A Blank Inspection Report Template for Quality Assurance provides a structured format to systematically document the inspection process and findings. This template ensures all critical quality checkpoints are evaluated consistently, enabling teams to identify defects and maintain product standards. Using a standardized report enhances communication, supports regulatory compliance, and drives continuous improvement in quality management.

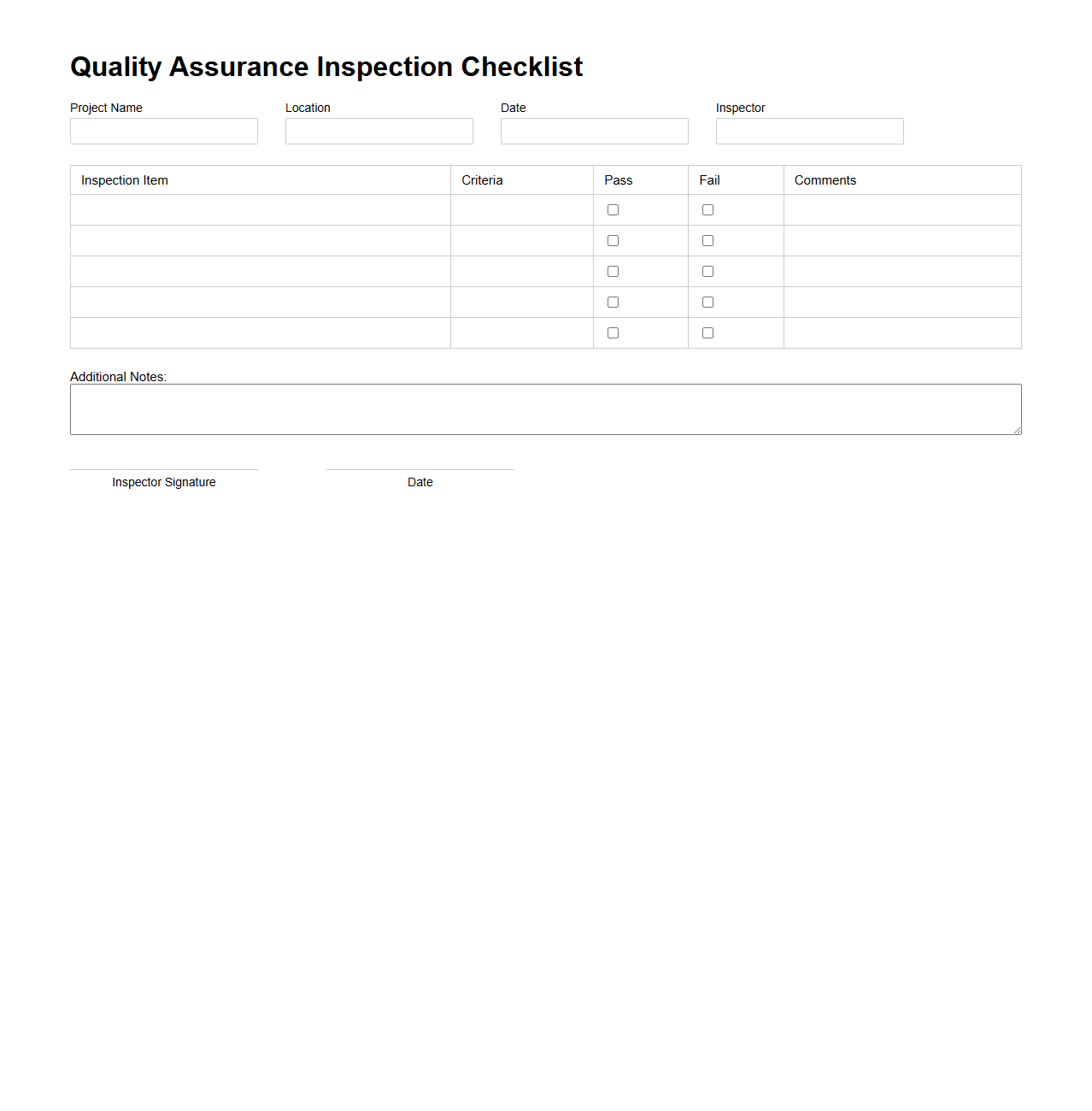

Quality Assurance Inspection Checklist Template

A

Quality Assurance Inspection Checklist Template document serves as a structured tool designed to systematically verify that products or services meet specified quality standards. It outlines detailed criteria and checkpoints for inspectors to evaluate processes, materials, and outputs, ensuring consistency and compliance with regulatory requirements. This template enhances accuracy, reduces errors, and supports continuous improvement in quality management systems.

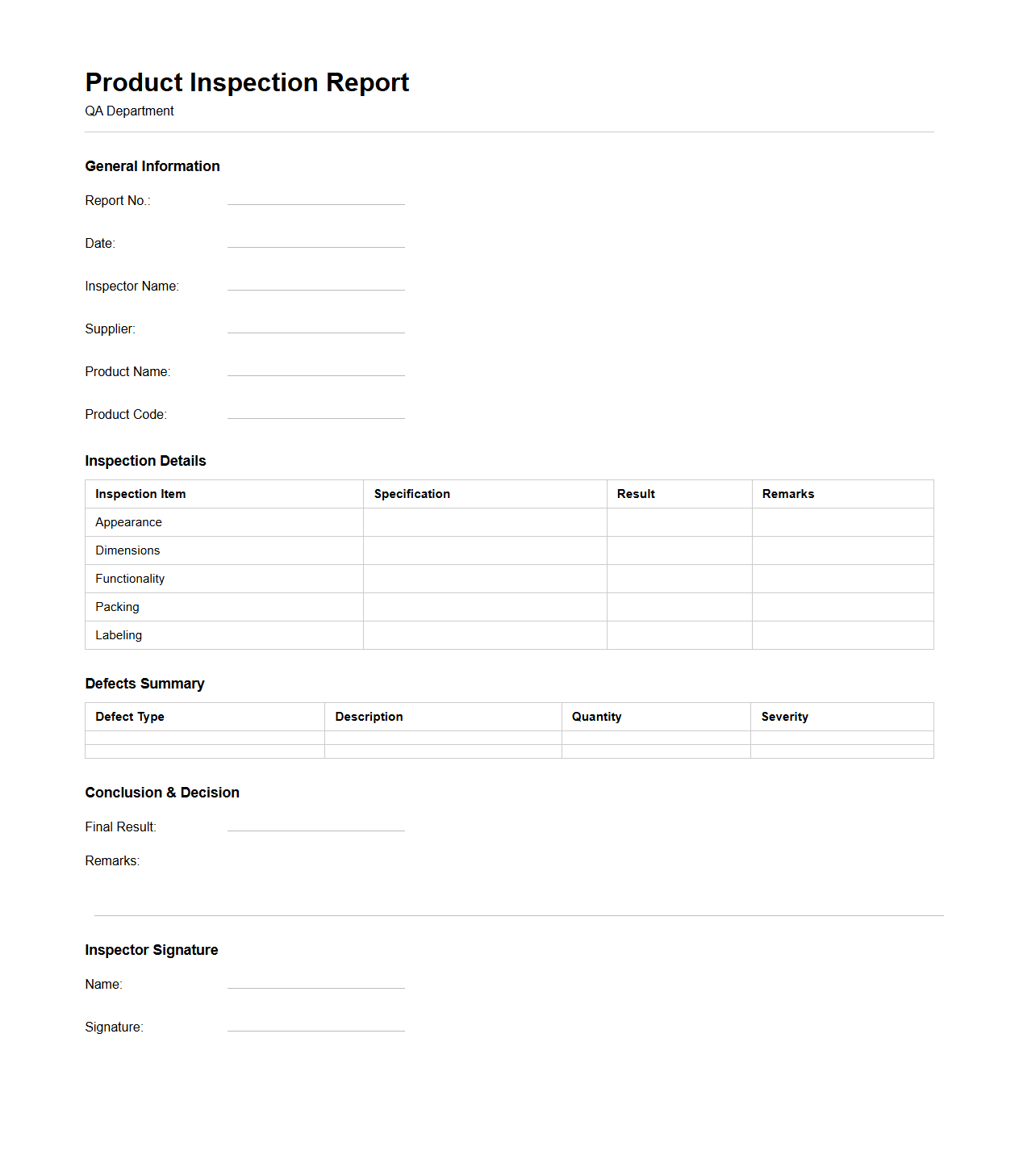

Product Inspection Report Format for QA

A

Product Inspection Report Format for QA documents serves as a standardized template to systematically record inspection findings, ensuring consistency and accuracy in quality assessment. It typically includes fields for product specifications, inspection criteria, defects identified, measurement results, and auditor comments to facilitate thorough evaluation. Proper use of this format supports compliance with industry standards, enhances traceability, and aids in making informed decisions to maintain product quality.

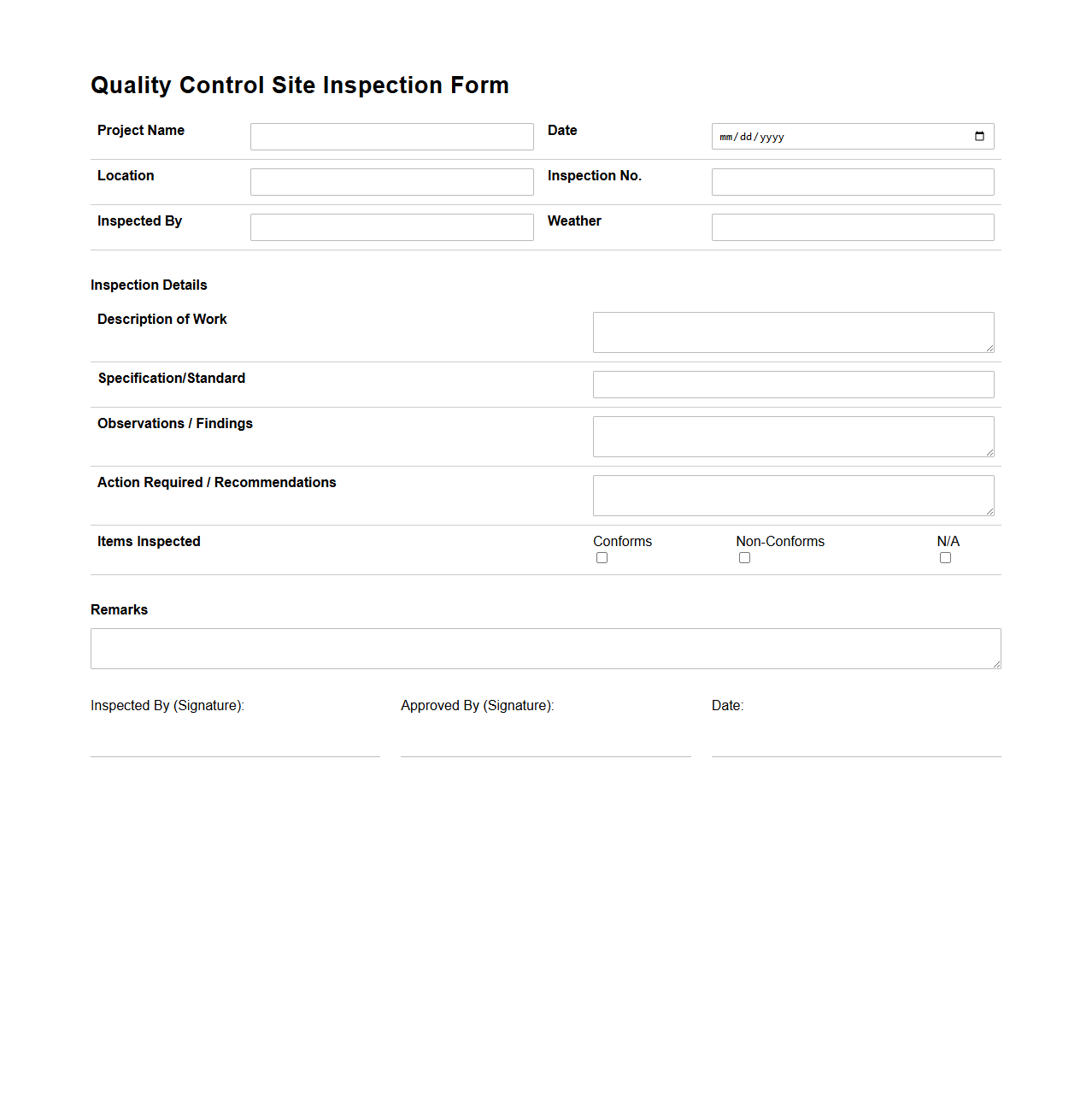

Quality Control Site Inspection Form

A

Quality Control Site Inspection Form is a standardized document used to systematically record observations and verify that construction activities comply with specified quality standards and contractual requirements. It includes detailed checklists covering materials, workmanship, safety measures, and regulatory compliance to ensure thorough evaluation during site inspections. This form facilitates consistent communication, traceability, and accountability throughout the project lifecycle, helping to identify defects early and implement corrective actions promptly.

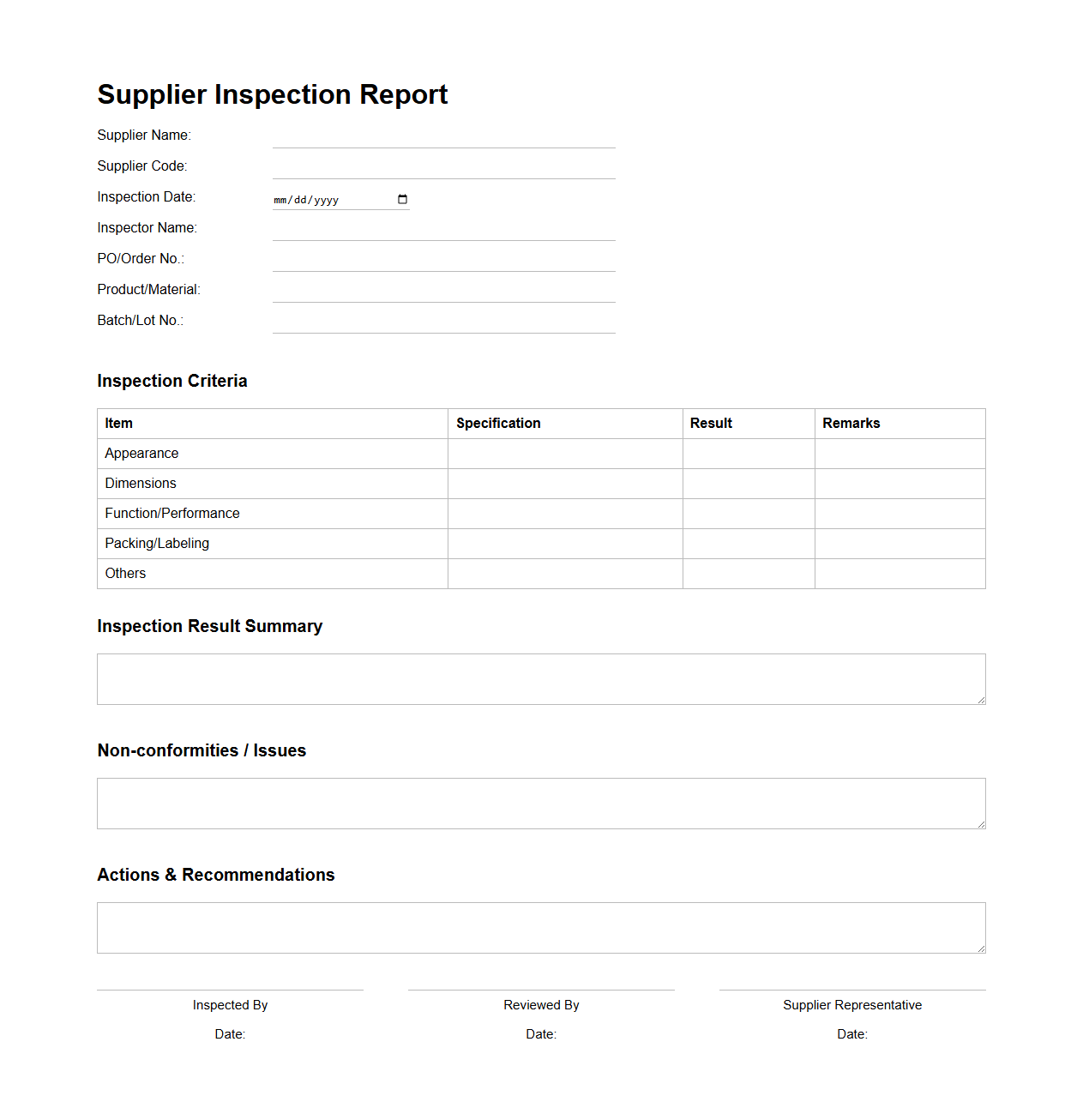

Supplier Inspection Report Template for Quality Teams

A

Supplier Inspection Report Template for Quality Teams is a standardized document designed to systematically evaluate and record the quality of materials or products delivered by suppliers. It helps quality teams identify compliance issues, track inspection results, and ensure suppliers meet predefined quality standards. This template typically includes sections for inspection criteria, observations, defect categorization, and corrective action recommendations.

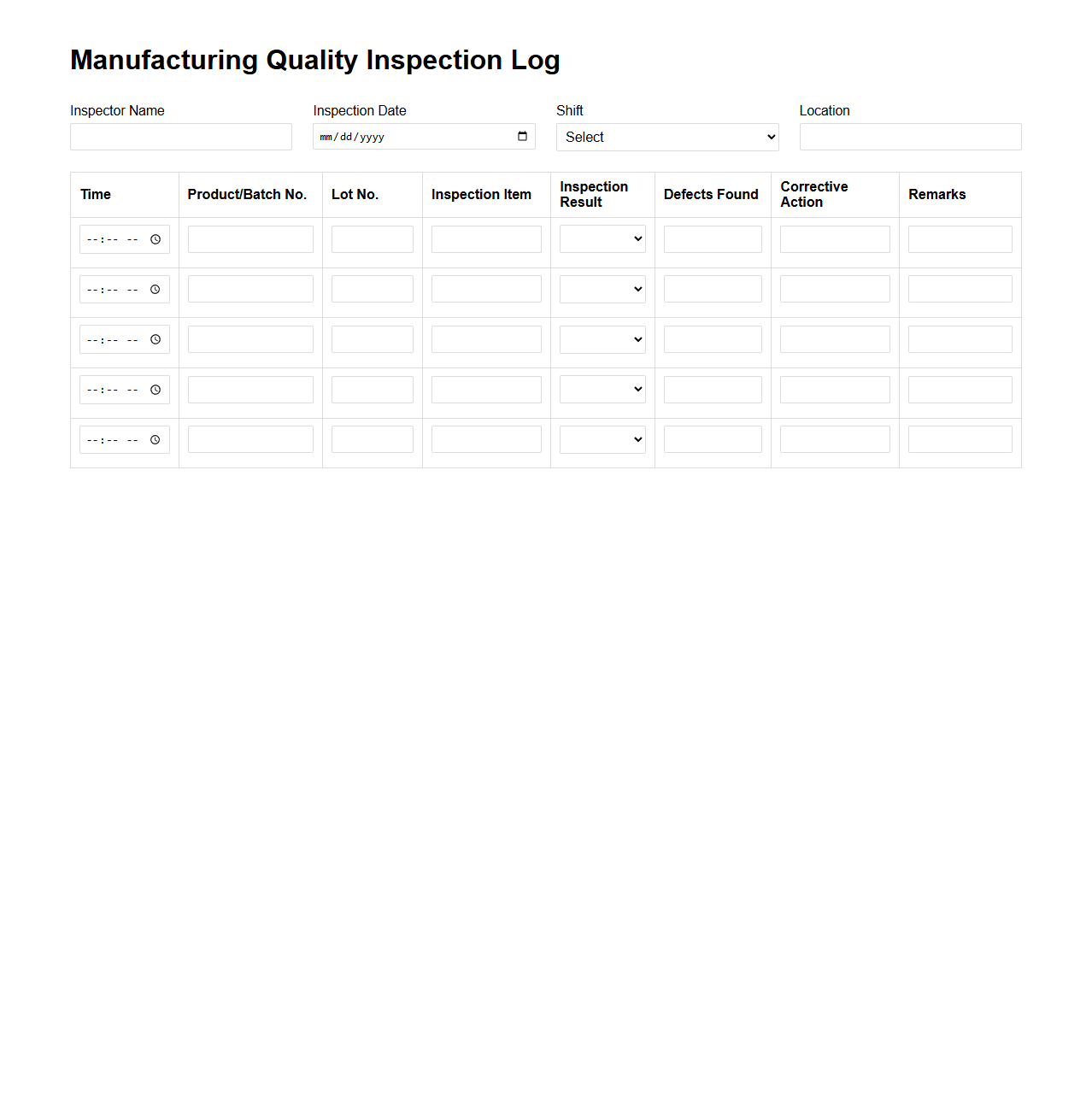

Manufacturing Quality Inspection Log

A

Manufacturing Quality Inspection Log document is a detailed record used to track and verify the quality of products during the manufacturing process. It contains inspection data such as measurement results, defect identification, and compliance with specified standards to ensure that each item meets quality requirements. This log supports quality control by providing traceability and facilitating corrective actions when deviations are detected.

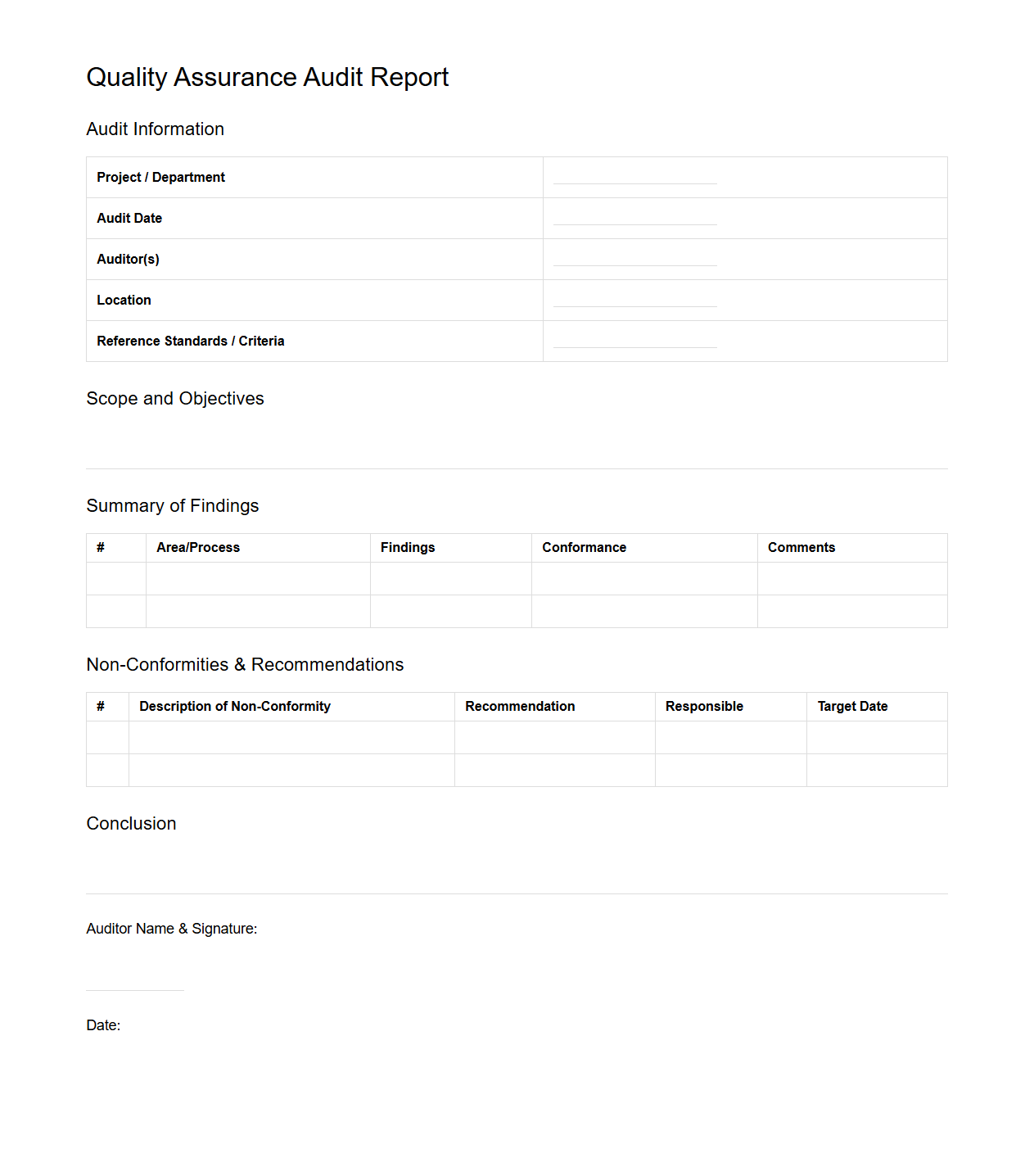

Quality Assurance Audit Report Template

A

Quality Assurance Audit Report Template document serves as a standardized framework to systematically record and evaluate the findings of a quality assurance audit. It helps ensure consistent documentation of compliance with industry standards, regulatory requirements, and internal quality policies. This template streamlines the reporting process by capturing audit objectives, scope, results, and recommendations for corrective actions.

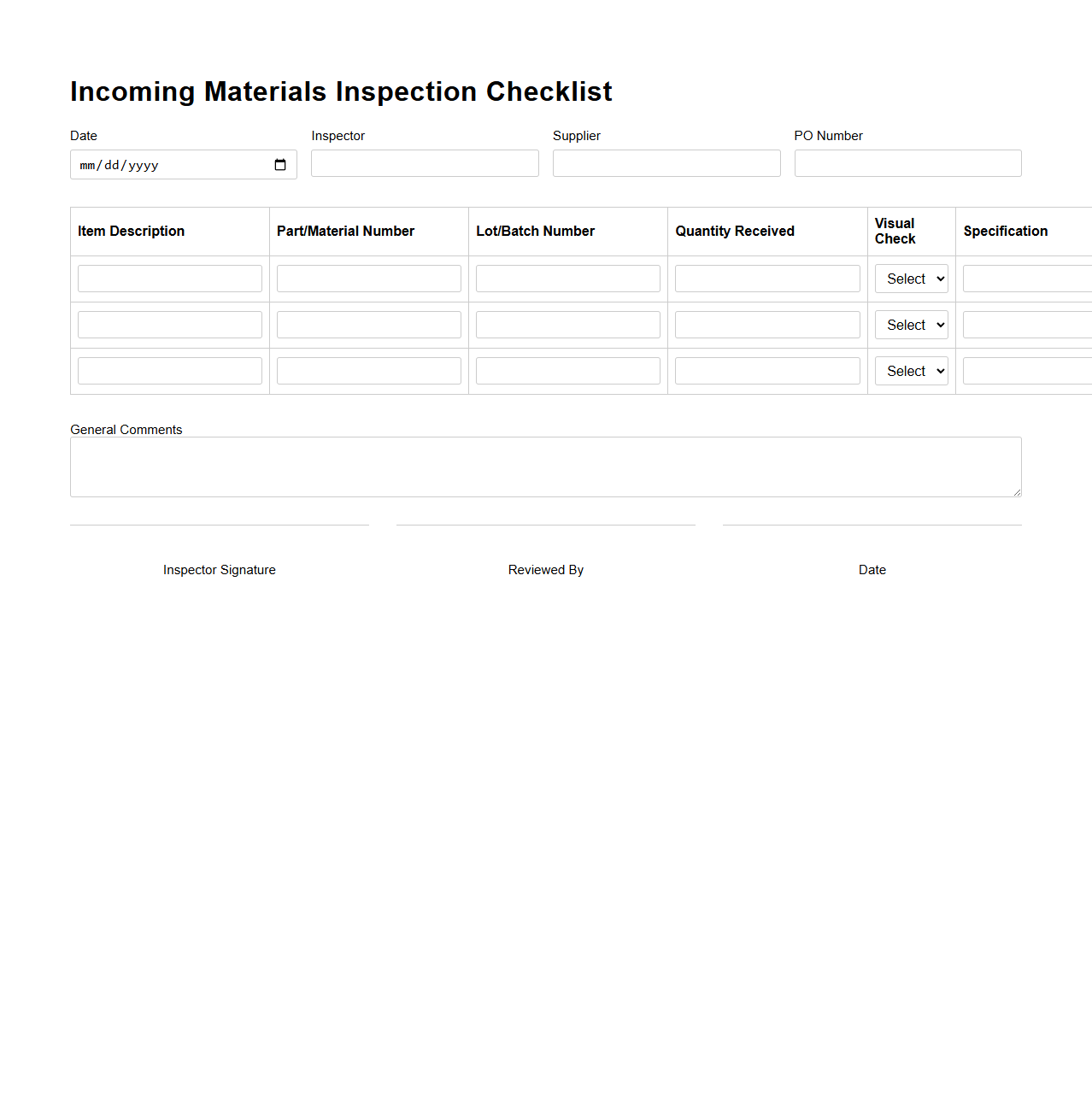

Incoming Materials Inspection Checklist

The

Incoming Materials Inspection Checklist document is a critical quality control tool used to verify that received materials meet specified standards and requirements before entering the production process. This checklist ensures compliance with supplier specifications, detects defects, and prevents substandard materials from impacting product quality. Accurate documentation facilitates traceability, supports audits, and enhances overall supply chain reliability.

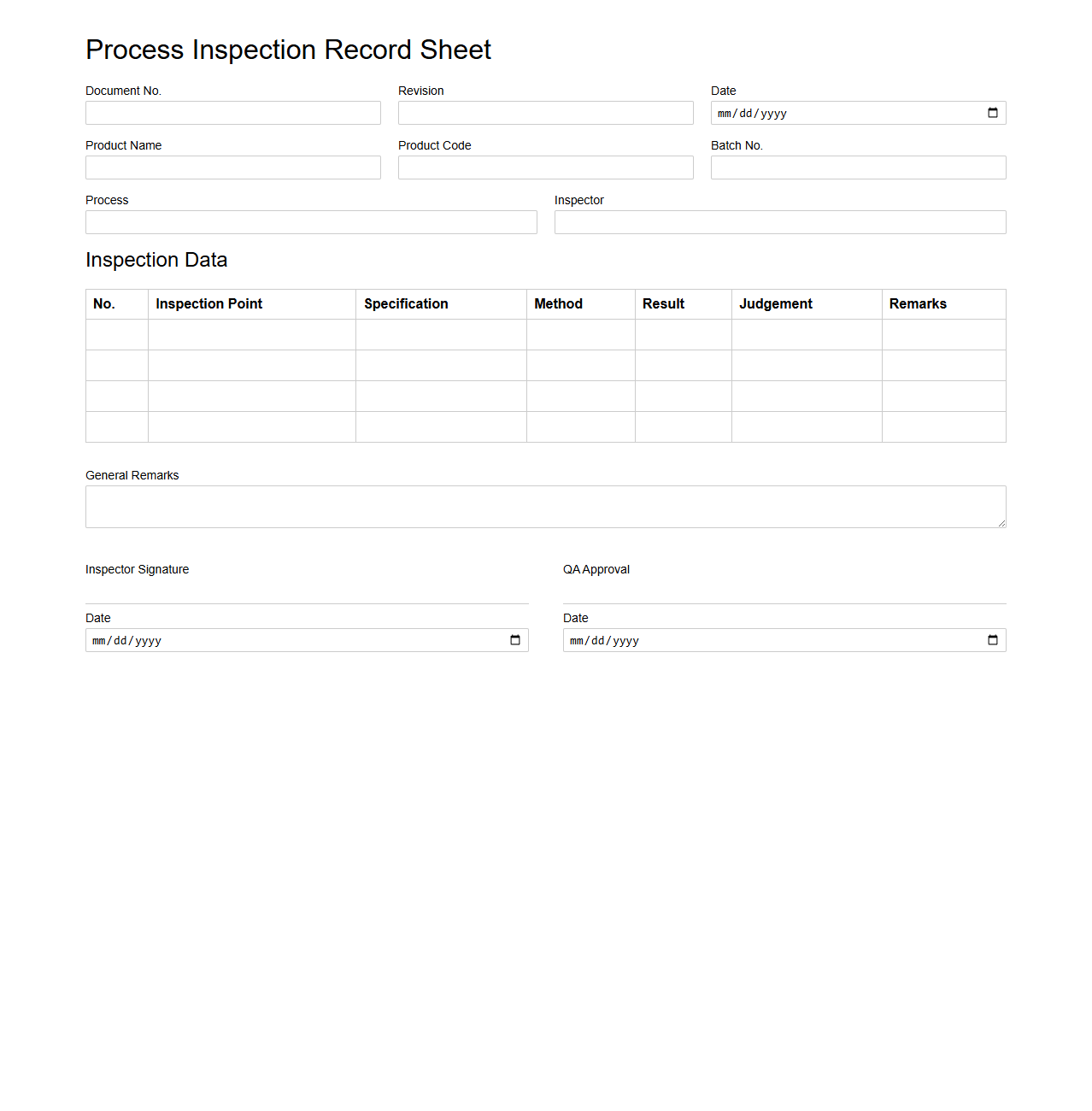

Process Inspection Record Sheet for QA

A

Process Inspection Record Sheet for QA documents serves as a detailed log that captures inspection data and observations during the manufacturing or production process. It ensures traceability and accountability by documenting critical parameters, inspection results, and deviations against set quality standards. This record is essential for maintaining product consistency, facilitating audits, and driving continuous improvement within the quality management system.

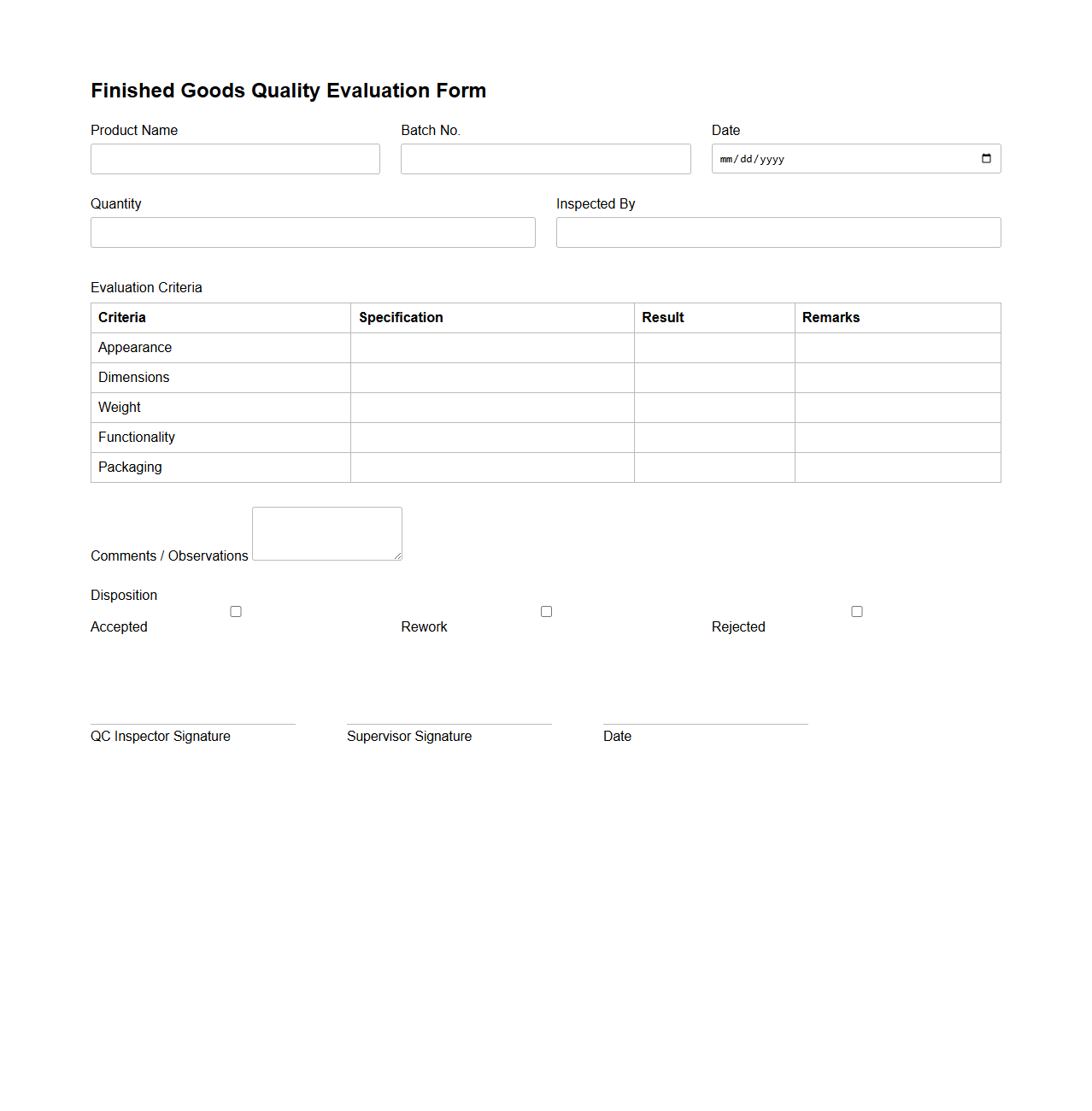

Finished Goods Quality Evaluation Form

The

Finished Goods Quality Evaluation Form document is a critical tool used to assess the quality and compliance of completed products before shipment or distribution. It systematically records inspection results, identifying defects, adherence to specifications, and overall product quality to ensure customer satisfaction and regulatory compliance. This form is essential for quality control teams to maintain product standards and facilitate continuous improvement in manufacturing processes.

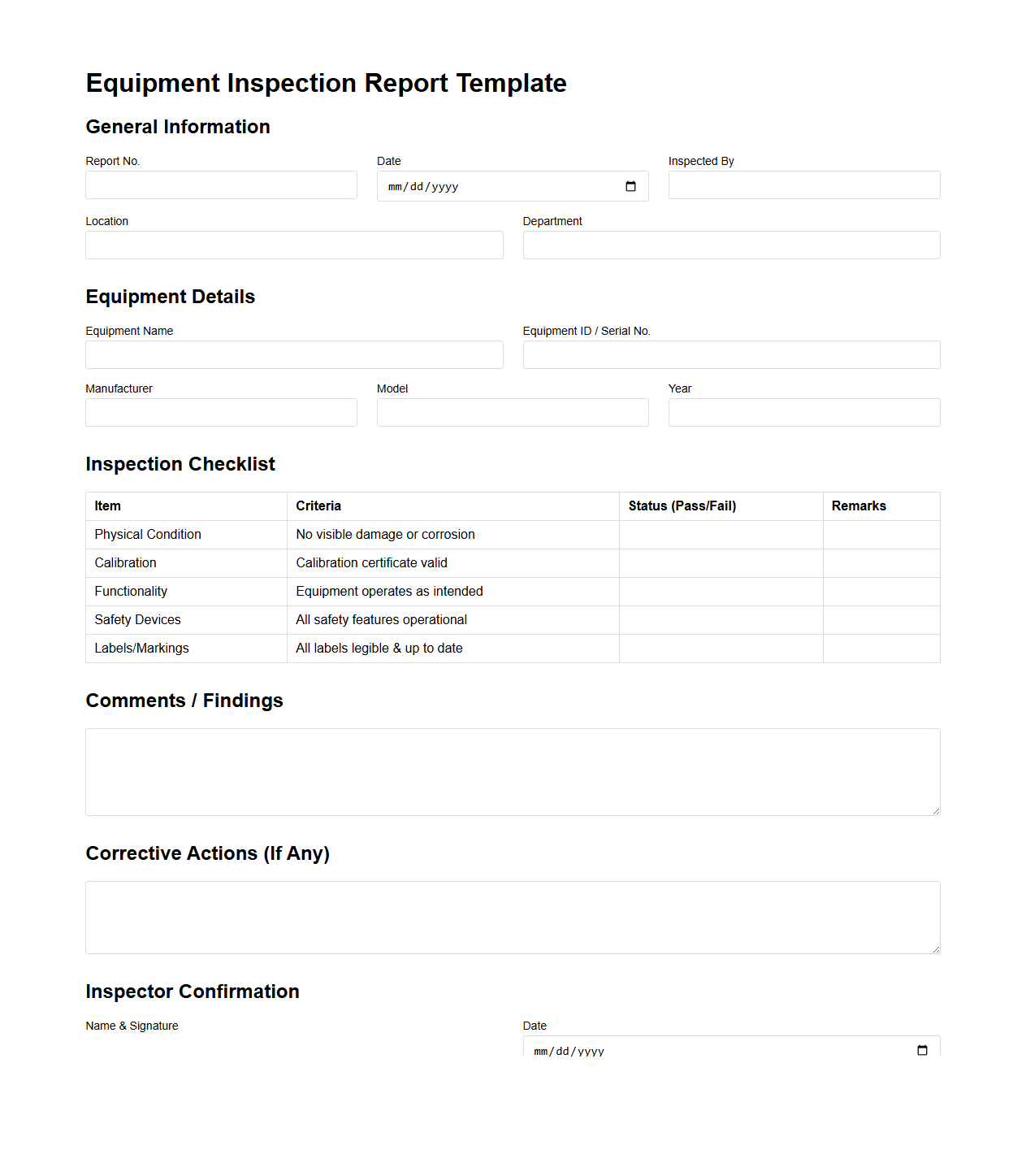

Equipment Inspection Report Template for Quality Compliance

An

Equipment Inspection Report Template for Quality Compliance is a standardized document designed to systematically record the condition and functionality of machinery and tools used in production or service processes. This template ensures consistent data collection related to equipment performance, safety checks, maintenance requirements, and compliance with industry standards or regulatory guidelines. Utilizing such a report enhances traceability, helps identify potential equipment failures early, and supports overall quality assurance efforts.

What key sections should be included in a blank inspection report template for quality assurance audits?

A blank inspection report template should include key sections such as the inspection date, location, and inspector's name to ensure traceability. It must also have predefined areas for detailing the scope, criteria, and methodology of the audit to maintain consistency. Lastly, spaces for observations, findings, corrective actions, and signatures are essential for comprehensive documentation.

How should nonconformance findings be documented in a blank inspection report letter?

Nonconformance findings should be precisely recorded in a dedicated section highlighting the deviation from standards. Each finding needs to include a clear description, severity rating, and the impact on overall quality. Additionally, the report should mandate documentation of proposed corrective actions and responsible parties to facilitate effective resolution.

What quality metrics should a blank inspection report emphasize for compliance tracking?

The template should emphasize critical quality metrics such as defect rates, compliance percentages, and frequency of nonconformities. Including trend analysis fields helps track improvements or deteriorations over time. Metrics related to corrective action effectiveness and audit closure rates further enhance compliance monitoring.

How can a blank inspection report template accommodate industry-specific standards?

To accommodate industry-specific standards, the report template should be customizable with sections aligned to relevant regulations and best practices. It should include checklists or prompts tailored to sector requirements, such as ISO standards or FDA guidelines. Providing flexibility for adding regulatory references ensures the report remains comprehensive and compliant.

What digital tools best support the creation and storage of blank inspection report letters?

Digital tools like document management systems and cloud-based platforms offer robust solutions for creating and storing inspection reports. Software such as Microsoft SharePoint, Google Workspace, and specialized audit management tools streamline collaboration and version control. These platforms also enhance report accessibility, security, and integration with other quality management systems.