A Blank Maintenance Checklist Template for Equipment provides a structured format to track routine inspections and repairs, ensuring optimal performance and longevity. This customizable template helps technicians systematically document maintenance tasks, identify potential issues early, and maintain compliance with safety standards. Using a blank template allows for easy adaptation to various types of equipment and maintenance schedules.

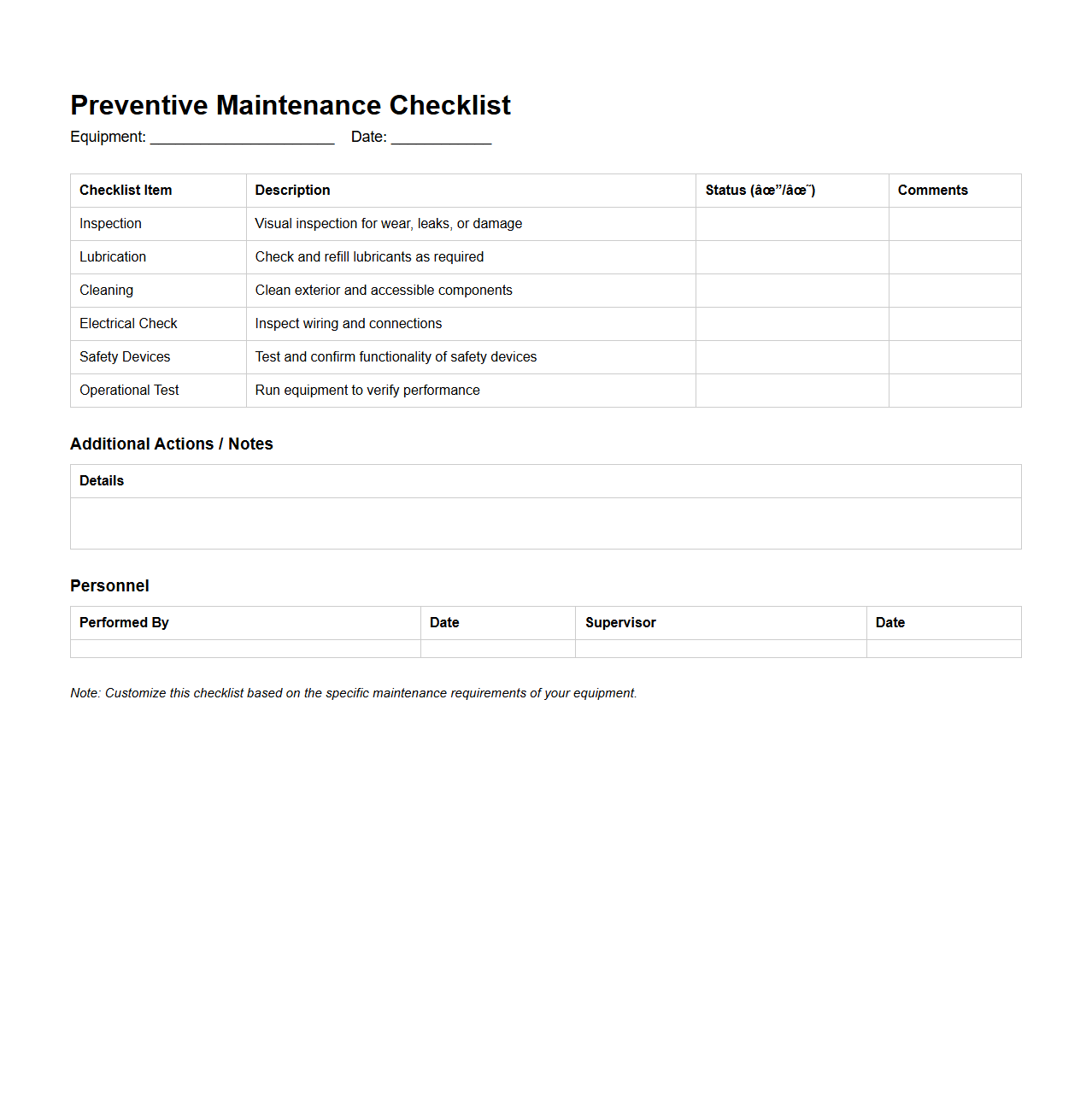

Preventive Maintenance Checklist Template for Equipment

A

Preventive Maintenance Checklist Template for Equipment is a structured document designed to systematically track and schedule routine inspections and servicing tasks for machinery. It ensures consistent evaluation of equipment condition, helps identify potential issues before failures occur, and extends the operational lifespan by maintaining optimal performance. This template typically includes fields for equipment details, maintenance tasks, inspection dates, and responsible personnel, promoting organized and efficient equipment management.

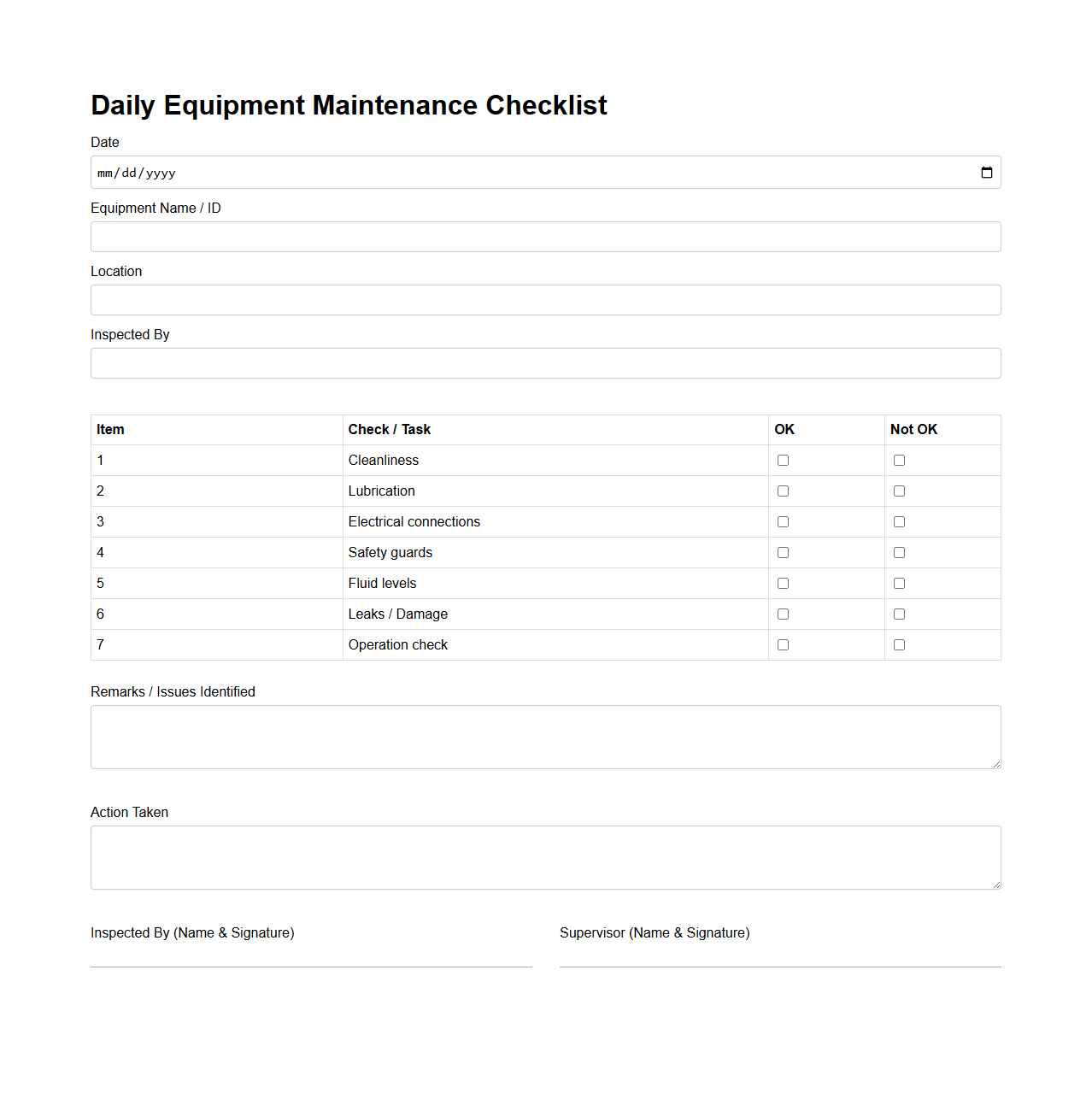

Daily Equipment Maintenance Checklist Form

A

Daily Equipment Maintenance Checklist Form is a structured document used to systematically record routine inspections and maintenance tasks for machinery or equipment. It ensures that all essential components are checked daily to prevent breakdowns and maintain operational efficiency. This form helps in tracking maintenance activities, identifying potential issues early, and promoting workplace safety.

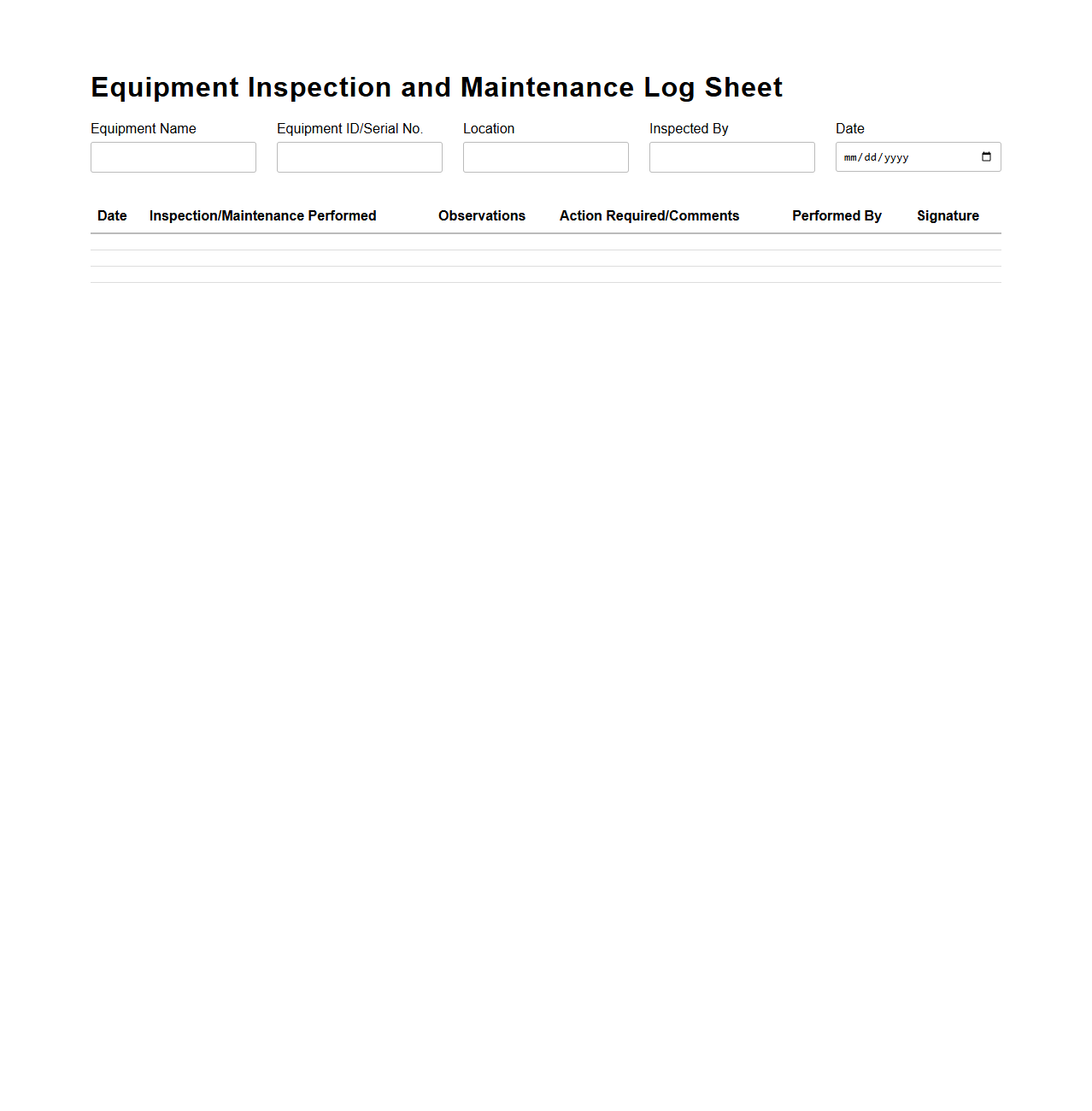

Equipment Inspection and Maintenance Log Sheet

An

Equipment Inspection and Maintenance Log Sheet document is a detailed record used to track the condition, servicing, and repairs of machinery or equipment. It ensures regular inspections are performed, maintenance tasks are documented, and potential issues are identified early to prevent breakdowns. This log sheet enhances operational efficiency, safety compliance, and asset longevity in industrial or commercial settings.

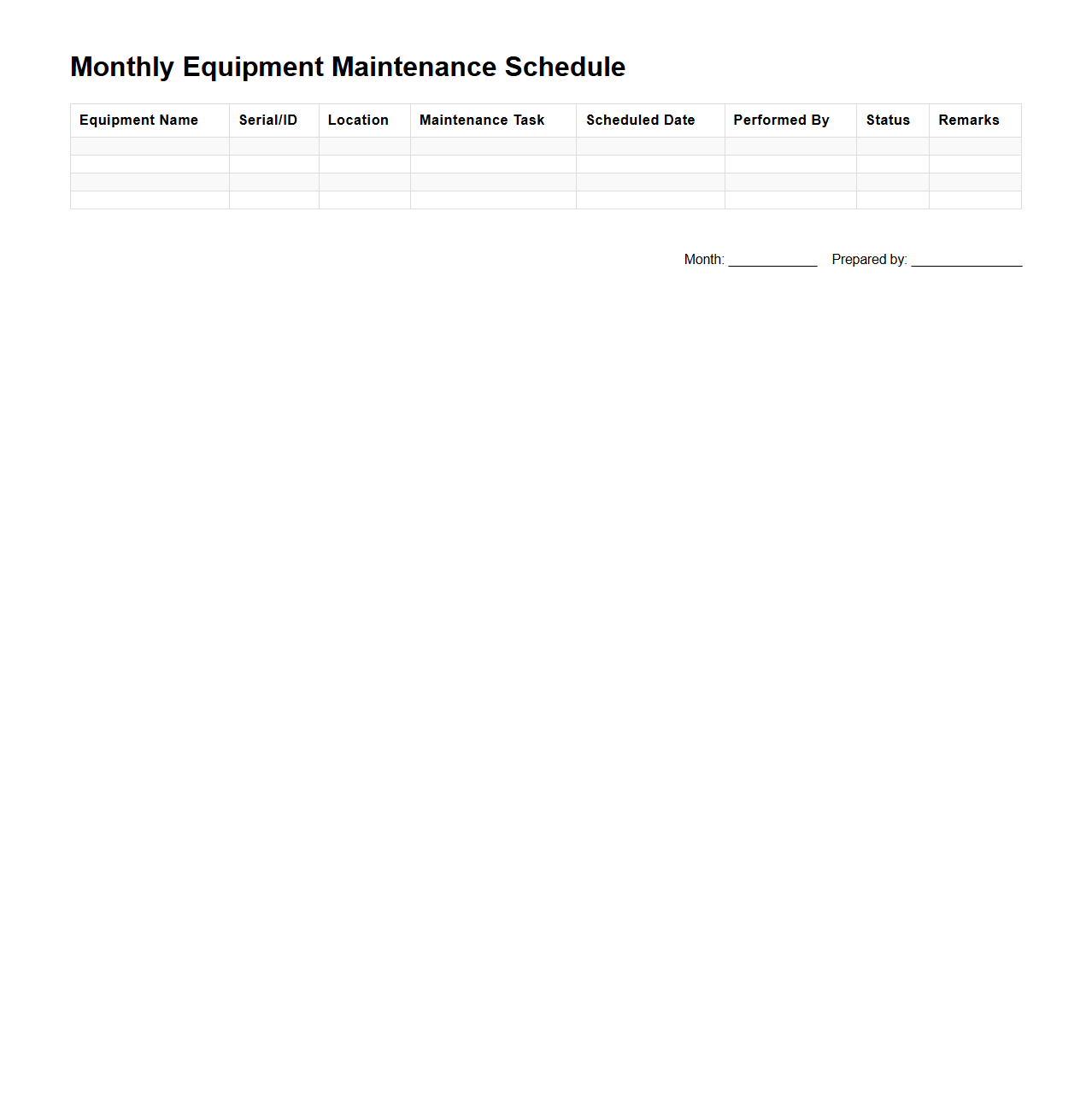

Monthly Equipment Maintenance Schedule Template

The

Monthly Equipment Maintenance Schedule Template document is a structured tool designed to organize and track routine maintenance tasks for machinery and equipment. It helps ensure timely inspections, preventive maintenance, and repairs, reducing equipment downtime and extending asset lifespan. This template typically includes fields for dates, task descriptions, responsible personnel, and status updates, promoting efficient maintenance management.

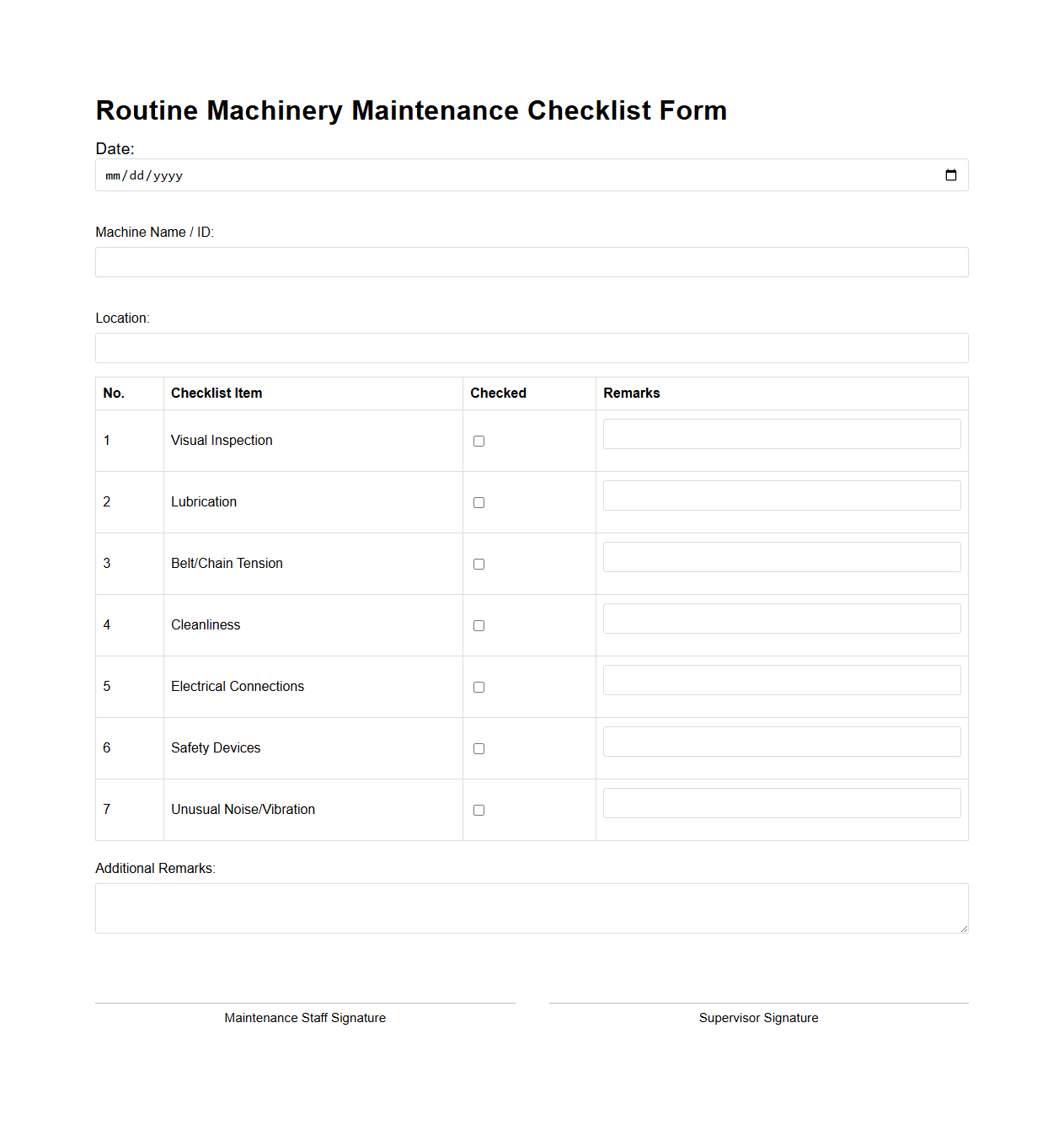

Routine Machinery Maintenance Checklist Form

A

Routine Machinery Maintenance Checklist Form document is a structured tool used to systematically inspect, service, and verify the operational status of machinery. It ensures that key components such as lubricants, belts, and electrical systems are regularly checked to prevent breakdowns and extend equipment lifespan. Maintenance personnel use this form to record findings, schedule repairs, and maintain compliance with safety and operational standards.

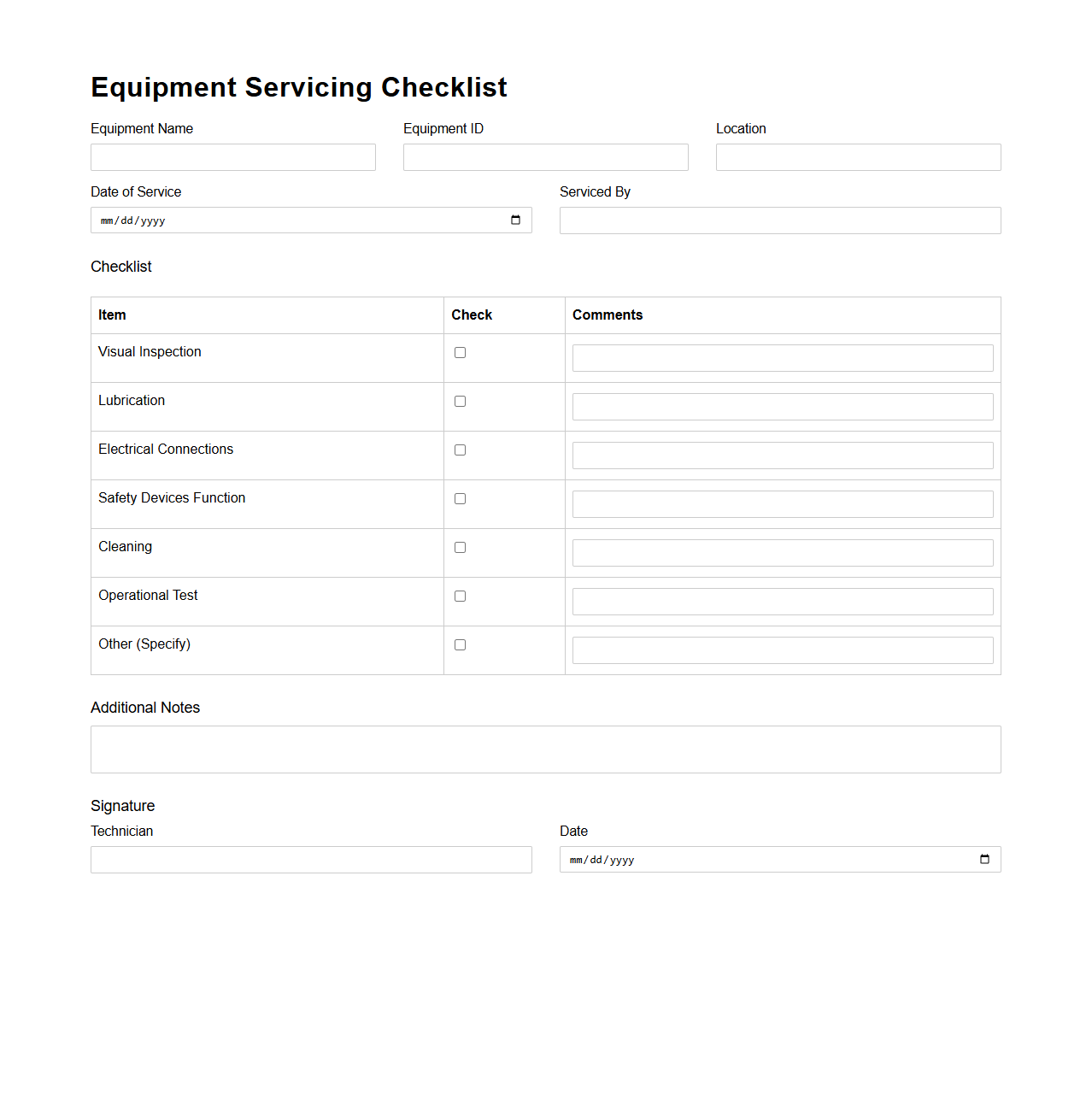

Equipment Servicing Checklist for Industrial Use

An

Equipment Servicing Checklist for industrial use is a structured document designed to ensure systematic inspection, maintenance, and repair of machinery and equipment in manufacturing or production facilities. This checklist helps technicians verify that all critical components, such as motors, sensors, and safety guards, are functioning correctly and meet industry standards. Using this document reduces downtime, enhances equipment reliability, and promotes workplace safety by preventing unexpected failures.

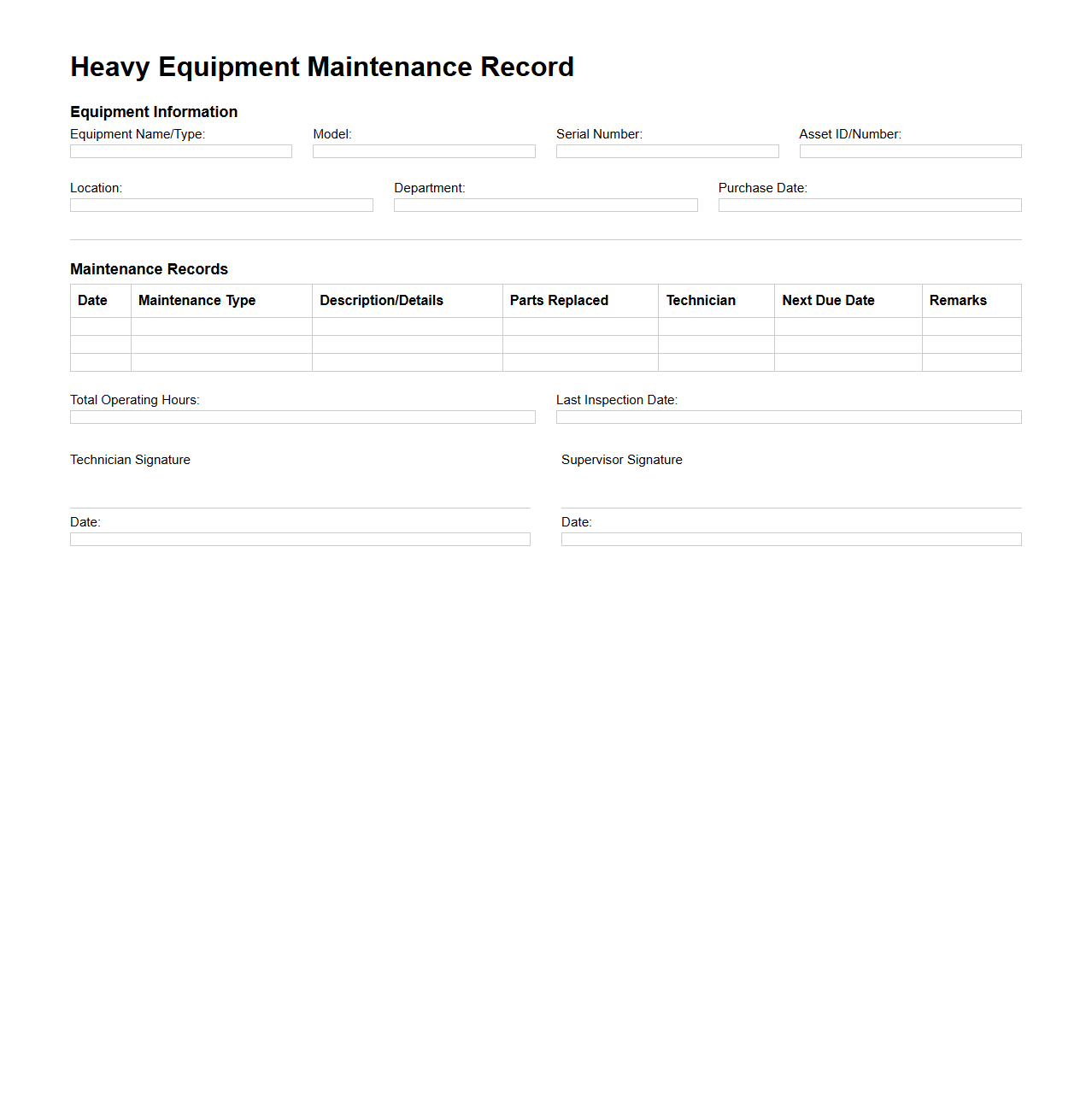

Heavy Equipment Maintenance Record Template

A

Heavy Equipment Maintenance Record Template document is a structured form designed to log detailed information about the servicing and repairs of construction and industrial machinery. It helps track maintenance schedules, equipment condition, parts replaced, and technician notes to ensure operational efficiency and extend equipment lifespan. Regular use of this template supports compliance with safety regulations and reduces unexpected breakdowns, optimizing asset management.

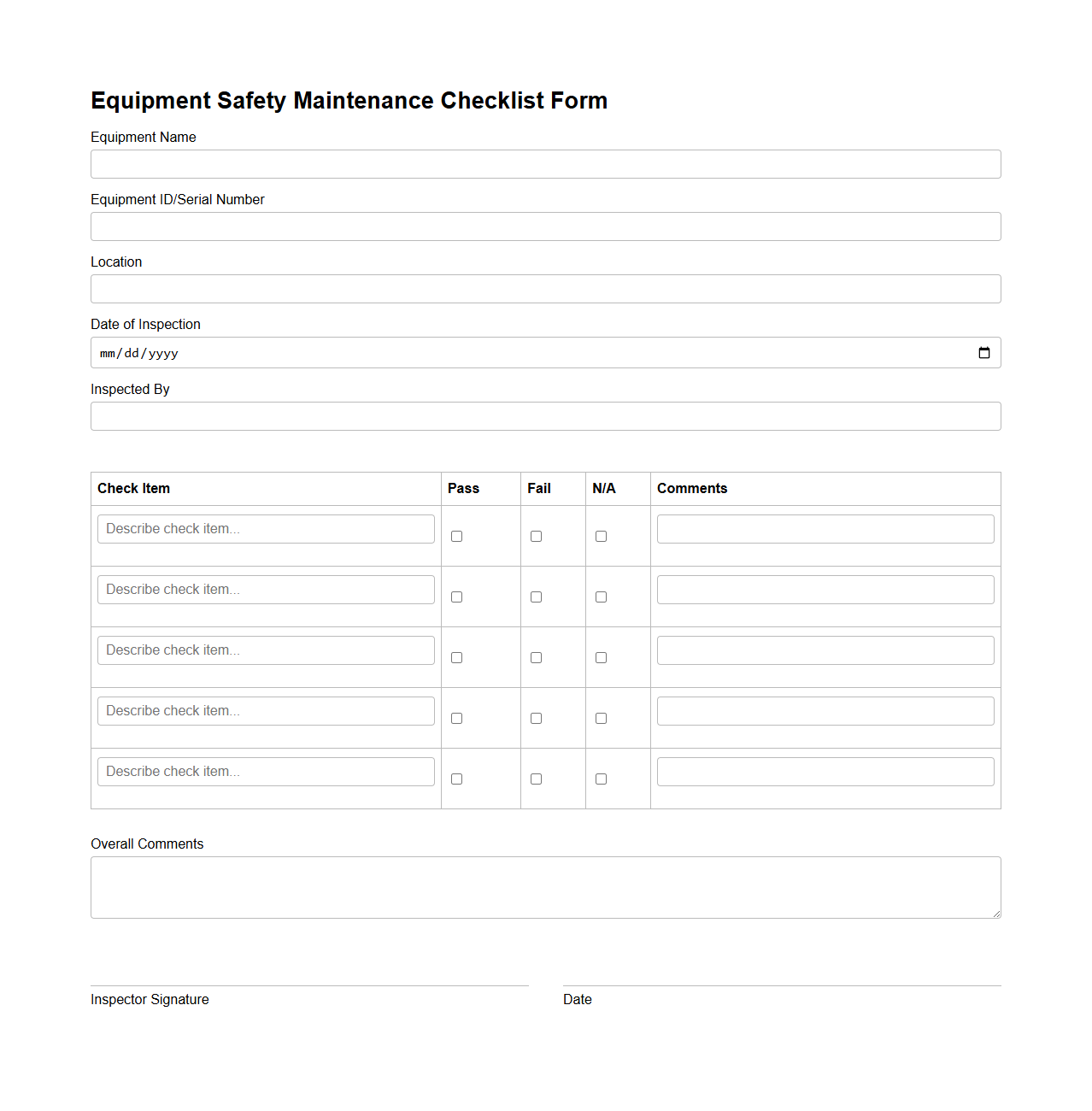

Equipment Safety Maintenance Checklist Form

An

Equipment Safety Maintenance Checklist Form is a critical document used to systematically record and verify the condition and functionality of machinery or equipment. It ensures that all essential safety checks, routine maintenance tasks, and operational standards are consistently met to prevent accidents, downtime, and costly repairs. This form supports compliance with workplace safety regulations and promotes a proactive approach to equipment management.

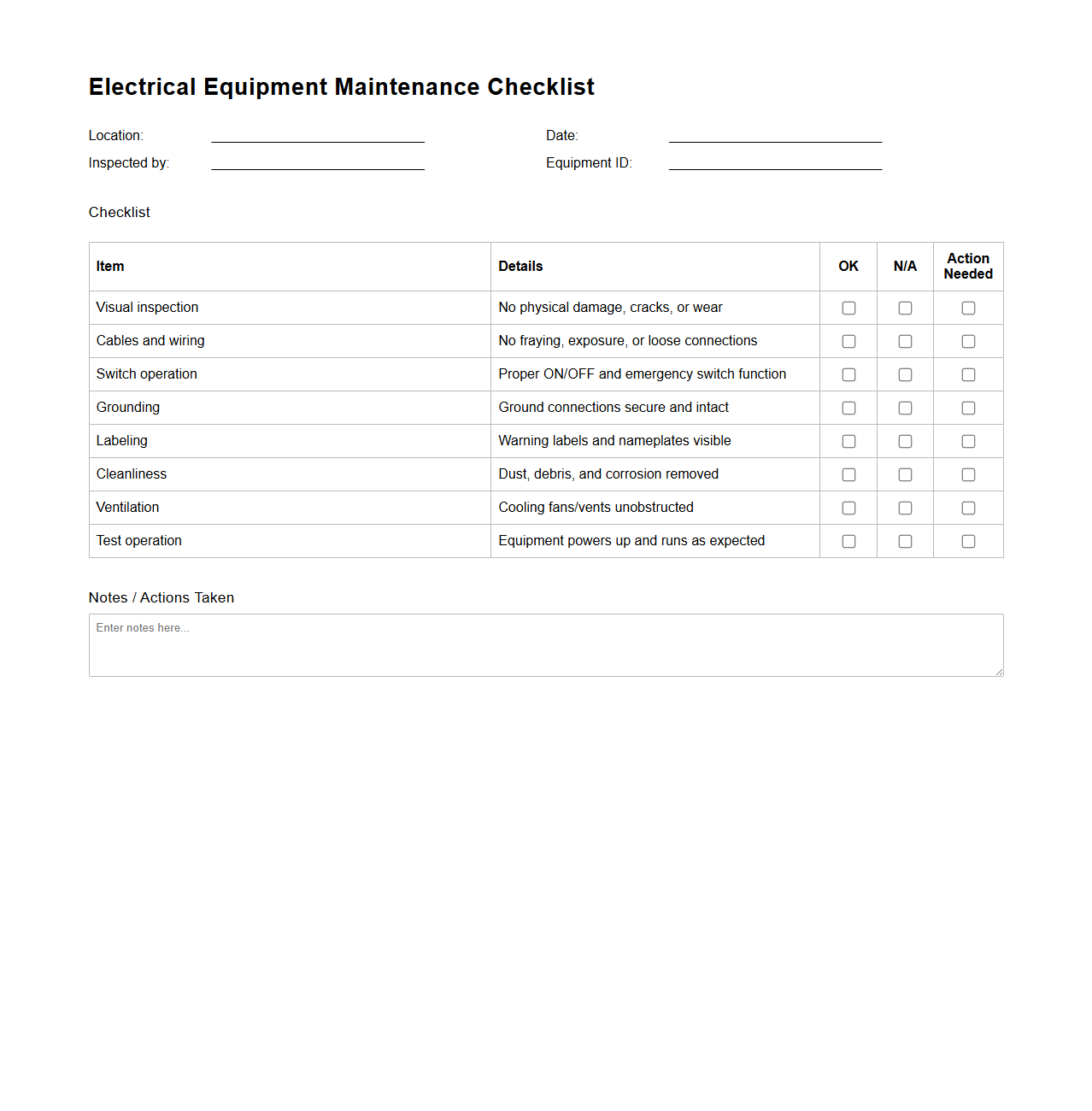

Electrical Equipment Maintenance Checklist Template

An

Electrical Equipment Maintenance Checklist Template document is a structured tool designed to systematically track and verify routine inspections, servicing, and repairs of electrical systems and devices. It ensures compliance with safety standards, enhances operational efficiency, and minimizes downtime by providing clear maintenance tasks, dates, and responsible personnel. This template is essential for managing preventive maintenance schedules and documenting the condition and performance of electrical equipment.

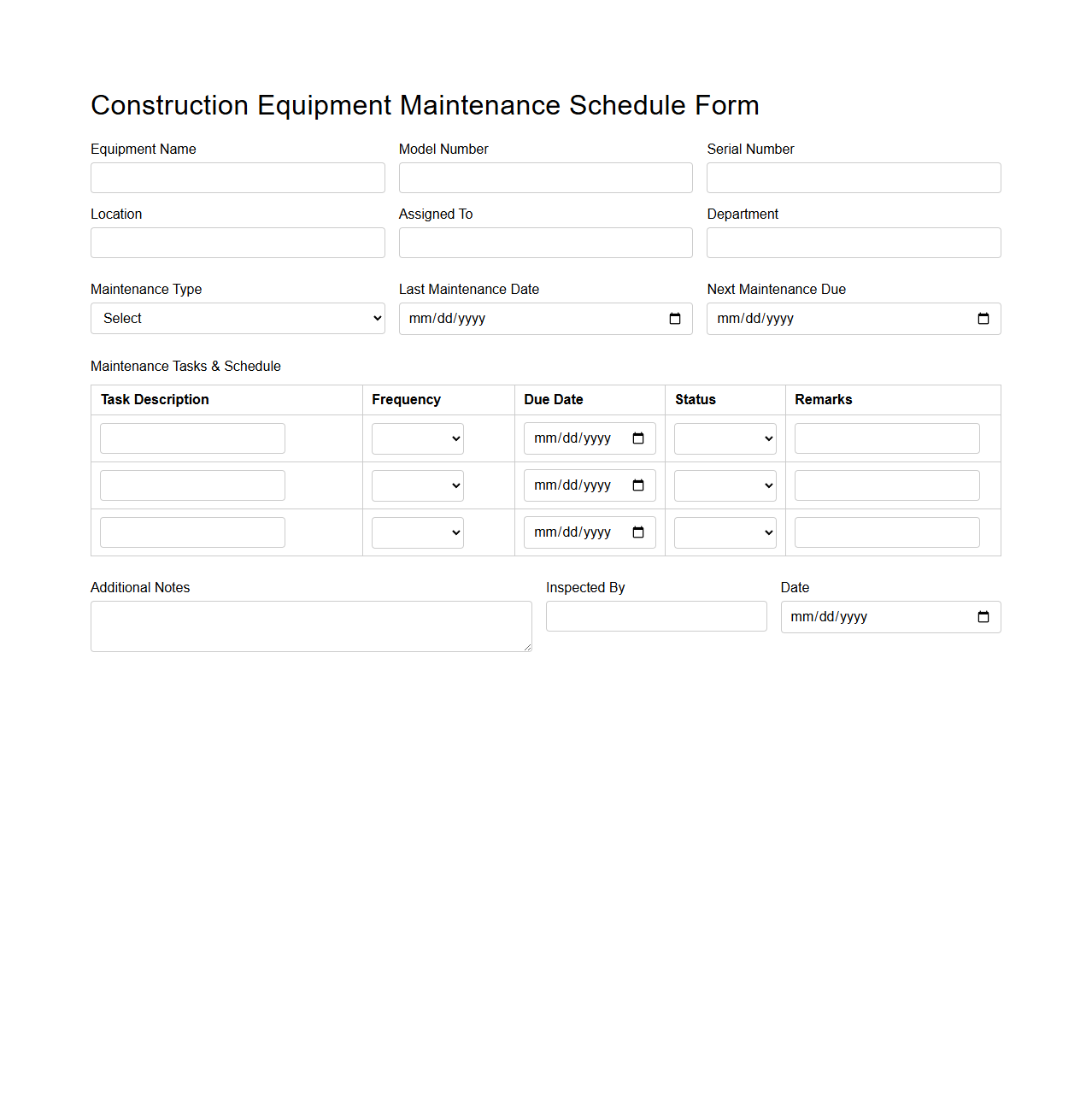

Construction Equipment Maintenance Schedule Form

A

Construction Equipment Maintenance Schedule Form is a document used to systematically track and plan routine maintenance tasks for machinery and equipment on construction sites. It details specific inspection dates, types of maintenance activities, and records of completed services to ensure optimal equipment performance and longevity. Regular use of this form helps prevent unexpected breakdowns, reduces repair costs, and maintains safety standards.

What are the essential fields to include in an equipment maintenance checklist template?

An equipment maintenance checklist should include fields such as equipment identification, date of maintenance, and technician's name. It must also detail specific tasks to be completed, with checkboxes for verification. Recording observations and actions taken is crucial for thorough maintenance documentation.

How often should a blank maintenance checklist for specific equipment be updated?

A blank maintenance checklist should be reviewed and updated at least annually or whenever equipment specifications change. Regular updates ensure alignment with the latest operational standards and safety protocols. This practice helps maintain accuracy and effectiveness in maintenance routines.

Which compliance standards should a blank equipment maintenance checklist meet?

The checklist must comply with industry-specific regulations such as OSHA, ISO, or ANSI standards depending on the equipment type. Ensuring regulatory compliance reduces the risk of legal penalties and enhances operational safety. Regular audits help confirm that the checklist adheres to applicable standards.

How can digital tools enhance a blank equipment maintenance checklist?

Digital tools can automate tracking, reminders, and reporting, increasing efficiency in maintenance processes. They enable real-time updates and easy access to historical data, improving transparency and accountability. Integration with mobile devices allows technicians to complete checklists on-site, saving time and reducing errors.

What are common errors found in draft maintenance checklist documents?

Common errors include missing critical fields, unclear instructions, and lack of space for notes or observations. Incomplete or inconsistent task descriptions can lead to improper maintenance activities. Failure to update checklists regularly also contributes to outdated and ineffective maintenance procedures.