A Blank Production Order Template for Manufacturing helps streamline the planning and execution of production processes by providing a structured format to record details like materials, quantities, and timelines. This template enhances efficiency, ensures consistency across manufacturing orders, and facilitates clear communication among teams. Using a standardized template reduces errors and improves tracking of production progress.

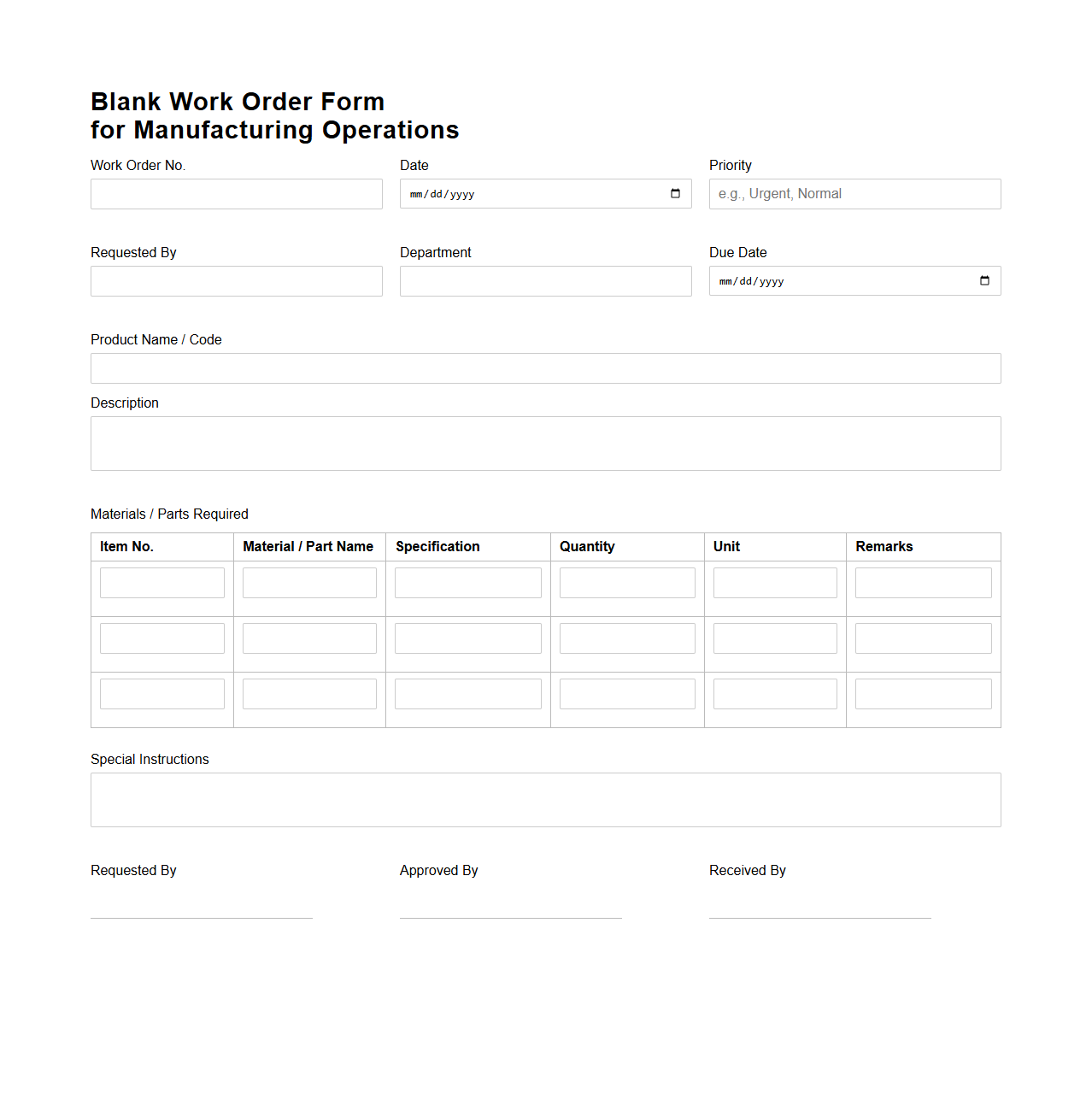

Blank Work Order Form for Manufacturing Operations

A

Blank Work Order Form for manufacturing operations is a standardized template used to initiate, track, and manage production tasks within a manufacturing facility. This document captures essential details such as job descriptions, materials required, labor allocation, and timelines, ensuring efficient workflow and resource utilization. It serves as a critical tool for improving production accuracy, accountability, and operational efficiency.

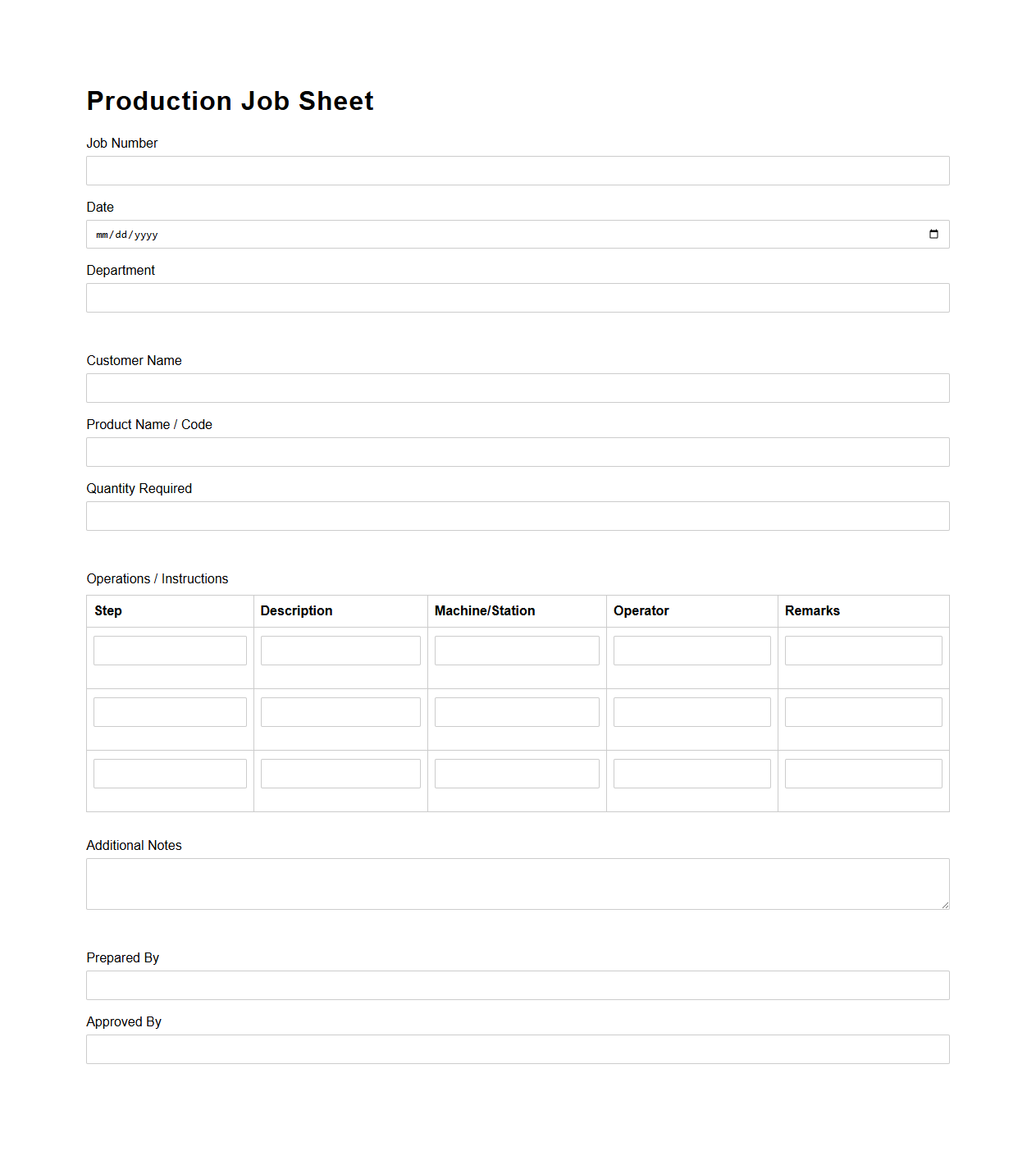

Simple Production Job Sheet for Factory Use

A

Simple Production Job Sheet for factory use is a streamlined document that outlines the essential details of a specific manufacturing task, including materials, labor requirements, machine settings, and production steps. This job sheet serves as a practical guide for factory workers to ensure consistent product quality and efficient workflow. It helps in tracking job progress, managing resources, and improving communication between production teams.

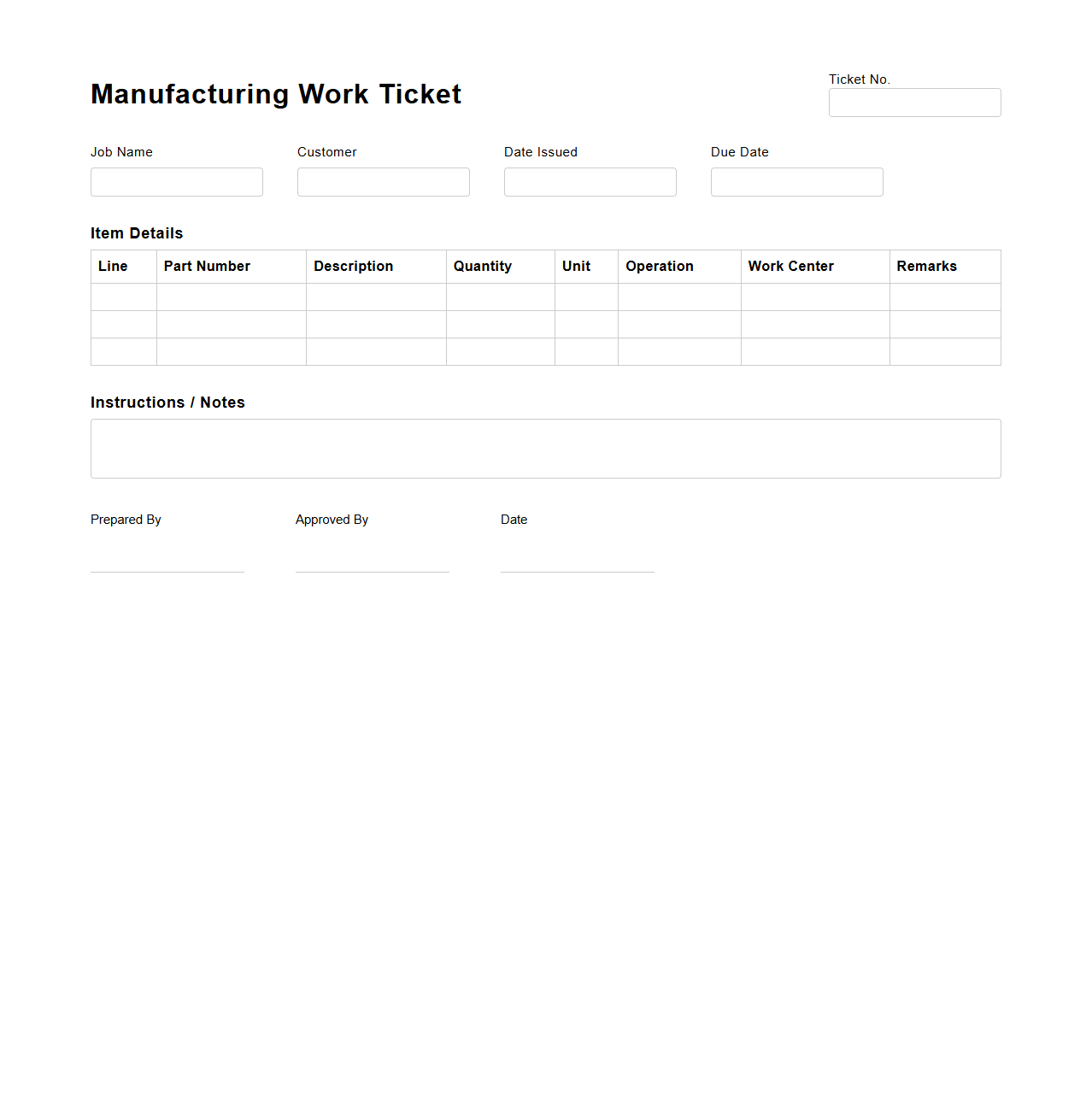

Empty Manufacturing Work Ticket Template

An

Empty Manufacturing Work Ticket Template document serves as a structured form used to record detailed information about production tasks, including job instructions, materials used, labor hours, and equipment involved. It helps streamline workflow management, ensuring accuracy and consistency in tracking manufacturing processes. This template enhances operational efficiency by standardizing data entry and facilitating communication between production teams and supervisors.

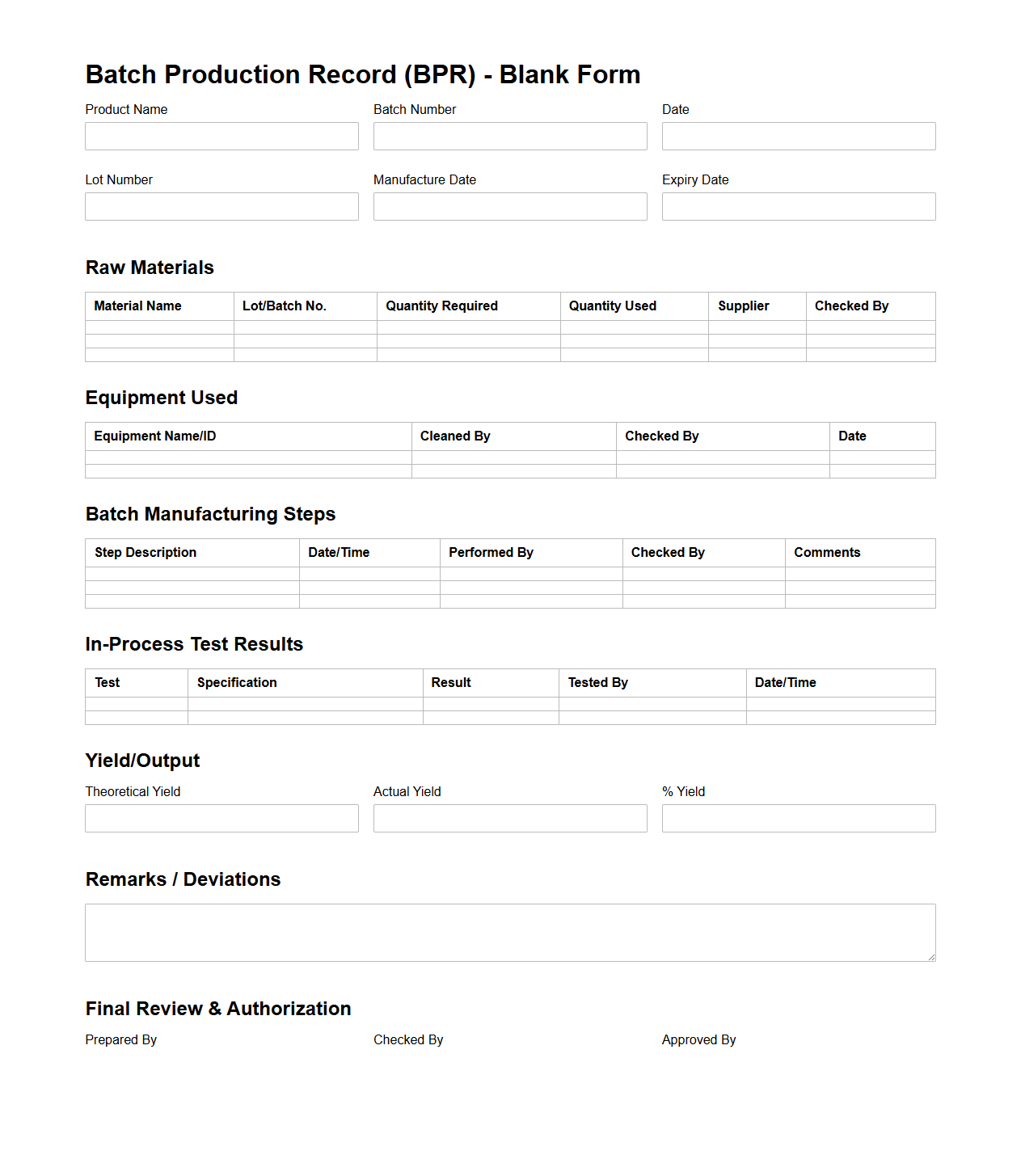

Blank Batch Production Record Form

The

Blank Batch Production Record Form document serves as a standardized template used in manufacturing to capture detailed information about each production batch. It includes critical data such as raw materials, process parameters, equipment used, and quality control checks, ensuring compliance with industry regulations. This form plays a crucial role in traceability, accountability, and maintaining consistent product quality throughout the production cycle.

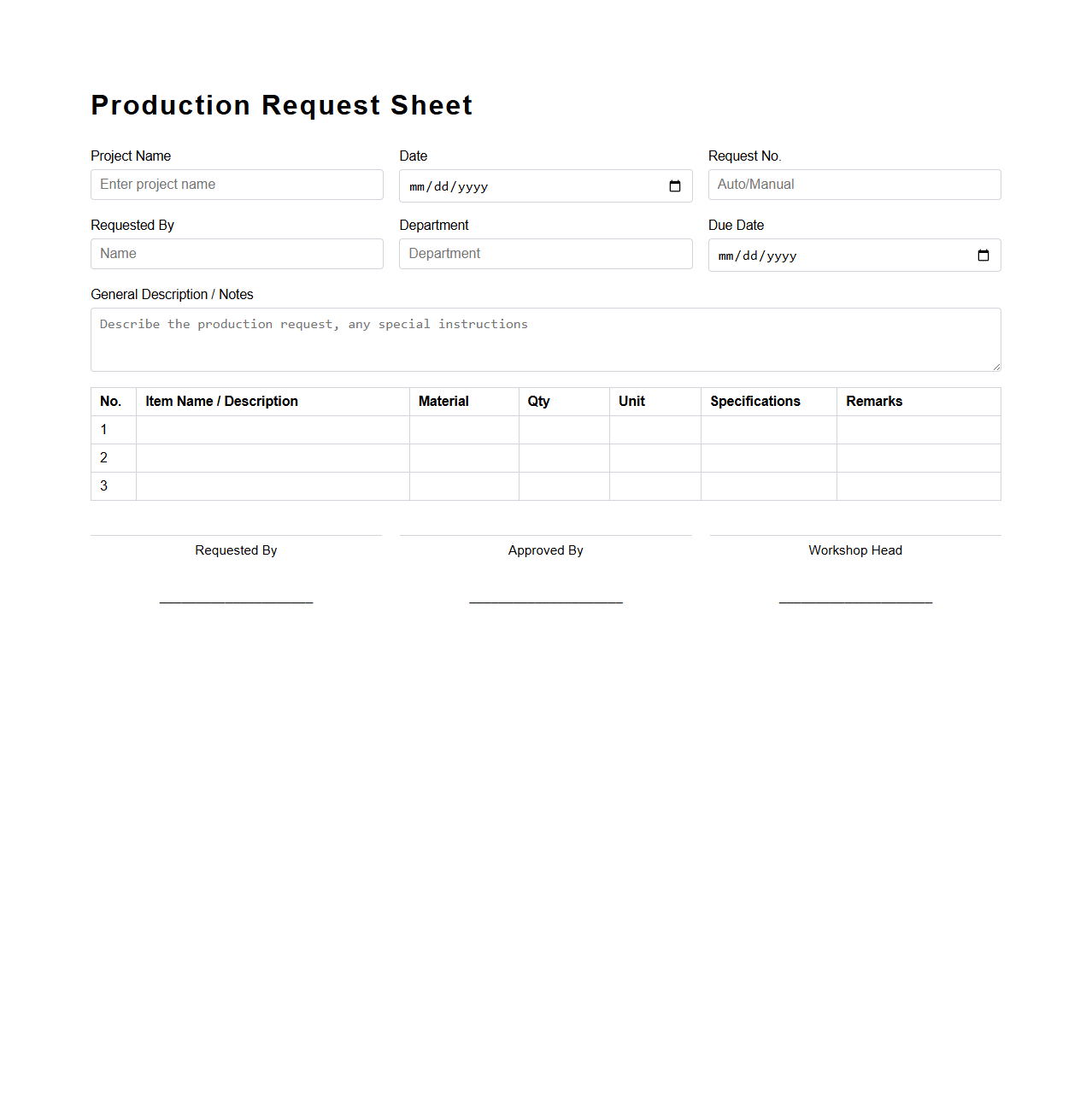

Customizable Production Request Sheet for Workshop

A

Customizable Production Request Sheet for a workshop is a tailored document designed to streamline the submission and tracking of production orders. It allows workshop managers and workers to specify detailed requirements such as materials, dimensions, quantities, and deadlines, ensuring clarity and precision in manufacturing processes. This sheet enhances operational efficiency by reducing errors and facilitating communication between departments.

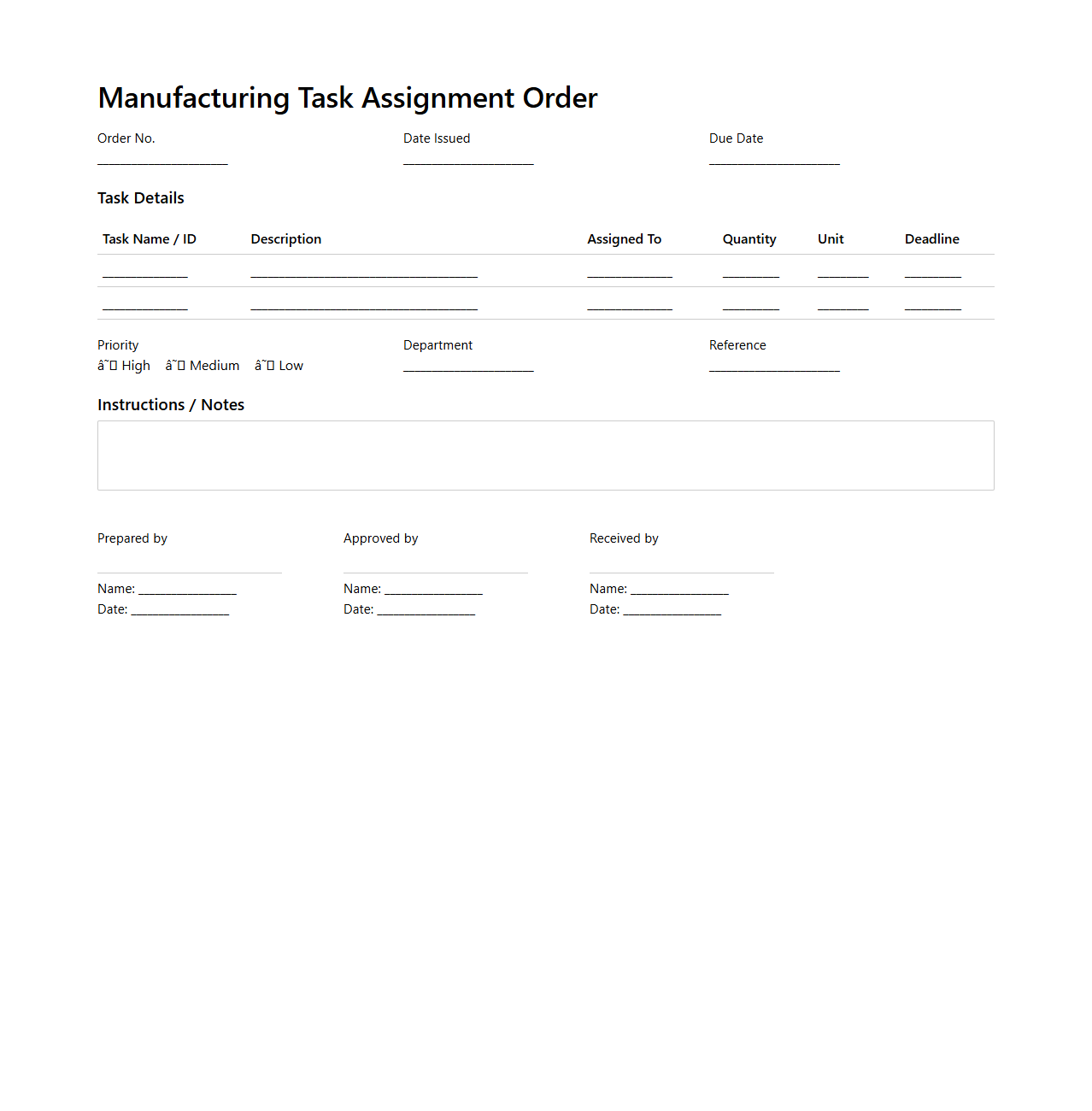

Manufacturing Task Assignment Order Document

A

Manufacturing Task Assignment Order Document is an essential record that outlines specific production tasks allocated to various teams or individuals within a manufacturing process. It details job assignments, deadlines, resource requirements, and expected outcomes to ensure efficient workflow and accountability. This document serves as a critical tool for coordinating operations, tracking progress, and maintaining quality standards in manufacturing environments.

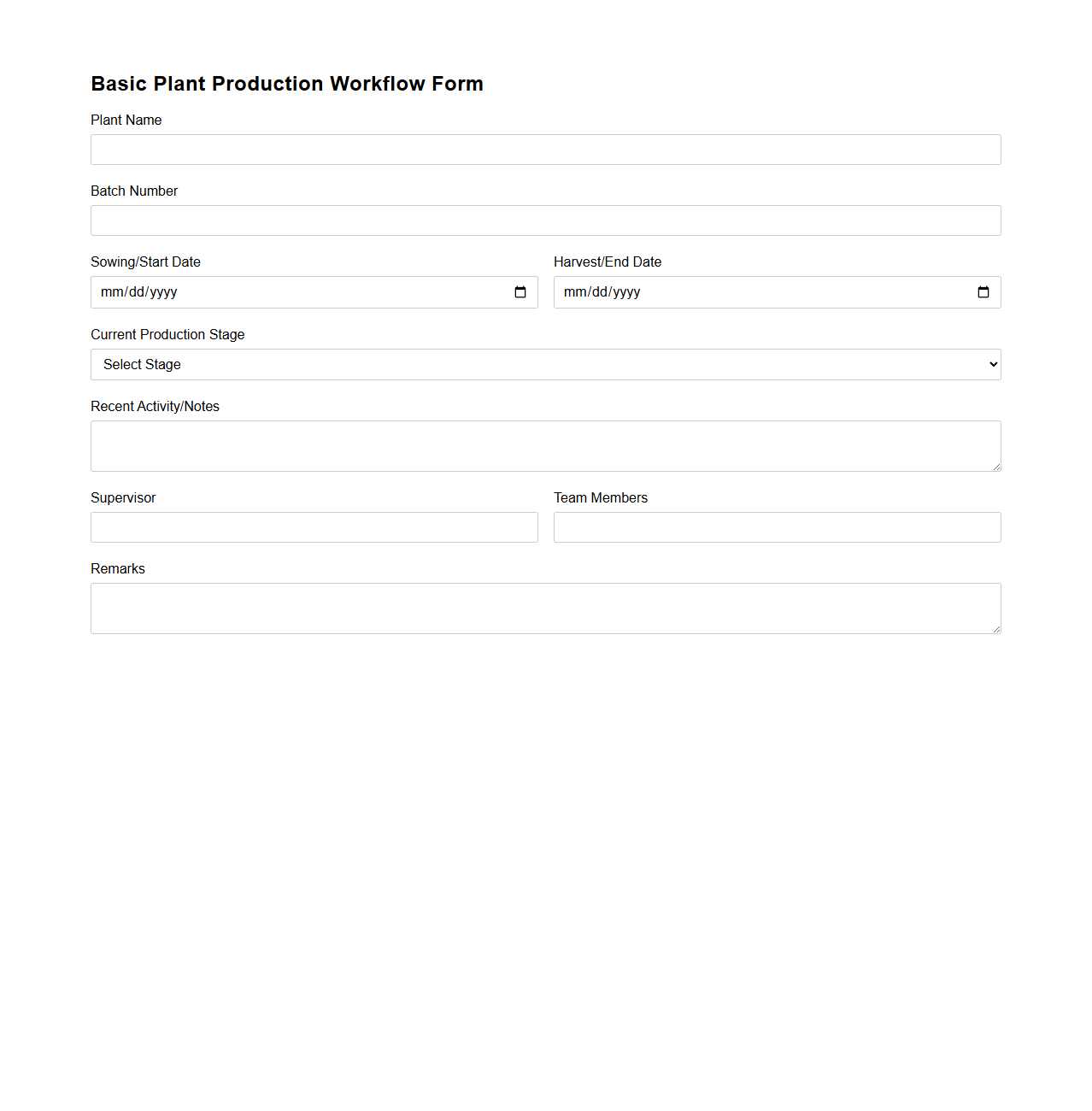

Basic Plant Production Workflow Form

The

Basic Plant Production Workflow Form document outlines the step-by-step procedures involved in the cultivation and management of plants from seedling to harvest. It typically includes sections for tracking planting dates, irrigation schedules, fertilization plans, pest control measures, and harvesting timelines to ensure optimal plant growth and yield. This form serves as a vital tool for farmers and agronomists to monitor and optimize production efficiency and crop quality.

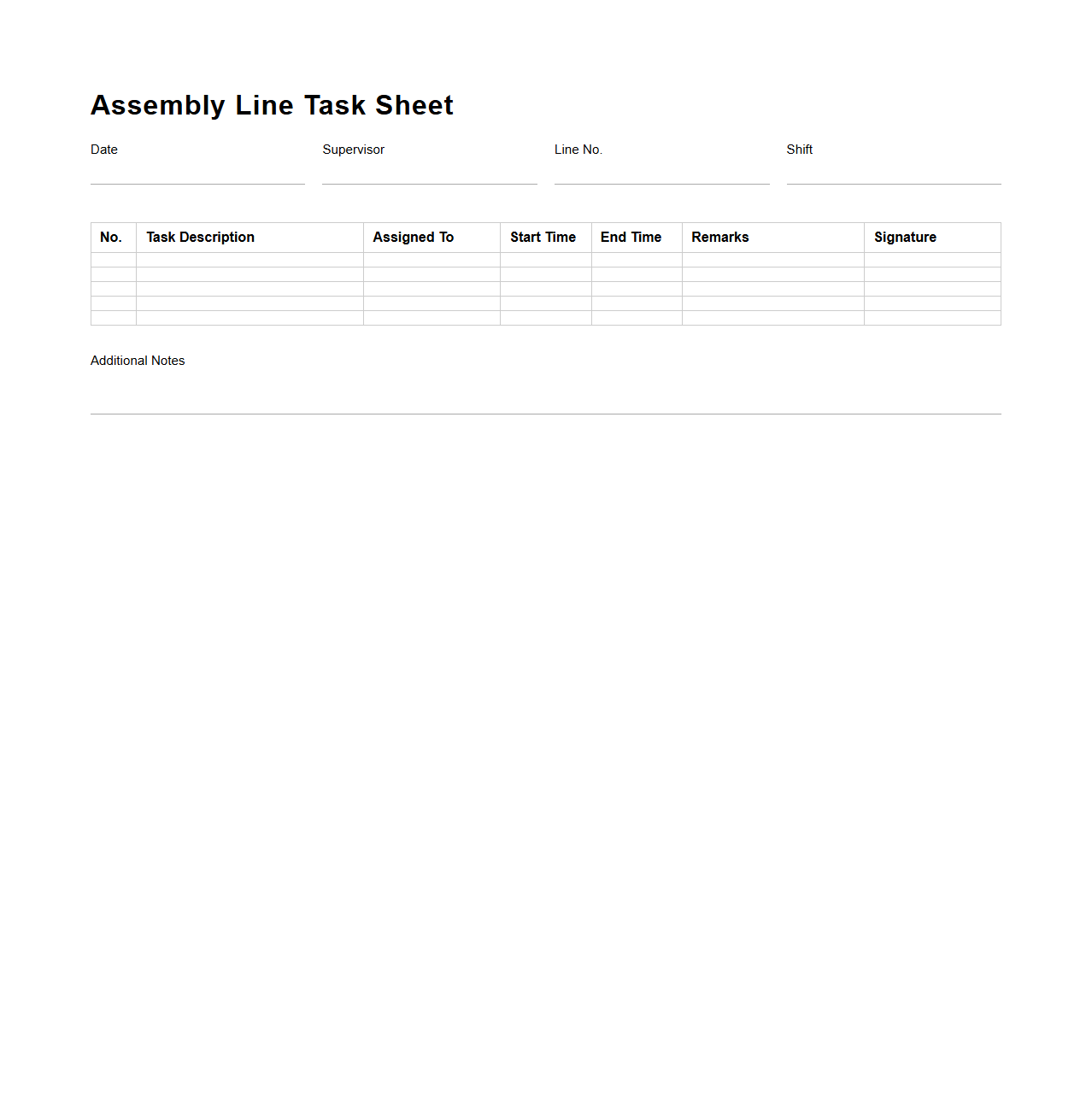

Blank Assembly Line Task Sheet

A

Blank Assembly Line Task Sheet is a standardized document used to outline specific tasks and responsibilities on an assembly line. It helps workers follow a clear sequence of operations, ensuring consistency and efficiency during production. This sheet can be customized to fit various manufacturing processes and improve overall workflow management.

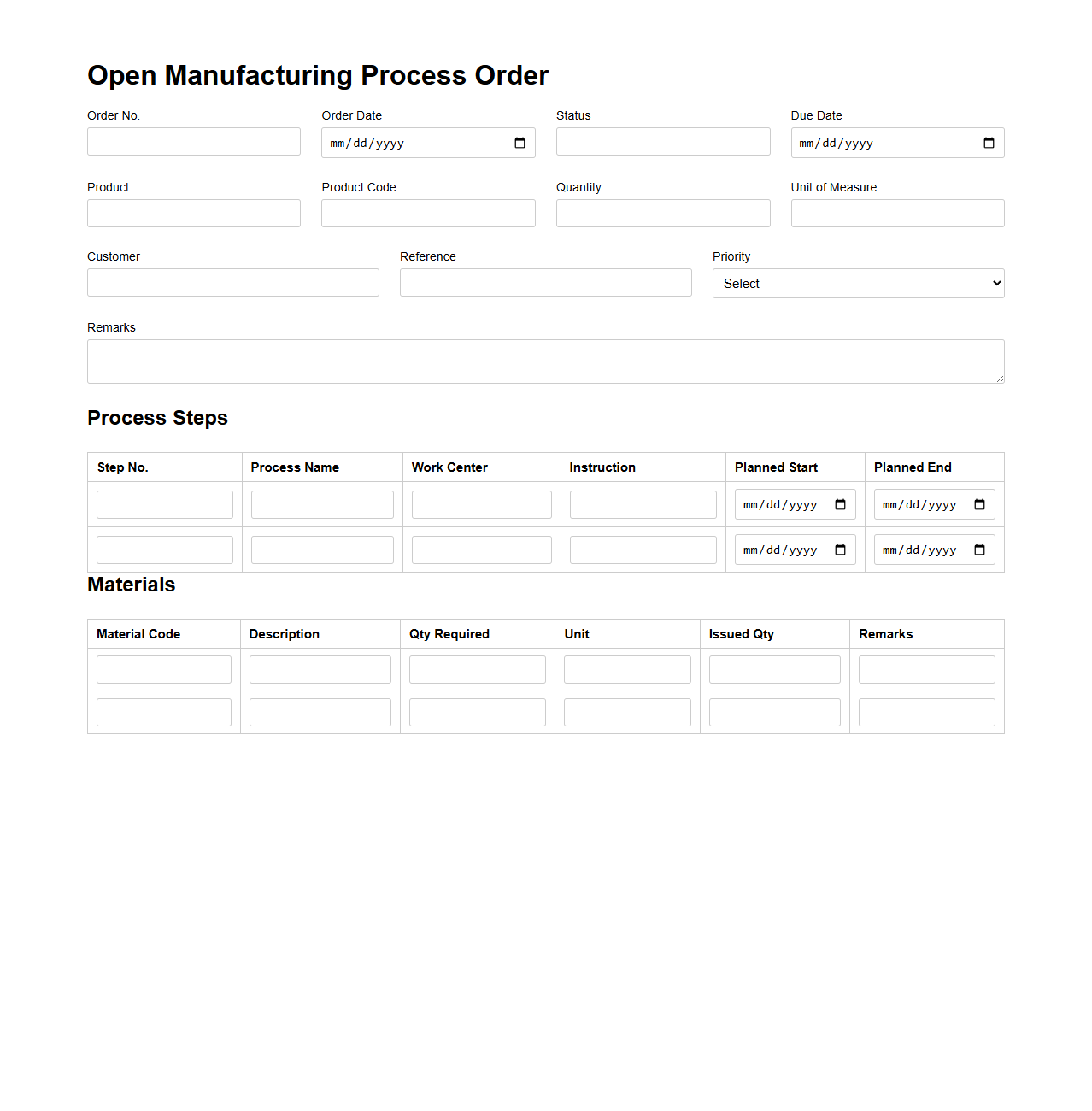

Open Manufacturing Process Order Template

The

Open Manufacturing Process Order Template document serves as a crucial framework used to initiate and standardize manufacturing workflows. It includes detailed specifications, resource allocations, and step-by-step instructions to ensure consistent production quality and efficiency. This template helps streamline operations, reduce errors, and maintain clear communication across production teams.

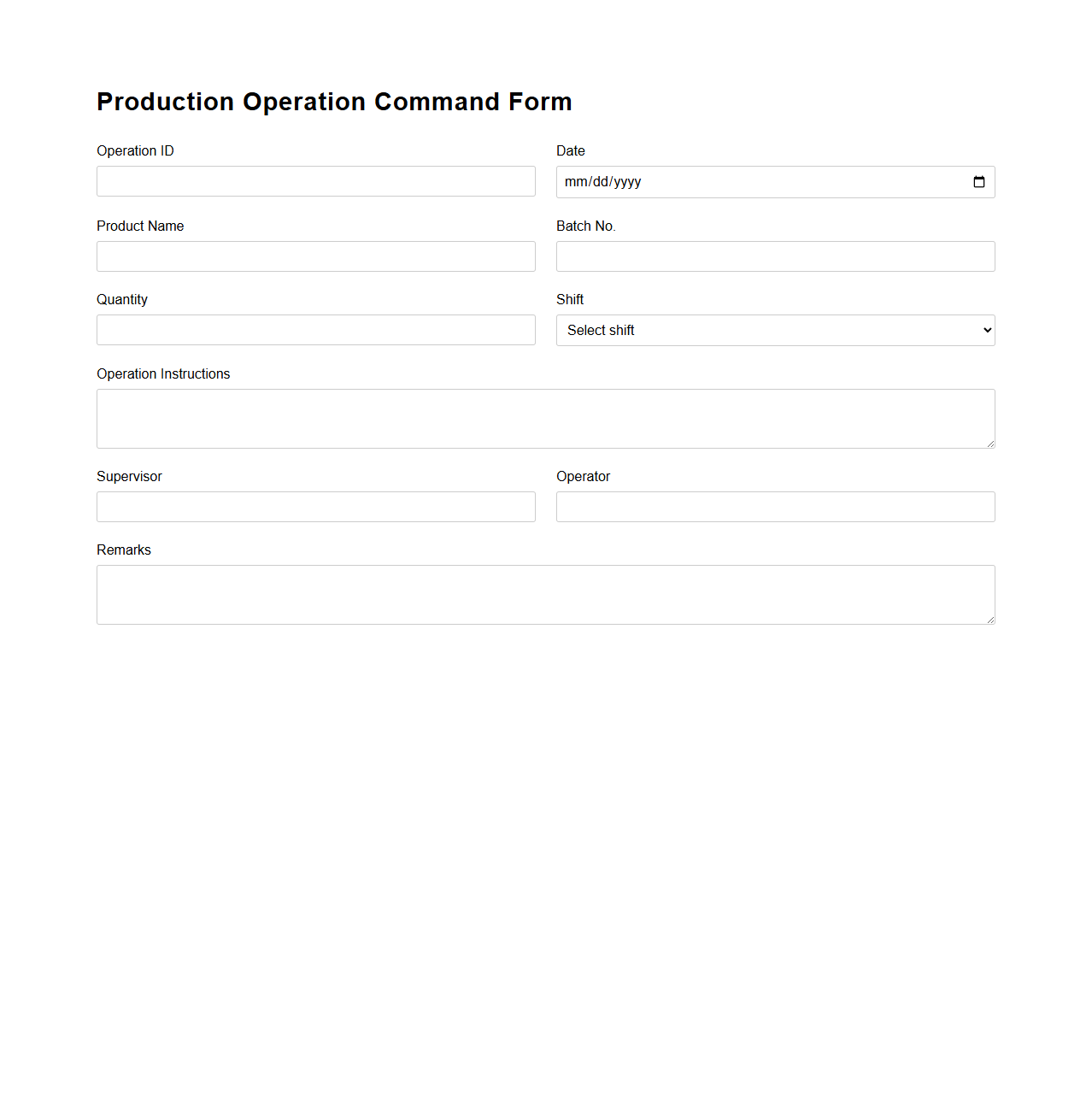

Production Operation Command Form

The

Production Operation Command Form document serves as a critical tool in manufacturing and production environments, providing detailed instructions and specifications required to execute a specific production task. It outlines operational steps, resource allocations, quality standards, and timelines to ensure efficient workflow and adherence to project goals. This document enhances communication between production teams and management, minimizing errors and optimizing overall productivity.

What mandatory fields must be included in a blank production order letter for compliance in manufacturing audits?

A blank production order letter must include mandatory fields such as the order number, product description, and quantity to ensure compliance. It should also specify the start and end dates for production to align with audit requirements. Additionally, fields for responsible personnel and approval signatures are crucial for traceability and accountability.

How do you structure material specifications in a blank production order document?

Material specifications in a blank production order are structured by listing each material's name, grade, and supplier details clearly. It is essential to include quantity requirements, batch numbers, and compliance certificates to maintain quality standards. This structured approach facilitates easy verification during audits and production monitoring.

What authorization protocols are commonly noted in blank production order letters for controlled manufacturing?

Authorization protocols typically include signature blocks for department heads such as production, quality control, and procurement. The document often requires timestamped approvals to ensure proper sequencing in controlled manufacturing environments. These protocols help in enforcing compliance with regulatory and internal control standards.

How does a blank production order address revision control and version tracking?

A blank production order incorporates revision control by including a version number and revision date prominently on the document. It often contains a change log section detailing updates and approval records for each revision. This ensures all stakeholders work with the most current production instructions while maintaining a historical audit trail.

What are best practices for integrating QC checkpoints into blank production order documentation?

Best practices for integrating QC checkpoints involve embedding specific inspection points and criteria at various production stages within the order. The document should clearly define acceptable quality limits and required actions if deviations occur. Including responsibilities for QC personnel at each checkpoint enhances process control and compliance verification.