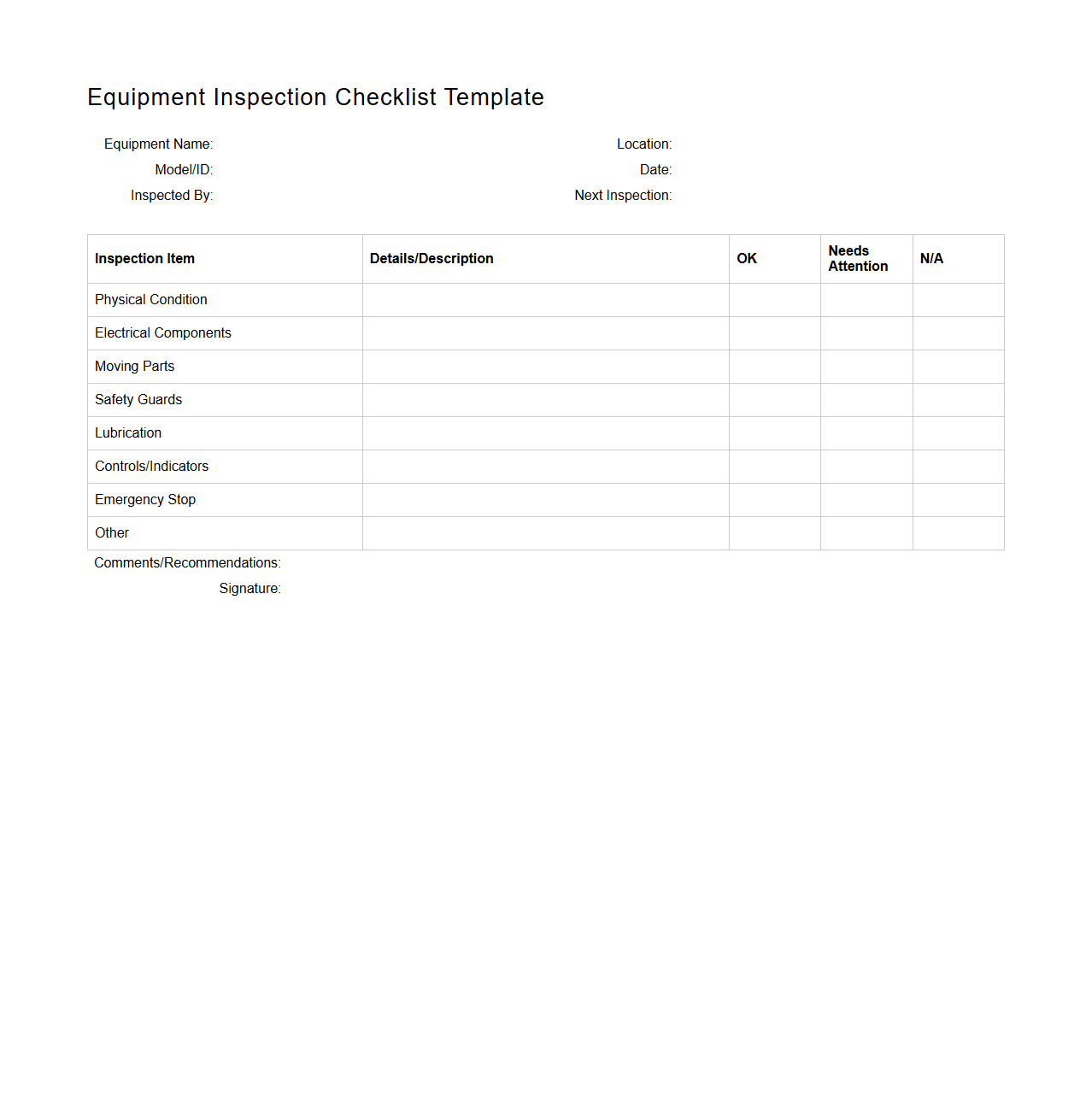

Equipment Inspection Checklist Template for Maintenance Monitoring

An

Equipment Inspection Checklist Template for Maintenance Monitoring document is a structured tool designed to systematically evaluate the condition and functionality of machinery and equipment. It helps maintenance teams identify potential issues, schedule timely repairs, and ensure safety compliance by listing specific inspection criteria such as operational status, wear and tear, and lubrication needs. By using this template, organizations can enhance asset reliability, reduce downtime, and extend equipment lifespan through consistent monitoring practices.

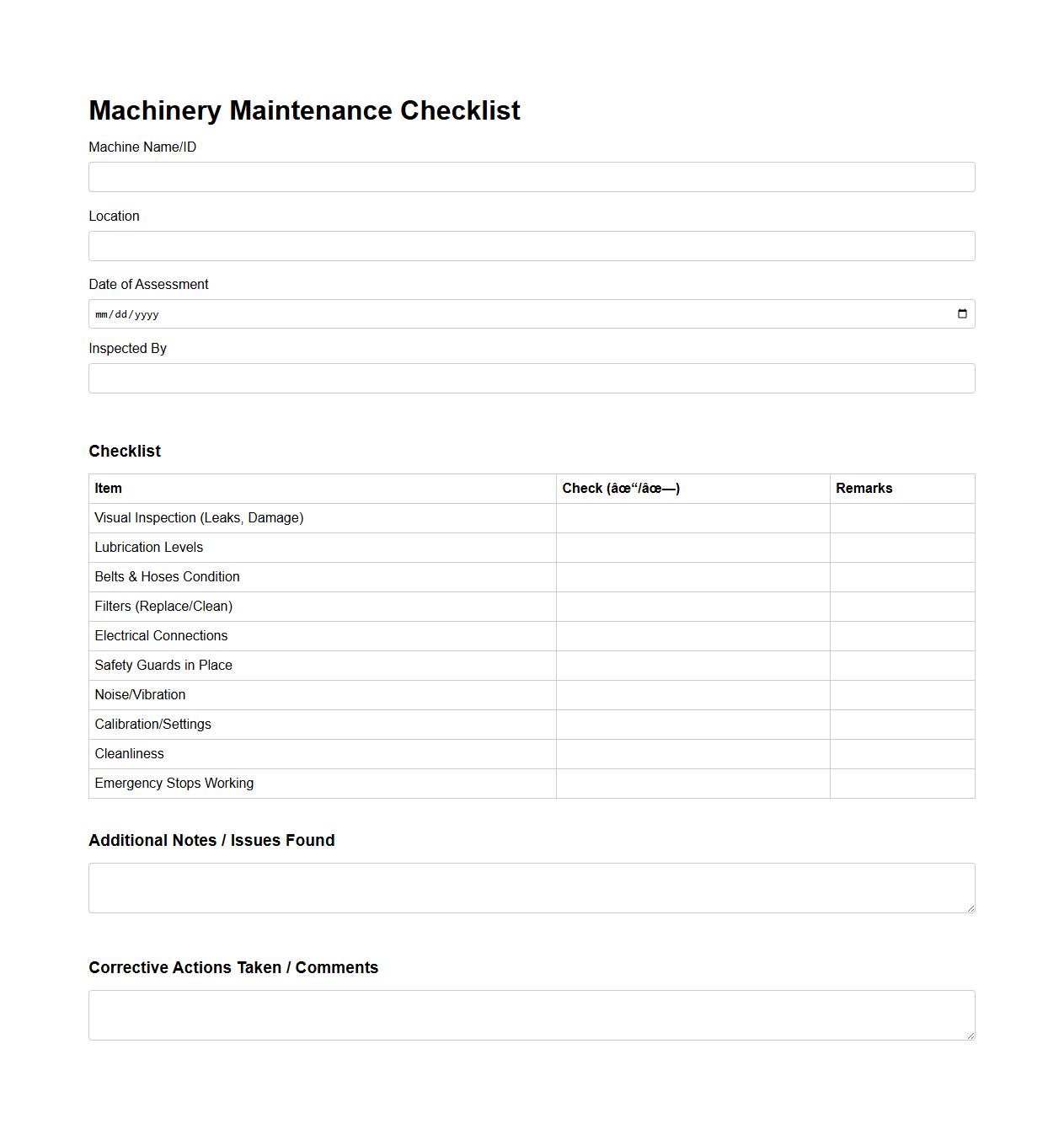

Machinery Maintenance Checklist Form for Regular Assessments

A

Machinery Maintenance Checklist Form for Regular Assessments is a structured document used to systematically inspect and evaluate the condition and performance of machinery. It includes specific criteria such as lubrication levels, wear and tear, alignment, and safety features to ensure operational efficiency and prevent breakdowns. Utilizing this checklist supports proactive maintenance, reduces downtime, and extends the lifespan of equipment.

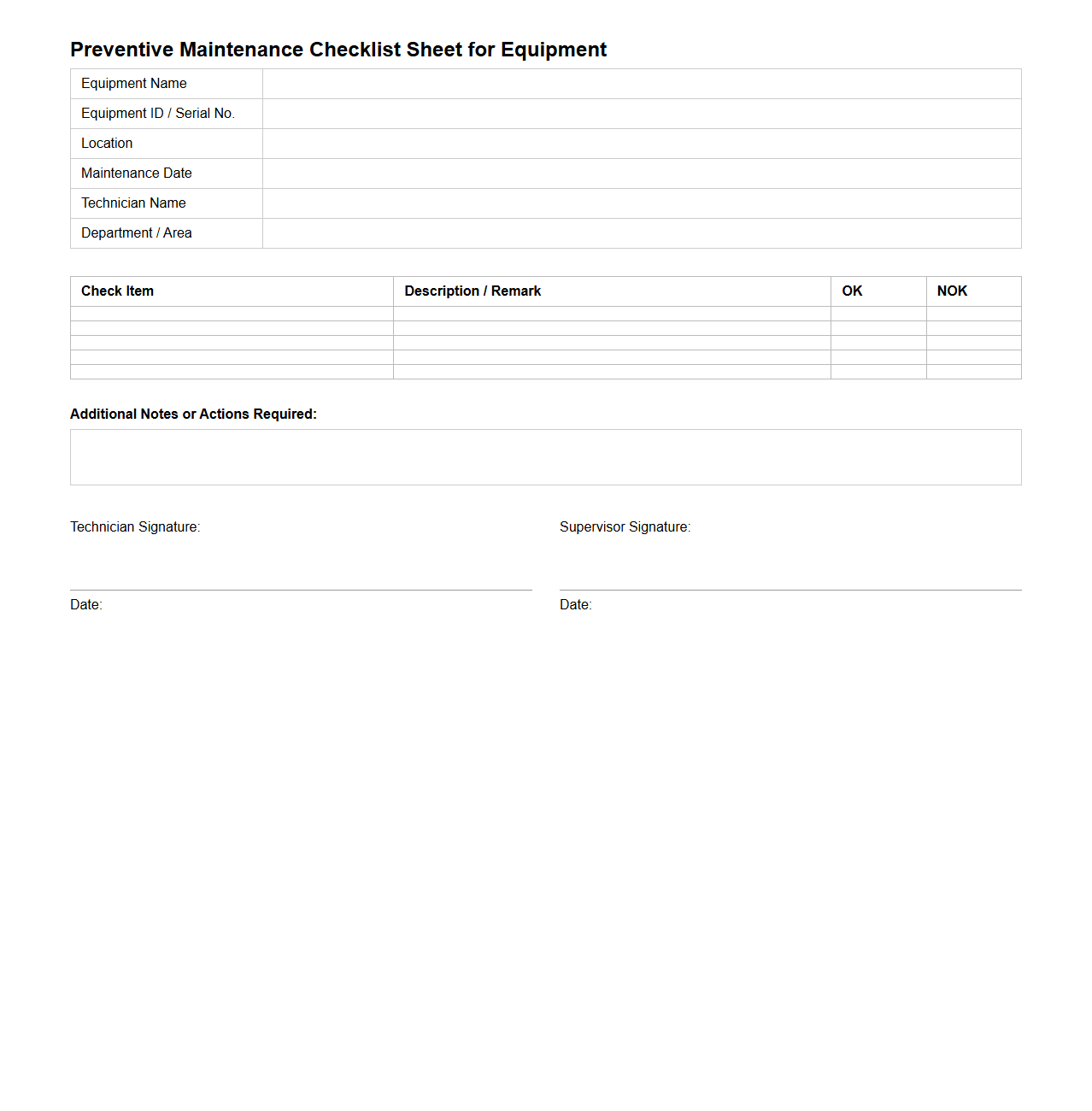

Preventive Maintenance Checklist Sheet for Equipment

A

Preventive Maintenance Checklist Sheet for Equipment is a structured document used to systematically inspect, service, and maintain machinery to prevent unexpected breakdowns and extend equipment lifespan. It outlines specific tasks, inspection points, and maintenance intervals tailored to each piece of equipment, ensuring consistent upkeep and operational efficiency. This checklist helps track completed maintenance activities, identify potential issues early, and support compliance with manufacturer and safety standards.

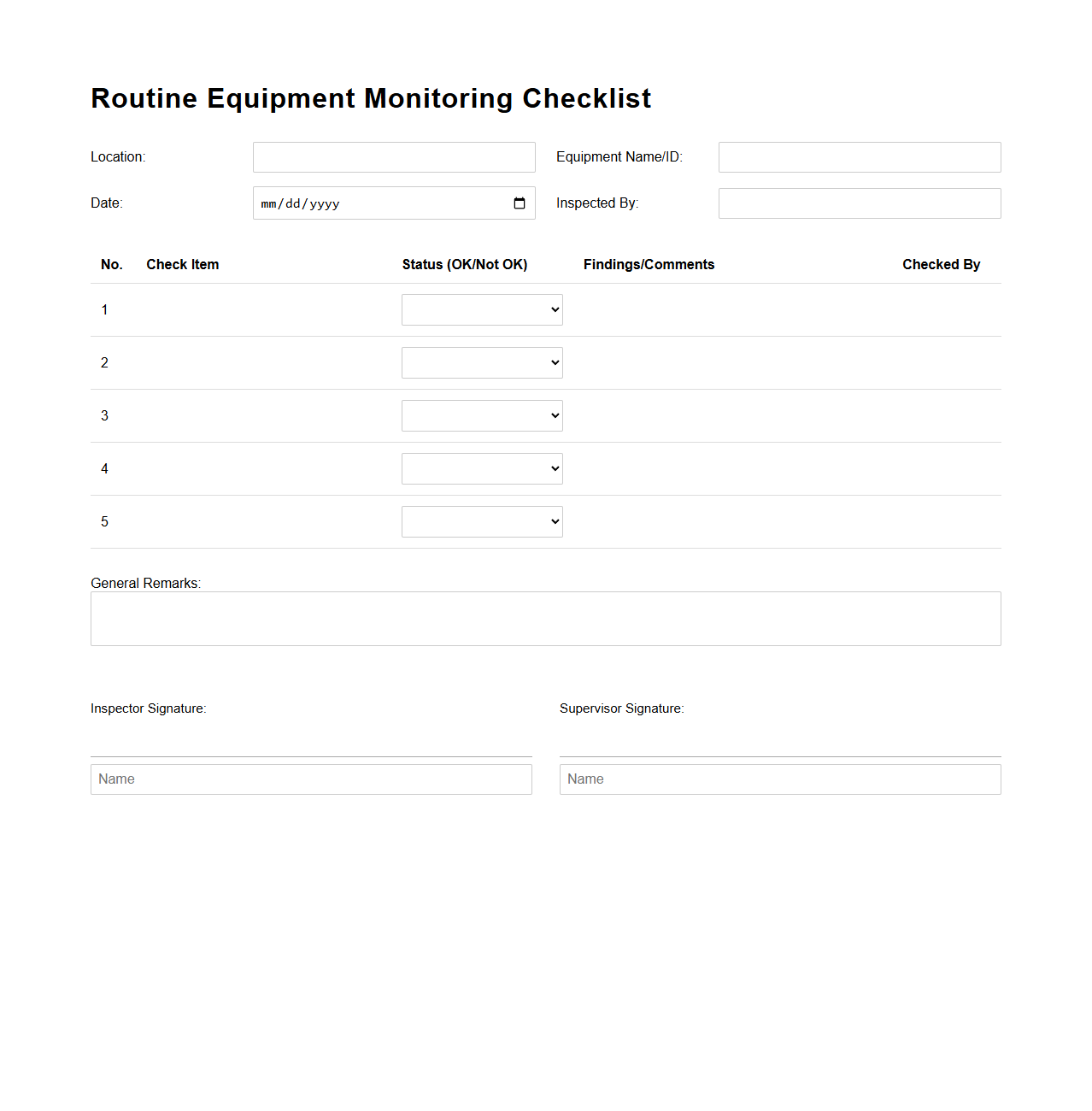

Routine Equipment Monitoring Checklist Format

The

Routine Equipment Monitoring Checklist Format document serves as a structured guide to systematically inspect and assess the operational status of equipment. It ensures consistent tracking of equipment conditions, maintenance needs, and performance metrics, which helps prevent unexpected failures and downtime. This format typically includes predefined criteria, observation points, and space for recording findings, promoting efficient equipment management and safety compliance.

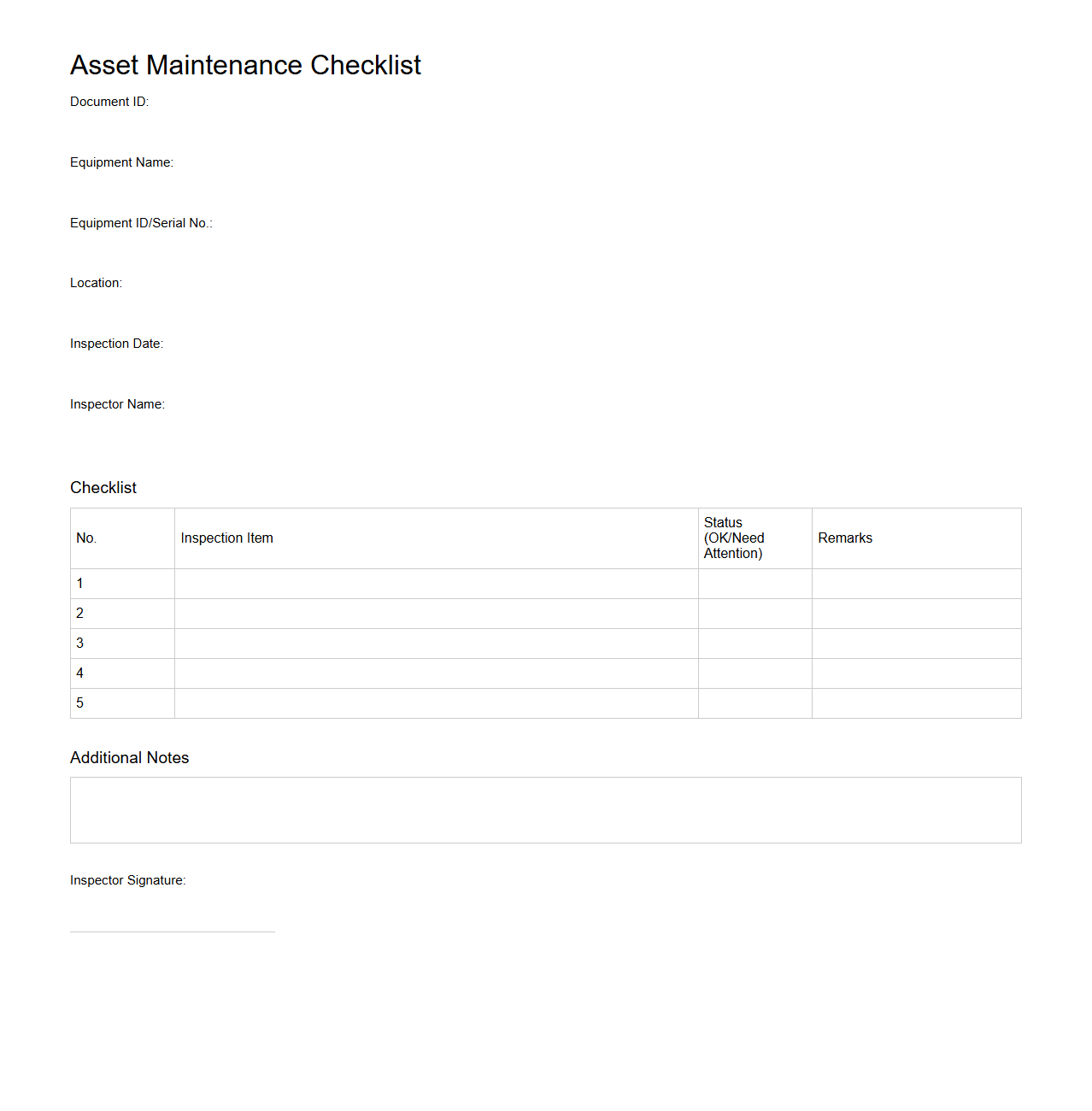

Asset Maintenance Checklist Document for Equipment Oversight

The

Asset Maintenance Checklist Document for Equipment Oversight is a structured tool used to systematically track and verify routine inspections, servicing, and repairs of machinery and equipment. This document ensures compliance with safety standards, operational efficiency, and prolongs asset lifespan by detailing specific maintenance tasks, schedules, and responsible personnel. It serves as a critical reference for maintenance teams and management to prevent equipment failures and optimize asset performance.

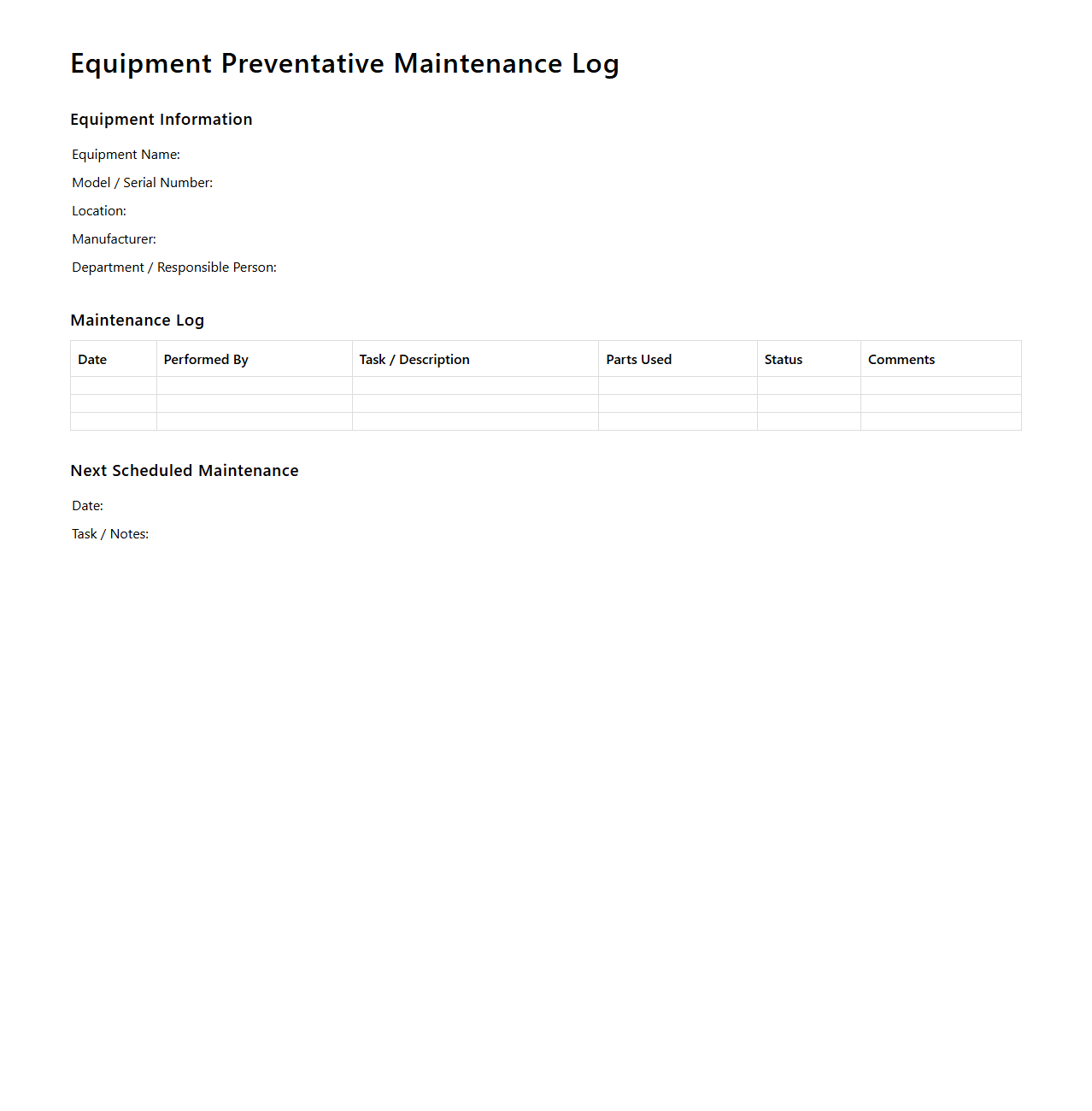

Equipment Preventative Maintenance Log Template

The

Equipment Preventative Maintenance Log Template document is designed to systematically record scheduled maintenance activities and inspections for machinery and equipment. It helps organizations track maintenance history, identify recurring issues, and ensure timely servicing to reduce unexpected breakdowns. This template enhances operational efficiency by providing a structured format for documenting dates, tasks performed, technician details, and equipment status.

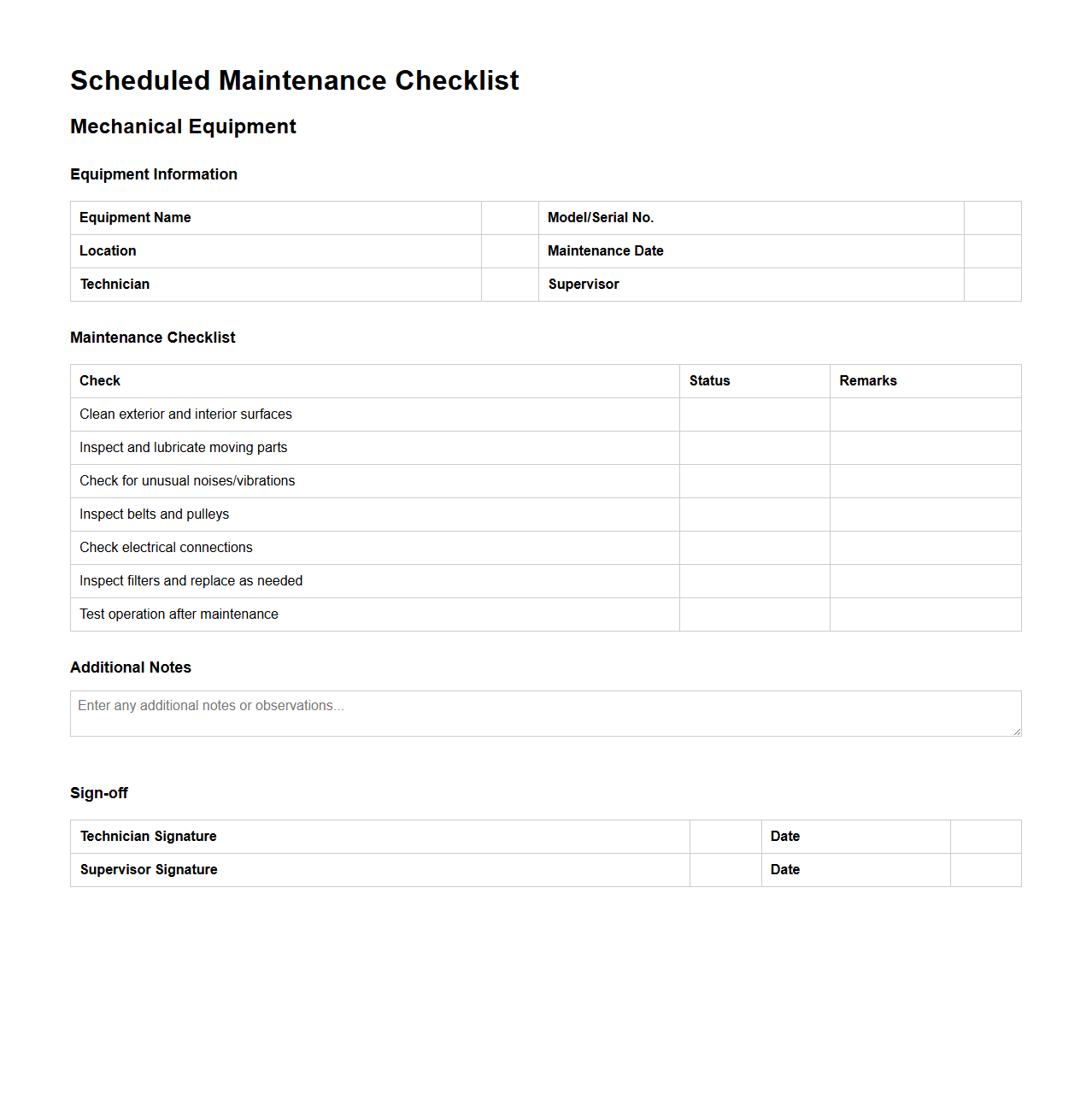

Scheduled Maintenance Checklist for Mechanical Equipment

A

Scheduled Maintenance Checklist for Mechanical Equipment document systematically outlines all routine inspections, lubrication, adjustments, and part replacements required to keep machinery operating efficiently. It serves as a critical tool to prevent unexpected breakdowns by ensuring timely maintenance tasks are completed according to manufacturer recommendations and industry standards. This checklist also helps maintenance teams track equipment condition, prioritize repairs, and maintain safety compliance.

Maintenance Tracking Checklist Sheet for Facility Equipment

A

Maintenance Tracking Checklist Sheet for Facility Equipment document serves as a systematic tool to monitor and record the maintenance activities performed on various pieces of equipment within a facility. It includes detailed information such as equipment identification, maintenance schedules, performed tasks, and inspection results to ensure optimal functionality and prevent unexpected breakdowns. This checklist enhances asset management by providing a clear audit trail and facilitating timely interventions based on equipment performance data.

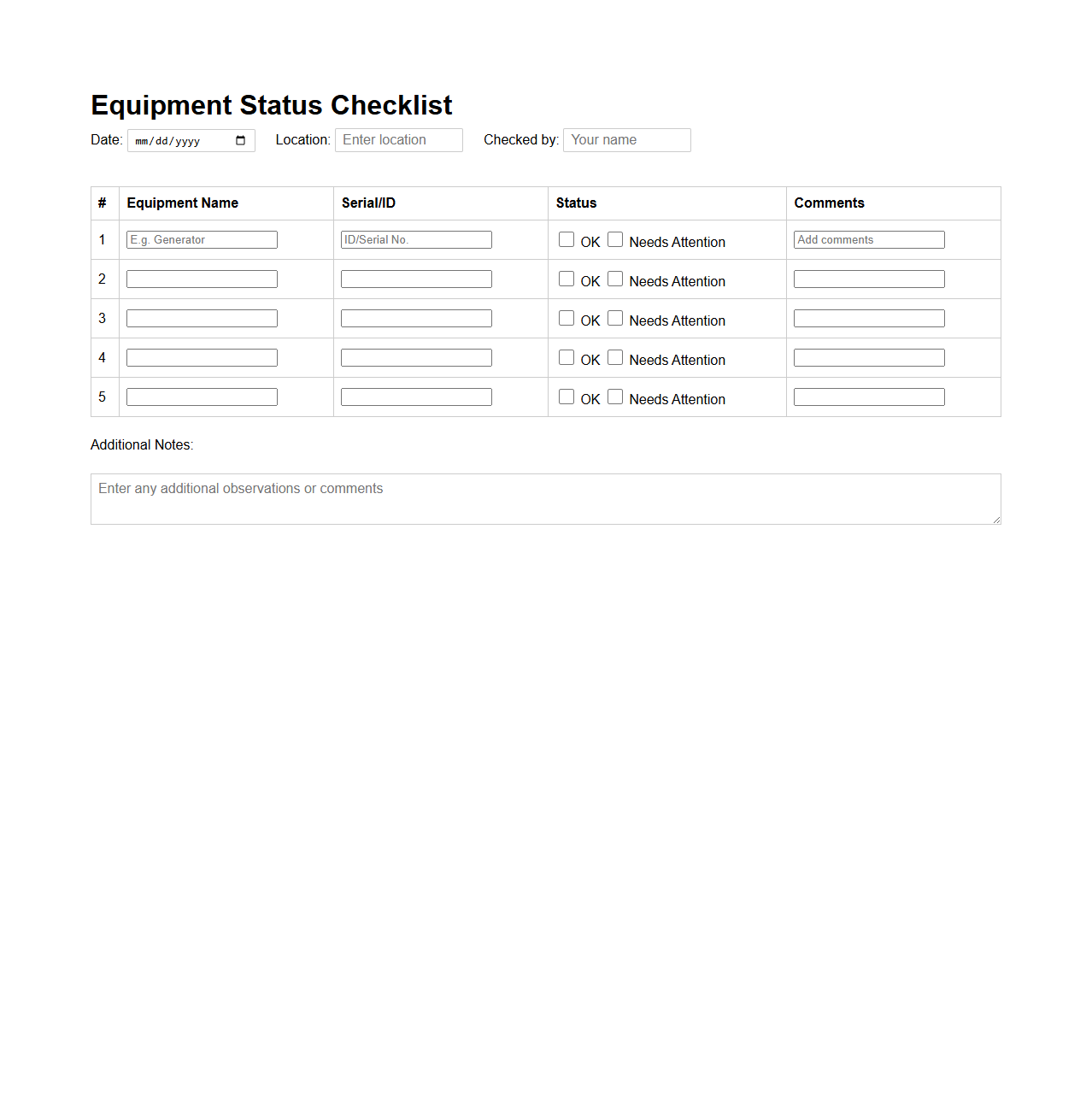

Equipment Status Checklist Template for Monitoring

An

Equipment Status Checklist Template for monitoring document is a structured tool designed to track and record the operational condition, maintenance needs, and inspection results of machinery or equipment. It ensures consistent data collection, promotes timely identification of issues, and supports maintenance scheduling to enhance equipment reliability. This template typically includes fields for equipment ID, status updates, observed problems, and corrective actions taken, facilitating efficient asset management and reducing downtime.

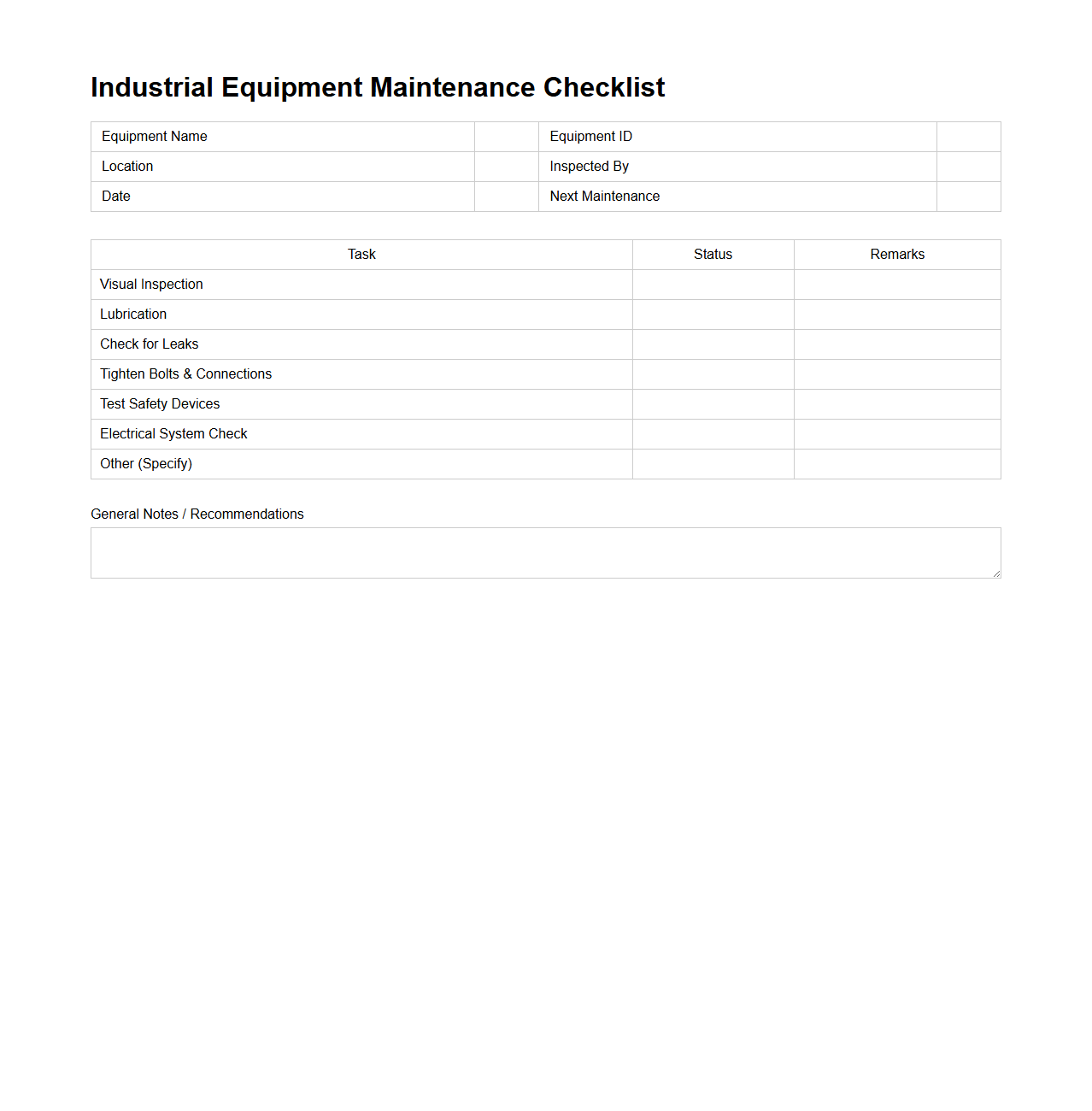

Industrial Equipment Maintenance Checklist Layout

An

Industrial Equipment Maintenance Checklist Layout document provides a structured format for systematically tracking and performing routine maintenance tasks on machinery. It ensures that critical components such as lubrication, inspections, repairs, and safety checks are consistently completed to optimize equipment performance and minimize downtime. This layout facilitates clarity, accountability, and adherence to maintenance schedules, improving overall operational efficiency.

What data fields are essential in a blank maintenance checklist for equipment monitoring?

A blank maintenance checklist should include equipment identification fields such as serial number and model. It must also have sections for inspection dates, task descriptions, and responsible personnel. Additionally, fields for observations, faults detected, and corrective actions taken are crucial for comprehensive monitoring.

How frequently should maintenance tasks be recorded on the checklist?

Maintenance tasks should be recorded regularly according to the manufacturer's recommendations or industry standards. Typically, tasks are logged after every inspection, which can be daily, weekly, or monthly based on equipment use. Consistent recording ensures timely detection of issues and prolongs equipment lifespan.

Which equipment parameters should be prioritized on the monitoring checklist?

The checklist should prioritize critical operational parameters such as temperature, pressure, and vibration levels. Monitoring these helps in early identification of equipment malfunctions. Additionally, parameters linked to safety and performance efficiency must be emphasized.

How can digital checklists improve the accuracy of equipment maintenance records?

Digital checklists enhance accuracy by minimizing manual errors and enabling real-time data entry. They also facilitate automatic reminders and easy access to historical maintenance data. This leads to improved accountability and more efficient maintenance workflows.

What compliance standards should a maintenance checklist for monitoring equipment meet?

The checklist should comply with industry-specific regulations such as ISO 55000 for asset management and OSHA standards for safety. Adherence to these ensures legal compliance and promotes best maintenance practices. It also supports audit readiness and enhances operational reliability.