The Blank Maintenance Order Template for Equipment Servicing streamlines the documentation process, ensuring accurate recording of service details for efficient equipment upkeep. It facilitates clear communication between maintenance teams and management, reducing downtime and preventing equipment failure. This customizable template aids in tracking maintenance schedules, parts used, and labor hours to optimize operational efficiency.

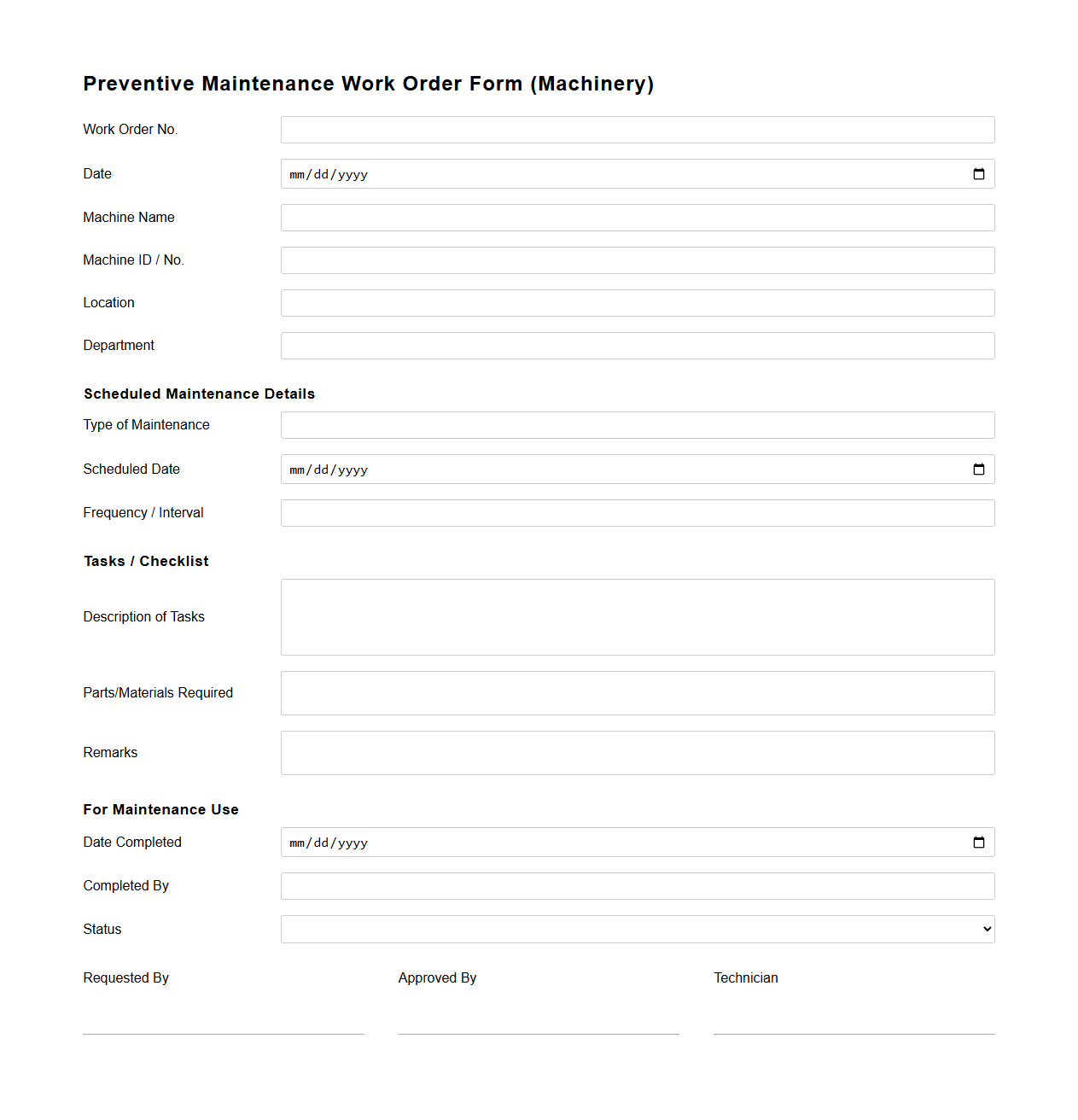

Blank Preventive Maintenance Work Order Form for Machinery

A

Blank Preventive Maintenance Work Order Form for Machinery is a standardized document used to schedule, track, and record regular maintenance tasks on machinery to prevent unexpected breakdowns and extend equipment life. It typically includes fields for equipment details, maintenance procedures, inspection checklists, and dates for upcoming service. This form ensures maintenance teams follow consistent protocols, improving operational efficiency and reducing downtime.

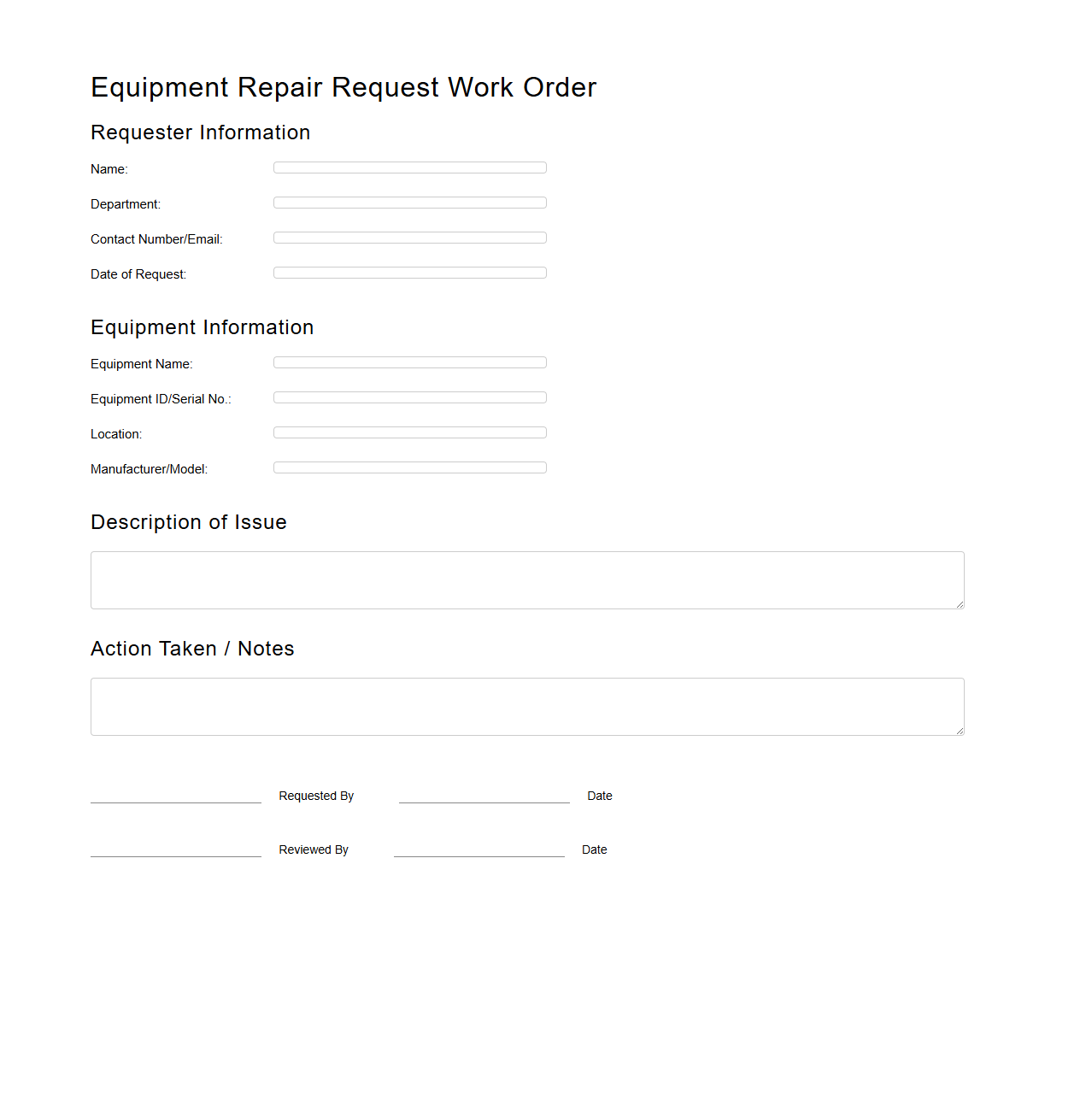

Blank Equipment Repair Request Work Order Template

A

Blank Equipment Repair Request Work Order Template document is a pre-formatted form designed to capture essential details for reporting and tracking equipment malfunctions and repair needs. It typically includes fields for equipment identification, description of the issue, requested service date, and technician assignment to ensure accurate and timely maintenance. Using this template helps streamline communication between departments and maintain organized records for equipment repair history.

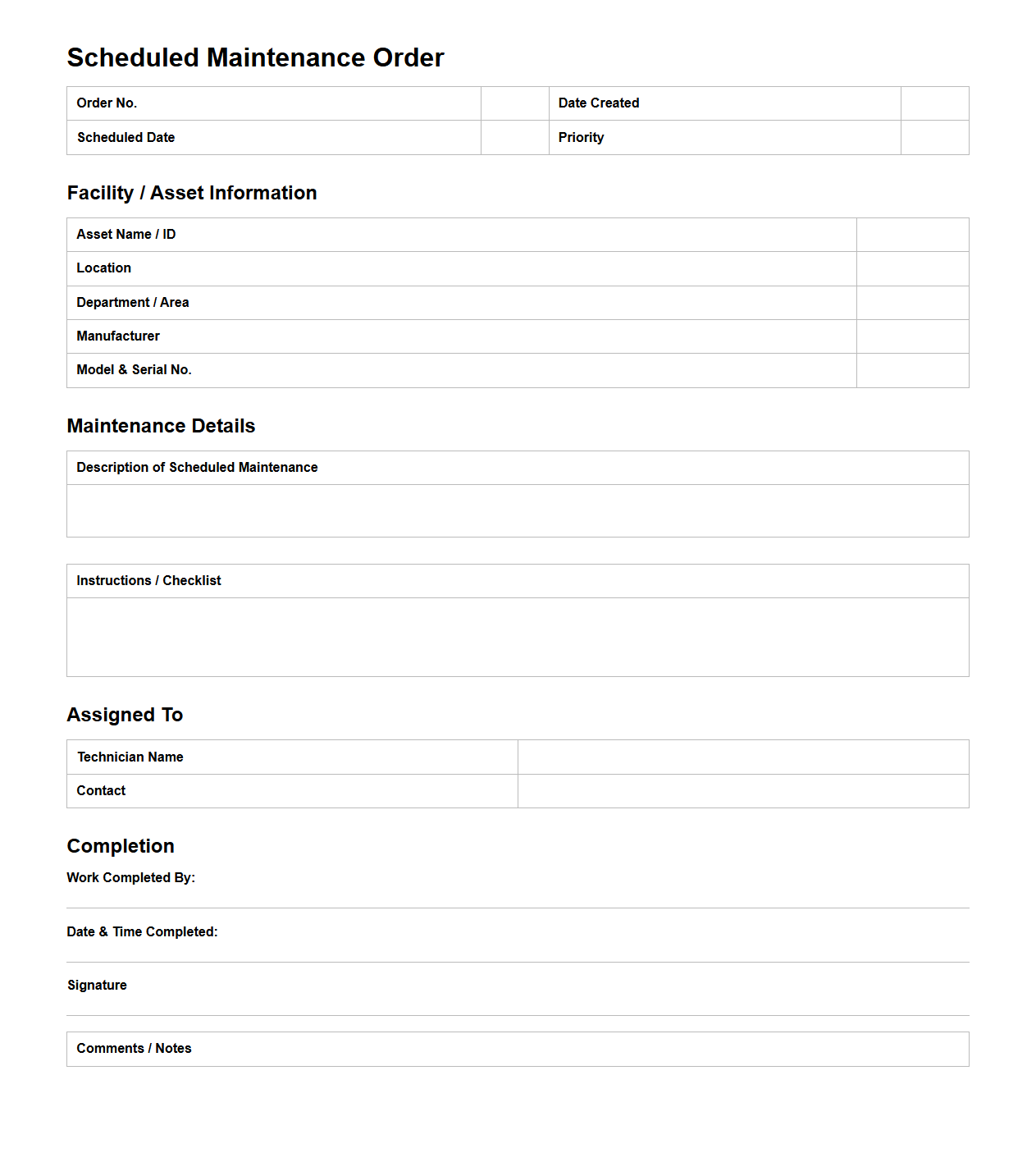

Blank Scheduled Maintenance Order Template for Facility Assets

The

Blank Scheduled Maintenance Order Template for Facility Assets is a standardized document designed to streamline the planning and execution of routine maintenance tasks on physical assets within a facility. It includes predefined fields for asset identification, maintenance activities, scheduling dates, responsible personnel, and required resources, ensuring consistent tracking and documentation. Utilizing this template enhances operational efficiency, reduces equipment downtime, and supports compliance with maintenance protocols.

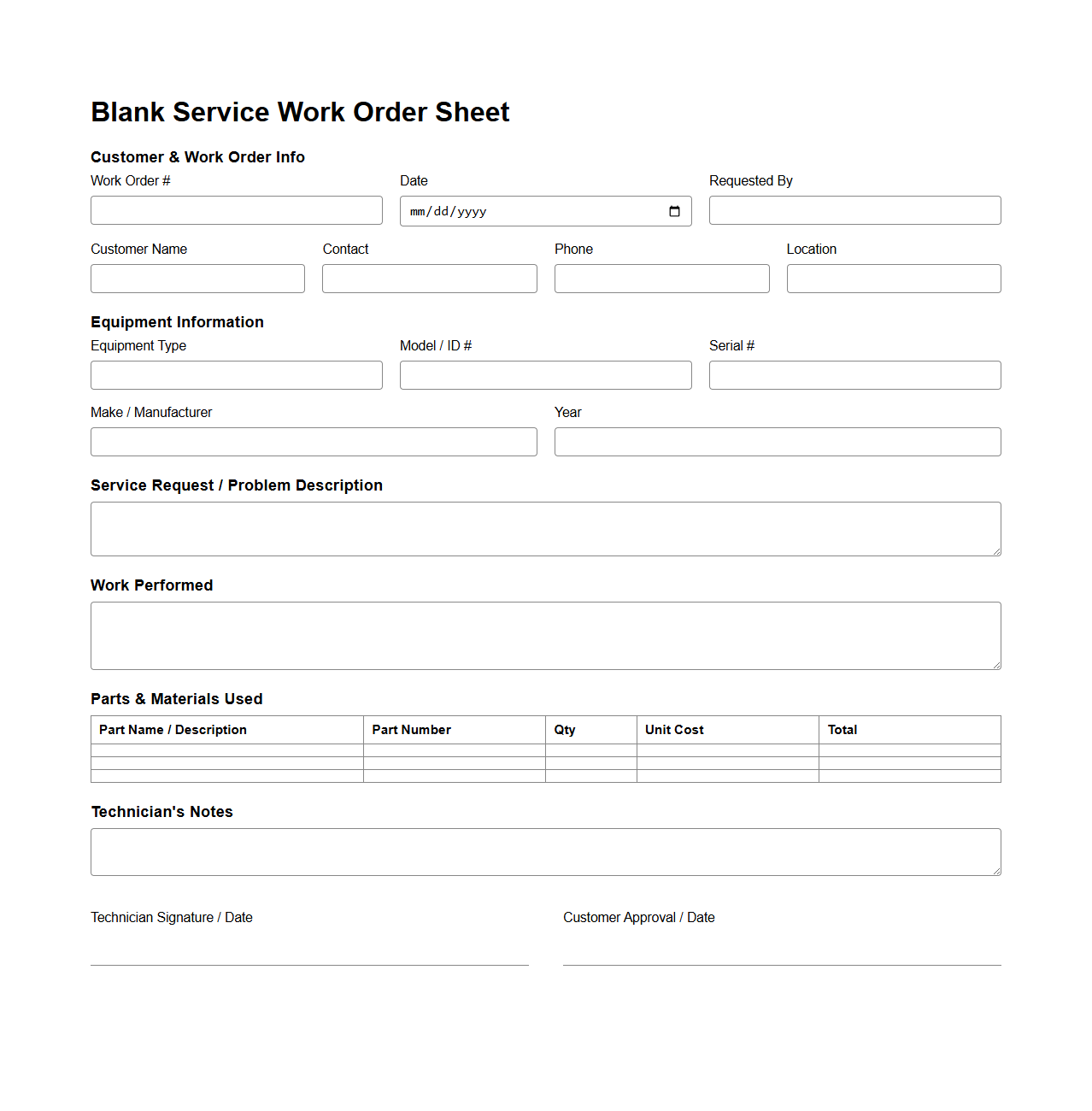

Blank Service Work Order Sheet for Industrial Equipment

A

Blank Service Work Order Sheet for industrial equipment is a standardized form used to document maintenance or repair tasks performed on machinery. It captures essential details such as equipment identification, service description, labor hours, parts used, and technician notes, ensuring accurate tracking of work performed. This sheet facilitates effective communication between service teams and management, improving equipment reliability and operational efficiency.

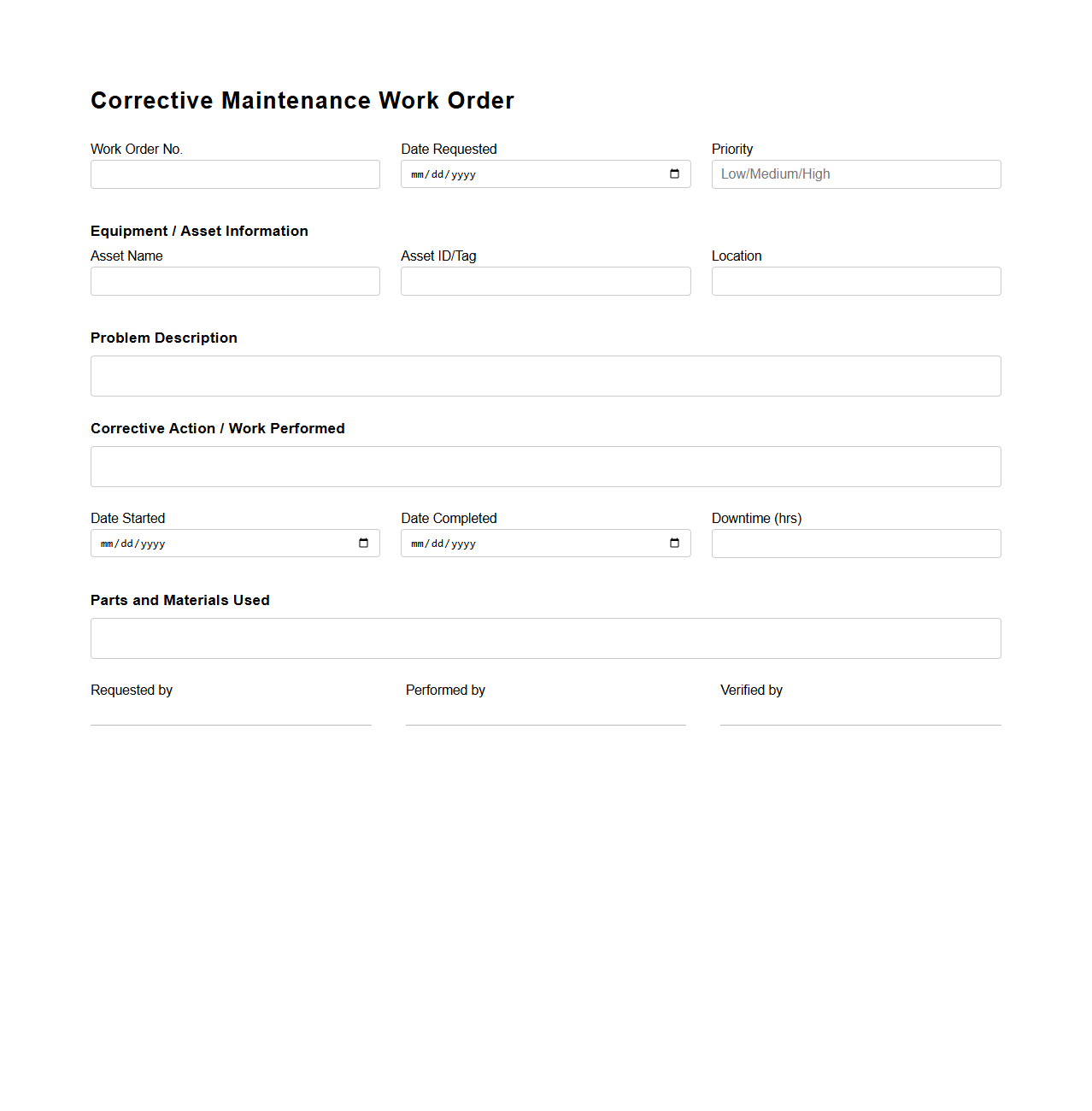

Blank Corrective Maintenance Work Order Template

A

Blank Corrective Maintenance Work Order Template document serves as a standardized form designed to record and organize details of maintenance tasks performed to fix equipment or system failures. This template typically includes fields for identifying the asset, describing the issue, outlining corrective actions taken, and tracking labor and materials used. Using such a template enhances efficiency, ensures consistent documentation, and facilitates better communication among maintenance teams.

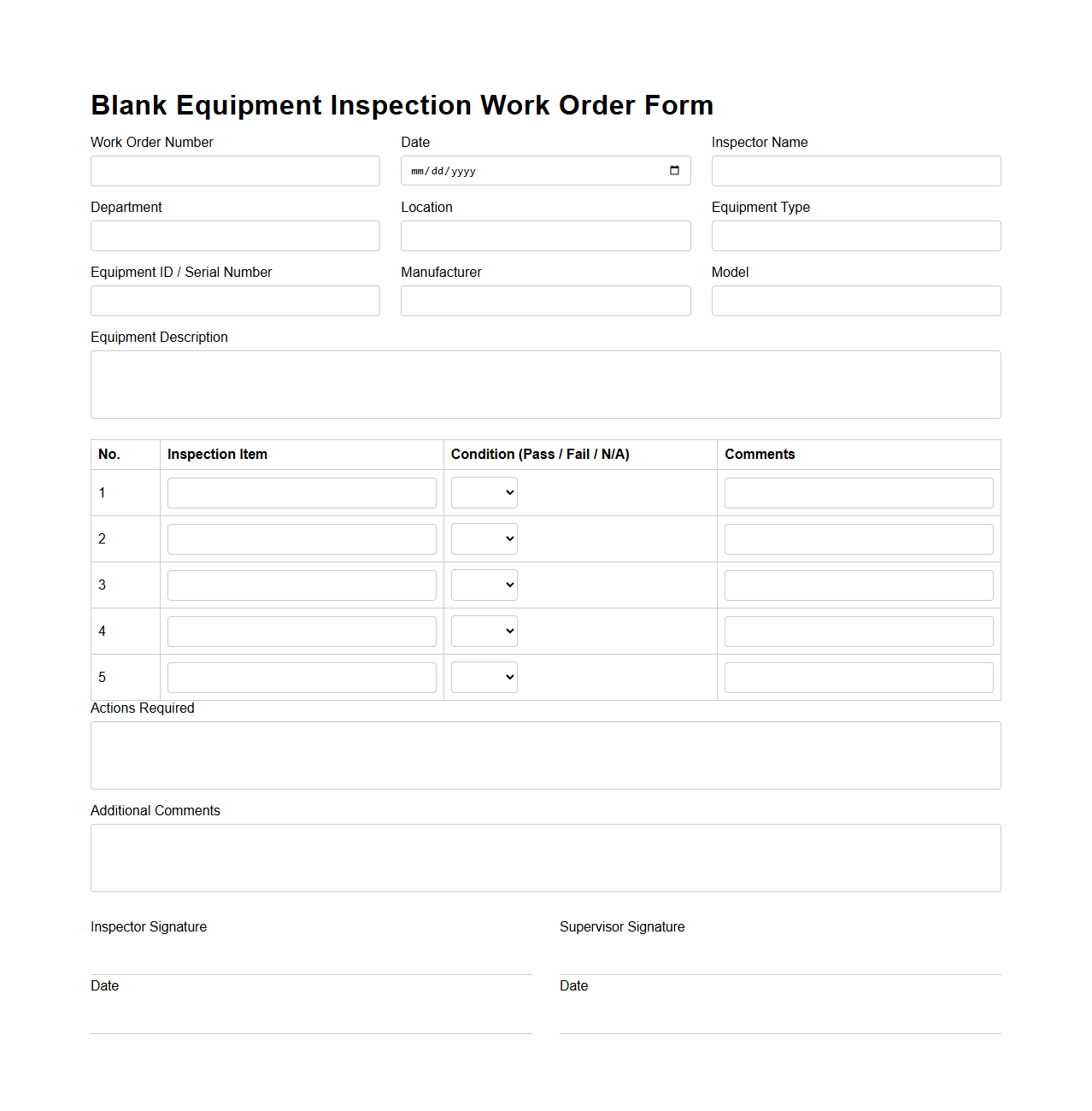

Blank Equipment Inspection Work Order Form

A

Blank Equipment Inspection Work Order Form is a document used to systematically record the condition and functionality of equipment before and after use. It includes fields for identifying equipment, noting inspection dates, listing any defects or maintenance needs, and authorizing repair work. This form ensures consistent maintenance tracking, enhances operational safety, and supports compliance with equipment management protocols.

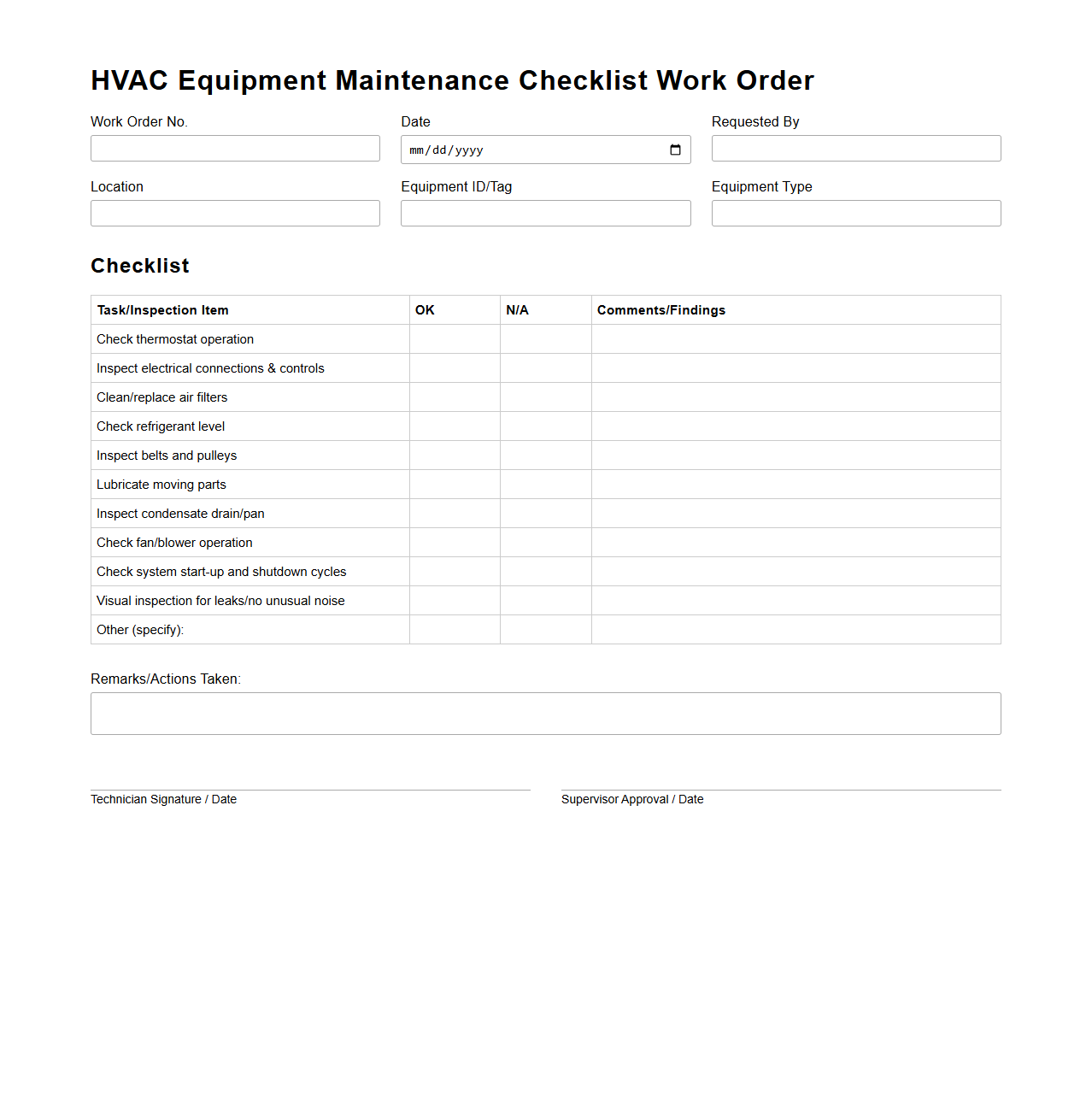

Blank Maintenance Checklist Work Order for HVAC Equipment

A

Blank Maintenance Checklist Work Order for HVAC equipment is a standardized document used to track routine inspection, servicing, and repair tasks. It ensures all necessary maintenance activities are consistently performed to optimize system performance and extend equipment lifespan. This checklist aids technicians in documenting completed work, identifying issues, and scheduling future maintenance efficiently.

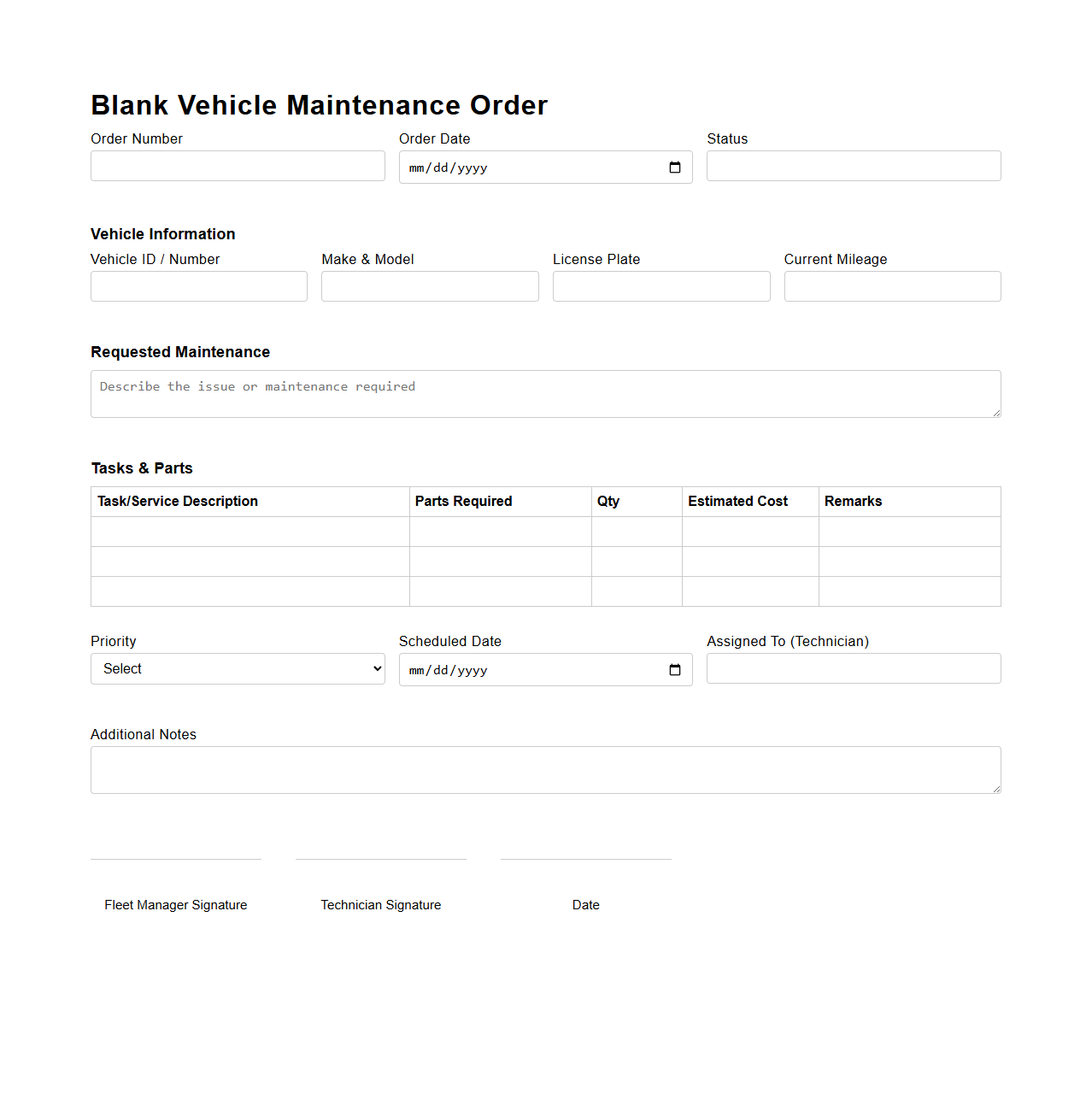

Blank Vehicle Maintenance Order Template for Fleet Management

A

Blank Vehicle Maintenance Order Template for fleet management is a standardized form used to document and schedule maintenance tasks for vehicles within a fleet. It ensures clear communication between fleet managers, mechanics, and service providers by detailing vehicle identification, maintenance requirements, and service dates. This template helps optimize fleet efficiency, reduce downtime, and maintain compliance with safety regulations.

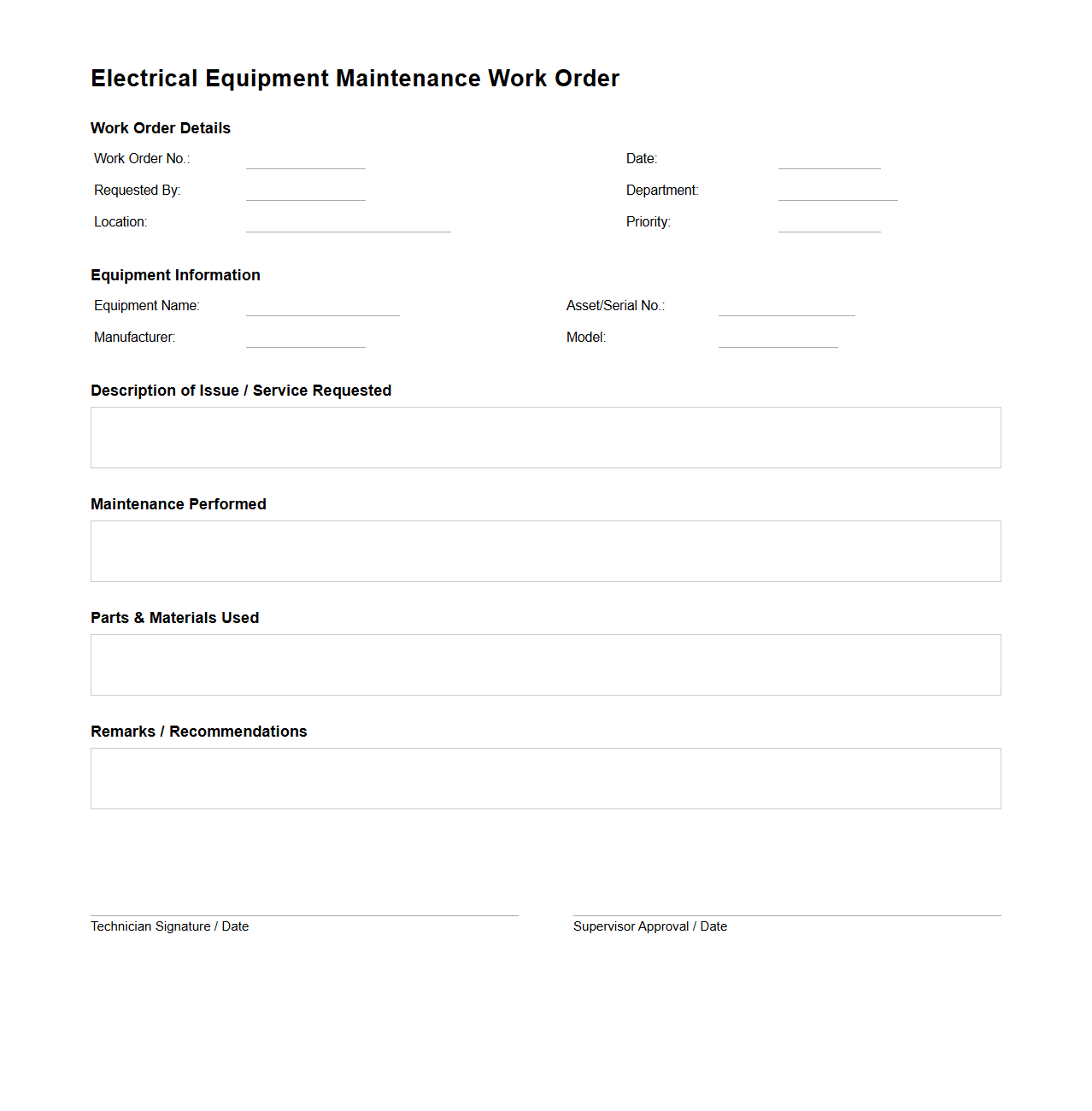

Blank Electrical Equipment Maintenance Work Order

A

Blank Electrical Equipment Maintenance Work Order document is a structured form used to record and manage maintenance tasks for electrical equipment. It outlines specific details such as the equipment identification, maintenance type, scheduled date, and technician assignments to ensure systematic upkeep and prevent equipment failure. This document is essential for tracking maintenance history and ensuring compliance with safety and operational standards.

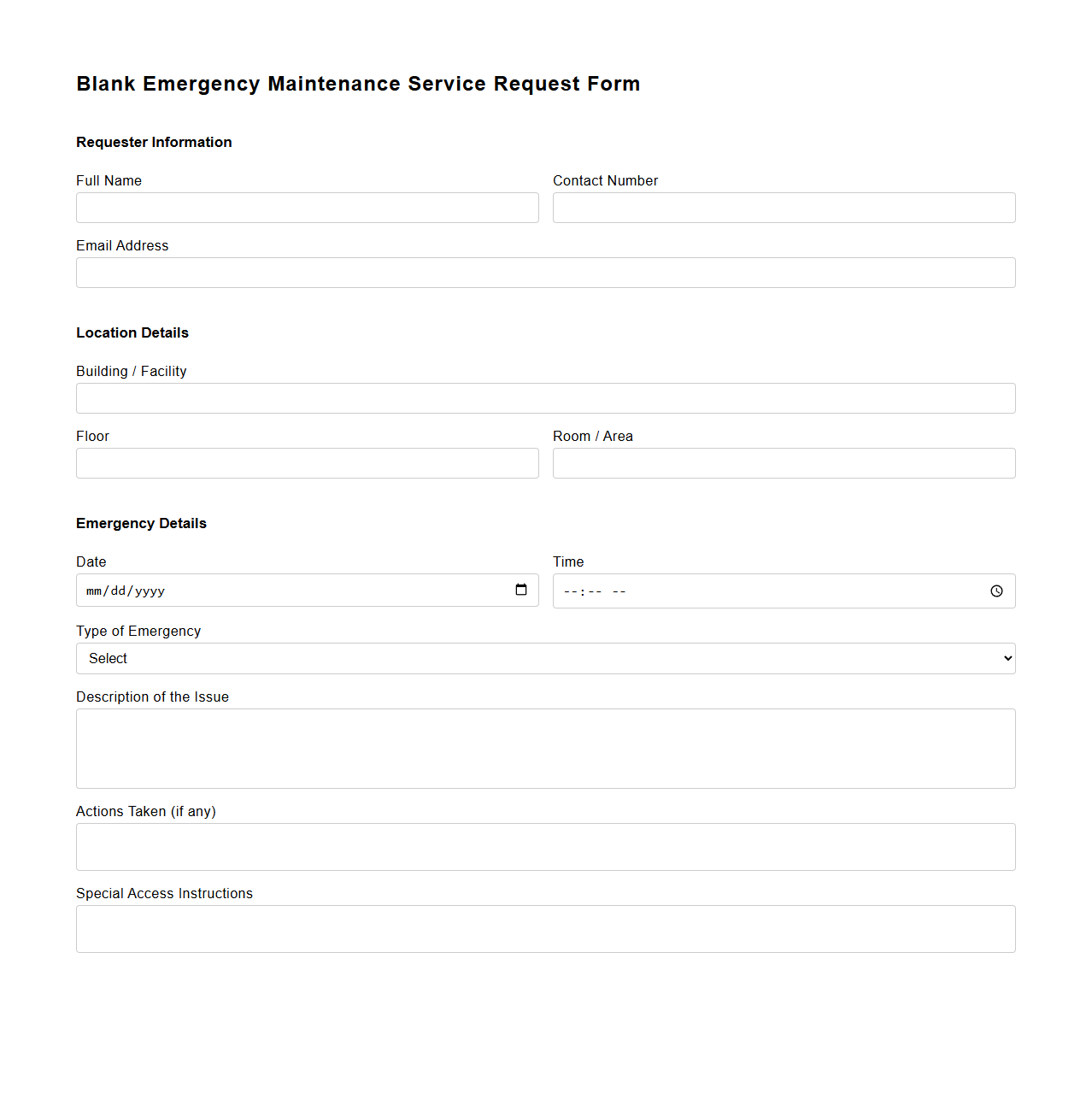

Blank Emergency Maintenance Service Request Form

A

Blank Emergency Maintenance Service Request Form is a standardized document used to report urgent repair or maintenance issues that require immediate attention. It captures essential details such as the nature of the problem, location, requester information, and the urgency level to facilitate prompt response. This form streamlines communication between employees and maintenance teams, ensuring quick resolution of critical facility or equipment failures.

What essential fields should be included in a blank maintenance order for equipment servicing?

A blank maintenance order must include essential fields such as equipment identification, description of the issue, and the service date. It should also capture the technician's details, materials used, and estimated labor hours. Including a section for approval and signatures ensures accountability and formal authorization for the work.

How can a blank maintenance order template ensure compliance with industry standards?

A well-designed maintenance order template incorporates mandatory fields reflecting industry regulations and safety protocols. It enforces standardized data entry, reducing errors and inconsistencies in equipment servicing records. Integrating audit trail capabilities within the template helps verify compliance during inspections and reviews.

What digital tools integrate best with custom blank maintenance order forms?

Popular digital tools such as CMMS (Computerized Maintenance Management Systems) and ERP (Enterprise Resource Planning) software integrate seamlessly with custom maintenance order forms. Cloud-based platforms like Microsoft PowerApps and Google Forms facilitate easy customization and real-time data access. These tools enhance workflow automation, collaboration, and reporting efficiency.

How does a blank maintenance order support traceability in equipment maintenance history?

A blank maintenance order records detailed service activities, creating a chronological log of all interventions. This traceability aids in monitoring equipment performance, scheduling preventive maintenance, and analyzing recurring issues. Reliable documentation supports compliance audits and informed decision-making for asset management.

What common errors occur when completing blank maintenance orders for equipment servicing?

Common errors include incomplete fields, inaccurate recording of service details, and missing approval signatures in a maintenance order. Miscommunication between technicians and supervisors often leads to inconsistent data entry. Regular training and standardized templates help minimize these mistakes and ensure accurate maintenance documentation.