delivery.

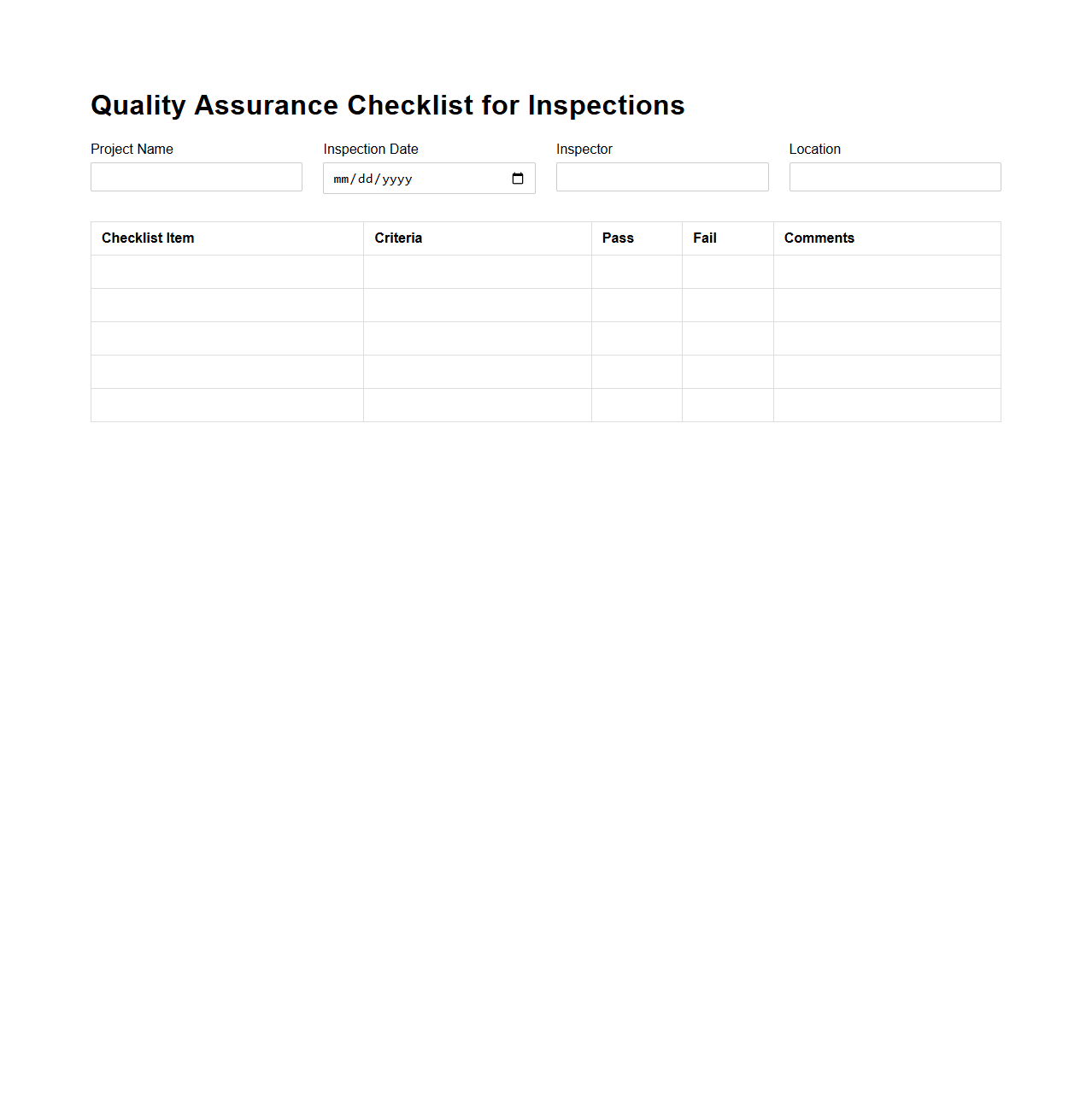

Empty Quality Assurance Checklist for Inspections

An

Empty Quality Assurance Checklist for Inspections document serves as a structured template designed to guide inspectors through the verification process without pre-filled data. It ensures all critical inspection points are consistently evaluated across various projects, enhancing accuracy and compliance with quality standards. This checklist supports systematic identification of defects, adherence to regulatory requirements, and documentation of findings for effective quality control.

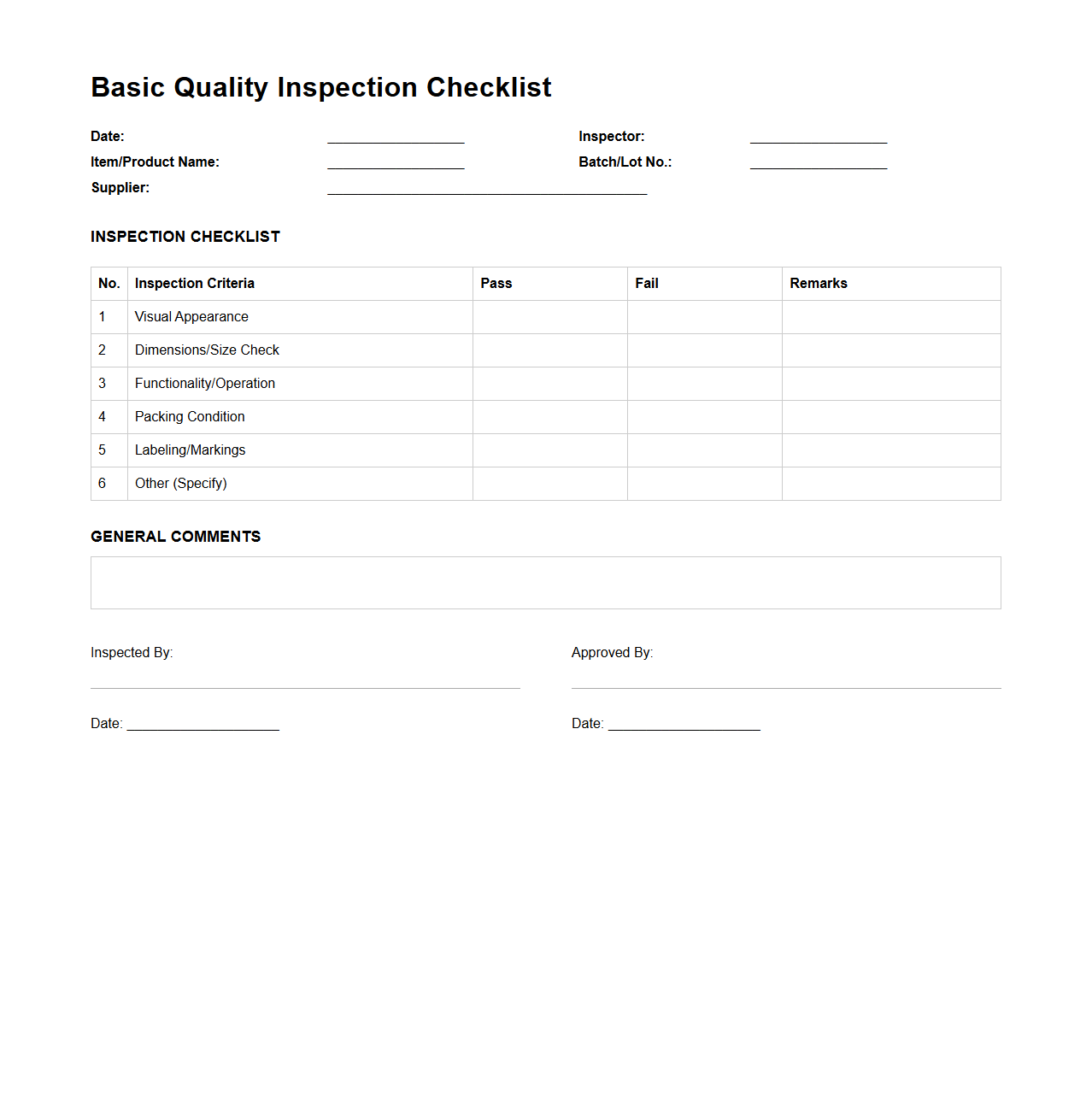

Basic Quality Inspection Checklist Format

A

Basic Quality Inspection Checklist Format document serves as a structured tool designed to ensure consistent evaluation of products or services against predefined quality standards. It systematically lists criteria, inspection points, and verification methods to facilitate thorough and accurate quality assessments. This format helps organizations maintain compliance, identify defects early, and enhance overall product reliability and customer satisfaction.

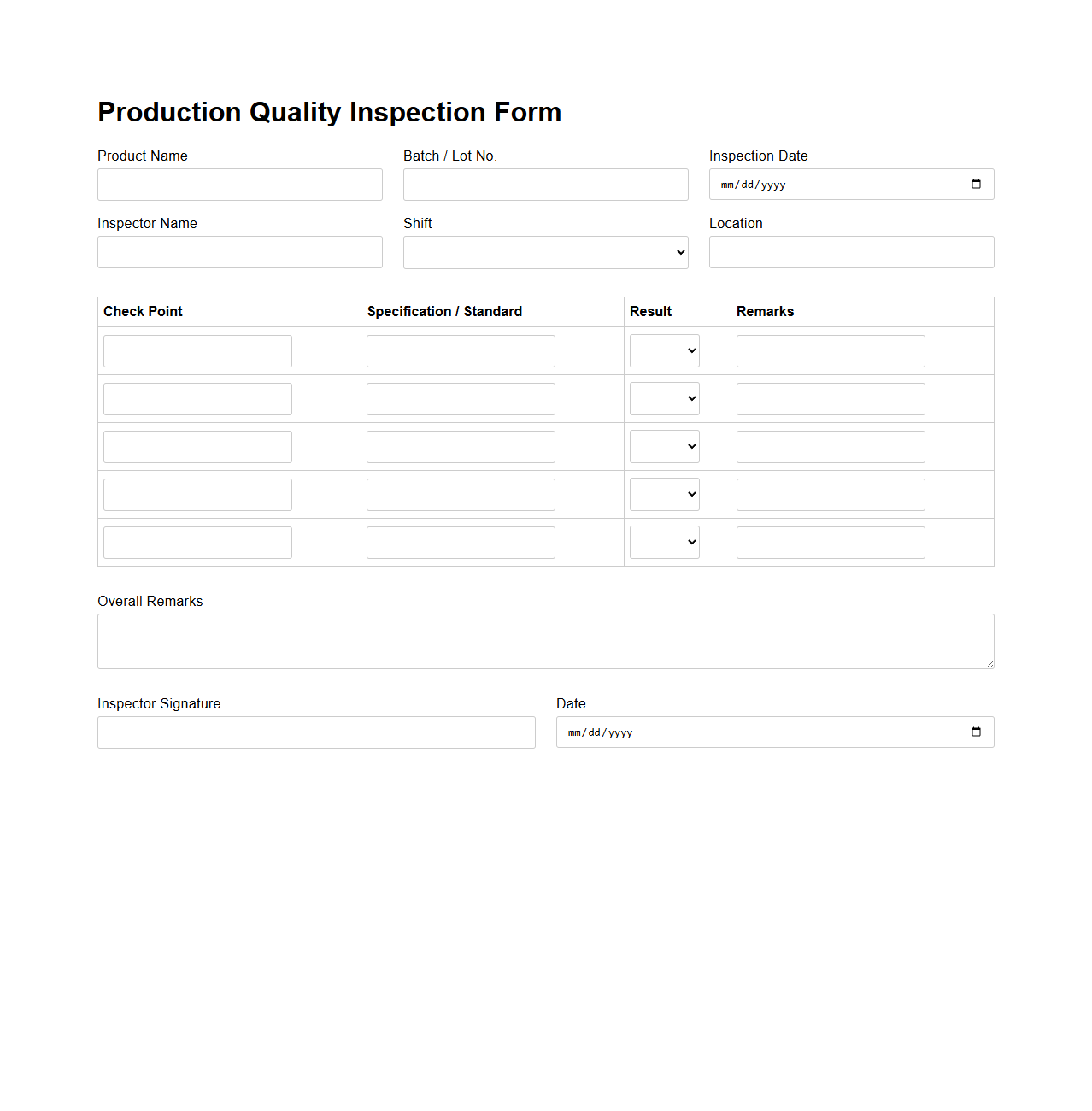

Blank Production Quality Inspection Form

A

Blank Production Quality Inspection Form is a standardized document used to assess and verify the quality of products during the manufacturing process. It typically includes sections for recording product specifications, inspection criteria, defects, and overall compliance with quality standards. This form ensures consistent quality control by providing a clear framework for inspectors to document findings and take corrective actions.

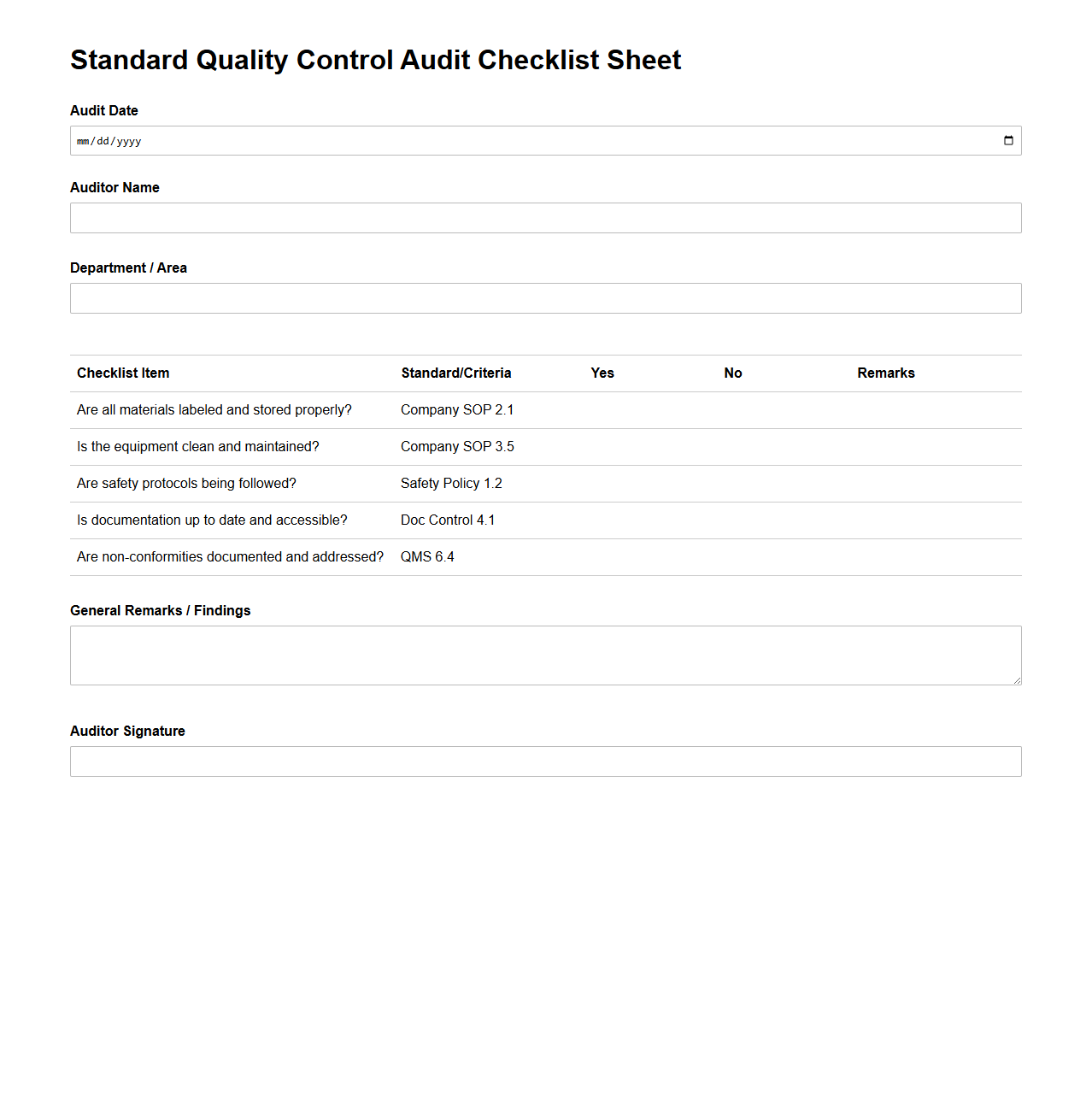

Standard Quality Control Audit Checklist Sheet

A

Standard Quality Control Audit Checklist Sheet document serves as a structured tool for systematically evaluating compliance with established quality standards in processes or products. It outlines specific criteria, procedures, and checkpoints to ensure consistency, accuracy, and adherence to regulatory requirements during internal or external audits. This checklist enhances process reliability, identifies non-conformities, and supports continuous improvement within quality management systems.

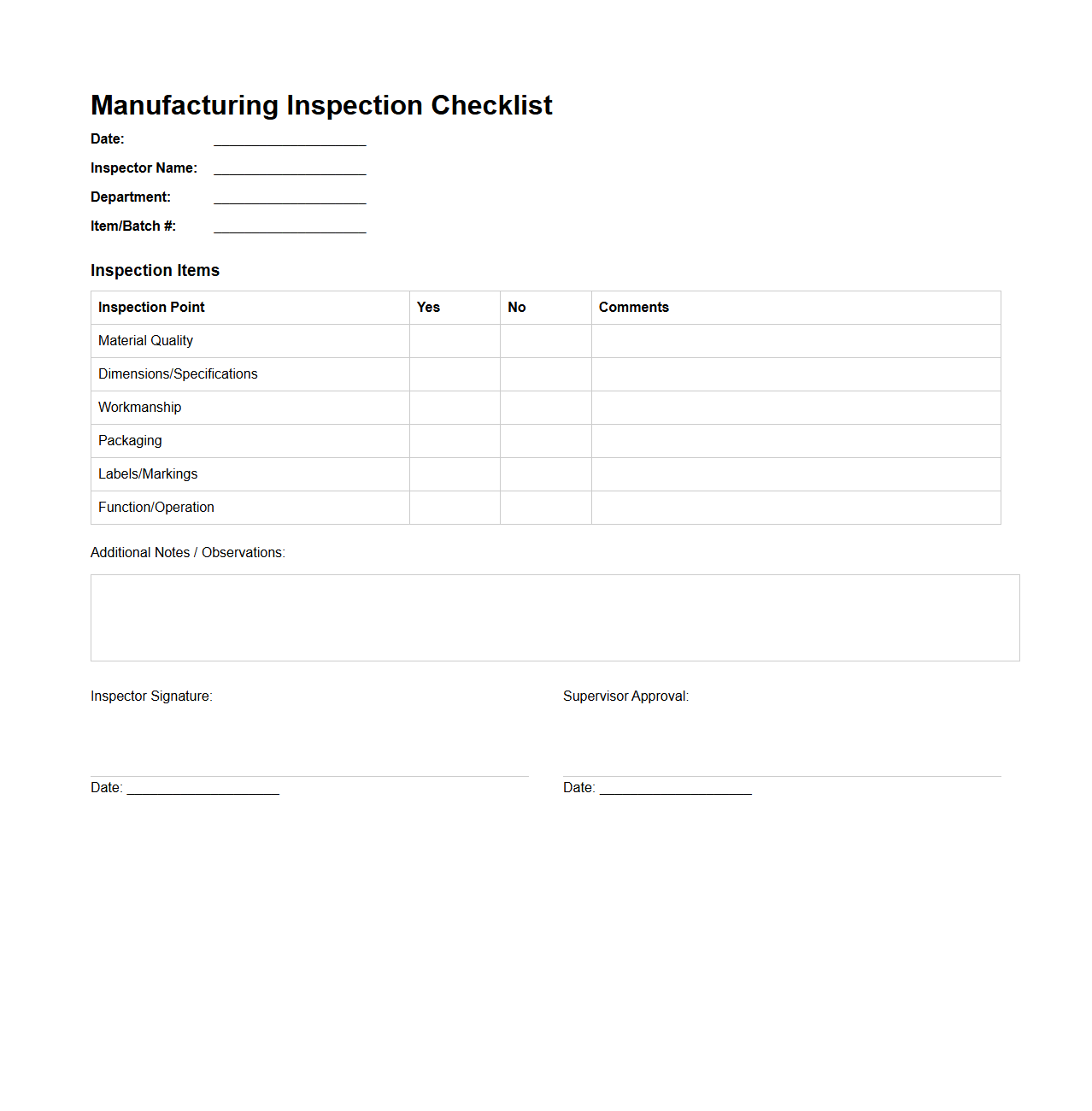

Simple Manufacturing Inspection Checklist Template

A

Simple Manufacturing Inspection Checklist Template document is a structured tool designed to ensure quality control by systematically verifying key production components and processes. It typically includes specific criteria such as equipment condition, material quality, and compliance with safety standards, enabling consistent and efficient inspections. This template helps manufacturers minimize errors, maintain regulatory compliance, and enhance overall product quality.

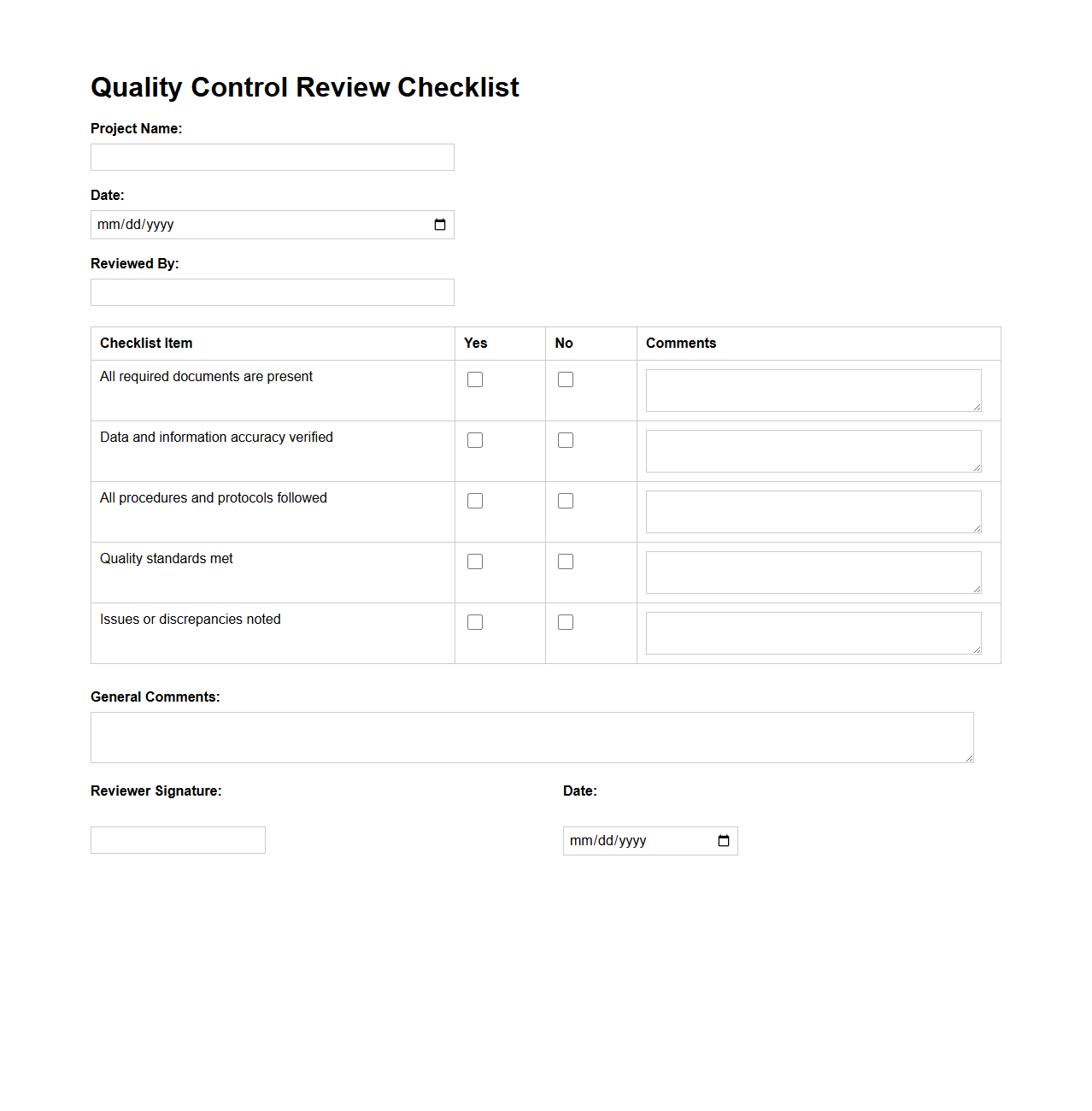

Unfilled Quality Control Review Checklist

The

Unfilled Quality Control Review Checklist document is a structured tool used to systematically identify incomplete or missing quality control steps in a process. It ensures all critical quality criteria are verified and documented before final approval, reducing errors and enhancing compliance with industry standards. This checklist supports continuous improvement by highlighting gaps in quality assurance practices that require attention.

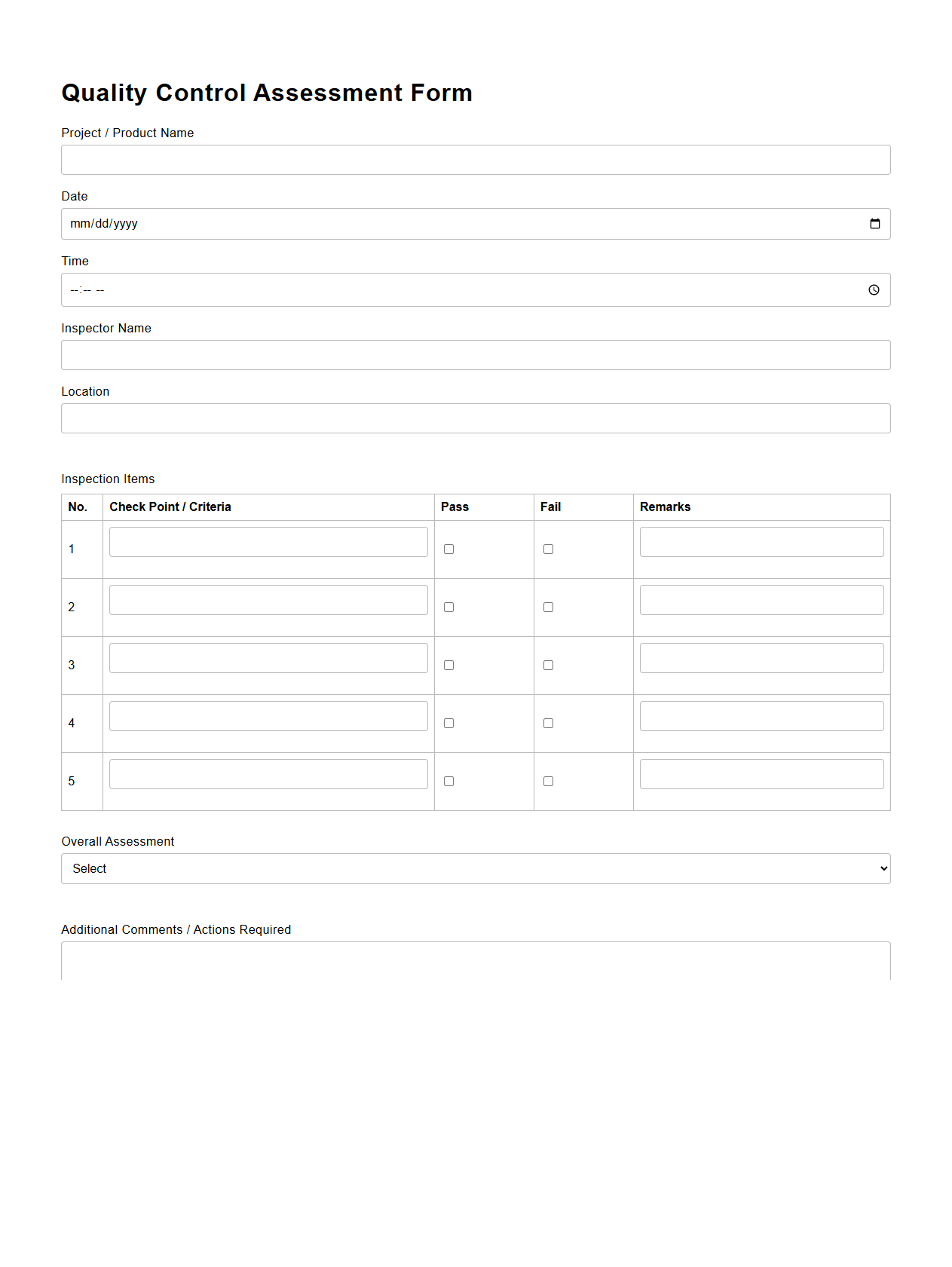

Blank Quality Control Assessment Form

The

Blank Quality Control Assessment Form is a standardized document used to evaluate and ensure the quality of products or services during various stages of production or delivery. It captures critical data points such as inspection criteria, defect identification, compliance checks, and corrective action recommendations. This form helps organizations maintain consistency, meet regulatory standards, and improve overall operational efficiency.

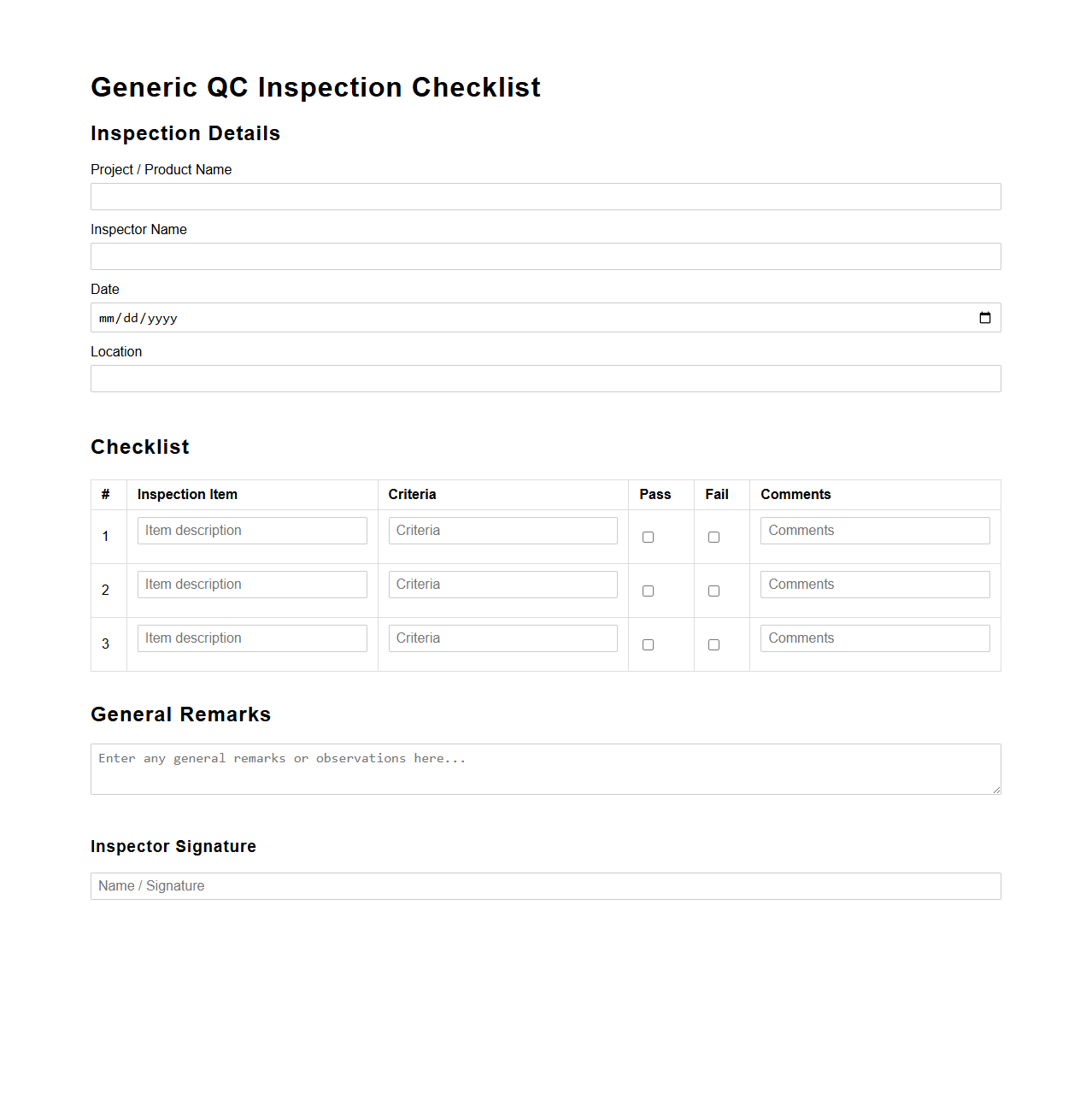

Generic QC Inspection Checklist Layout

The

Generic QC Inspection Checklist Layout document serves as a standardized framework for quality control processes across various industries, ensuring consistent evaluation of products or services. It outlines critical inspection points, criteria, and procedures to systematically identify defects or deviations from standards. This layout enhances operational efficiency by promoting thorough and uniform assessments, thereby supporting compliance and quality assurance goals.

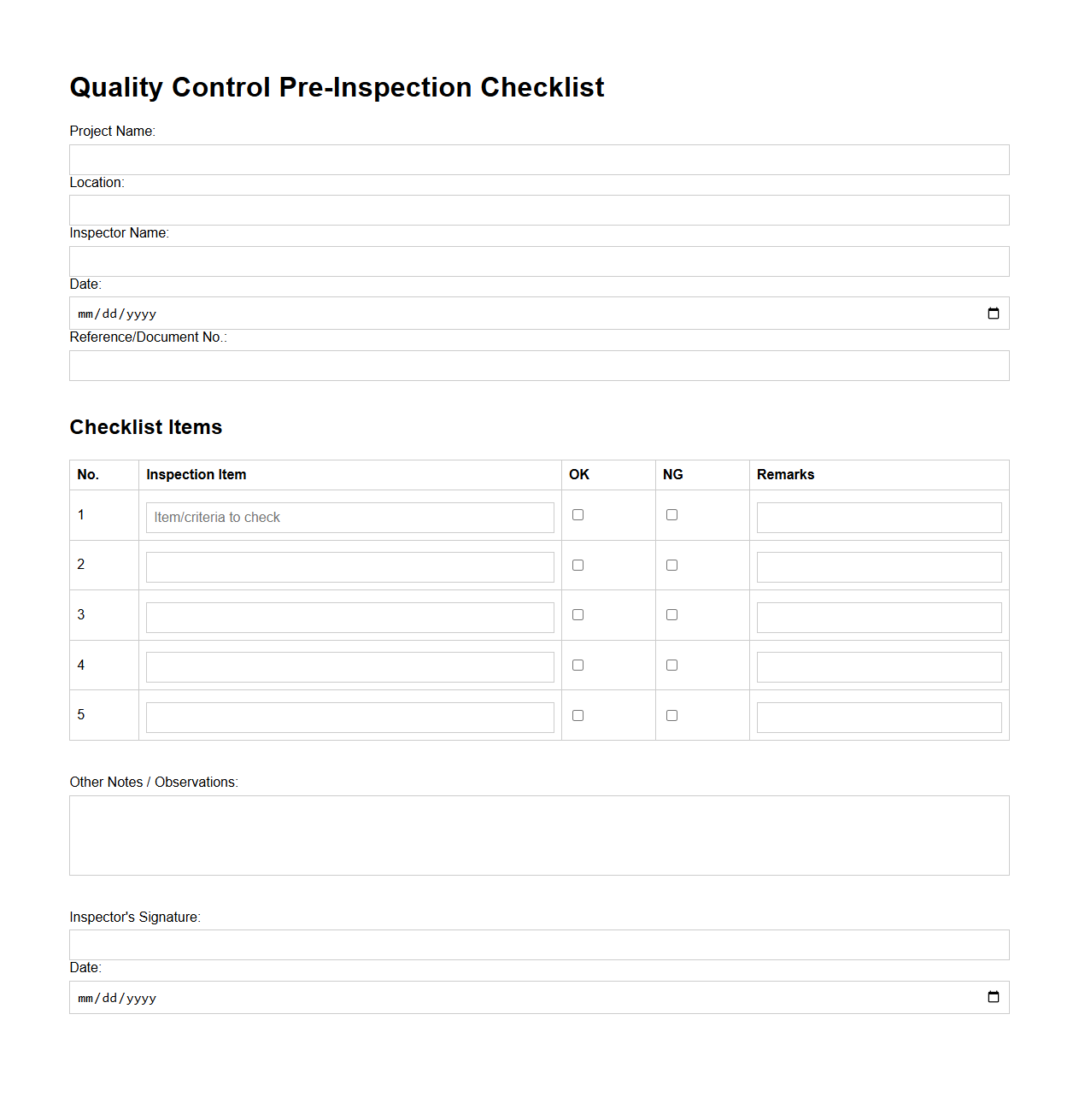

Quality Control Pre-Inspection Blank Checklist

A

Quality Control Pre-Inspection Blank Checklist document serves as a structured tool to ensure all critical inspection criteria are verified before product assessment begins. It outlines specific checkpoints related to materials, dimensions, and compliance standards to identify potential defects early in the production process. This checklist enhances consistency, reduces errors, and supports adherence to industry quality standards.

What are the essential sections to include in a blank inspection checklist for quality control?

An essential blank inspection checklist should include inspection criteria, detailing the specific attributes or characteristics to be checked. Additionally, it must have a section for inspection results to document pass/fail or measurements. Finally, comments or observations allow inspectors to note any abnormalities or issues discovered during the inspection.

How do you customize a blank inspection checklist for different product types?

Customizing a blank inspection checklist involves tailoring the inspection criteria to the unique specifications and standards of each product type. Incorporate product-specific quality standards and potential failure modes relevant to the item being inspected. This customization ensures the checklist addresses critical control points and enhances the accuracy of quality assessments.

What format is recommended for digital vs. paper-based blank inspection checklists?

For digital checklists, a structured, interactive format such as fillable forms or applications is recommended to facilitate easy data entry and storage. Paper-based checklists should be designed with clear, concise fields for manual marking, ensuring legibility and simplicity. Both formats benefit from a logical flow and space for optional comments to capture additional details.

How can a blank inspection checklist ensure traceability and accountability in quality control audits?

A blank inspection checklist ensures traceability by including fields for inspector identification, date, and batch or lot numbers. This information creates an audit trail linking inspections to specific products and personnel. Furthermore, structured documentation promotes accountability by clearly recording results and observations for review and follow-up actions.

Which common quality metrics are pre-listed in a blank inspection checklist template, if any?

Common quality metrics pre-listed in blank inspection templates often include dimensional accuracy, surface defects, and functional performance checks. Additionally, metrics like conformity to specifications, safety compliance, and packaging integrity are frequently integrated. These pre-listed metrics help standardize quality control across various inspection processes.