A Blank Maintenance Checklist Template for Equipment Upkeep provides a structured format to track routine inspections and repairs efficiently. This customizable tool helps ensure timely maintenance, preventing equipment failures and reducing downtime. Using this template supports organized record-keeping and enhances overall operational reliability.

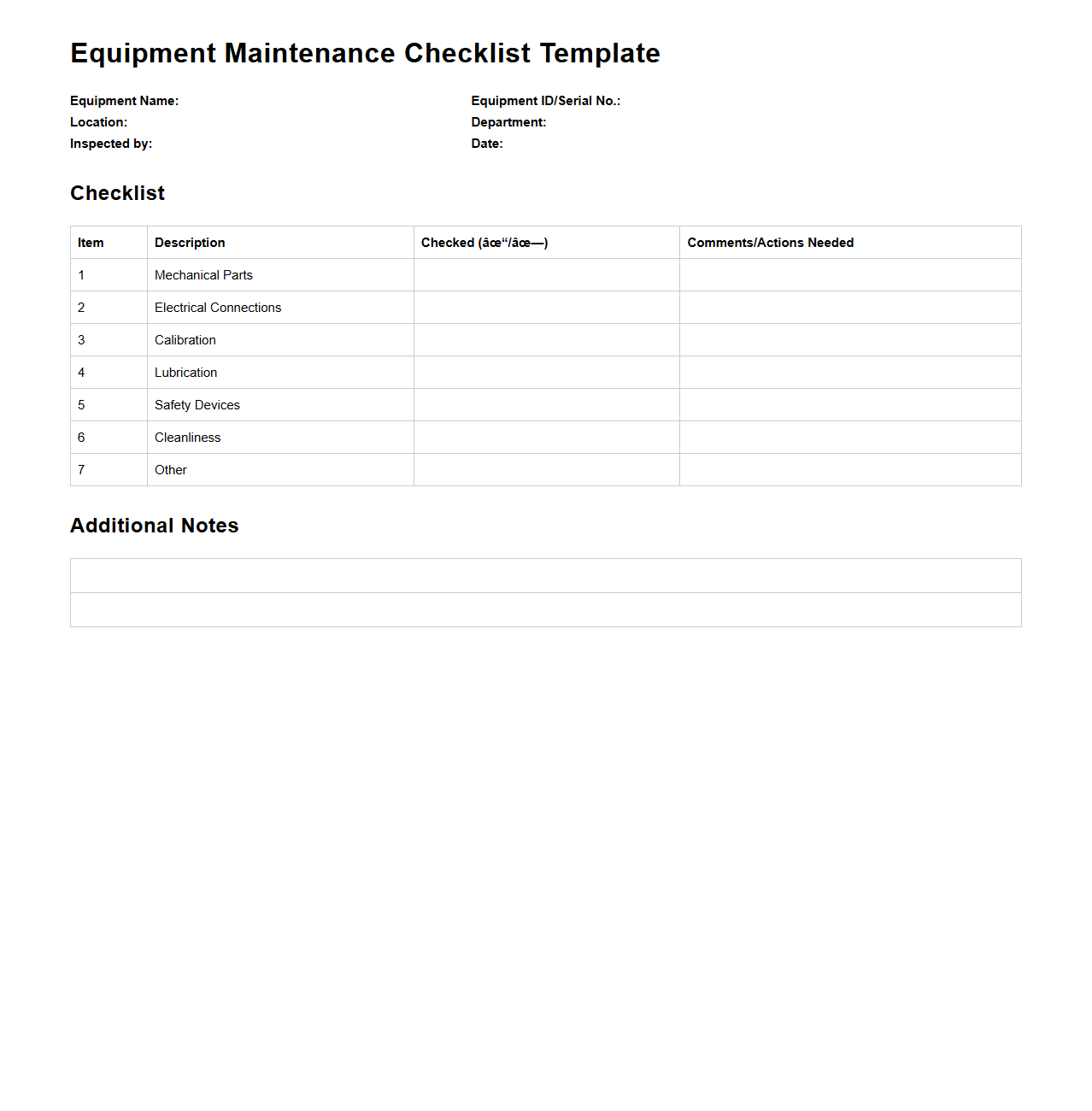

Equipment Maintenance Checklist Template

An

Equipment Maintenance Checklist Template document provides a structured format to systematically track and schedule regular maintenance tasks for machinery and equipment. It ensures consistent inspections, timely repairs, and compliance with safety standards, reducing downtime and extending equipment lifespan. This template typically includes sections for task descriptions, frequencies, responsible personnel, and completion status.

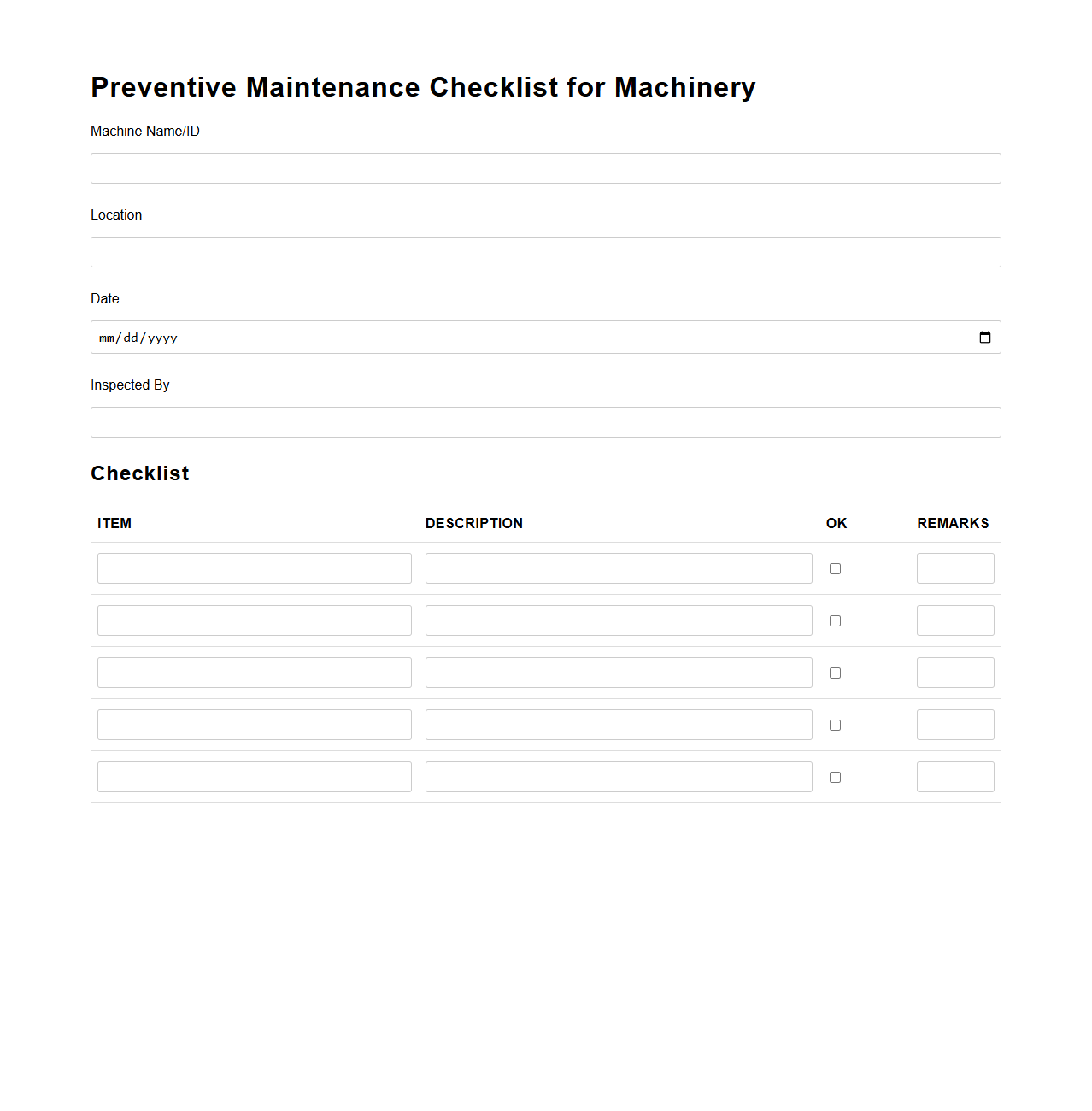

Preventive Maintenance Checklist for Machinery

A

Preventive Maintenance Checklist for Machinery document outlines essential tasks and inspection points designed to keep equipment operating efficiently and reduce the risk of unexpected breakdowns. It includes detailed schedules for lubrication, cleaning, adjustments, and part replacements to ensure optimal machine performance. Regular use of this checklist supports increased machinery lifespan, lowers repair costs, and enhances workplace safety.

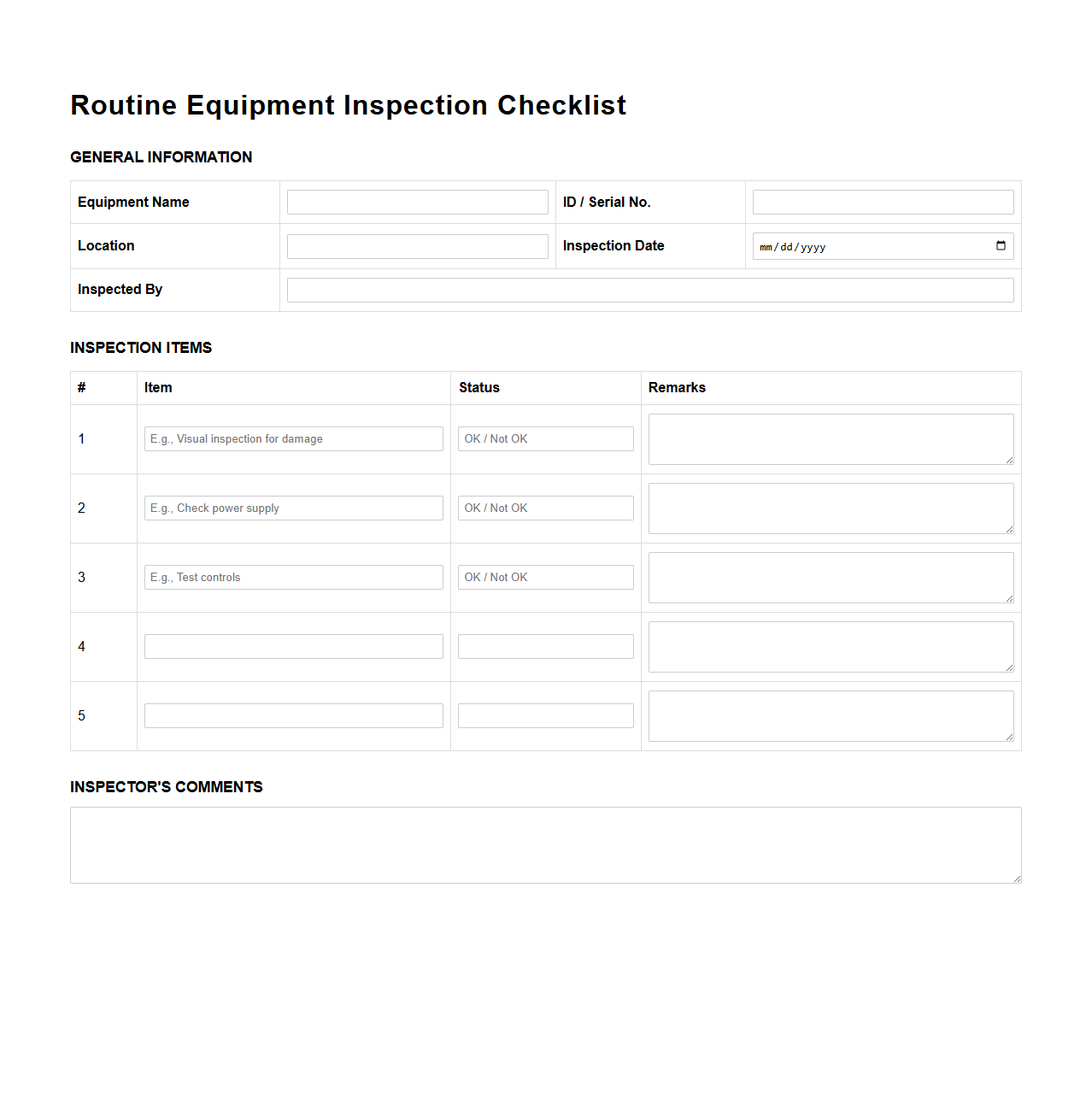

Routine Equipment Inspection Checklist

A

Routine Equipment Inspection Checklist document is a systematic tool used to verify the operational status and safety of machinery and tools before use. It ensures compliance with industry standards by itemizing specific inspection points such as wear, damage, and functionality. Regular utilization of this checklist helps prevent equipment failure, reduce downtime, and maintain workplace safety.

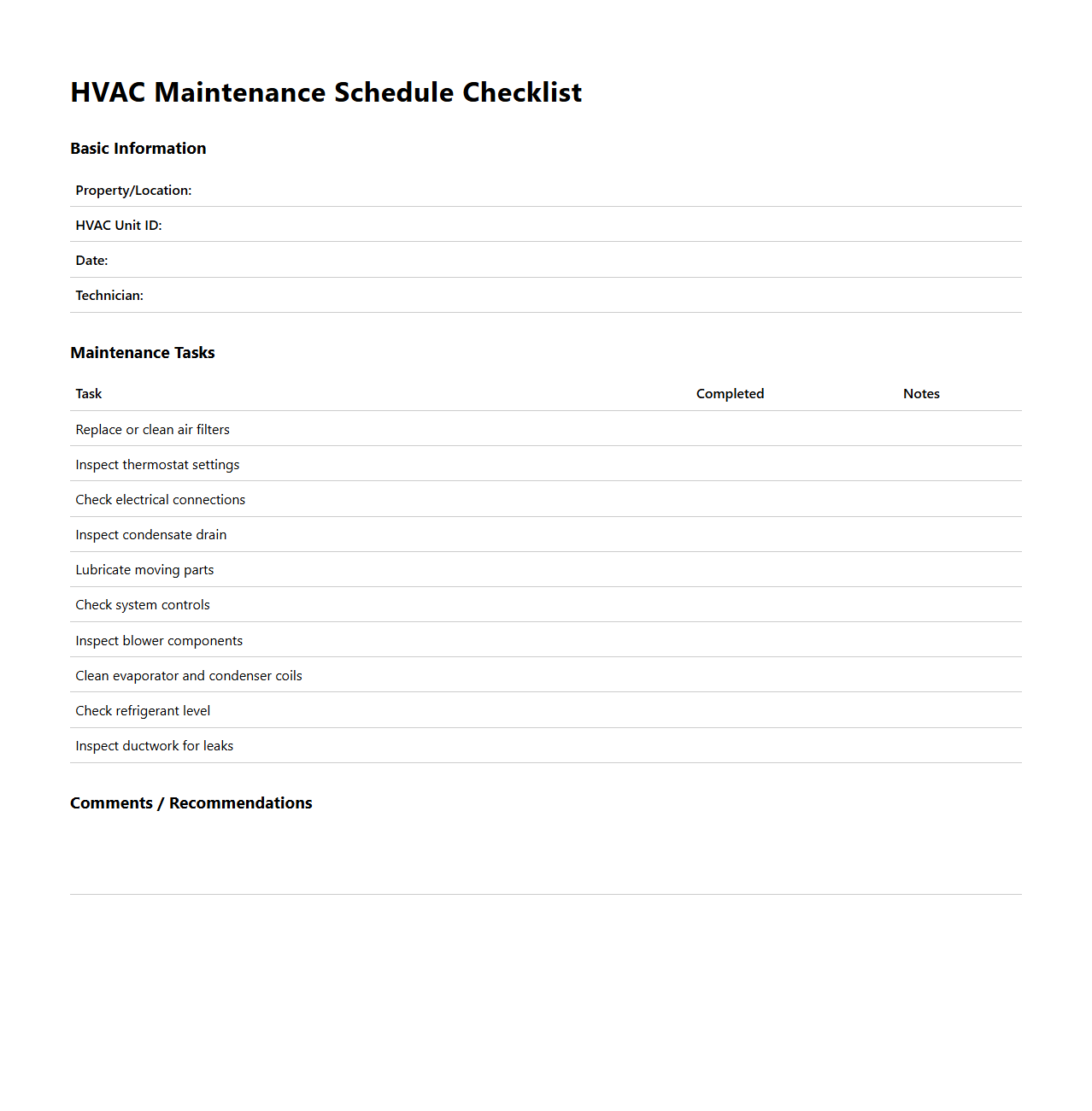

HVAC Maintenance Schedule Checklist

An

HVAC Maintenance Schedule Checklist document is a detailed guide outlining routine inspection and servicing tasks for heating, ventilation, and air conditioning systems to ensure optimal performance and longevity. It typically includes schedules for filter replacement, coil cleaning, refrigerant level checks, and system calibration, which help prevent unexpected breakdowns and improve energy efficiency. Regular use of this checklist enables facility managers and technicians to maintain system reliability while reducing costly repairs and downtime.

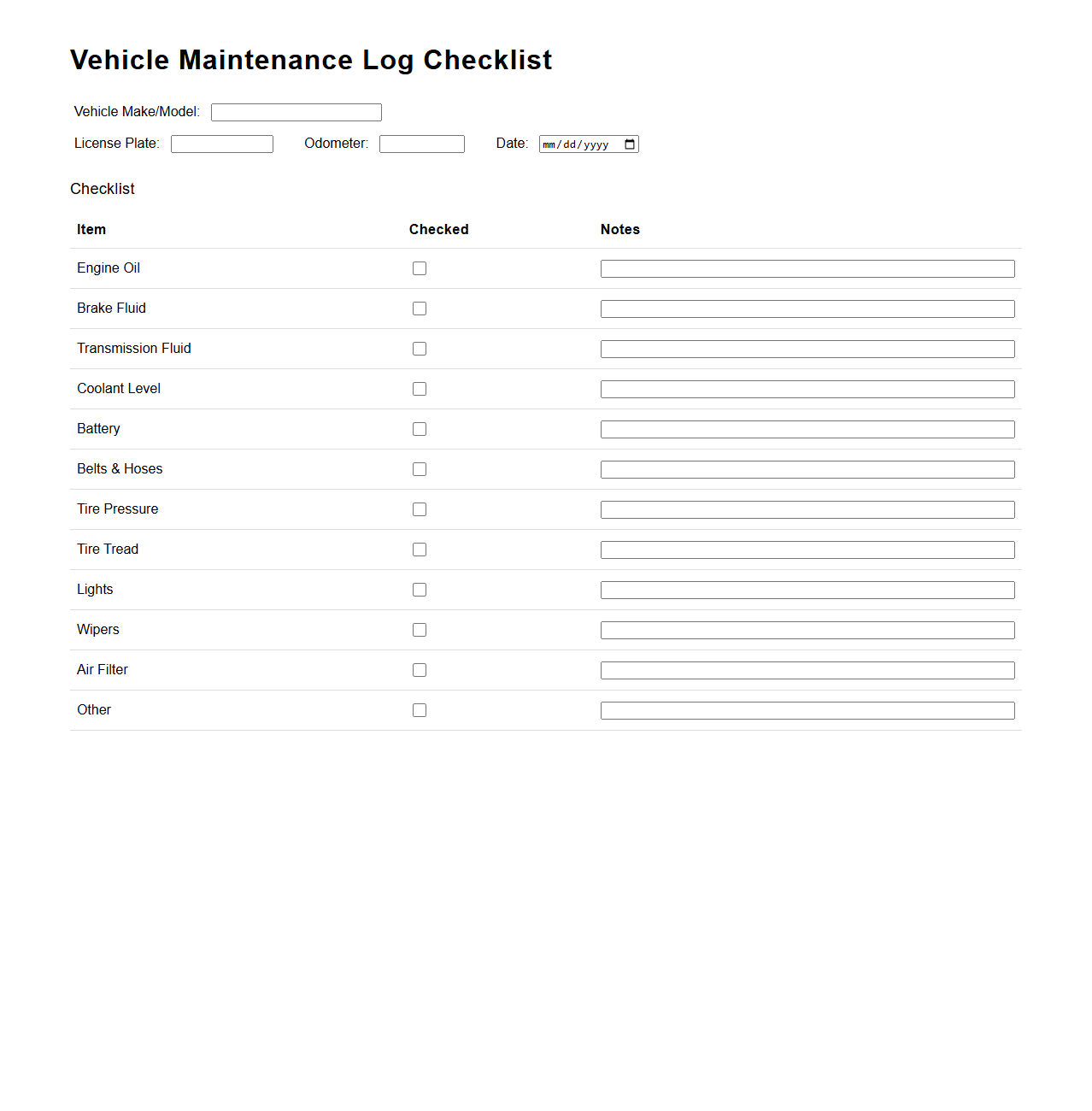

Vehicle Maintenance Log Checklist

A

Vehicle Maintenance Log Checklist document is a systematic record used to track and schedule regular vehicle service tasks such as oil changes, tire rotations, brake inspections, and fluid level checks. This document ensures timely maintenance, helps identify potential issues early, and extends the lifespan of a vehicle by maintaining optimal performance. It serves as an essential tool for fleet managers, individual vehicle owners, and mechanics to maintain accurate maintenance history and compliance with safety standards.

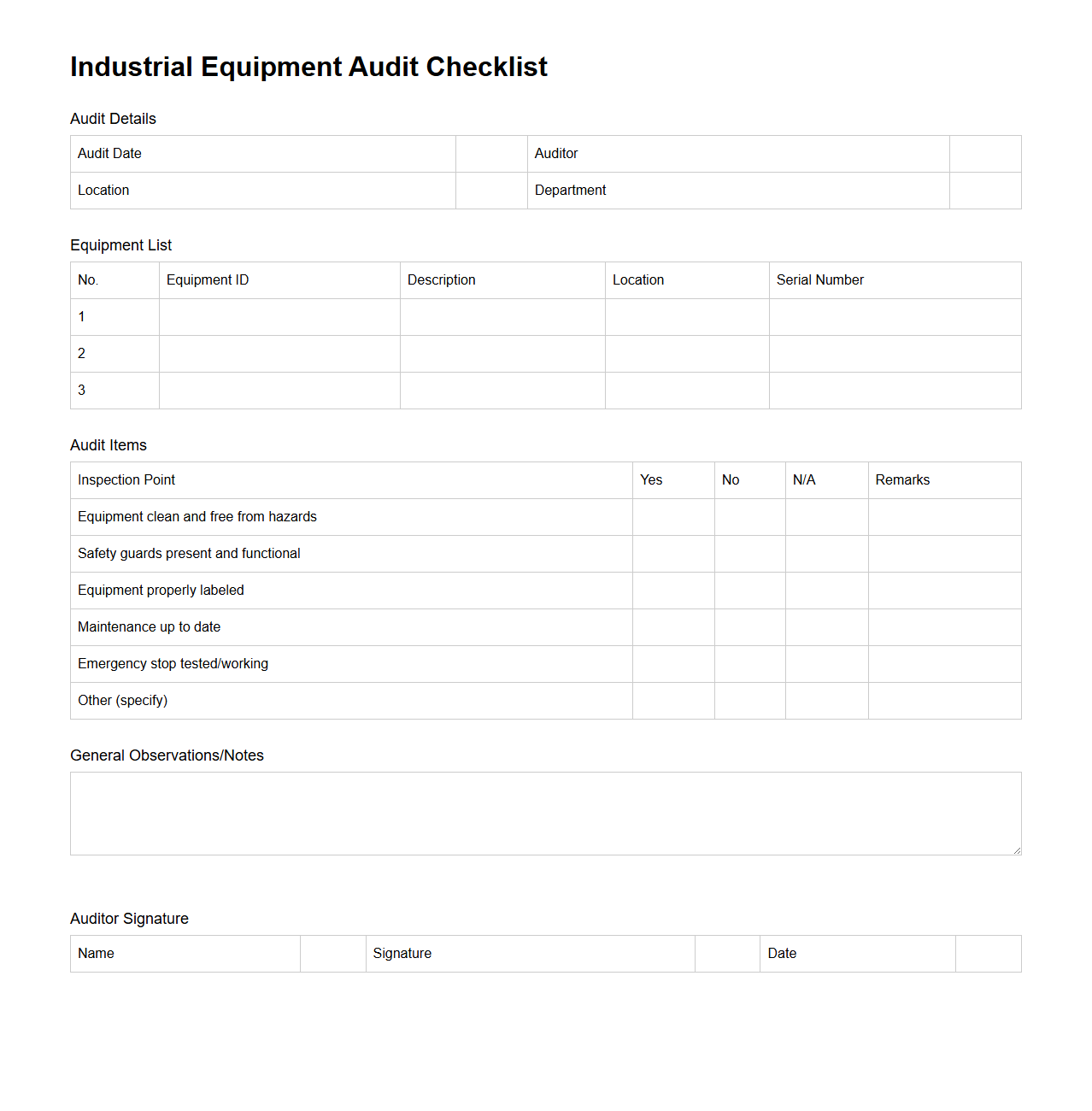

Industrial Equipment Audit Checklist

An

Industrial Equipment Audit Checklist document is a systematic tool used to evaluate the condition, performance, and safety compliance of machinery and equipment in industrial settings. It ensures regular inspections, identifies potential faults or inefficiencies, and helps maintain operational standards to prevent costly downtime. This checklist typically includes criteria such as equipment functionality, maintenance records, calibration status, and safety features.

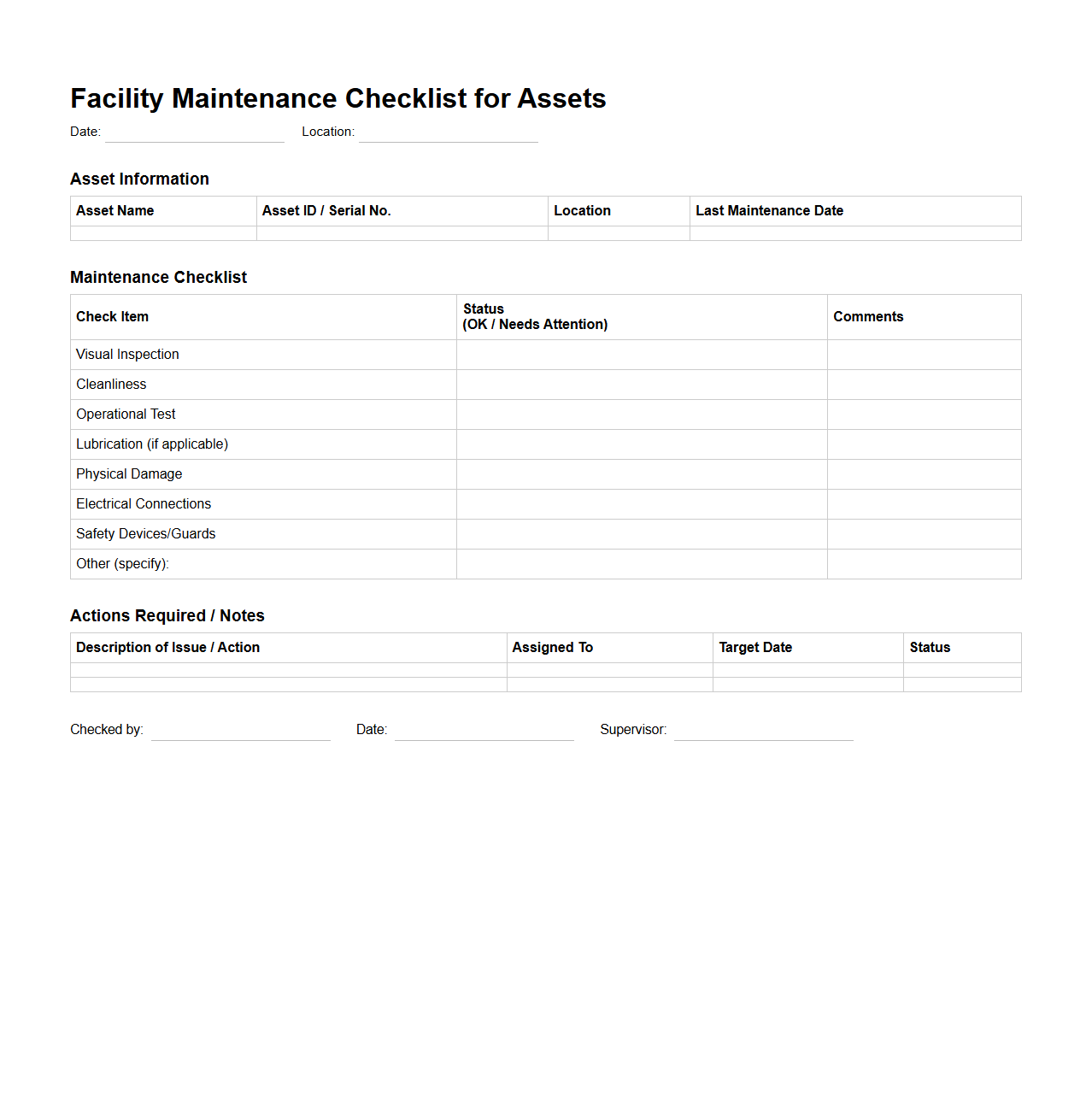

Facility Maintenance Checklist for Assets

A

Facility Maintenance Checklist for Assets document is a structured tool used to systematically track the condition and upkeep of physical assets within a facility. It outlines specific maintenance tasks needed for equipment, machinery, and infrastructure, ensuring timely inspections, repairs, and preventive measures. This checklist supports asset longevity, operational efficiency, and compliance with safety standards.

Monthly Machine Maintenance Tracking Sheet

A

Monthly Machine Maintenance Tracking Sheet is a document used to systematically record and monitor the maintenance activities performed on machinery over a month. It includes details such as maintenance dates, tasks completed, machine condition, and any issues identified to ensure optimal equipment performance. This tracking sheet helps in preventing unexpected breakdowns, extending machine lifespan, and improving operational efficiency.

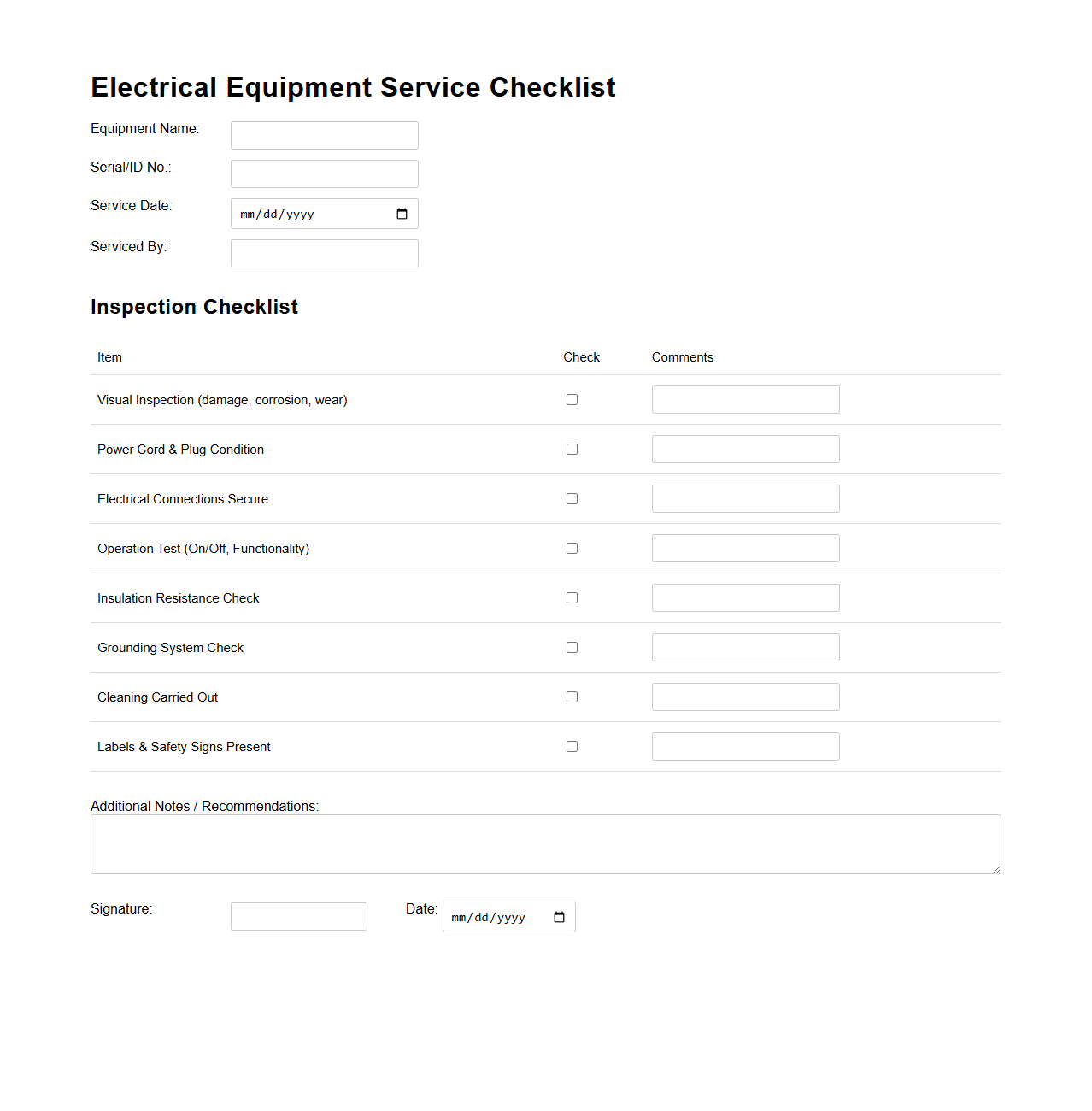

Electrical Equipment Service Checklist

An

Electrical Equipment Service Checklist document is a detailed record used to ensure all necessary maintenance and safety checks on electrical equipment are systematically completed. It helps technicians verify operational integrity, identify potential faults, and comply with safety regulations to prevent electrical hazards. This checklist enhances equipment reliability and prolongs its lifespan through routine inspections and timely servicing.

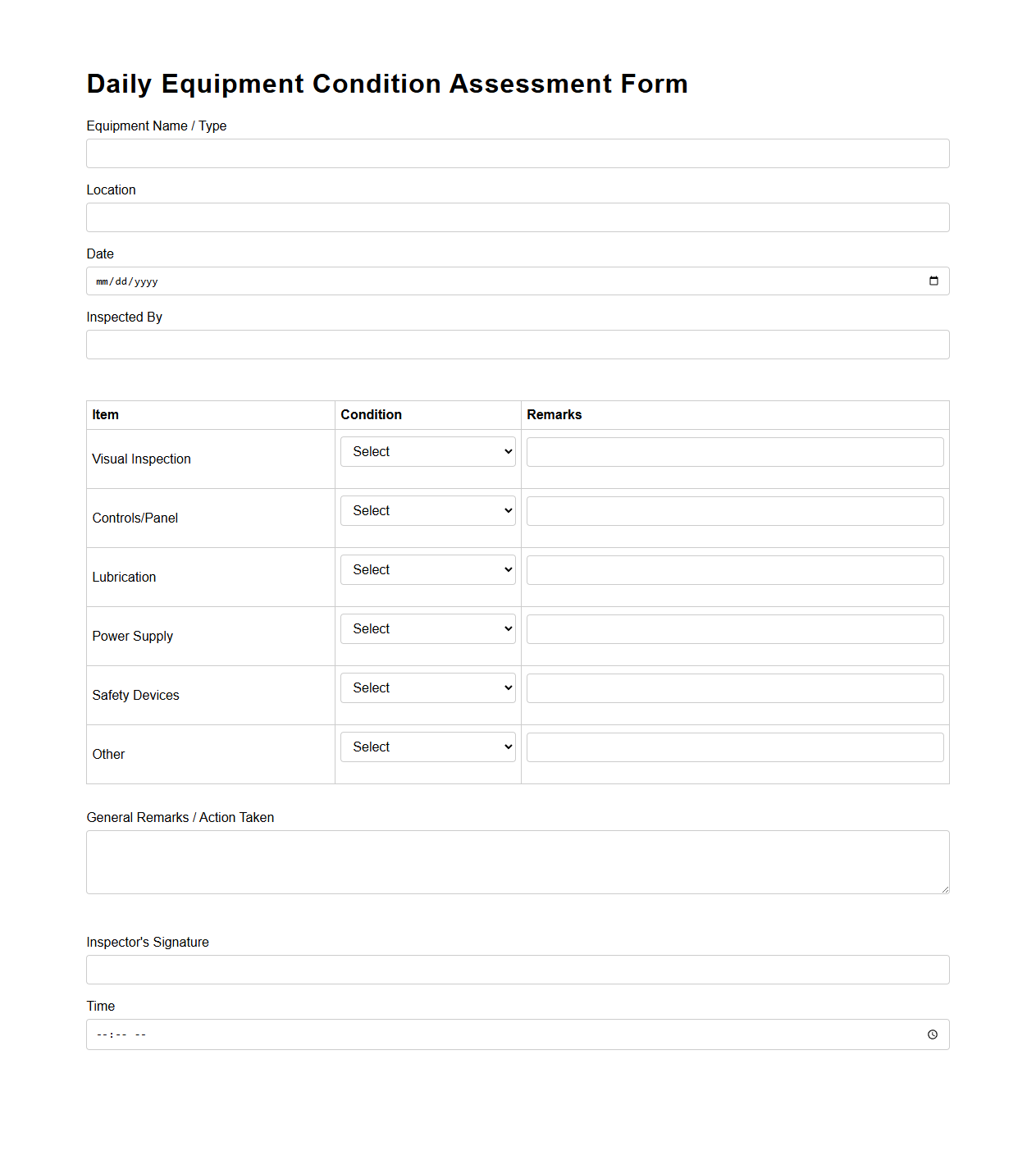

Daily Equipment Condition Assessment Form

A

Daily Equipment Condition Assessment Form document is a standardized tool used to record the operational status and maintenance needs of machinery or equipment on a daily basis. It captures critical data such as performance metrics, detected faults, safety concerns, and any irregularities observed during inspections, facilitating timely repairs and preventing equipment failure. This document enhances equipment reliability, safety compliance, and overall operational efficiency in industrial and manufacturing environments.

How is data from the blank maintenance checklist systematically archived for future equipment performance analysis?

Data from a blank maintenance checklist is systematically archived using digital databases or cloud storage systems, ensuring easy access and secure backup. The archived information allows for trend analysis and helps in identifying recurring issues in equipment performance. This systematic archiving plays a crucial role in proactive maintenance and decision-making.

What are essential fields to include on a blank maintenance checklist for specialized industrial machinery?

Essential fields on a blank maintenance checklist should include equipment identification, date and time of maintenance, and technician details. It must also have specific inspection points, safety checks, and notes for anomalies or repairs required. Including these fields ensures comprehensive documentation tailored to industrial machinery needs.

How frequently should each item on a blank maintenance checklist for equipment upkeep be reviewed or updated?

Each item on the maintenance checklist should be reviewed or updated based on the equipment manufacturer's recommendations, typically ranging from monthly to annually. Regular reviews ensure the checklist remains relevant to evolving equipment conditions and industry standards. This practice helps maintain operational efficiency and safety.

Who is authorized to modify or approve changes on a blank maintenance checklist template?

Only designated personnel such as maintenance managers, quality assurance supervisors, or compliance officers are authorized to modify or approve changes on a blank maintenance checklist. This controlled authorization ensures that all updates align with operational protocols and regulatory requirements. Such governance maintains checklist integrity and reliability.

What compliance standards must a blank maintenance checklist for equipment upkeep adhere to in regulated industries?

A blank maintenance checklist must comply with relevant standards such as ISO 9001, OSHA regulations, and industry-specific safety requirements. Adherence guarantees that the equipment upkeep process meets legal and safety obligations. Compliance also supports audit readiness and continuous improvement initiatives.